Numerical Simulation of Lead-bismuth Alloy Solidification in Lead-water Reaction

-

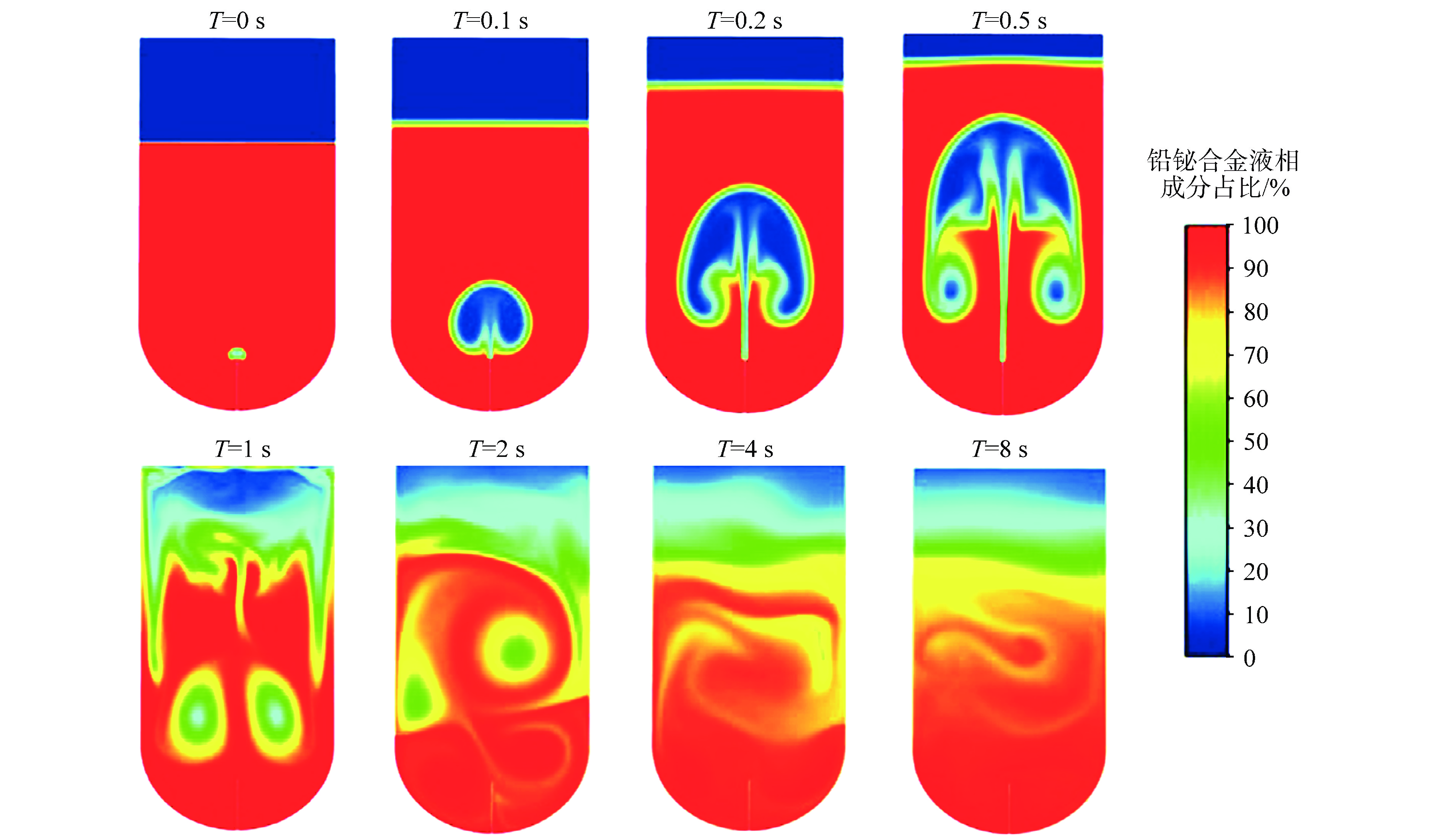

摘要: 为了研究铅铋合金在蒸汽发生器传热管破裂(SGTR)事故所引发的铅铋合金与水反应过程中的凝固机理,通过耦合VOF模型、Realizable k-ε湍流模型、凝固传热模型,利用FLUENT软件建立了铅铋合金与水反应过程的二维仿真模型,并将该模型与现有反应实验的结果进行对比验证。随后基于热焓法建立可以直观描述铅铋合金凝固现象的凝固传热特性热焓方程,通过控制模型变量研究影响铅铋合金凝固发生的因素及条件,最后将该模型应用于复杂结构场景中。结果表明,铅铋合金与水的温差、水流喷射初始速度、注水管径是影响铅铋合金凝固的主导因素,本文提出的模型具有较高可靠性,能够模拟实际工况中铅铋合金的凝固现象。本研究所得到的机理性结论与现象学结论能够为铅基快堆安全分析提供理论支撑。

-

关键词:

- 铅水反应 /

- 铅基快堆 /

- 铅铋合金 /

- 凝固 /

- 蒸汽发生器传热管破裂(SGTR)

Abstract: In order to study the solidification mechanism of lead-bismuth alloy in the reaction between lead-bismuth alloy and water caused by steam generator tube rupture (SGTR), in this paper, by coupling the VOF model, the Realizable k-ε turbulence model, the solidification heat transfer model, and using the FLUENT software, a two-dimensional simulation model of the reaction process of lead-bismuth alloy and water is established, and the model is compared and verified with the results of the existing reaction experiments. Then, based on the enthalpy method, the enthalpy equation of solidification heat transfer characteristics which can directly describe the solidification phenomenon of lead-bismuth alloy is established, the factors and conditions affecting the solidification of lead-bismuth alloy are studied by controlling the model variables. Finally, the model is applied to the scene with complex structure. The results show that the temperature difference between lead-bismuth alloy and water, the initial speed of water jet and the diameter of water injection are the main factors affecting the solidification of lead-bismuth alloy. The model proposed in this paper has high reliability and can simulate the solidification phenomenon of lead-bismuth alloy under actual working conditions. The mechanistic and phenomenological conclusions obtained in this study can provide theoretical support for the safety analysis of lead-based fast reactor. -

-

[1] 周丽丽. 液态金属铅凝固过程中微观结构演变特性的模拟研究[D]. 长沙: 湖南大学, 2012: 8-23. [2] 王龙. 先进核反应堆用铅铋合金热物理性能实验研究[D]. 合肥: 合肥工业大学, 2014: 7-10. [3] CIAMPICHETTI A, BERNARDI D, CADIOU T, et al. LBE–water interaction in LIFUS 5 facility under different operating conditions[J]. Journal of Nuclear Materials, 2011, 415(3): 449-459. doi: 10.1016/j.jnucmat.2011.04.051 [4] 张朝东. 蒸汽发生器管道破裂对铅基堆热工安全特性影响分析[D]. 合肥: 中国科学技术大学, 2018: 41-89. [5] MELICHAR T, FRÝBORT O, MATOUŠ P, et al. Design and the first experimental data from sesame-stand for lead solidification experiments[C]//SESAME International Workshop. Petten, The Netherlands, 2019. [6] PROFIR M, MOREAU V, MELICHAR T. Numerical and experimental campaigns for lead solidification modelling and testing[J]. Nuclear Engineering and Design, 2020, 359: 110482. doi: 10.1016/j.nucengdes.2019.110482 [7] IANNONE M, DOFEK I, MELICHAR T, et al. Development of CFD models and pre-test calculations for thermal-hydraulics and freezing experiments on lead coolant[C]//Proceedings of the 26th International Conference Nuclear Energy for New Europe. Bled, Slovenia, 2017 [8] 杜晓超,刘帅,刘鹏,等. 基于DPM模型的铅铋合金中颗粒物对管道冲蚀的数值模拟研究[J]. 核动力工程,2021, 42(1): 48-53. [9] 许裕恒,牛风雷,张瑜,等. 饱和氧浓度铅铋共晶合金中Cu/Cu2O型氧传感器性能研究[J]. 核动力工程,2020, 41(4): 181-184. -

下载:

下载: