Transient Characteristics Analysis of 2000 kW High Temperature and High Pressure Test Loop of HFETR during Loss of Power Accident of Main Pump

-

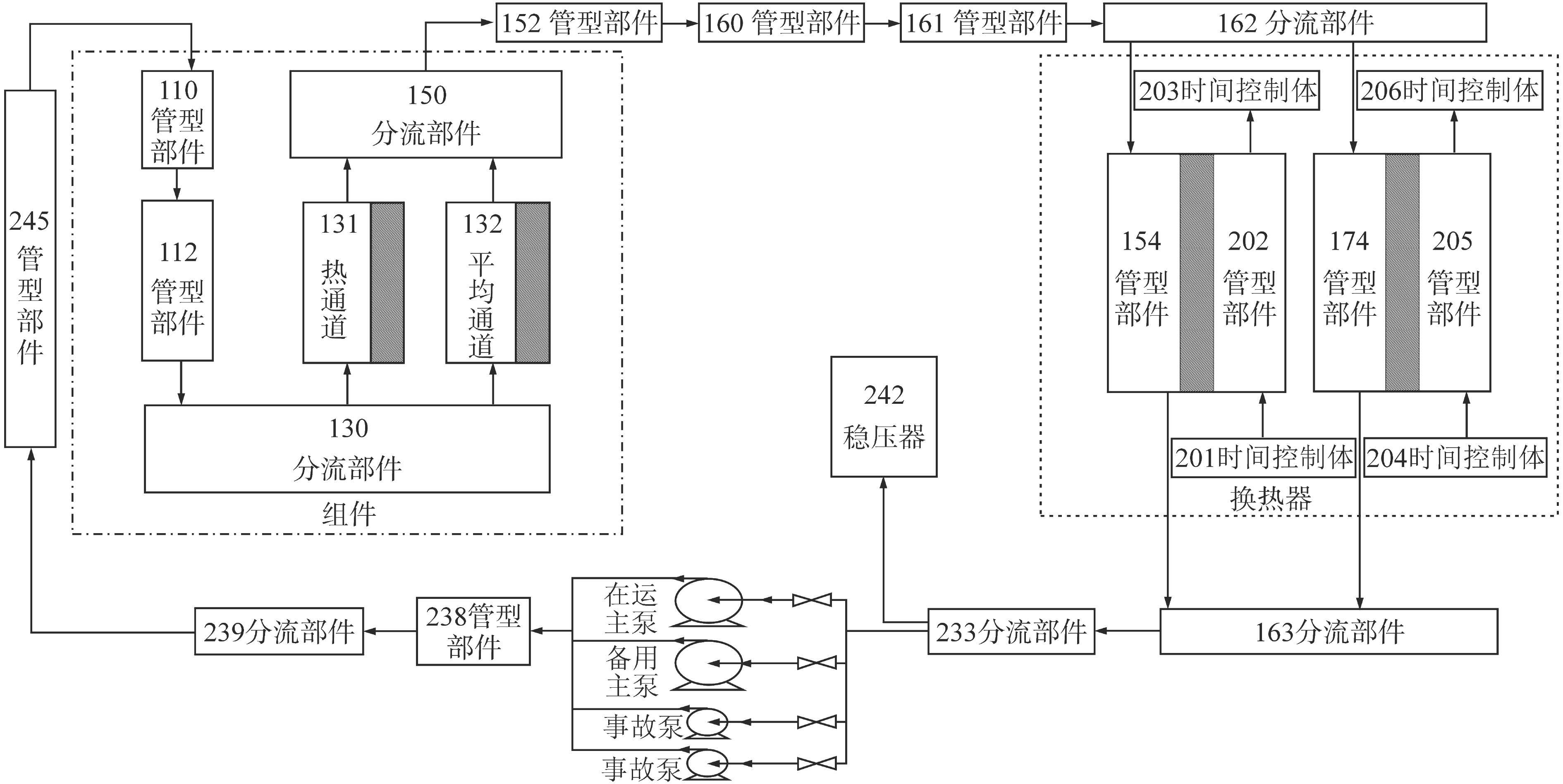

摘要: 为了研究高通量工程试验堆(HFETR)内2000 kW高温高压考验回路在主泵断电事故过程中的安全特性,基于RELAP5程序建立了考验回路的仿真模型,采用验证后的模型开展了主泵断电事故瞬态特性分析。计算结果表明,在主泵断电事故过程中,主泵高速工况会切换至2台事故泵低速工况,流量下降较快并最终稳定至初始流量的一半,燃料包壳在4.34 s达到峰值温度763 K;之后由于功率的不断下降,包壳温度随之不断下降;事故过程中最小偏离泡核沸腾比大于1.3,表明不会发生偏离泡核沸腾,满足安全要求。

-

关键词:

- RELAP5 /

- 辐照考验回路 /

- 主泵断电事故 /

- 高通量工程试验堆(HFETR)

Abstract: In order to study the safety characteristics of 2000 kW high temperature and high pressure test loop in high flux engineering test reactor (HFETR) in the process of loss of power accident of main pump, the simulation model of test loop is established based on RELAP5 code, and the transient characteristics of loss of power accident of main pump are analyzed by using the verified model. The calculation results show that in the process of loss of power accident of main pump, the high-speed working condition of the main pump switches to the low-speed working condition of the two accident pumps, the flow rate decreases rapidly and finally stabilizes to half of the initial flow rate, and the fuel cladding reaches a peak temperature of 763 K at 4.34 s; Then, due to the continuous decline of power, the cladding temperature decreases continuously; The minimum departure from nucleate boiling ratio during the accident is greater than 1.3, which indicates that departure from nucleate boiling will not occur and meets the safety requirements. -

表 1 主要参数的初始值

Table 1. Initial Values of Main Parameters

主要参数 参数值 初始核功率/kW 270 初始稳压器压力/MPa 13.7 初始入口水温/K 518 初始冷却剂流量/( kg·s-1) 1.41 二次侧给水温度/K 297 二次侧给水流量/ ( kg·s-1) 2.21 二次侧压力/MPa 0.6 主泵出口流量低整定值/%(额定值) 75 停堆信号延迟时间/s 0.25 表 2 主泵断电事故主要事件序列

Table 2. Main Event Sequence during Loss of Power Accident of Main Pump

事件序列 时间/s 两路外电源失电 0 流量低停堆信号产生 3.36 控制棒开始下插 3.61 DNBR达到最小 3.79 燃料包壳温度达到峰值 4.34 衰减到额定流量一半时间 5.48 辐照装置出口水温开始下降 5.90 -

[1] 曹娜,孙胜. HFETR 2000 kW辐照考验回路节流装置设计[J]. 机械,2016, 43(6): 63-66. [2] 胡泊,郭斯茂,王冠博,等. CMRR堆内高温高压辐照考验回路典型事故分析[J]. 强激光与粒子束,2019, 31(9): 096001. doi: 10.11884/HPLPB201931.190023 [3] 张毅. CARR高温高压试验回路事故分析[D]. 北京: 中国原子能科学研究院, 2007. [4] CARLSON K E, RIEMKE R A, ROUHANL S Z, et al. RELAP5/MOD3 code manual volume III: developmental assessment problems (DRAFT): NUREG/CR-5535, EGG-2596[R]. America: EG&G Idaho, Inc. , 1990. [5] KIM Y S, BAE B U, PARK C H, et al. RELAP5/MOD3.3 analysis of coolant depletion tests after safety injection failure during a large-break loss-of-coolant accident[J]. Nuclear Engineering and Design, 2005, 235(22): 2375-2390. doi: 10.1016/j.nucengdes.2005.04.010 -

下载:

下载: