Fine Calculation of Decay Heat Power in Xi’an Pulsed Reactor

-

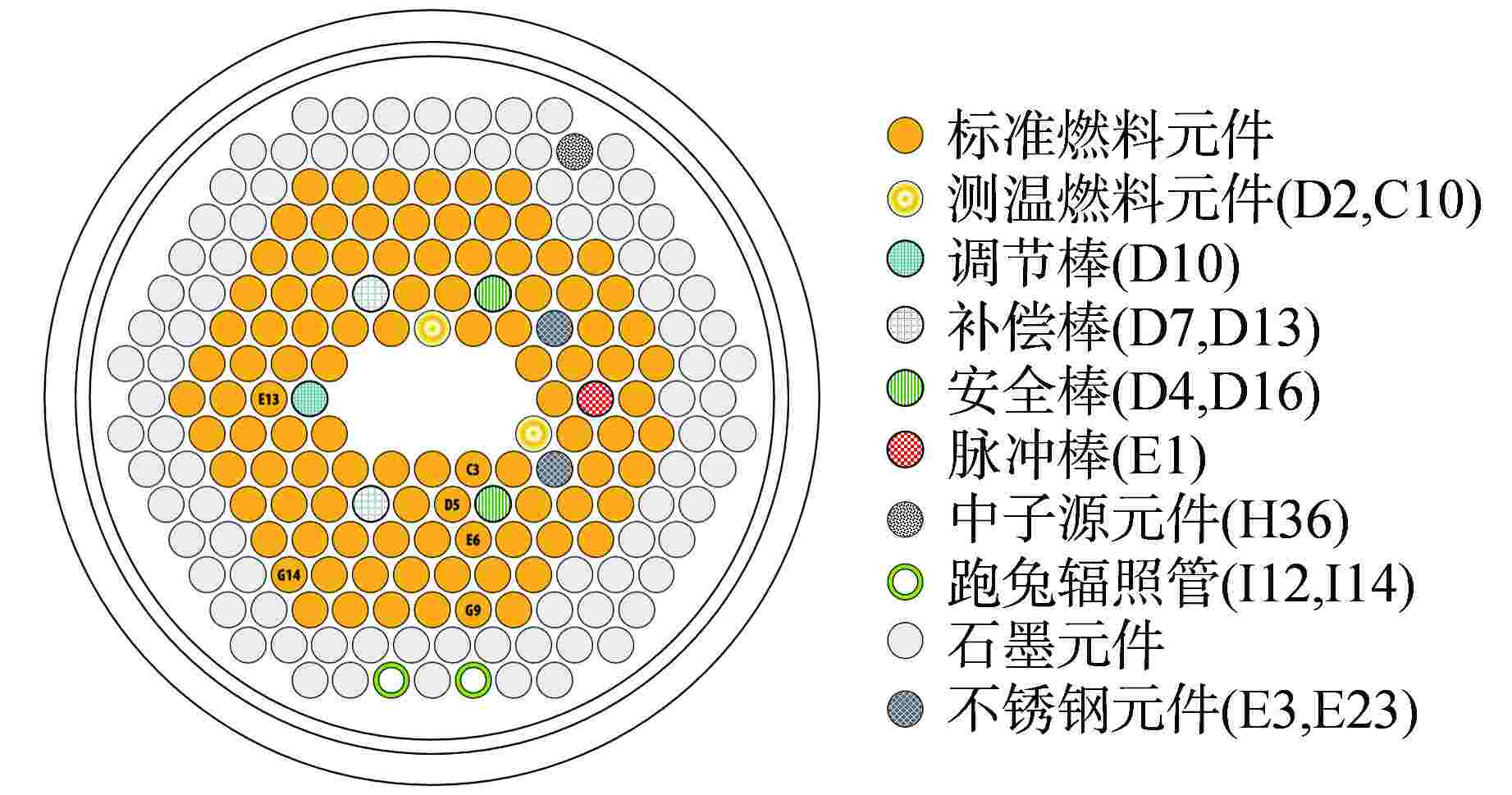

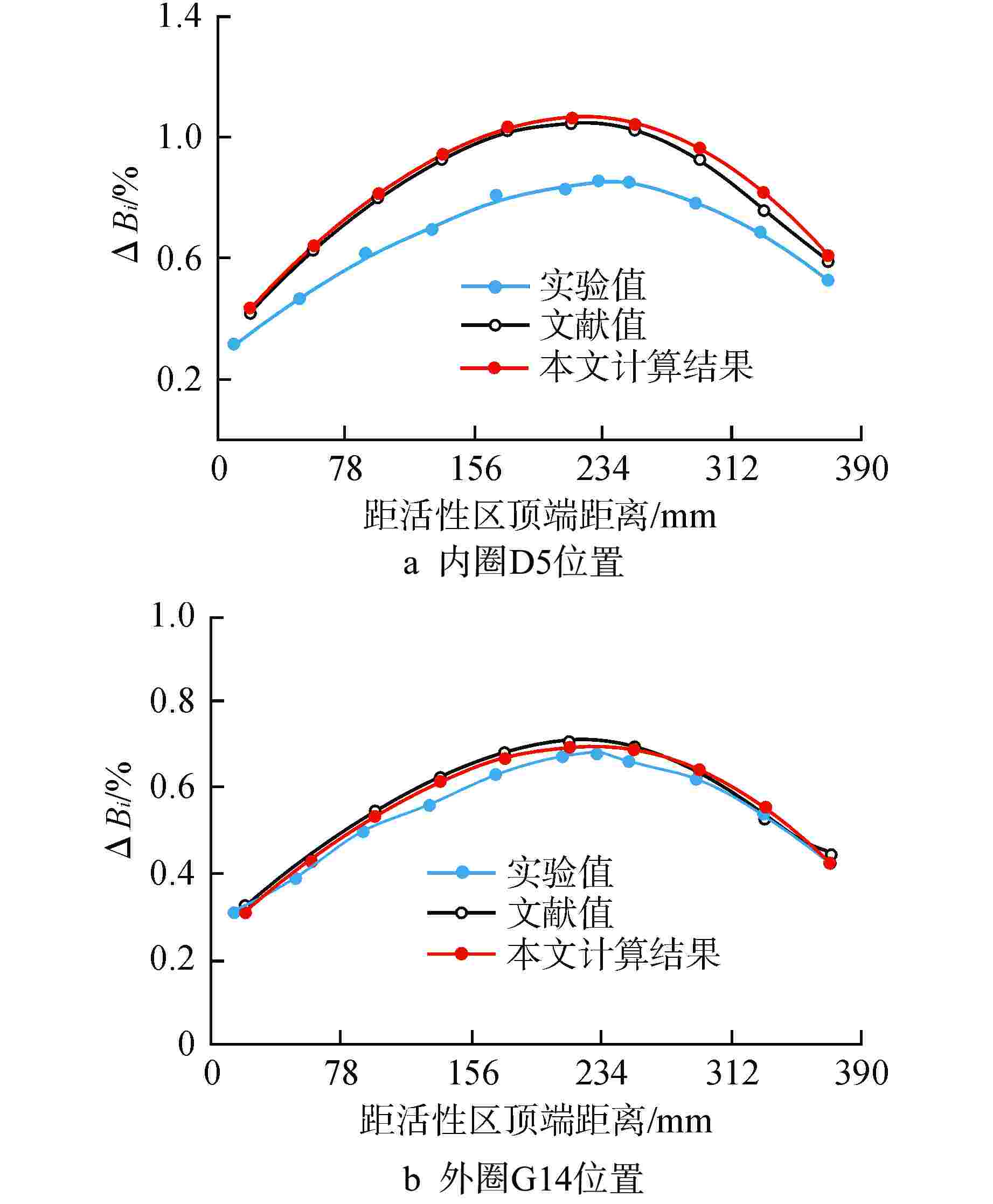

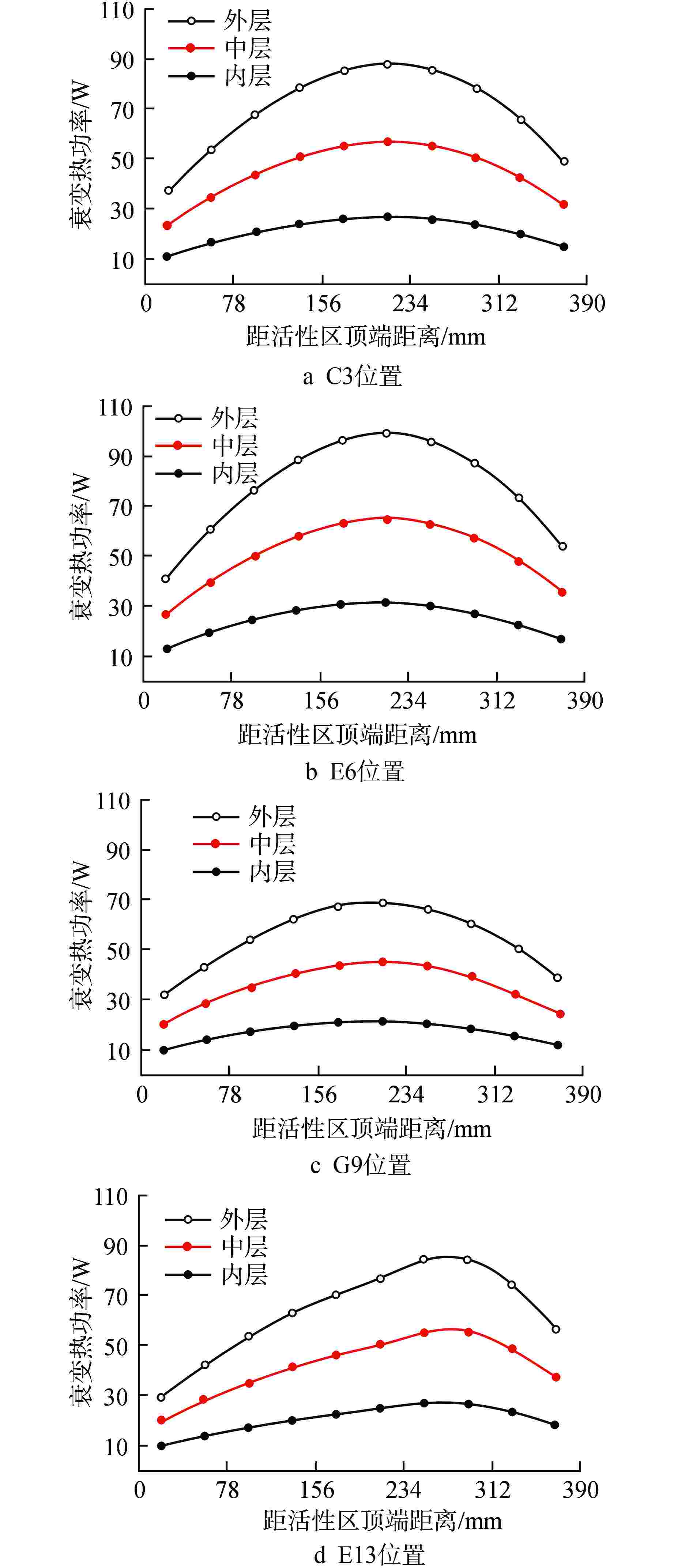

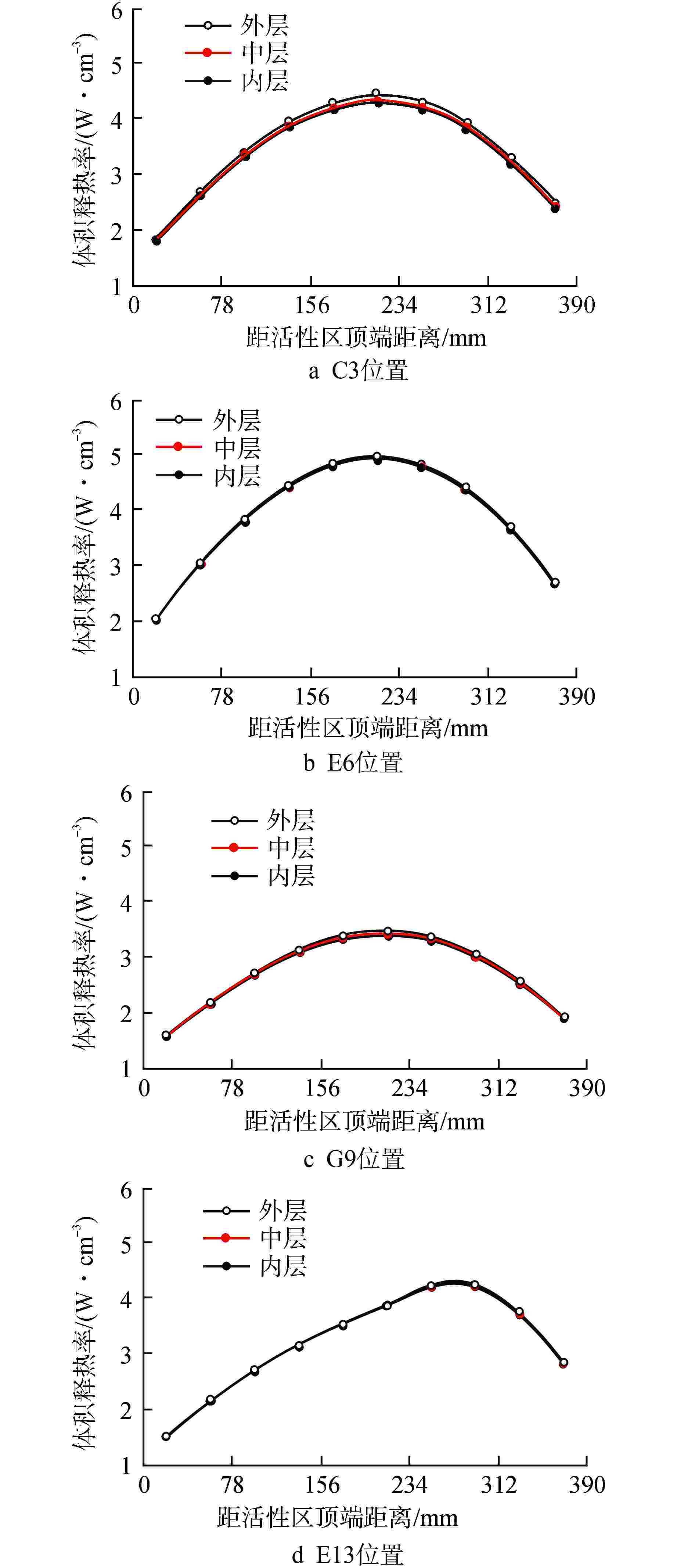

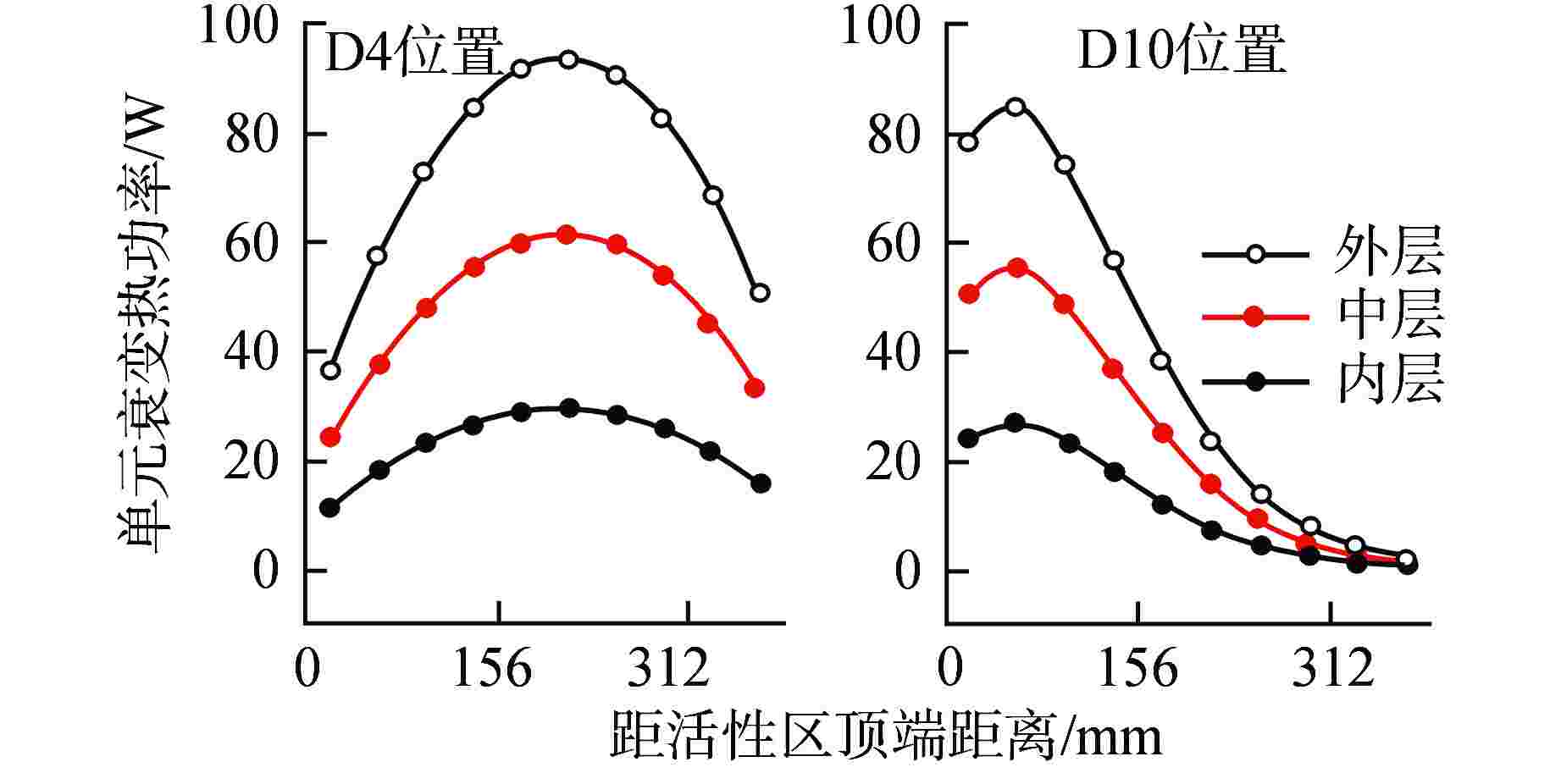

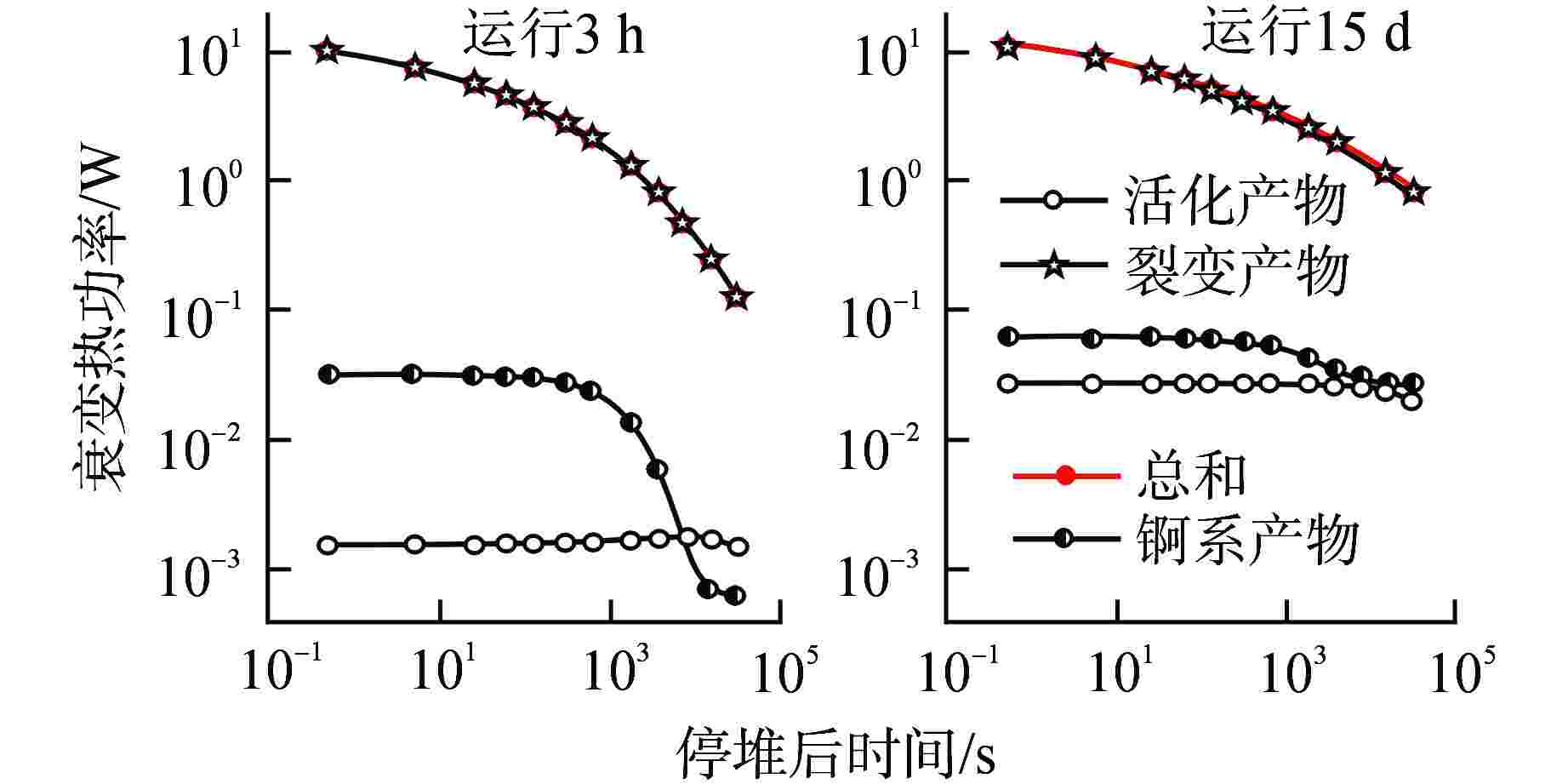

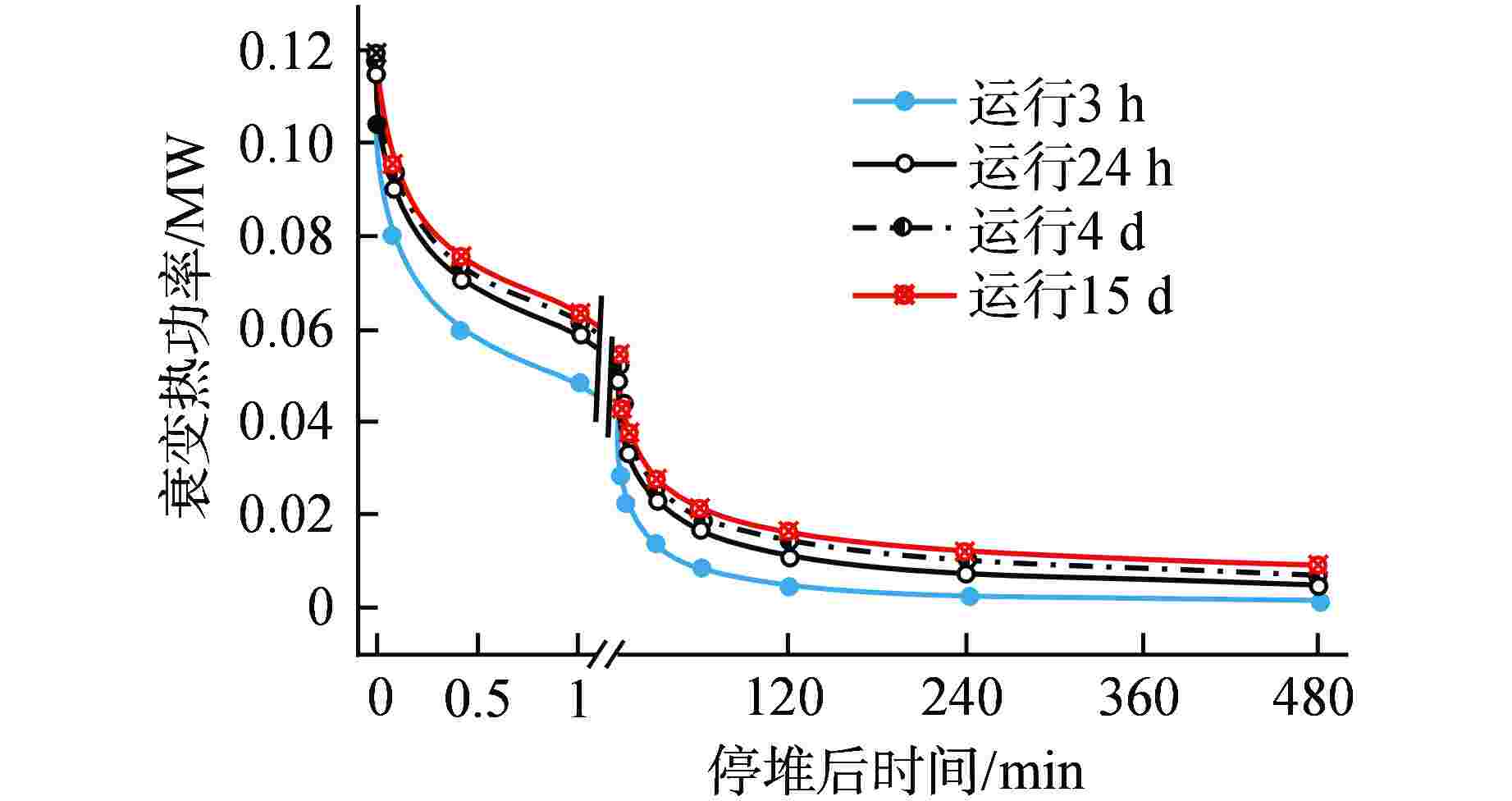

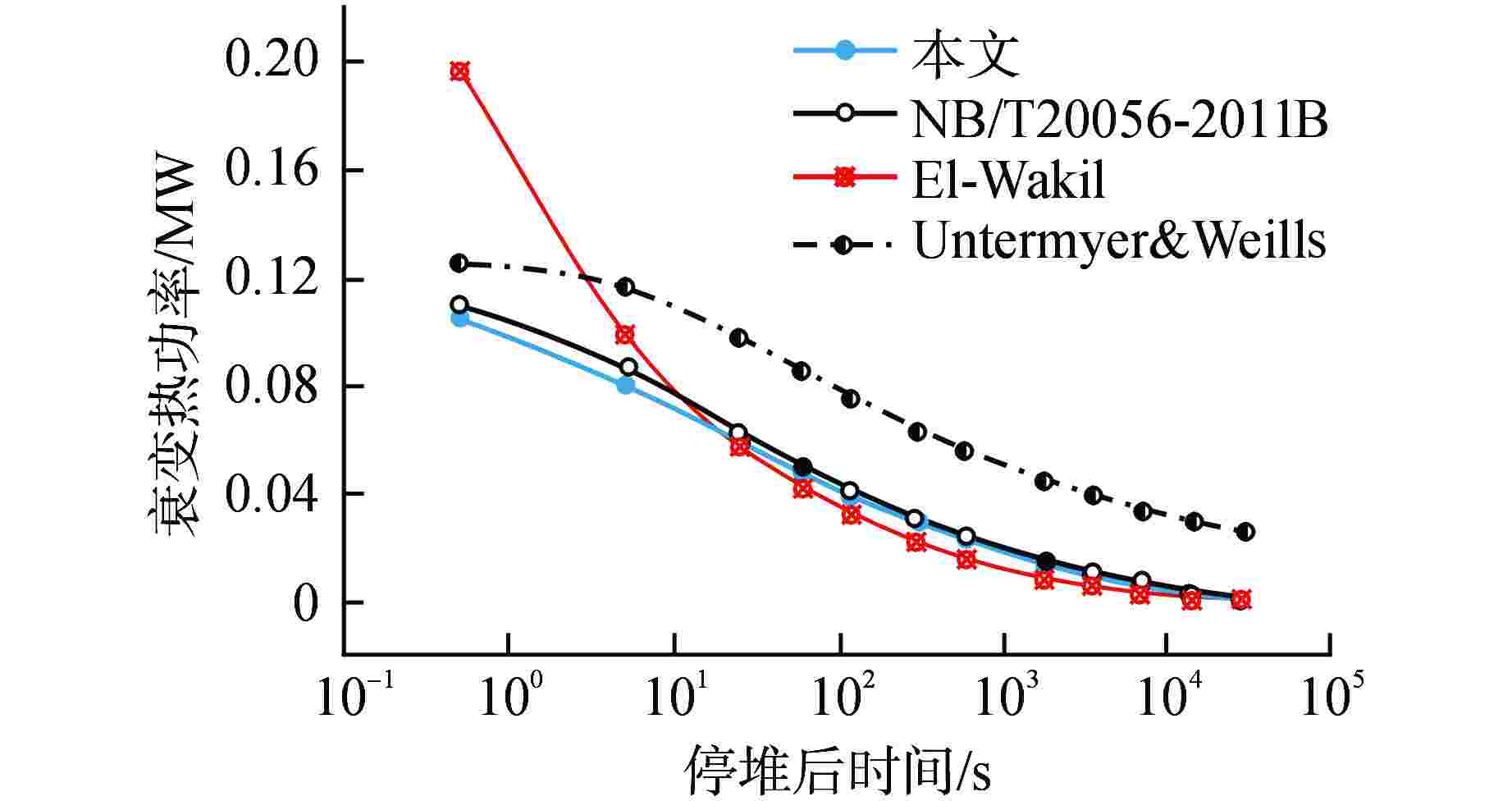

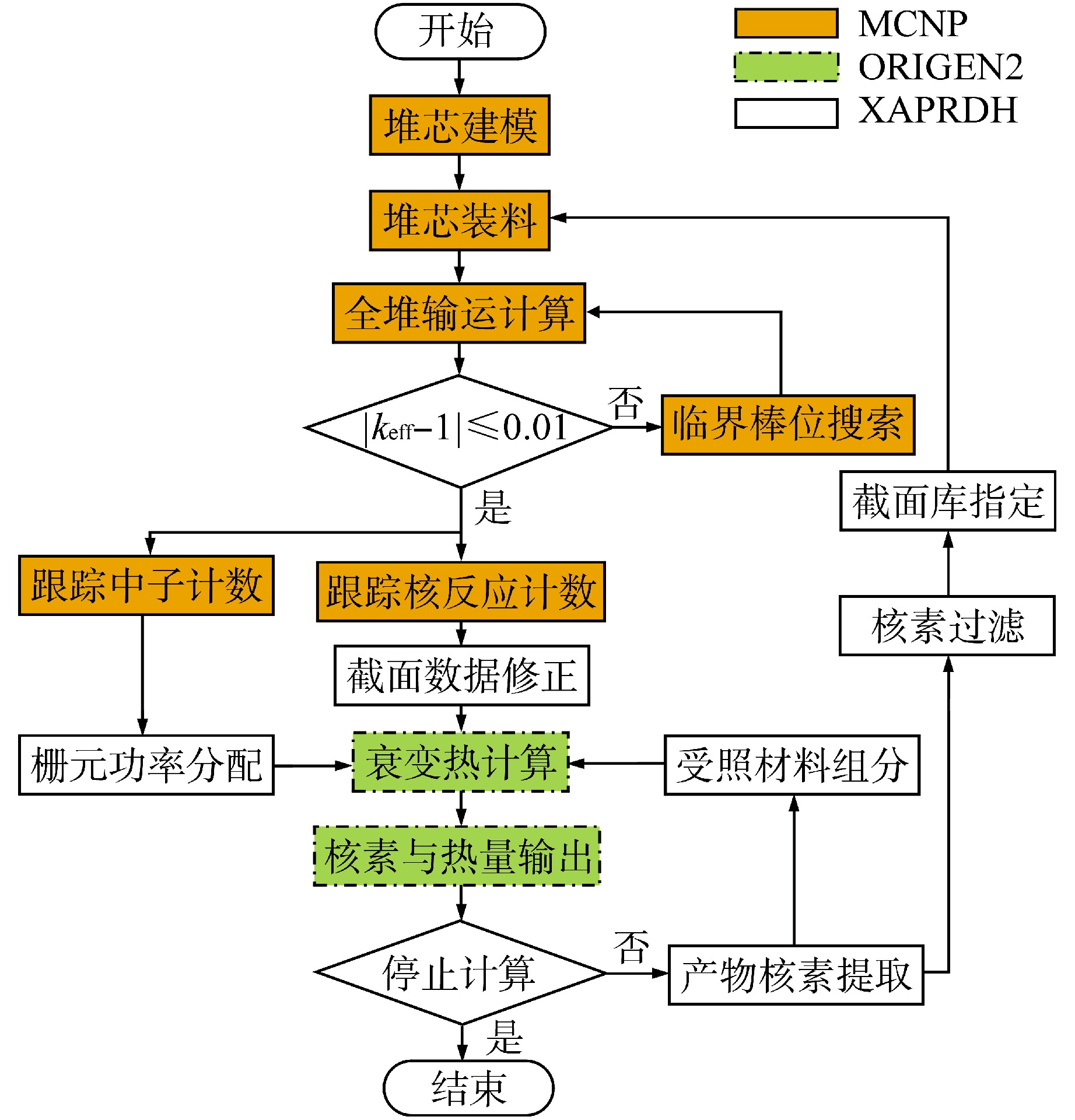

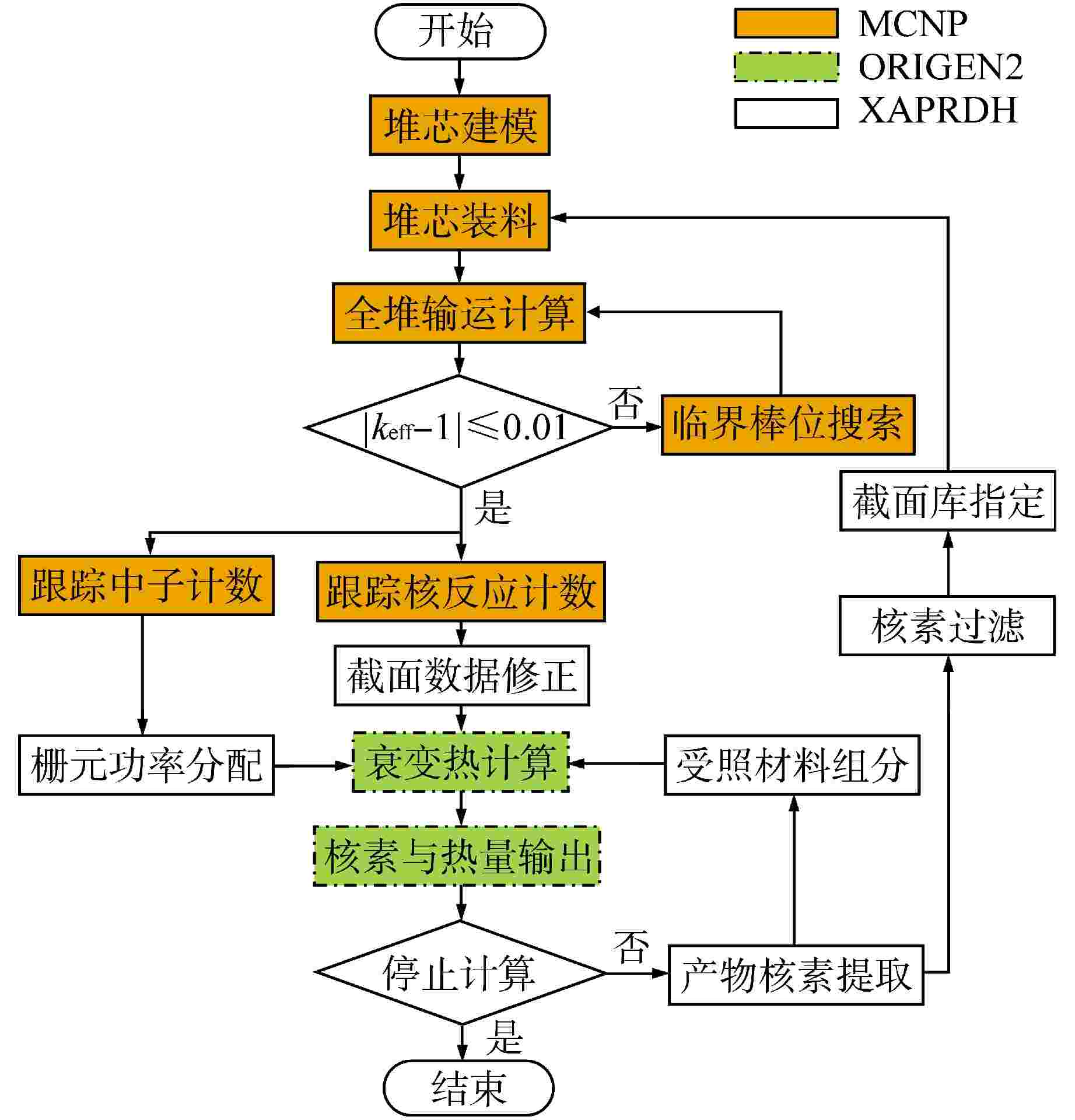

摘要: 为了给脉冲堆的余热导出数值计算提供更为精细可信的能量源项,通过耦合MCNP程序和ORIGEN2程序,提出了计算方法XAPRDH以及开发了同名程序。方法实现上,首先将每个燃料元件的燃料部分(含控制棒跟随体)以轴向10等分、径向3等分的形式分割为30个独立单元,全堆共形成3180个单元;然后通过灵活调用MCNP程序和ORIGEN2程序获取每个单元的材料组分、核反应截面、中子通量密度和裂变功率,最终实现对各单元衰变热的独立计算和跟踪。分析表明,本文的燃耗评价数据与文献值符合较好,与实验值在测量误差范围内吻合,全堆衰变热计算结果也与行业标准符合,说明本文建立的衰变热精细化计算方法可行,计算结果可信。Abstract: In order to provide a more precise and reliable energy source term for the numerical calculation of waste heat export of pulsed reactor, the calculation method XAPRDH and the program with the same name are developed by coupling MCNP program and ORIGEN2 program. In terms of method realization, firstly, the fuel part of each fuel element (including the control rod follower) is divided into 30 independent units in the form of 10 equal parts in the axial direction and 3 parts in the radial direction, forming a total of 3180 units in the whole reactor; Then, the material composition, nuclear reaction cross section, neutron flux density and fission power of each unit are obtained by flexibly calling MCNP program and ORIGEN2 program, and finally the decay heat of each unit is calculated and tracked independently. The analysis shows that the burnup evaluation data in this paper are in good agreement with the literature values, and are consistent with the experimental values within the measurement error range. The decay heat calculation results of the whole reactor are also in line with the industry standards, indicating that the fine calculation method of decay heat established in this paper is feasible and the calculation results are reliable.

-

Key words:

- Coupling /

- Decay heat /

- Cell /

- Control volume

-

表 1 西安脉冲堆MCNP建模参数

Table 1. MCNP Modeling Parameters for XAPR

部件名称 结构体 材料 密度/(g·cm−3) 内径/cm 外径/cm 长度/cm 燃料元件 锆棒 Zr 6.44 0 0.46 39 燃料芯块 UZrH1.6 6.1792 0.46 3.61 39 上反射层 石墨 1.65 0 3.61 9.6 下反射层 石墨 1.65 0 3.61 9.75 气隙 4He 1.6094×10−4 3.61 3.62 58.35 上端塞 0Cr18Ni11Ti 7.9 0 3.62 1.6 下端塞 0Cr18Ni11Ti 7.9 0 3.62 1.45 包壳 0Cr18Ni11Ti 7.9 3.62 3.72 61.4 石墨元件 石墨芯块 石墨 1.65 0 3.4 58.5 气隙 4He 1.6094×10−4 3.4 3.5 58.5 上下端塞 Al 2.707 0 3.5 1.45 包壳 Al 2.707 3.5 3.7 61.4 稳态控制棒 吸收体 B4C 1.851 0 3.57 39 锆棒 Zr 6.44 0 0.46 39 燃料跟随体 UZrH1.6 6.1792 0.46 3.61 39 上反射层 石墨 1.65 0 3.61 16 下反射层 石墨 1.65 0 3.61 14 气隙 4He 1.6094×10−4 3.57/3.61 3.62 78 上下端塞 0Cr18Ni11Ti 7.9 0 3.62 2.25 包壳 0Cr18Ni11Ti 7.9 3.62 3.72 112.5 脉冲控制棒 吸收体 B4C 1.851 0 2.97 39 气隙 空气 1.293×10−3 2.97 3.02 39 下部气腔 空气 1.293×10−3 0 3.02 54.6 上部簧室 空气 1.293×10−3 0 3.02 15 上下端塞 0Cr18Ni11Ti 7.9 0 3.02 1.95 包壳 0Cr18Ni11Ti 7.9 3.02 3.12 112.5 中子源元件 源盒内腔 AmO2−Be 1.5 0 1.6 3 源盒外壁 0Cr18Ni11Ti 7.9 1.6 3.1 3 源盒上下端盖 0Cr18Ni11Ti 7.9 0 3.1 0.9 上部气腔 空气 1.293×10−3 0 3.1 6.85 下部气腔 空气 1.293×10−3 0 3.1 7.15 上下端塞 0Cr18Ni11Ti 7.9 0 3.1 6.63 外套管 0Cr18Ni11Ti 7.9 3.1 3.6 72.06 围筒及堆池 内层围筒 Al 2.699 69.8 72.2 71 水隙 水 0.9982 72.2 73.4 71 铝反射层 Al 2.699 73.4 75 71 铅屏蔽层 Pb 11.35 75 80 71 外层围筒 Al 2.699 80 81.6 71 堆池 水 0.9982 0 120 200 -

[1] 黄洪文,刘汉刚,米向秒,等. 池式研究堆衰变热计算与实验研究[J]. 核动力工程,2012, 33(5): 12-15,21. doi: 10.3969/j.issn.0258-0926.2012.05.003 [2] 杨磊, 桂学文, 商学利, 等. RELAP5程序衰变热计算误差及其对典型事故进程的影响分析[C]//第十四届全国反应堆热工流体学术会议暨中核核反应堆热工水力技术重点实验室2015年度学术年会论文集. 北京: 清华大学先进反应堆工程与安全教育部重点实验室, 2015: 827-831. [3] 孔军红,徐銤. 实验快堆FFR燃料的衰变热计算[J]. 核动力工程,1993, 14(5): 469-472. [4] MAEDA S, SEKINE T, AOYAMA T. Measurement and analysis of decay heat of fast reactor spent MOX fuel[J]. Annals of Nuclear Energy, 2004, 31(10): 1119-1133. doi: 10.1016/j.anucene.2003.11.002 [5] 陈海英,王韶伟,韩静茹,等. 核电厂堆芯衰变热计算及影响因素分析[J]. 工业安全与环保,2014, 40(9): 68-70,89. doi: 10.3969/j.issn.1001-425X.2014.09.022 [6] 廖玮,张敏杰,田宇. 典型压水堆停堆后衰变热分布变化规律研究[J]. 河南科技,2016, 43(1): 133-135. doi: 10.3969/j.issn.1003-5168.2016.01.045 [7] NOH J M, BAE K M. Decay heat analysis of a VHTR Core using the HELIOS and ORIGEN2 codes[C]//Proceedings of ICAPP 2008. U.S.: American Nuclear Society, 2009: 2533-2539. [8] CROFF A G. A user’s manual for the ORIGEN2 computer code[R]. Tennessee: Oak Ridge National Laboratory, 1980. [9] 杨宁,唐秀欢,张文首,等. 极端事故假设下西安脉冲堆源项计算[J]. 核动力工程,2014, 35(6): 11-16. [10] CROFF A G. Comparison of experimentally determined spent fuel compositions with ORIGEN2 calculations[R]. Oak Ridge: Oak Ridge National Laboratory, 1981. [11] HEEB C M. Comparison of spent fuel decay heat rate ORIGEN2 prediction and calorimeter measurements[R]. PNL-SA-13870, Richland: Pacific Northwest Lab, 1986. [12] 郭和伟,江新标,赵柱民,等. 西安脉冲堆WIMS和MCNP耦合燃耗计算方法[J]. 科技导报,2012, 30(20): 52-55. doi: 10.3981/j.issn.1000-7857.2012.20.008 [13] 阿景烨. γ能谱法无损测定铀氢锆反应堆单棒燃料元件燃耗技术研究[Z]. 西安: 西北核技术研究所, 2006. [14] KOK K D. Nuclear engineering handbook[M]. Boca Raton: CRC Press, 2009: 647. [15] 国家能源局. 轻水堆核燃料衰变热功率的计算: NB/T 20056-2011[S]. 北京: 中国原子能出版社, 2011: 4-6, 37-38. -

下载:

下载: