CFD Analysis on Characteristics of High Temperature Heat Pipe

-

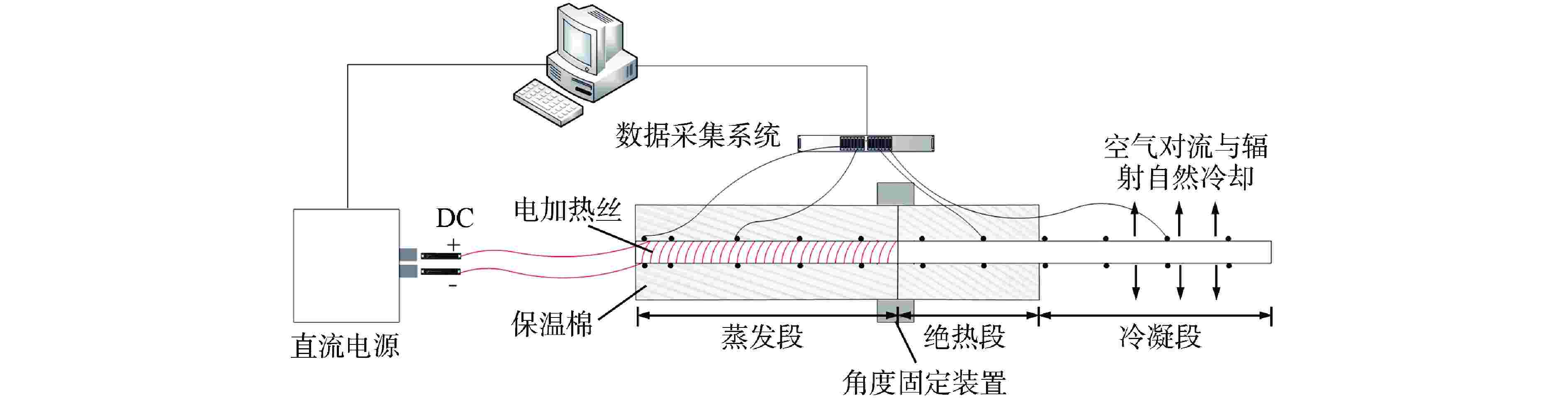

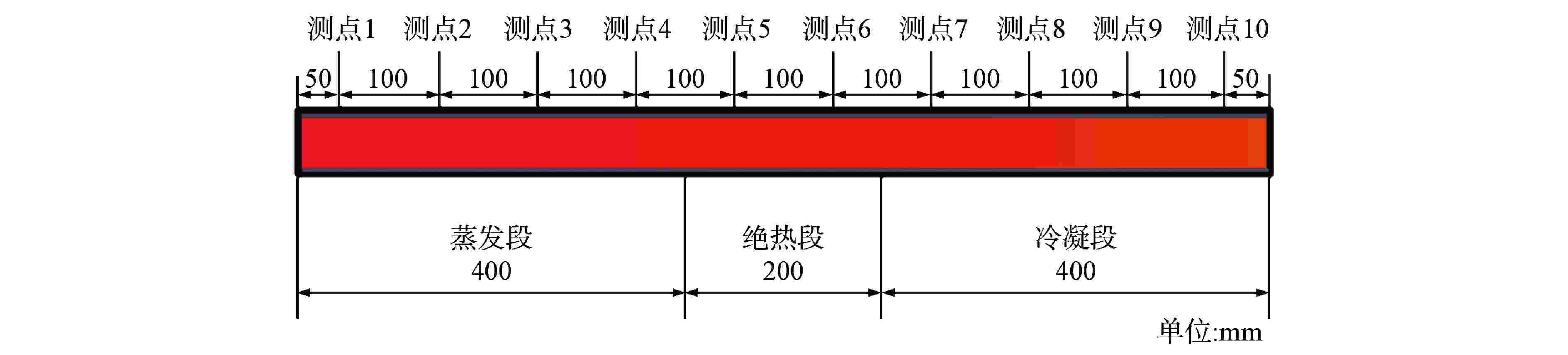

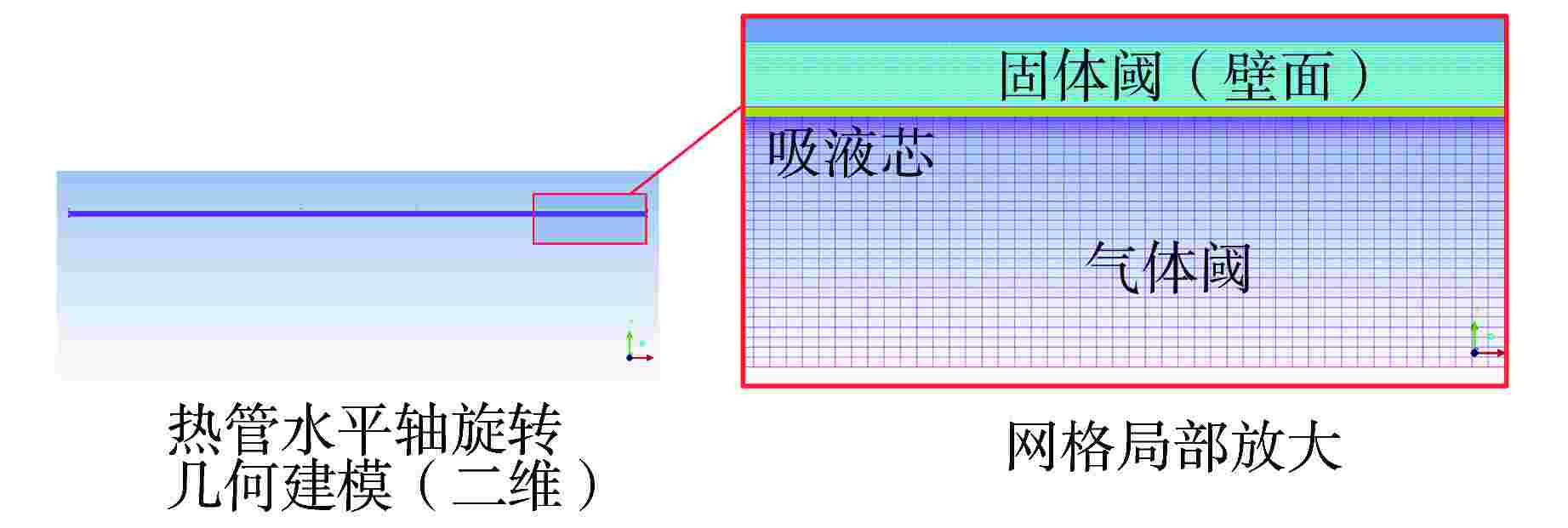

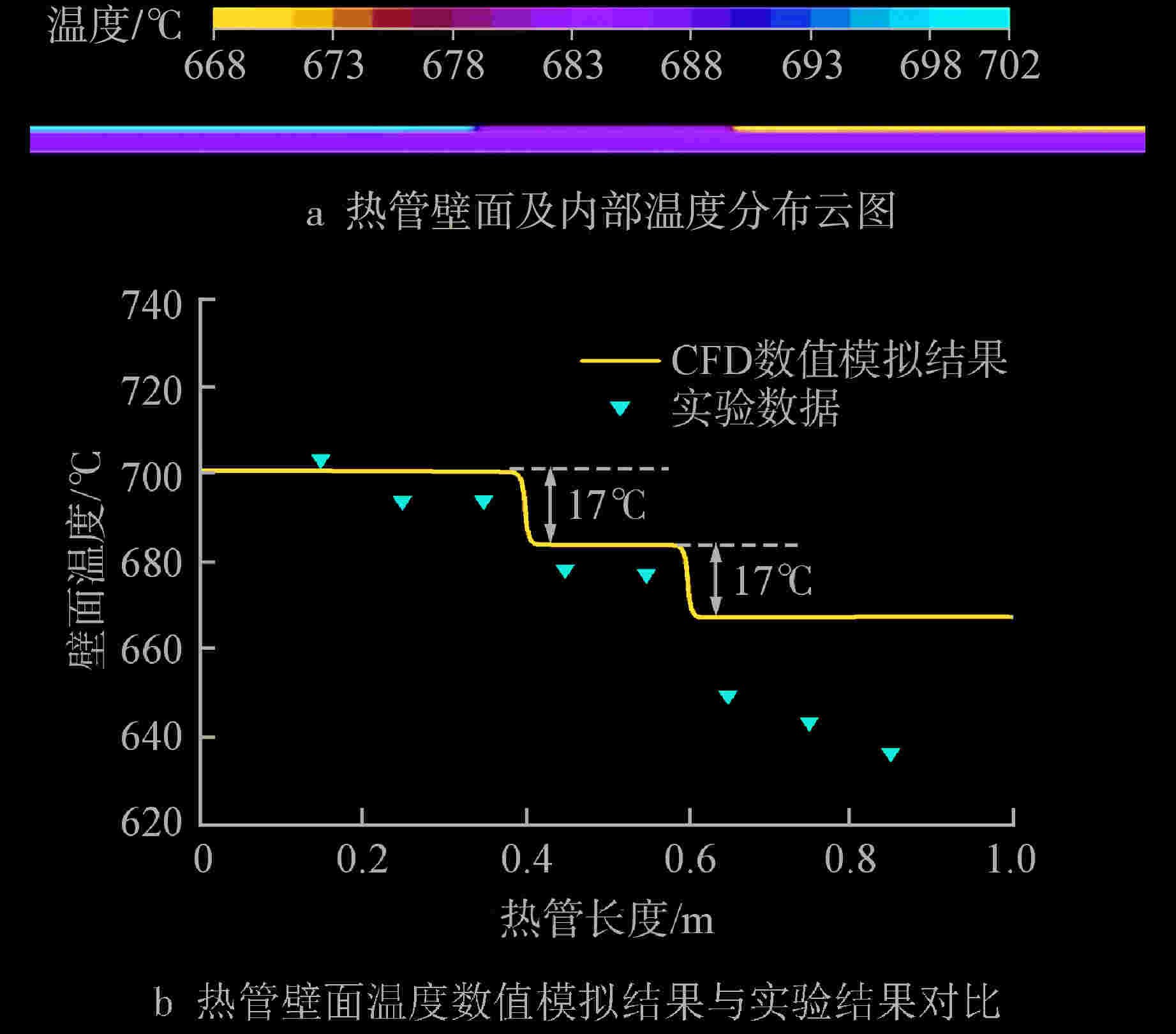

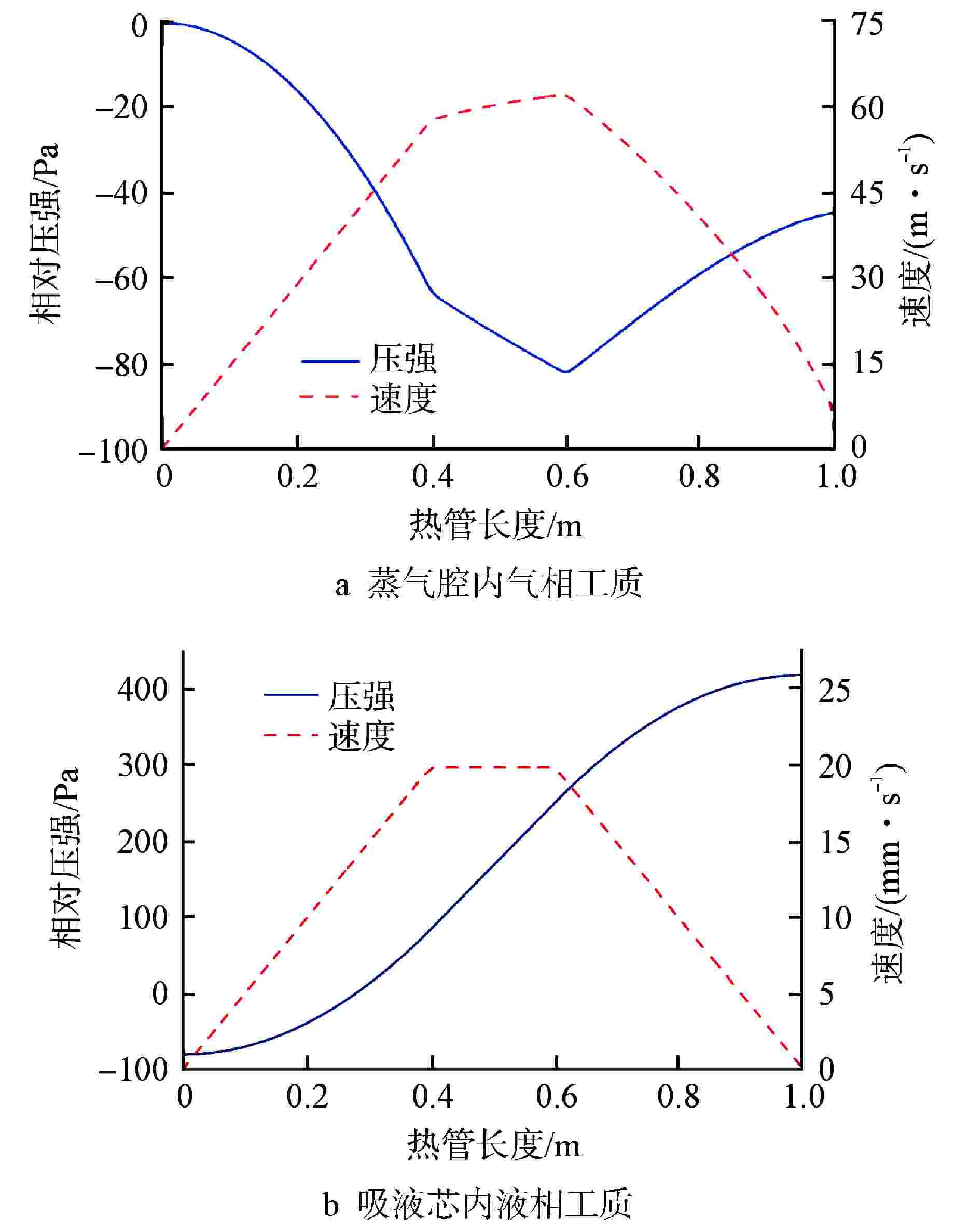

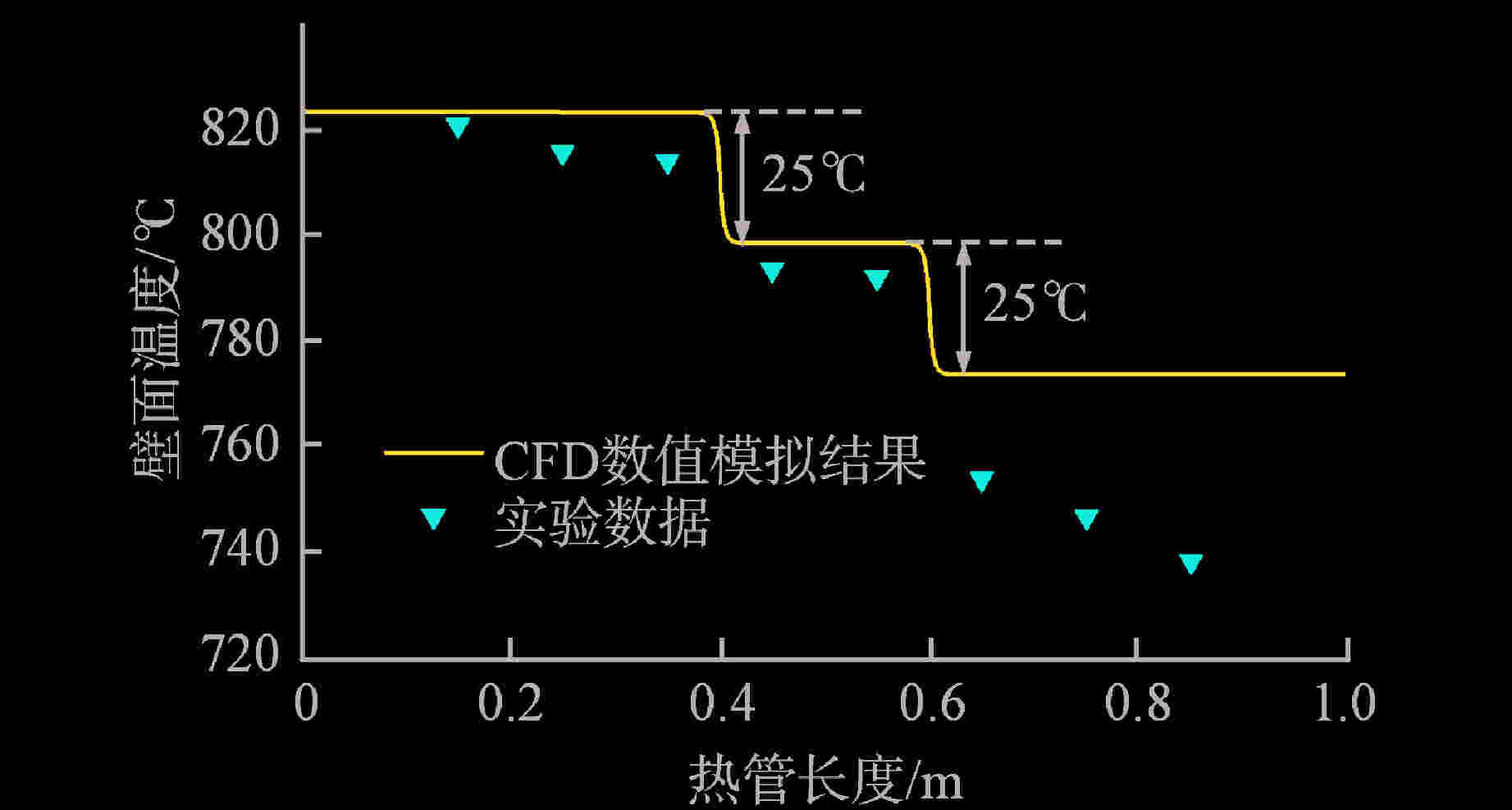

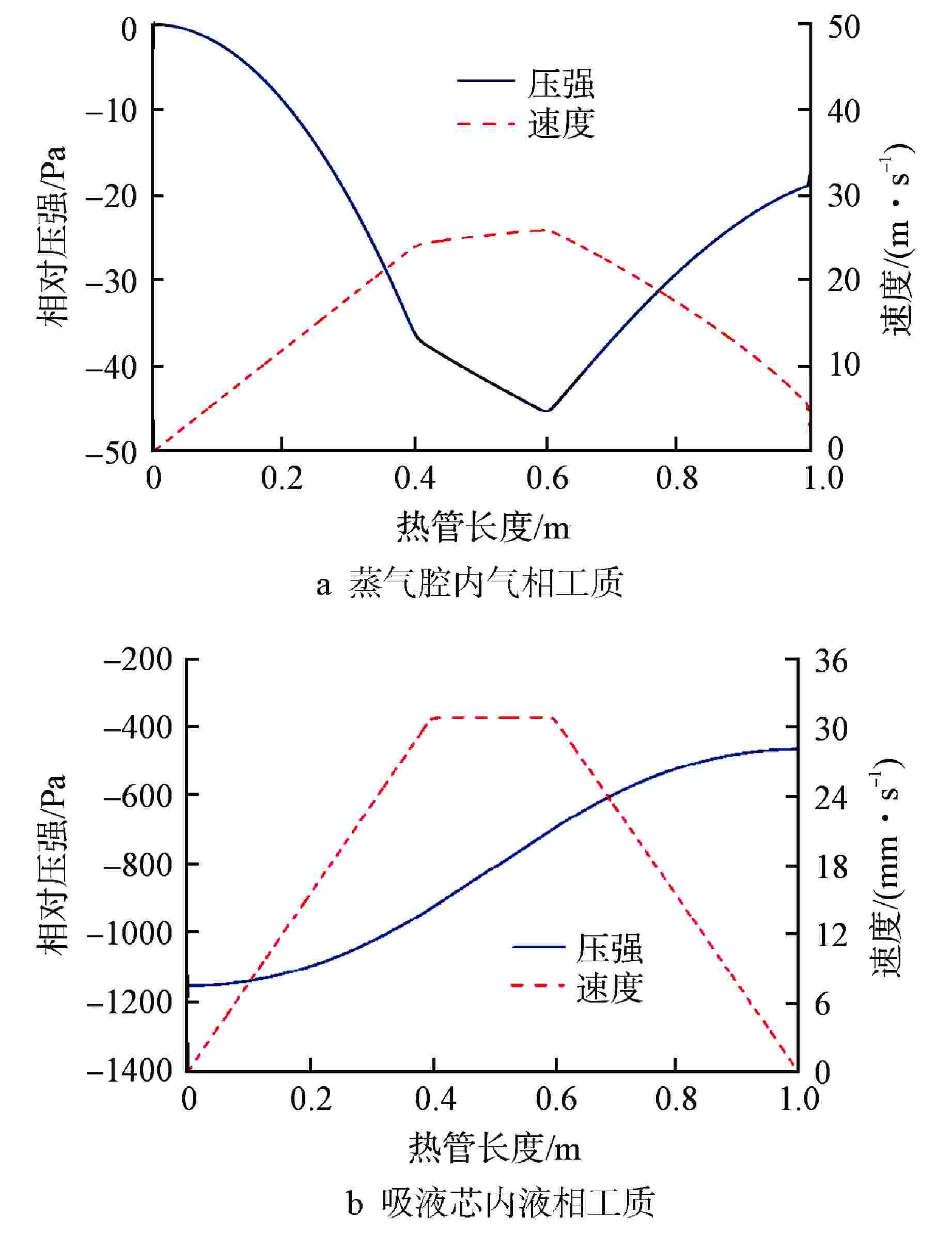

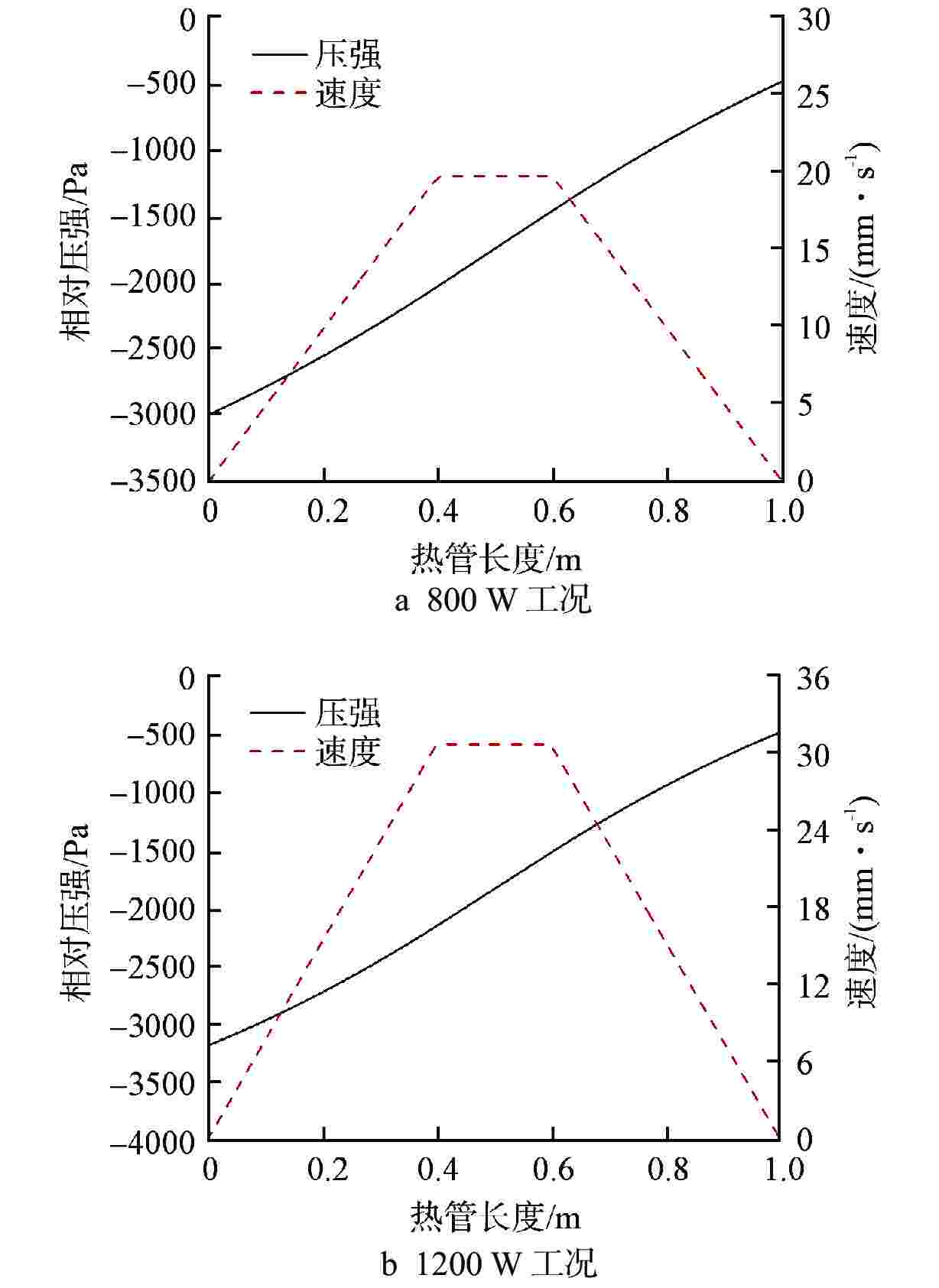

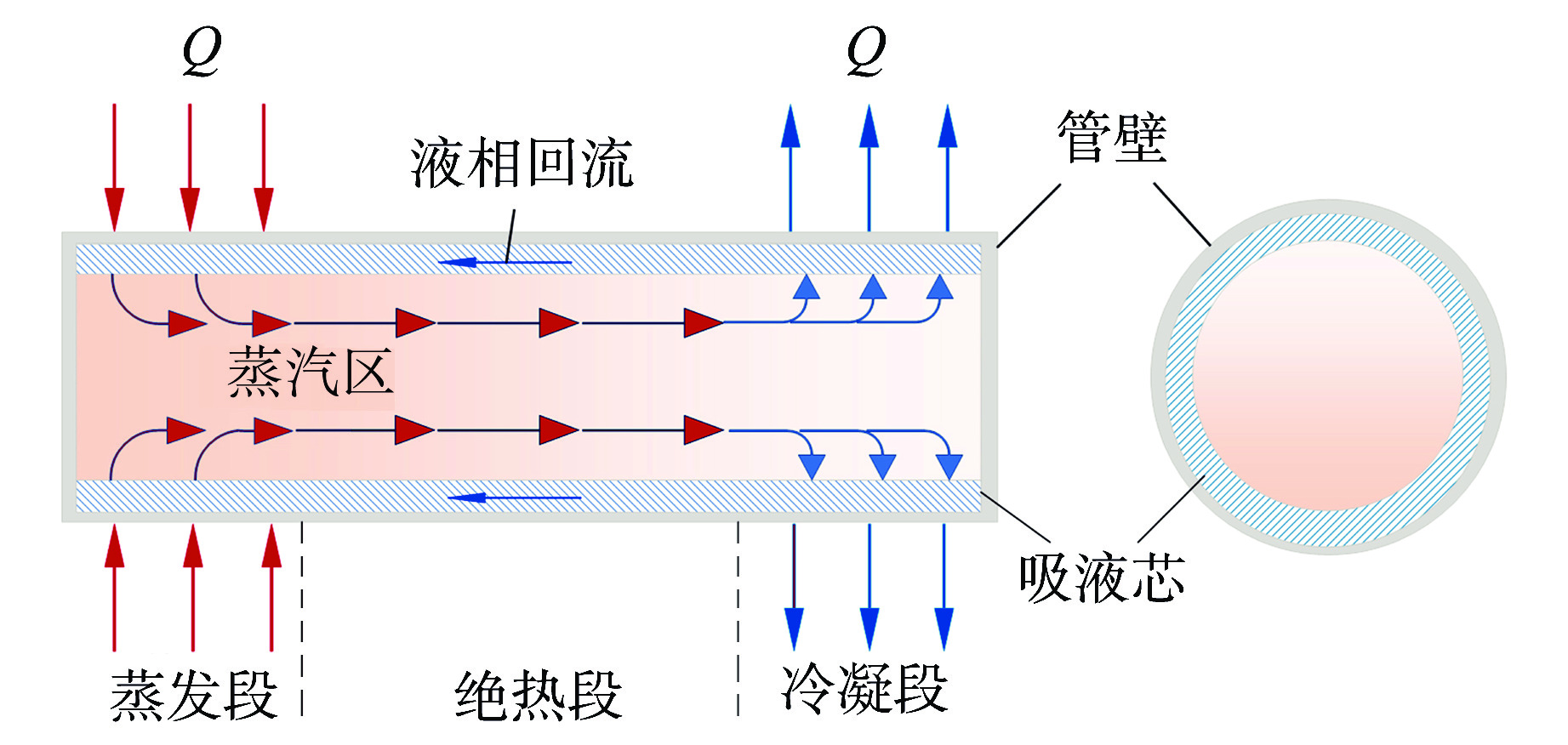

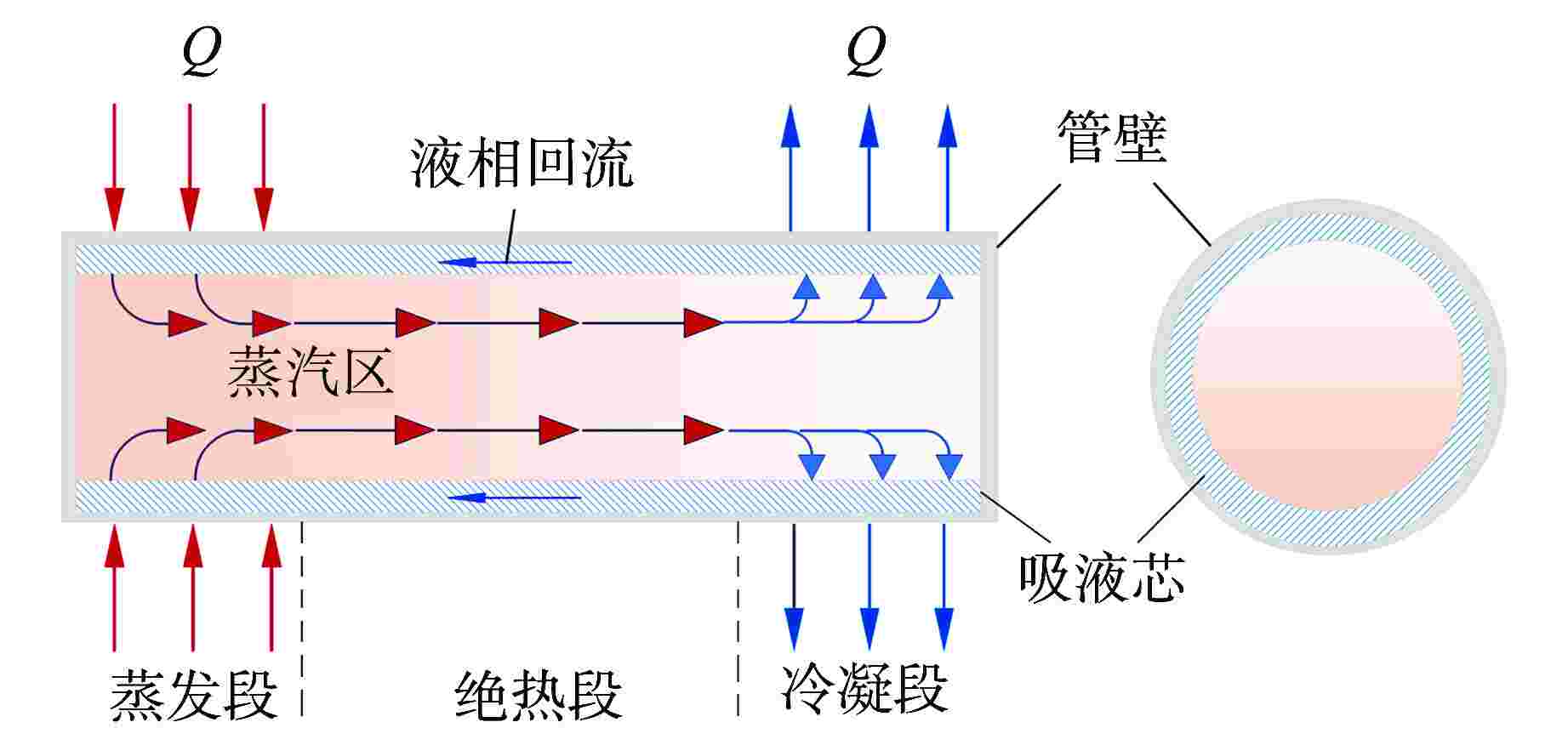

摘要: 高温热管运行特性的分析与预测,对热管设计和应用具有重要意义。为分析高温热管内两相流动传热特性,首先建立钠热管的计算流体力学(CFD)分析模型,并对模型计算值与钠热管稳态实验数据进行对比校核,模拟结果与实验测点温度的绝对误差小于40℃,相对误差在5%以内;其次,利用本文模型与方法对不同传热功率和倾角下的热管内部流场特性进行分析研究。研究表明,均匀加热条件下,蒸气腔内的速度在蒸发段接近线性变化,而在冷凝段,气体流速减小致使压强回升,同时,蒸气的流动压降和速度随加热功率增加呈下降趋势;在热管水平和倾角运行工况,热管内两相流动压降中液相压降均占主导;而气液间剪切效应中,气体流动速度为主导效应。本文模型可为热管堆等高温热管应用领域提供热管设计与分析方法。

-

关键词:

- 高温热管 /

- 计算流体力学(CFD) /

- 温度场 /

- 两相流场

Abstract: The analysis and prediction of the operating characteristics of high temperature heat pipe are of great significance to the design and application of heat pipe. In order to analyze the heat transfer characteristics of two-phase flow in high temperature heat pipe, first, the computational fluid dynamics (CFD) analysis model of sodium heat pipe is established, and the calculated values of the model are compared with the steady-state experimental data of sodium heat pipe. The absolute error between the simulation results and the temperature of the experimental measuring point is less than 40℃, and the relative error is within 5%; Second, the flow field characteristics of heat pipe under different heat transfer power and inclination angle are analyzed and studied by using the model and method in this paper. The results show that under the condition of uniform heating, the velocity in the steam chamber changes nearly linearly in the evaporation section, while in the condensation section, the decrease of gas velocity leads to the rise of pressure. At the same time, the flow pressure drop and velocity of steam decrease with the increase of heating power; Under the horizontal and inclined operating conditions of heat pipe, the liquid phase pressure drop is dominant in the two-phase flow pressure drop in heat pipe; in the gas-liquid shear effect, the gas flow velocity is the dominant effect. The model presented in this paper can provide heat pipe design and analysis methods for high temperature heat pipe applications such as heat pipe reactor. -

表 1 热管模型的边界条件设置

Table 1. Boundary Condition Setting of Heat Pipe Model

边界 边界条件 蒸发段 ${k_{\rm{w}}}\left( {\partial T/\partial n} \right) = q$ 冷凝端 ${ { - } }{k_{\rm{w}}}\left( {\partial T/\partial n} \right) = {h_\infty }(T - {T_\infty }) + \varepsilon \sigma \left( { {T^4} - T_\infty ^4} \right)$ 绝热面 ${k_{\rm{w}}}\left( {\partial T/\partial n} \right) = 0$ 固体壁面与保温层、

吸液芯接触面${k_{\rm{w} } }\left( {\partial T/\partial n} \right) = {k_{\rm{{eff}}} }\left( {\partial {T_{{\rm{wick}}} }/\partial n} \right)$ kw—为壁面热导率;q—热流通量;h∞—冷凝段对流换热系数;T∞—冷凝段边界换热温度;Twick—吸液芯温度;σ—发射率;n—界面法向方向 表 2 钠热管参数

Table 2. Sodium Heat Pipe Parameters

参数名 参数值 参数名 参数值 热管尺寸/mm Φ20×1000 工质 钠 管壁厚度/mm 2 工质充液率/% 20 蒸发段长度/mm 400 管壁材料 316不锈钢 绝热段长度/mm 200 吸液芯类型 不锈钢丝网 冷凝段长度/mm 400 吸液芯结构 100目和400目复合丝网 工作温度/℃ 550~900 吸液芯厚度/mm 0.3 -

[1] FAGHRI A. Review and advances in heat pipe science and technology[J]. Journal of Heat Transfer, 2012, 134(12): 123001. doi: 10.1115/1.4007407 [2] 余红星,马誉高,张卓华,等. 热管冷却反应堆的兴起和发展[J]. 核动力工程,2019, 40(4): 1-8. [3] WANG C L, TANG S M, LIU X, et al. Experimental study on heat pipe thermoelectric generator for industrial high temperature waste heat recovery[J]. Applied Thermal Engineering, 2020, 175: 115299. doi: 10.1016/j.applthermaleng.2020.115299 [4] CHAUDHRY H N, HUGHES B R, GHANI S A. A review of heat pipe systems for heat recovery and renewable energy applications[J]. Renewable and Sustainable Energy Reviews, 2012, 16(4): 2249-2259. doi: 10.1016/j.rser.2012.01.038 [5] 马誉高,杨小燕,刘余,等. MW级热管冷却反应堆反馈特性及启堆过程研究[J]. 原子能科学技术,2021, 55(S2): 213-220. [6] 马誉高,刘旻昀,余红星,等. 热管冷却反应堆核热力耦合研究[J]. 核动力工程,2020, 41(4): 191-196. [7] 冯踏青. 液态金属高温热管的理论和试验研究[D]. 杭州: 浙江大学, 1998: 11. [8] 李桂云,屠进. 高温热管工质的选择[J]. 节能技术,2001, 19(1): 42-44. doi: 10.3969/j.issn.1002-6339.2001.01.018 [9] 田智星,刘逍,王成龙,等. 高温钾热管稳态运行传热特性研究[J]. 原子能科学技术,2020, 54(10): 1771-1778. [10] MA Y G, YU H X, HUANG S F, et al. Effect of inclination angle on the startup of a frozen sodium heat pipe[J]. Applied Thermal Engineering, 2022, 201: 117625. doi: 10.1016/j.applthermaleng.2021.117625 [11] CAO Y, FAGHRI A. A numerical analysis of high-temperature heat pipe startup from the frozen state[J]. Journal of Heat Transfer, 1993, 115(1): 247-254. doi: 10.1115/1.2910657 [12] FERRANDI C, IORIZZO F, MAMELI M, et al. Lumped parameter model of sintered heat pipe: transient numerical analysis and validation[J]. Applied Thermal Engineering, 2013, 50(1): 1280-1290. doi: 10.1016/j.applthermaleng.2012.07.022 [13] TIAN Z X, WANG C L, HUANG J L, et al. Code development and analysis on the operation of liquid metal high temperature heat pipes under full condition[J]. Annals of Nuclear Energy, 2021, 160: 108396. doi: 10.1016/j.anucene.2021.108396 [14] ZUO Z J, FAGHRI A. A network thermodynamic analysis of the heat pipe[J]. International Journal of Heat and Mass Transfer, 1998, 41(11): 1473-1484. doi: 10.1016/S0017-9310(97)00220-2 [15] BEAM J E. Transient heat pipe analysis[C]//Proceedings of the 20th Thermophysics Conference. Williamsburg: AIAA, 1985. [16] 焦永刚,夏国栋,周明正,等. 基于“平面前锋”启动模型的计量用钠热管启动特性[J]. 化工学报,2012, 63(3): 781-787. doi: 10.3969/j.issn.0438-1157.2012.03.015 [17] ALIZADEHDAKHEL A, RAHIMI M, ALSAIRAFI A A. CFD modeling of flow and heat transfer in a thermosyphon[J]. International Communications in Heat and Mass Transfer, 2010, 37(3): 312-318. doi: 10.1016/j.icheatmasstransfer.2009.09.002 [18] ASMAIE L, HAGHSHENASFARD M, MEHRABANI-ZEINABAD A, et al. Thermal performance analysis of nanofluids in a thermosyphon heat pipe using CFD modeling[J]. Heat and Mass Transfer, 2013, 49(5): 667-678. doi: 10.1007/s00231-013-1110-6 [19] SOLOMON A B, RAMACHANDRAN K, ASIRVATHAM L G, et al. Numerical analysis of a screen mesh wick heat pipe with Cu/water nanofluid[J]. International Journal of Heat and Mass Transfer, 2014, 75: 523-533. doi: 10.1016/j.ijheatmasstransfer.2014.04.007 [20] FADHL B, WROBEL L C, JOUHARA H. CFD modelling of a two-phase closed thermosyphon charged with R134a and R404a[J]. Applied Thermal Engineering, 2015, 78: 482-490. doi: 10.1016/j.applthermaleng.2014.12.062 [21] 刘鹤青. 金属丝编织密纹网的孔隙率[J]. 过滤与分离,2007, 17(4): 26-27,33. doi: 10.3969/j.issn.1005-8265.2007.04.008 [22] SUN H, TANG S M, WANG C L, et al. Numerical simulation of a small high-temperature heat pipe cooled reactor with CFD methodology[J]. Nuclear Engineering and Design, 2020, 370: 110907. doi: 10.1016/j.nucengdes.2020.110907 [23] RANJAN R, MURTHY J Y, GARIMELLA S V, et al. A numerical model for transport in flat heat pipes considering wick microstructure effects[J]. International Journal of Heat and Mass Transfer, 2011, 54(1-3): 153-168. doi: 10.1016/j.ijheatmasstransfer.2010.09.057 [24] 庄骏, 张红. 热管技术及其工程应用[M]. 北京: 化学工业出版社, 2000: 65. -

下载:

下载: