Parameter Autoregression Algorithm-Based Early Warning Method for Critical Equipment in Nuclear Power Plants

-

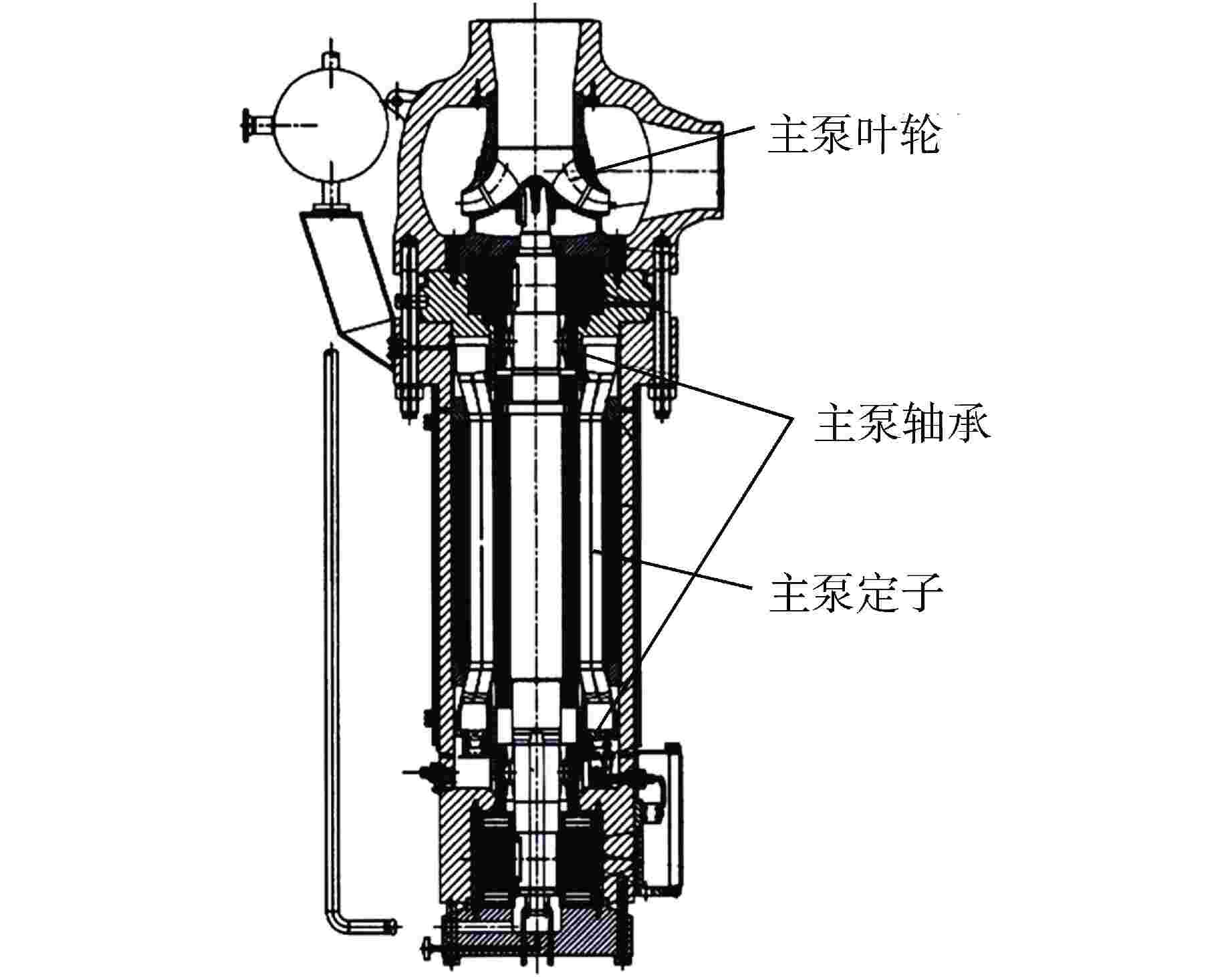

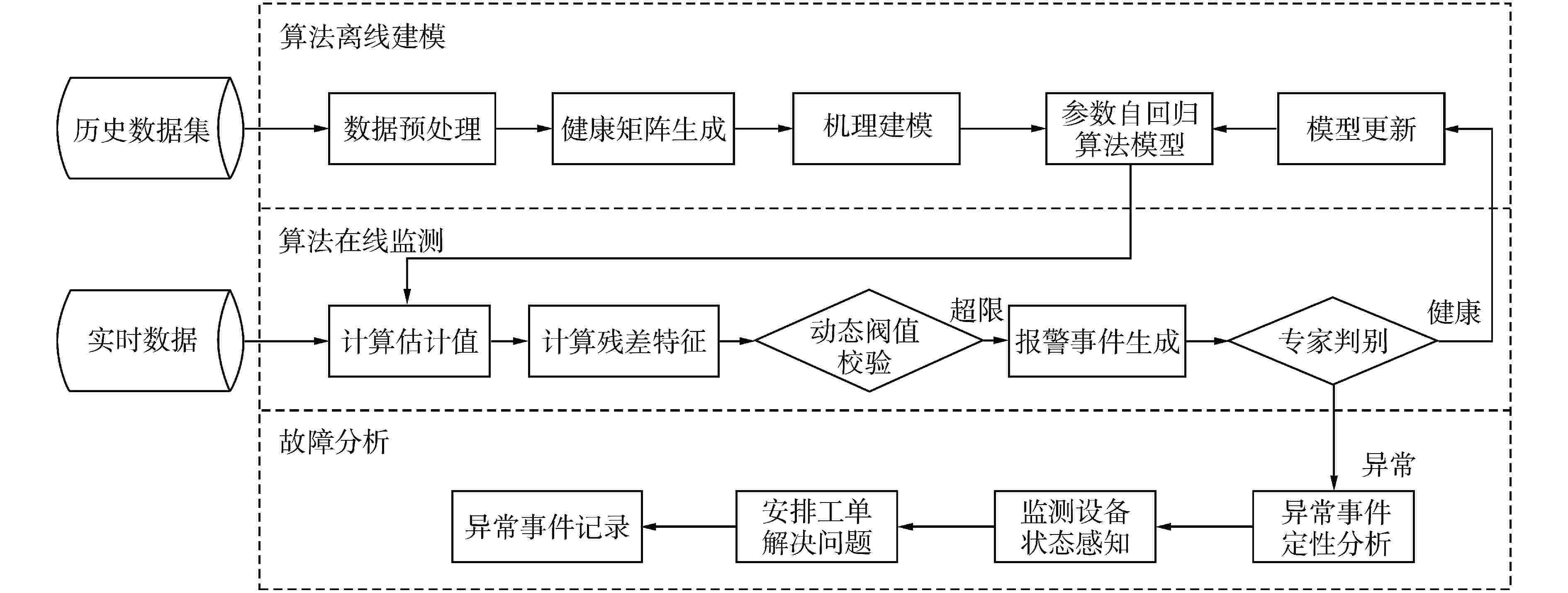

摘要: 本研究设计并开发了一种基于参数自回归算法的用于核电厂关键设备早期预警的方法,该方法创新性地引入了基于多维度时序数据的参数自回归算法,对设备正常运行状态下的参数进行估计,并通过与实测值分析比较来提取残差特征,从而实现了基于动态阈值的设备状态监测机制。此外,结合设备机理,本研究提出并采用了测点重要度的关键概念,通过对设备核心部件拆分建模,实现了对设备运行状态的识别、异常征兆的早期预警、故障部件的确定和相关报警事件的生成。本研究在AP1000核电机组的核心设备——反应堆冷却剂泵(简称主泵)上对设计开发的方法进行了测试验证,通过对主泵实际运行数据和异常事件的相关数据分析,结果表明,与现有设备状态监测方法相比,新建立的关键设备早期预警方法可以在早期发现相关设备的异常征兆,进行预警,并给出关键信息协助工程师进行故障的分析和定位,从而显著缩短了故障诊断和排故的时间,同时极大降低了关键设备监测的人力投入。Abstract: A methodology based on the parameter autoregression algorithm is designed and developed for the early warning of critical equipment in nuclear power plants. The method innovatively introduces a parameter autoregression algorithm based on multi-dimensional time sequence data, which estimates the parameters under normal operation of the equipment and extracts the residual characteristics by comparing them with the measured values, thus realizing a dynamic threshold-based equipment condition monitoring mechanism. In addition, combined with the equipment mechanism, this study proposes and adopts the key concept of measurement point importance, and through the modeling of the core components of the equipment, the identification of the equipment operating state, the early warning of abnormal signs, the identification of faulty components and the generation of relevant alarm events are achieved. This study tests and validates the designed and developed method on the reactor coolant pump (hereinafter referred to as the main pump), the core equipment of AP1000 nuclear power unit. Through the analysis of the actual operation data and abnormal events of the main pump, compared with the existing equipment condition monitoring methods, the newly established early warning method for critical equipment can detect abnormal signs of relevant equipment at an early stage, produce early warning, and provide key information to assist engineers in fault analysis and localization, thus significantly shortening the time for fault diagnosis and troubleshooting, and greatly reducing the manpower input for critical equipment monitoring.

-

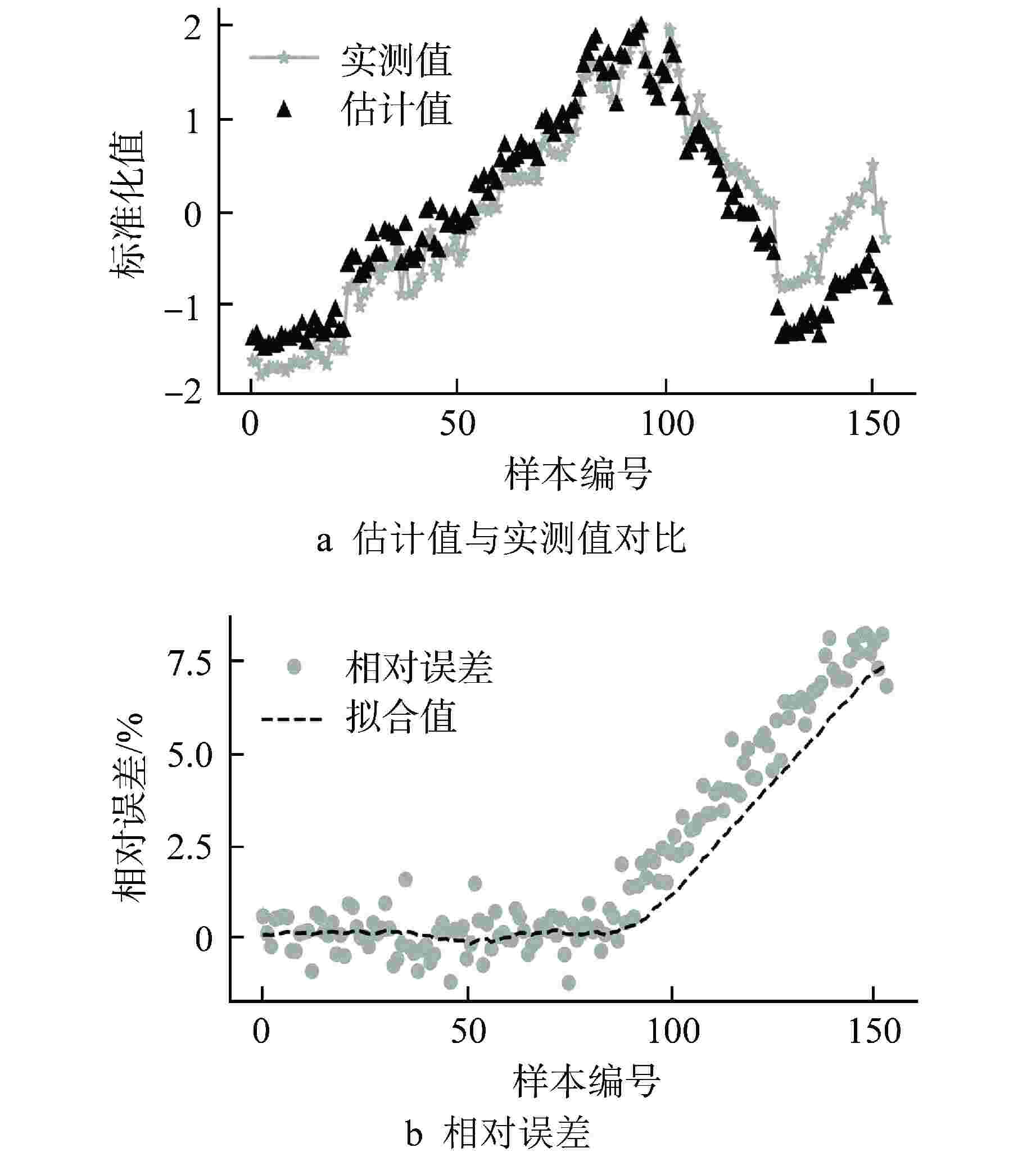

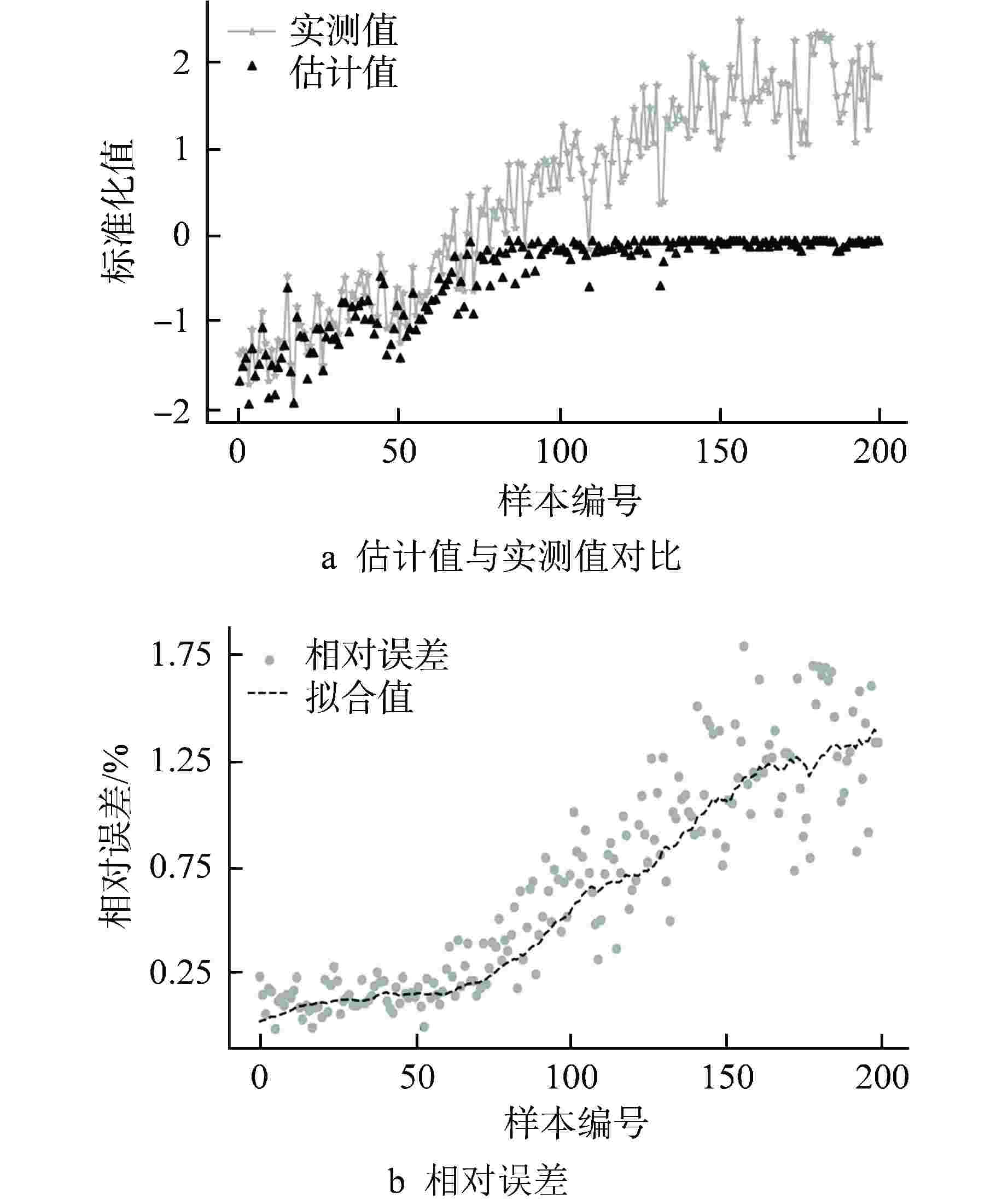

表 1 验证集下轴承模型估计结果与部分测点信息

Table 1. Estimated Results of the Bearing Model under Validation Set and Partial Measurement Points Information

核心测点 平均绝对误差 最大绝对误差 平均相对误差/% 测点重要度 主泵轴承水温度 0.2512℃ 0.9341℃ 0.4140 最重要 主泵功率 7.6639 kW 28.4718 kW 0.0981 重要 主泵转速 0.0143 r/min 0.0367 r/min 0.0114 最重要 轴承振动测点振动幅值 0.0003 mm 0.0011 mm 9.6764 重要 表 2 算法在正常样本与异常样本下识别结果

Table 2. Algorithm Identified Results under Normal and Abnormal Samples

核心测点 平均绝对误差 最大误差 正常样本 异常样本 正常样本 异常样本 主泵轴承水温度/℃ 0.24798 2.61611 0.93408 5.24965 主泵功率/kW 8.12086 8.99024 28.47180 28.56510 主泵转速/(r·min−1) 0.01169 0.01010 0.03372 0.03438 轴承振动测点振动幅值/mm 0.00026 0.00025 0.00088 0.00102 -

[1] 张明乾,刘昱,李承亮. 浅谈压水堆核电站AP1000屏蔽式电动主泵[J]. 水泵技术,2008(4): 1-5. [2] 毛昌森,陈富彬. AP1000蒸汽发生器与主泵泵壳焊接接头无损检测问题分析[J]. 核动力工程,2013, 34(6): 143-147. doi: 10.3969/j.issn.0258-0926.2013.06.034 [3] 官益豪. 三门核电AP1000机组无损检验技术能力验证实践探讨及分析[J]. 无损检测,2014, 36(5): 73-77+79. [4] 魏士源. 三门核电AP1000机组系统工程师巡检方案的策划与实施[J]. 科技创新导报,2018, 15(11): 61-62. [5] 郑华文,曹衍龙,杨将新,等. 基于支持向量机的核电站松动件质量估计方法[J]. 浙江大学学报:工学版,2010, 44(8): 1525-1529. [6] 李彬. 时频分析技术在AP1000特殊监测系统中的应用研究[D]. 哈尔滨: 哈尔滨工程大学, 2015. [7] 陈志辉,夏虹,王涛涛. 基于小波分析的主冷却剂泵转子故障诊断方法研究[J]. 核动力工程,2008, 29(3): 108-112. [8] HINES J W, GARVEY D, SEIBERT R, et al. Technical review of on-line monitoring techniques for performance assessment, Volume 2: Theoretical issues[R]. Washington: U.S. Nuclear Regulatory Commission, 2007. -

下载:

下载: