Design and Analysis of Irradiation Test Scheme for Fast Reactor Fuel Slug with HFETR

-

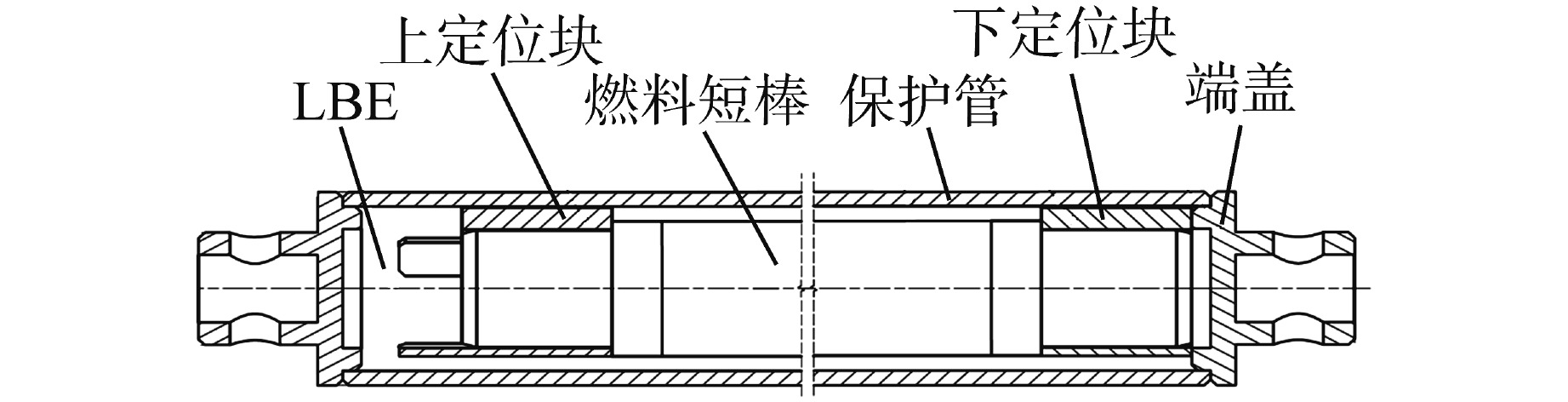

摘要: 综合考虑辐照试验指标与燃料试验安全、高通量工程试验堆(HFETR)运行要求、试验段压差波动等因素,基于HFETR开展了快堆燃料短棒辐照试验方案设计与分析,确定了铅铋合金层厚度、冷却水流道结构、阻力塞结构、冷却水流量等关键参数,获得了热棒包壳最高温度为(490±60)℃的高线功率密度辐照试验方案。试验结果表明,热棒最大线功率密度为68~85 kW/m时,包壳与燃料芯体温度满足辐照试验要求且留有余量;在200~300 kPa堆芯压差范围内,相同压差下试验段流量的计算流体力学(CFX)计算值比试验值偏小9% ~11%;试验段外侧窄缝流道的流量份额为7.3%,显著低于该流道的流通面积份额,满足线功率密度为85 kW/m时燃料短棒的冷却要求。本文提出的辐照试验方案可为快堆燃料棒的高线功率密度辐照试验提供参考。

-

关键词:

- 高通量工程试验堆(HFETR) /

- 燃料辐照试验 /

- 快堆燃料棒 /

- 热工水力

Abstract: Considering the irradiation test index and fuel test safety, the operation requirements of high flux engineering test reactor (HFETR), the pressure difference fluctuation in the test section and other factors, in this paper, based on HFETR, the design and analysis of the fast reactor fuel slug irradiation test plan were carried out, and the key parameters such as the thickness of the lead-bismuth alloy layer, the structure of the cooling water channel, the structure of the thimble plug, and the flow rate of the cooling water were determined, and a high linear power density irradiation test plan with the maximum temperature of the hot rod cladding at (490±60)℃ was obtained. The results show that when the maximum linear power density of the hot rod is 68~85 kW/m, the temperature of the cladding and the fuel core meets the requirements of the irradiation test and has a margin; In the range of 200~300 kPa core pressure difference, the calculated CFX value of the flow in the test section under the same pressure difference is about 9%~11% smaller than the test value; The flow share of the narrow channel outside the test section is 7.3%, which is significantly lower than the flow area share of the channel, meeting the cooling requirements of fuel slugs when the linear power density is 85 kW/m. The irradiation test plan proposed in this paper can provide a reference for the high linear power density irradiation test of fast reactor fuel rods.-

Key words:

- HFETR /

- Fuel irradiation test /

- Fast reactor fuel rod /

- Thermal-hydraulics

-

表 1 辐照试验件(含燃料段)温度分布计算结果

Table 1. Calculation Results of Temperature Distribution of Irradiation Test Piece (Including Fuel Section)

燃料芯体 零燃耗燃料芯体 目标燃耗燃料芯体 最大线功率密度/( kW·m−1) 85 68 85 68 计算方法 一维模型 CFX 一维模型 CFX 一维模型 CFX 一维模型 CFX 燃料芯体内侧温度/℃ 674 649 566 543 801 785 674 654 燃料包壳内侧温度/℃ 550 522 460 436 550 523 460 436 LBE层内侧温度/℃ 476 453 401 380 476 453 401 380 LBE层外侧温度/℃ 265 250 221 211 265 251 221 211 保护管外壁温度/℃ 125 110 109 98 125 110 109 98 -

[1] LOCATELLI G, MANCINI M, TODESCHINI N. Generation IV nuclear reactors: current status and future prospects[J]. Energy Policy, 2013, 61: 1503-1520. doi: 10.1016/j.enpol.2013.06.101 [2] CARMACK W J, BRAASE L A, WIGELAND R A, et al. Technology readiness levels for advanced nuclear fuels and materials development[J]. Nuclear Engineering and Design, 2017, 313: 177-184. doi: 10.1016/j.nucengdes.2016.11.024 [3] CRAWFORD D C, PORTER D L, HAYES S L, et al. An approach to fuel development and qualification[J]. Journal of Nuclear Materials, 2007, 371(1-3): 232-242. doi: 10.1016/j.jnucmat.2007.05.029 [4] MEDVEDEV P, HAYES S, BAYS S, et al. Testing fast reactor fuels in a thermal reactor[J]. Nuclear Engineering and Design, 2018, 328: 154-160. doi: 10.1016/j.nucengdes.2017.12.034 [5] CHRYSANTHOPOULOU N, SAVVA P, VARVAYANNI M, et al. Compilation of existing neutron screen technology[J]. Science and Technology of Nuclear Installations, 2014, 2014: 395795. doi: 10.1155/2014/395795 [6] CHRYSANTHOPOULOU N, SAVVA P, VARVAYANNI M, et al. Preliminary selection of device materials to locally transform thermal into SFR neutron spectrum[J]. Science and Technology of Nuclear Installations, 2018, 2018: 1896309. doi: 10.1155/2018/1896309 [7] 徐传效, 周永茂, 钱锦辉, 等. 高通量工程试验堆(HFETR)[C]//高通量工程试验堆(HFETR)运行十年(1980~1990)论文集. 四川: 四川科学技术出版社, 1991: 1-12 [8] 杨文华,张亮,斯俊平,等. 燃料试样堆内辐照温度设计与实验研究[J]. 核动力工程,2018, 38(6): 43-48. [9] 杨文华,赵国正,张亮,等. 高通量工程试验堆辐照试验能力和辐照试验技术[J]. 核科学与工程,2018, 38(6): 986-994. doi: 10.3969/j.issn.0258-0918.2018.06.011 [10] IDELCHIK I E. Handbook of hydraulic resistance[M]. Redding: Begell House Inc. , 2007: 624-625, 655-666. -

下载:

下载: