Design and Heat Transfer Performance Analysis of Ultra-High Temperature Lithium Heat Pipe

-

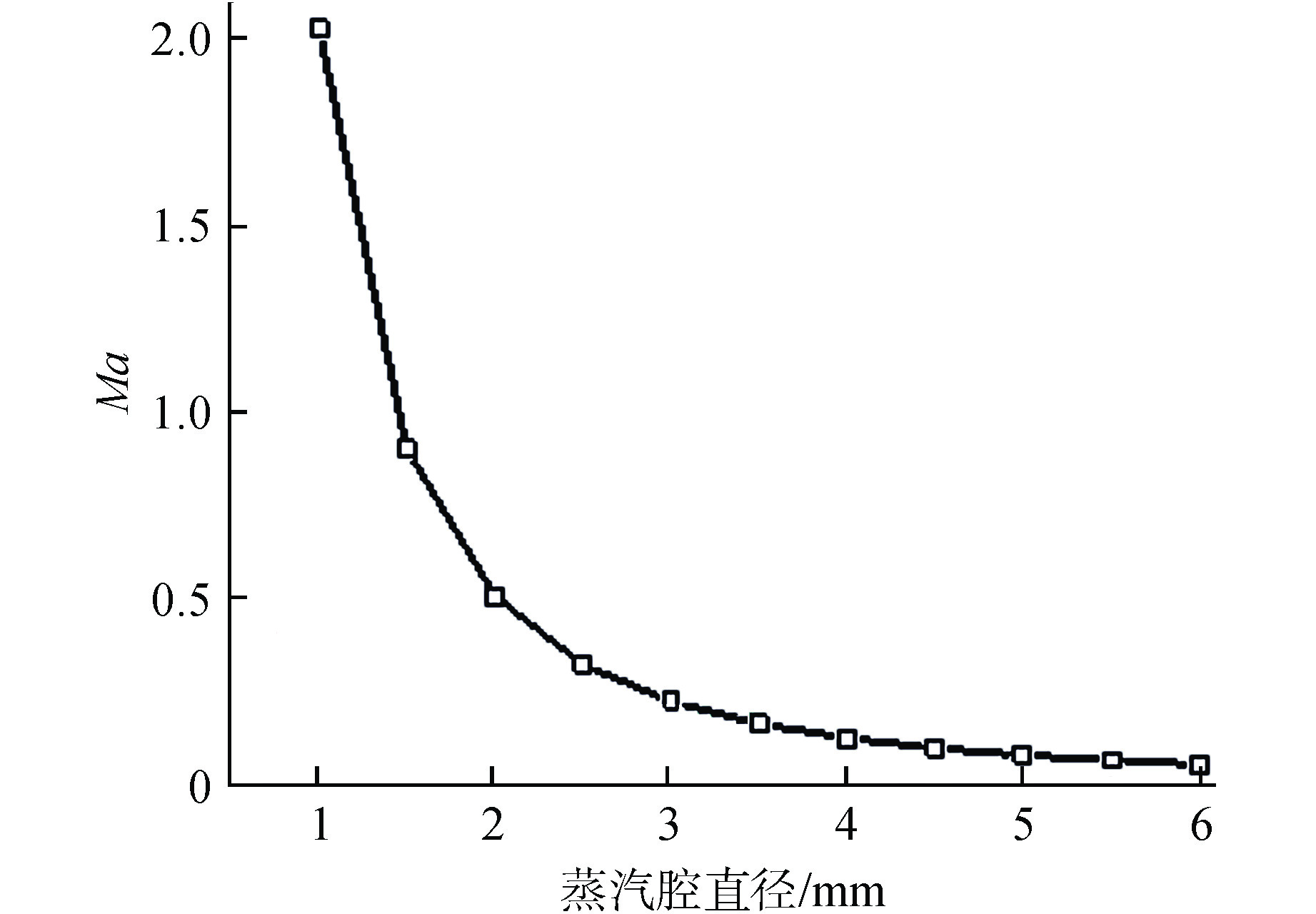

摘要: 超高温锂热管冷却的核反应堆因其静默性、体积小等优势,在深海核动力和深空探测方面具有广泛的应用前景。为掌握超高温锂热管的传热特性,开展了超高温锂热管设计,并基于热阻网格法开发了超高温锂热管的Python程序,在此基础上对锂热管进行热输运性能分析。通过与其他现有模型和实验数据对比,验证了本文开发的模型精度,且应用该程序校核了本文设计的超高温锂热管,并分析了超高温锂热管在变功率工况下热管结构对热管达到新的稳定状态所需转变时间的影响。结果表明,本文设计的超高温锂热管符合设计要求;增加管壁厚度和吸液芯厚度会增加转变时间;增加冷凝段长度有利于减少转变时间。本文研究为热管堆的优化设计和安全分析提供了依据。Abstract: Ultra-high temperature lithium (Li) heat pipe cooled nuclear reactor has broad application prospects in the areas of deep-sea nuclear power and deep-space exploration due to its silence, small size and other advantages. In order to master the heat transfer characteristics of ultra-high temperature lithium heat pipe, the design of ultra-high temperature lithium heat pipe is carried out, and the Python program of ultra-high temperature lithium heat pipe is developed based on the thermal resistance grid method. On this basis, the heat transport performance of lithium heat pipe is analyzed. By comparing with other existing models and experimental data, the accuracy of the model developed in this paper is verified, and the ultra-high temperature lithium heat pipe designed in this paper is checked by using this program, and the influence of heat pipe structure on the transition time of ultra-high temperature lithium heat pipe to reach a new stable state under variable power condition is analyzed. The results show that the ultra-high temperature lithium heat pipe designed in this paper meets the design requirements; increasing the wall thickness and wick thickness increase the transition time; increasing the length of the condensation section is beneficial to reduce the transition time. The research in this paper provides the basis for the optimization design and safety analysis of the heat pipe reactor.

-

Key words:

- Lithium heat pipe /

- Model development /

- Python /

- Transition time /

- Heat pipe reactor

-

表 1 锂热管的结构参数

Table 1. Structural Parameters of the Lithium Heat Pipe

参数 数值 壳体及端盖材料 Nb-1%Zr 吸液芯材料 铌合金 蒸汽腔直径/mm 9.3 环形空隙厚度/mm 0.1 管壁厚度/mm 1 热管外径/mm 12 热管蒸发段长度/mm 300 热管绝热段长度/mm 100 热管冷凝段长度/mm 600 -

[1] YUAN Y, SHAN J Q, ZHANG B, et al. Study on startup characteristics of heat pipe cooled and AMTEC conversion space reactor system[J]. Progress in Nuclear Energy, 2016, 86: 18-30. doi: 10.1016/j.pnucene.2015.10.002 [2] SUN H, WANG C L, MA P, et al. Conceptual design and analysis of a multipurpose micro nuclear reactor power source[J]. Annals of Nuclear Energy, 2018, 121: 118-127. doi: 10.1016/j.anucene.2018.07.025 [3] MCCLURE P, RAY, DIXON D, et al. Mobile heat pipe cooled fast reactor system: US, 14/773, 405[P]. 2014-10-30. [4] FAGHRI A. Heat pipe science and technology[M]. Washington DC: Taylor & Francis, 1995: 41-55. [5] LIU X, ZHANG R, LIANG Y, et al. Core thermal-hydraulic evaluation of a heat pipe cooled nuclear reactor[J]. Annals of Nuclear Energy, 2020, 142: 107412. doi: 10.1016/j.anucene.2020.107412 [6] MCCLURE P R, POSTON D I, DASARI V R, et al. Design of megawatt power level heat pipe reactors: LA-UR-15-28840[R]. Los Alamos: Los Alamos National Lab, 2015. [7] 张文文,刘逍,田文喜,等. 兆瓦级空间热管反应堆动力系统概念设计[J]. 原子能科学技术,2017, 51(12): 2160-2164. doi: 10.7538/yzk.2017.51.12.2160 [8] 赵蔚琳,庄骏. 碱金属热管轴向传热极限的研究[J]. 南京化工大学学报,1994(S1): 111-114. [9] 于萍,张红,许辉,等. 高温钠热管再启动特性研究[J]. 中国电机工程学报,2015, 35(2): 404-410. [10] ZHOU R W, XIANG L, HAO P, et al. Thermal characteristics of the combined flat plate heat receiver in solar power tower plant[J]. Energy, 2018, 165: 275-289. doi: 10.1016/j.energy.2018.09.073 [11] 赵蔚琳,庄骏,张红. 水平放置高温热管翅起动性能分析[J]. 石油化工设备,2003, 32(4): 8-10. doi: 10.3969/j.issn.1000-7466.2003.04.003 [12] 王成龙,田文喜,苏光辉,等. 新概念熔盐堆非能动余热排出系统中钠热管的特性研究[J]. 原子能科学技术,2013, 47(12): 2254-2260. doi: 10.7538/yzk.2013.47.12.2254 [13] 牛涛,张艳苓,侯红亮,等. 高温热管性能分析与试验[J]. 航空学报,2016, 37(S1): 59-65. [14] 冯踏青. 液态金属高温热管的理论和试验研究[D]. 杭州: 浙江大学, 1998. [15] 王成龙,田文喜,苏光辉,等. 熔盐堆新型非能动余热排出系统中高温热管的数值分析[J]. 核动力工程,2014, 35(1): 32-35. [16] 贾先剑,郭航,郭青,等. 不同加热温度下钠钾合金热管传热性能[J]. 应用能源技术,2016(3): 7-11. doi: 10.3969/j.issn.1009-3230.2016.03.002 [17] 柴宝华,杜开文,卫光仁,等. 钾热管稳态数值模拟分析[J]. 原子能科学技术,2010, 44(5): 553-557. [18] 卫光仁,柴宝华,魏国锋,等. 干道式高温热管的传热性能试验研究[J]. 原子能科学技术,2014, 48(3): 447-452. doi: 10.7538/yzk.2014.48.03.0447 [19] 韩冶,柴宝华,卫光仁,等. 有芯和无芯高温重力钾热管启动性能试验研究[J]. 原子能科学技术,2019, 53(1): 38-44. [20] 田智星,刘逍,王成龙,等. 高温钾热管稳态运行传热特性研究[J]. 原子能科学技术,2020, 54(10): 1771-1778. [21] 刘逍,田智星,王成龙,等. 高温热管传热特性实验研究[J]. 核动力工程,2020, 41(S1): 106-111. [22] DOS SANTOS BERNARDES M A. Developments in heat transfer[M]. Rijeka: InTech, 2011: 508-510. [23] REAY D A, REAY K P, MCGLEN R J. Heat pipes theory design & applications[M]. Burlington: Elsevier, 2006: 116 [24] CHI S W. 热管理论与实用[M]. 蒋章焰, 译. 北京: 科学出版社, 1981: 186-214 [25] 陈富财,钱益昊,罗英,等. 倾角对重力热管携带极限影响的实验研究[J]. 核动力工程,2020, 41(S2): 21-26. [26] 庄骏, 张红. 热管技术及其工程应用[M]. 北京: 化学工业出版社, 2000: 31-66. [27] ZUO Z J, FAGHRI A. A network thermodynamic analysis of the heat pipe[J]. International Journal of Heat and Mass Transfer, 1998, 41(11): 1473-1484. doi: 10.1016/S0017-9310(97)00220-2 -

下载:

下载: