Analysis on the Improved Control Rod Drop Behavior among Deformation Channels Based on the Rigid-flexible Coupling

-

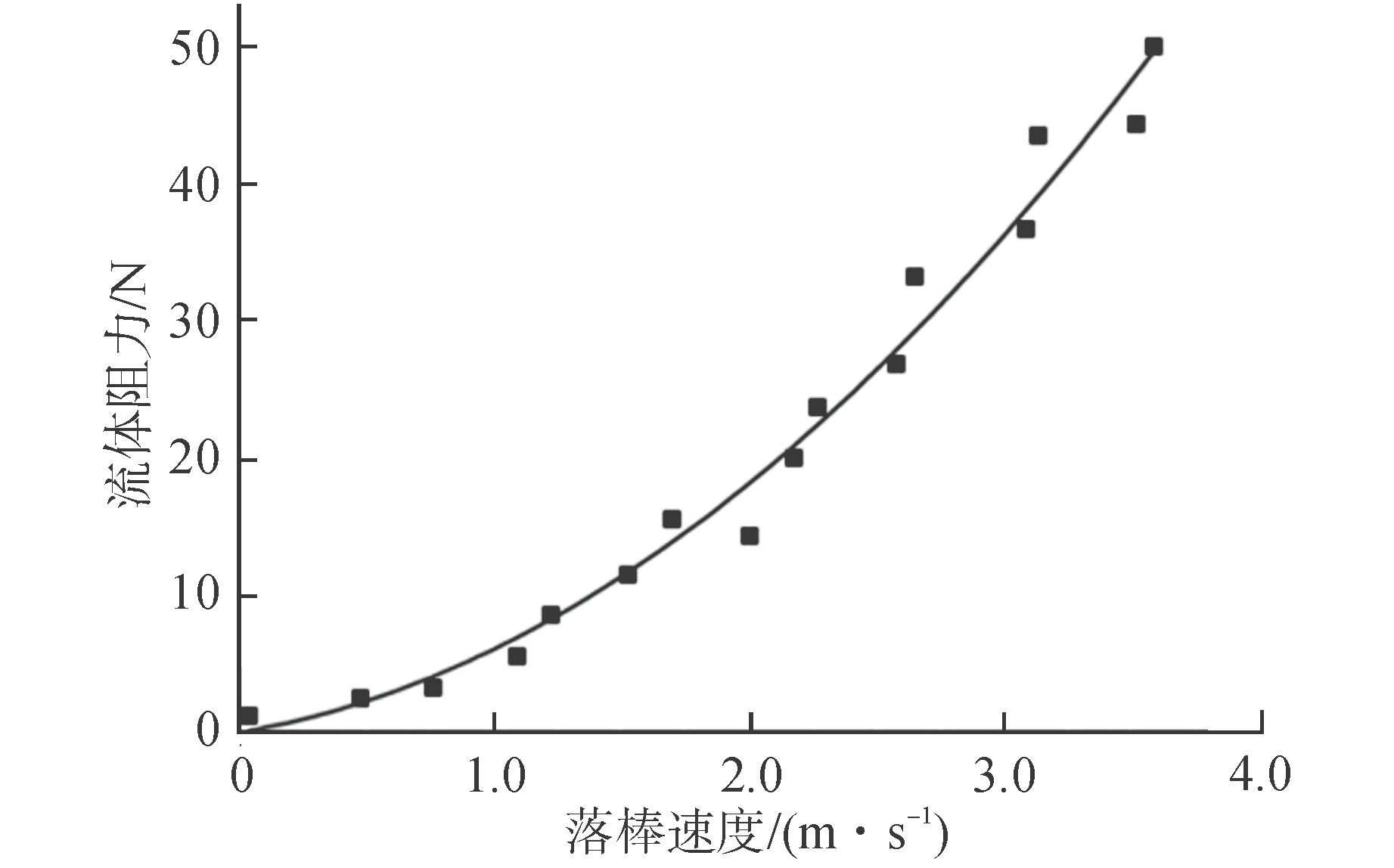

摘要: 燃料组件在堆芯内经历长期辐照后易产生弯曲形变,影响控制棒的安全落棒,因此亟需研究变形通道下控制棒落棒行为影响机制。通过数值模拟手段对导向管发生弯曲变形后的落棒行为规律进行分析研究,利用刚柔耦合方法分别计算直型、C型、S型导向管内的落棒行为,分析整个落棒行程、速度、加速度、沿程碰撞力随时间的变化情况,对比直型和2种不同变形通道对落棒行为的影响。研究结果表明,刚柔耦合方法可以较好地模拟变形通道下的落棒行为,C型落棒未发生卡滞,S型落棒卡滞于第2道弯折处。本研究将有助于为弯曲变形导致落棒卡涩问题的极限弯曲阈值提供判断依据,为工程设计提供参考。Abstract: The fuel assembly is prone to bend after long-term irradiation in the core, which affects the safe drop of the control rod. Therefore, it is urgent to study the influence mechanism of the control rod drop behavior under the deformation channel. By means of numerical simulation, the law of rod drop behavior after bending deformation of guide tube is analyzed and studied, the rigid-flexible coupling method is used to calculate the rod drop behaviors in the straight, C-shaped and S-shaped guide tubes respectively, analyze the variation of the entire rod drop journey, velocity, acceleration, and collision force along the journey with time, and the effects of straight and two different deformation channels on rod drop behavior are compared. The results show that the rigid flexible coupling method can better simulate the rod drop behavior under the deformation channel. The C-shaped rod drop does not get stuck, and the S-shaped rod drop is stuck at the second bend. This study will help to provide a basis for judging the ultimate bending threshold of the problem of rod drop sticking caused by bending deformation, and provide a reference for engineering design.

-

Key words:

- Control rod drop /

- Deformation channel /

- Rigid-flexible coupling /

- Rod stick /

- Numerical simulation

-

表 1 控制棒组件及其导向通道结构参数

Table 1. Structural Parameters of Control Rod Assembly and its Guide Channel

设计参数 参数值 控制棒外径/mm 17 导向管外径/mm 20 导向管内径/mm 19 导向管缩颈段内径/mm 18 导向管下端流水孔直径/mm 3 导向管缩径段长度/mm 850 导向管总长度/mm 4290 导向管中心距/mm 20.5 控制棒组件改进型落棒通道尺寸

(长×宽×厚)/mm×mm×mm185×185×21 控制棒落棒行程/mm 4100 控制棒驱动线质量/kg 90 表 2 连接柄-燃料组件(刚-刚)碰撞力设置

Table 2. Setup of the Contact Force between Joint and Fuel Assembly (Rigid-to-Rigid)

刚度/(N·mm−1) 力指数 阻尼/( N·s·mm−1) 穿透深度/mm 1×108 2.2 1×104 1×10−6 表 3 通道-控制棒(刚-柔)碰撞力及摩擦力设置

Table 3. Setup of the Contact Force and Friction between Channel and Control Rods (Rigid-to-Flexible)

刚度/(N·mm−1) 力指数 阻尼/( N·s·mm−1) 穿透深度/mm 1×108 2.2 1×104 1×10−4 静摩擦系数 动摩擦系数 静滞速度/(m·s−1) 滑动速度/(m·s−1) 0.3 0.1 0.1 1.0 -

[1] 粟敏,李垣明,陈平,等. 非均匀辐照环境下燃料组件变形的初步数值模拟[J]. 核动力工程,2017, 38(S2): 7-10. [2] 朱发文,雷涛,程华旸,等. 一种适用于十字形控制棒的超临界燃料组件设计[J]. 核动力工程,2013, 34(1): 35-39. doi: 10.3969/j.issn.0258-0926.2013.01.008 [3] 朱发文, 冯琳娜, 庞华, 等. 一种内插束棒型控制棒的燃料组件: 中国, CN201610303241.2[P]. 2016-05-10. [4] ANDRIAMBOLOLONA H, BOSSELUT D, MASSIN P, et al. Methodology for a numerical simulation of an insertion or a drop of the rod cluster control assembly in a PWR[J]. Numerical Engineering and Design, 2007, 237(6): 600-607. [5] 张吉斌,高希龙,何航行,等. 控制棒落棒动力学数值计算[J]. 核动力工程, 2020,41(6): 218-223. -

下载:

下载: