Analysis and Optimization of Flow Field in an Axial Flow Lead-Bismuth Pump

-

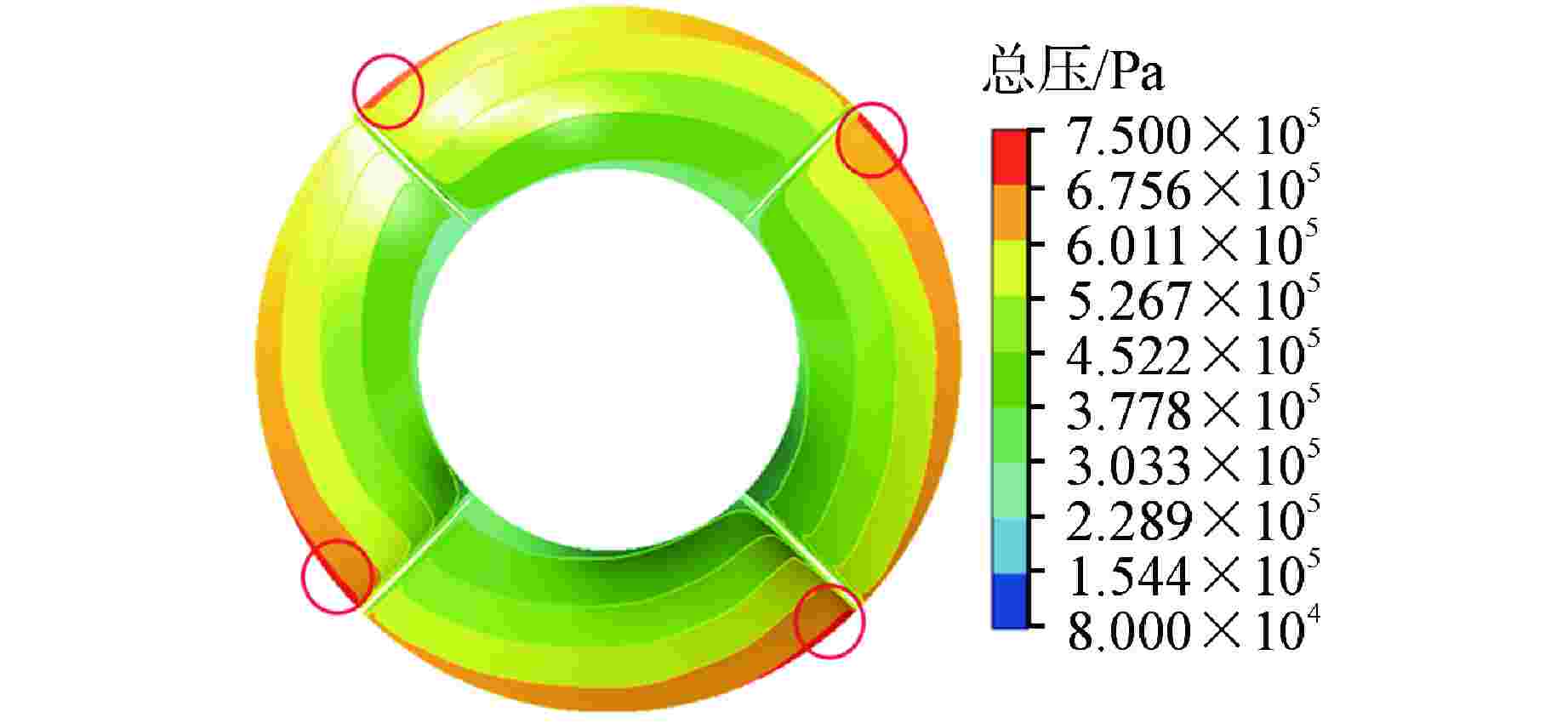

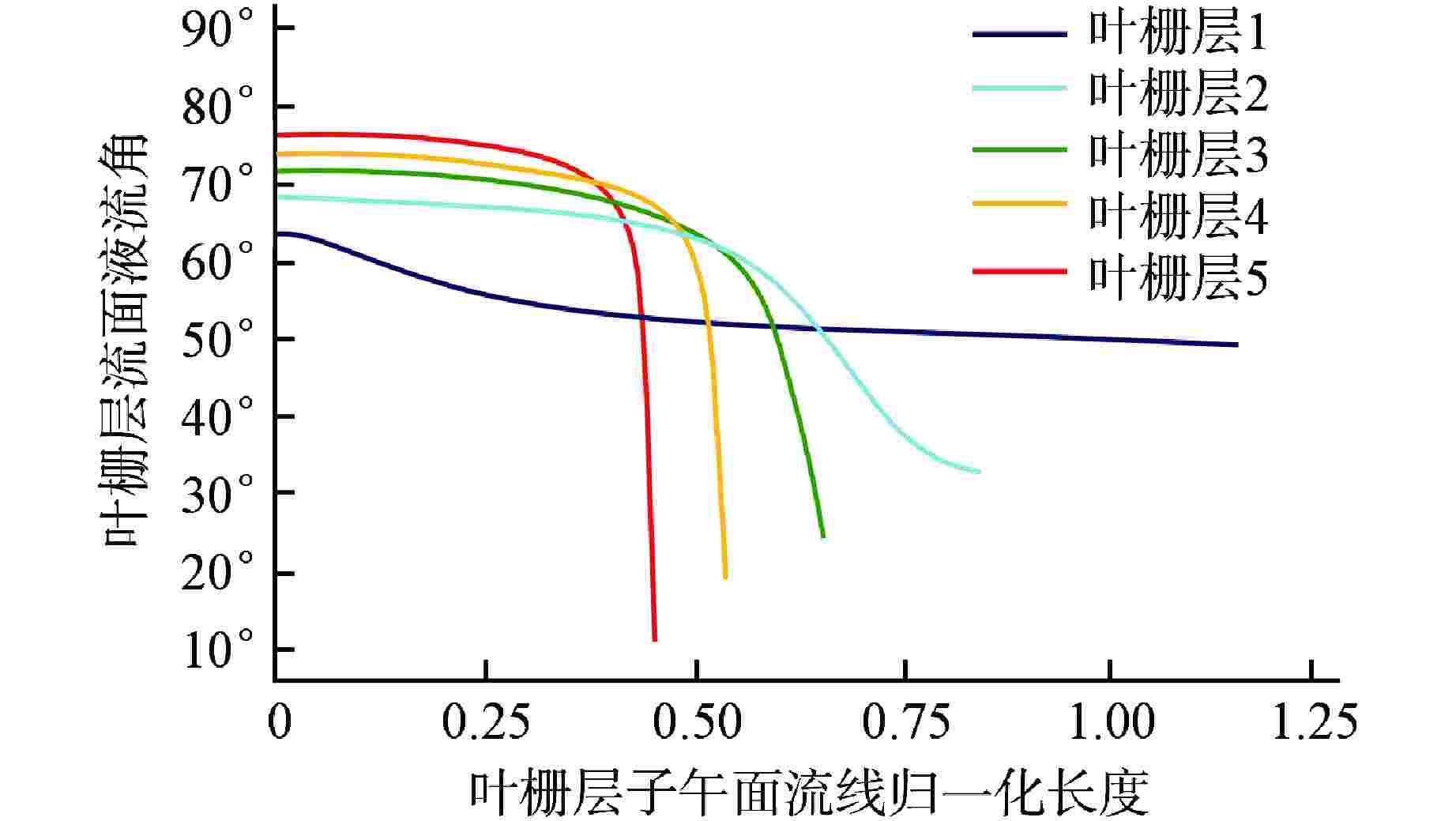

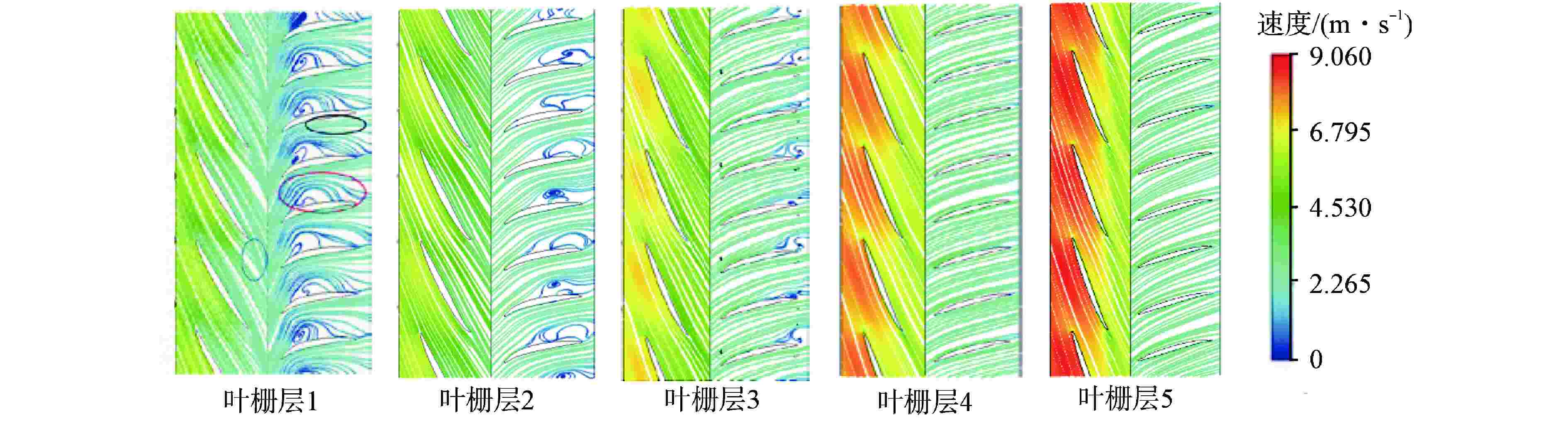

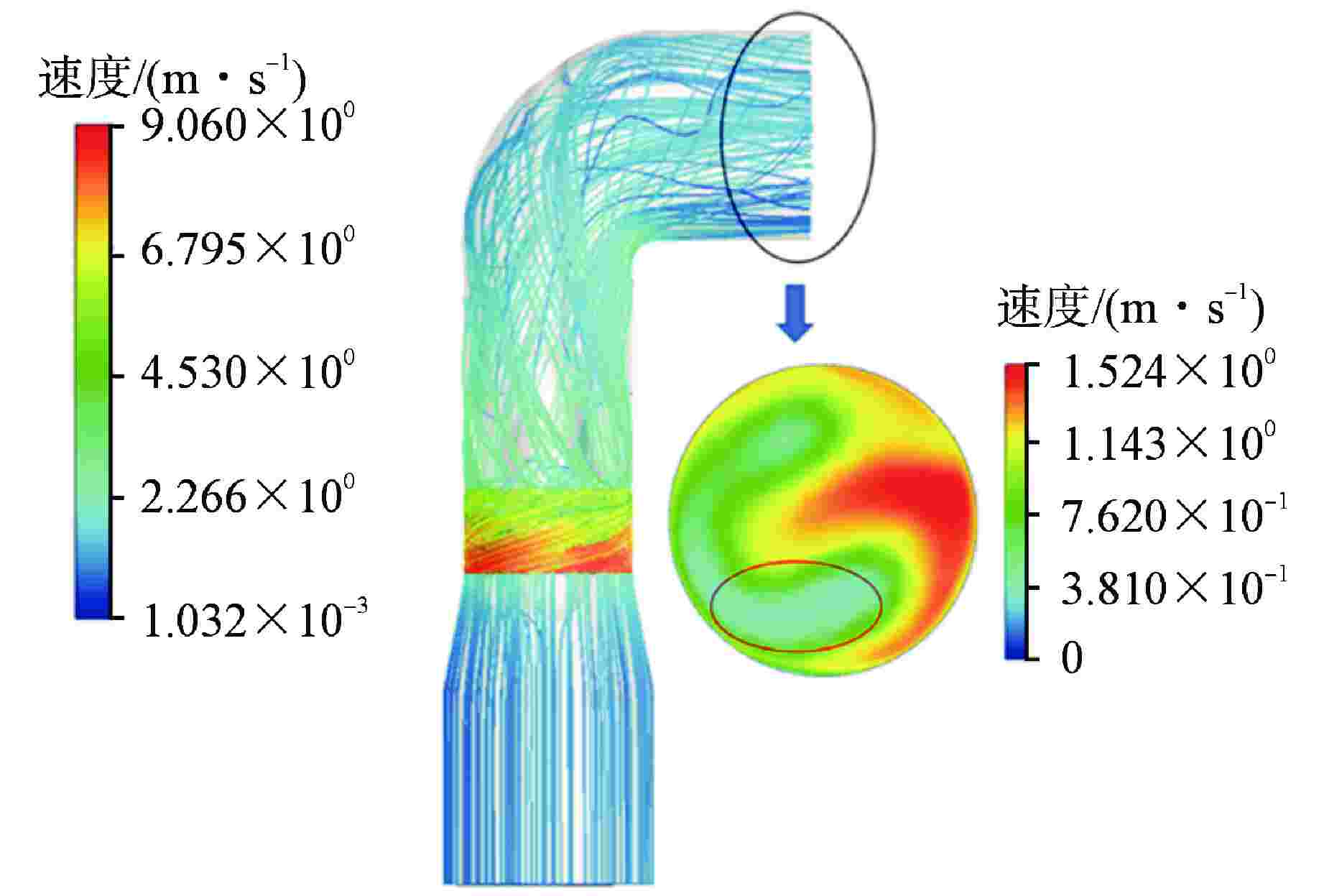

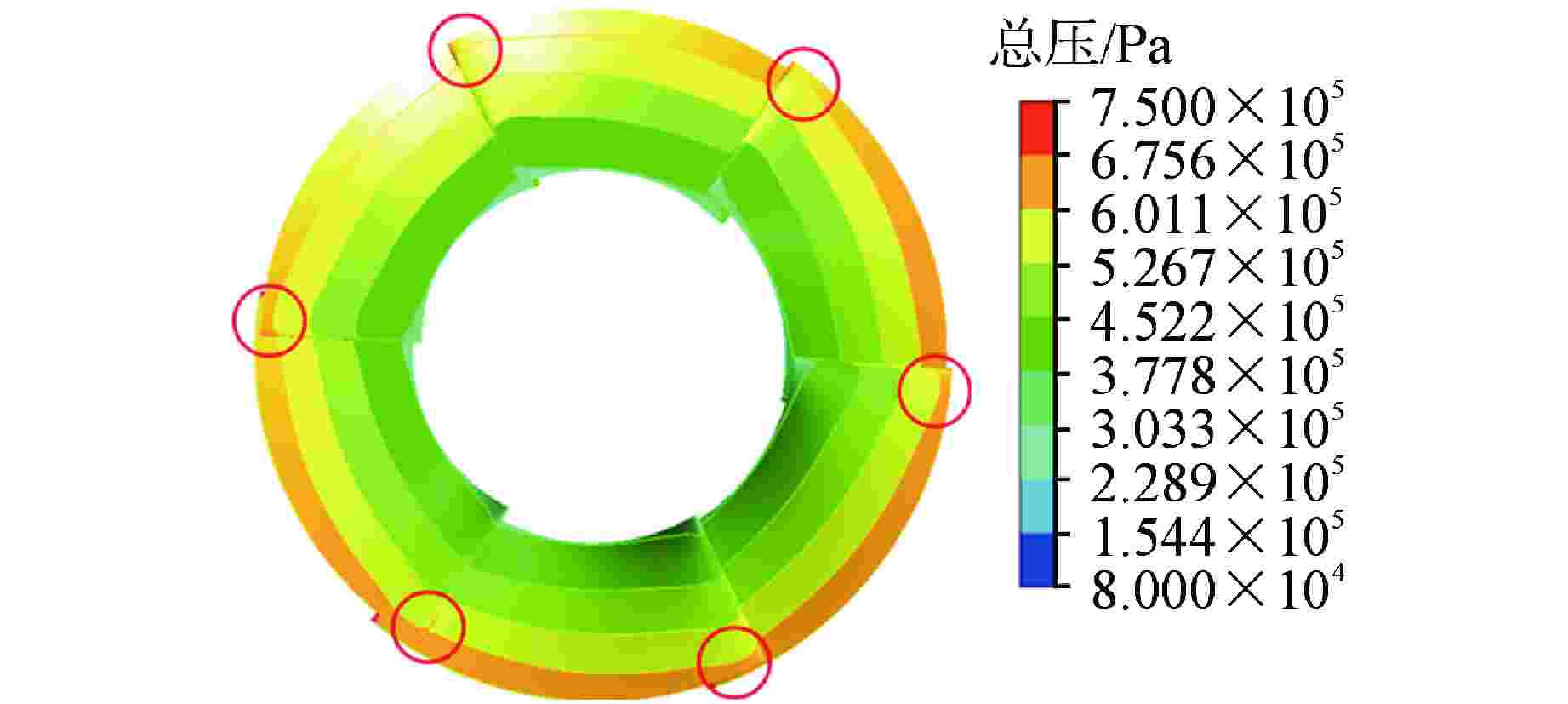

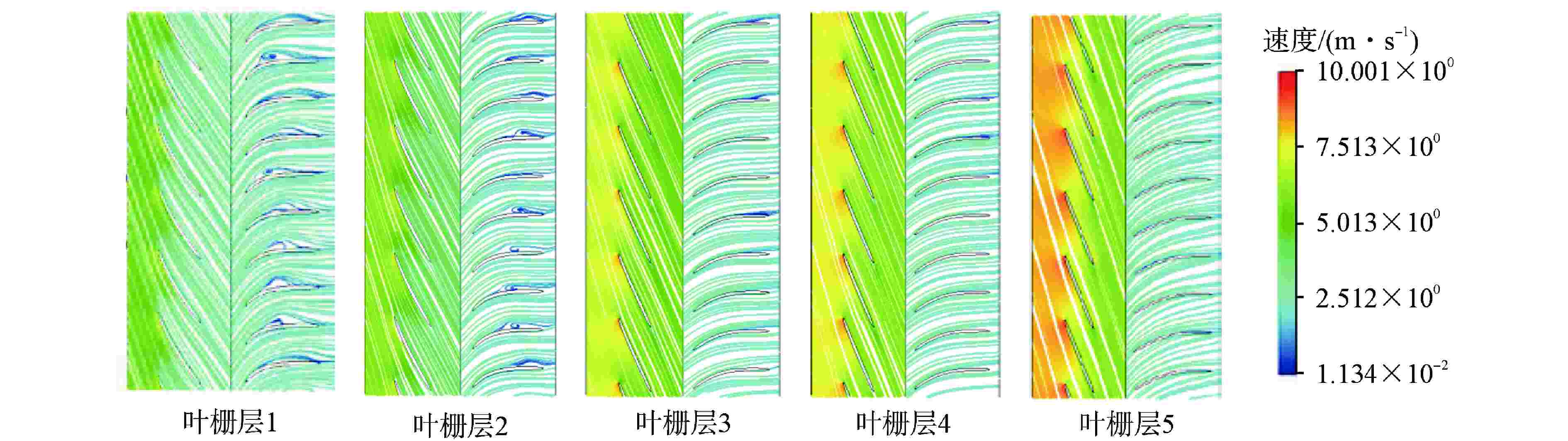

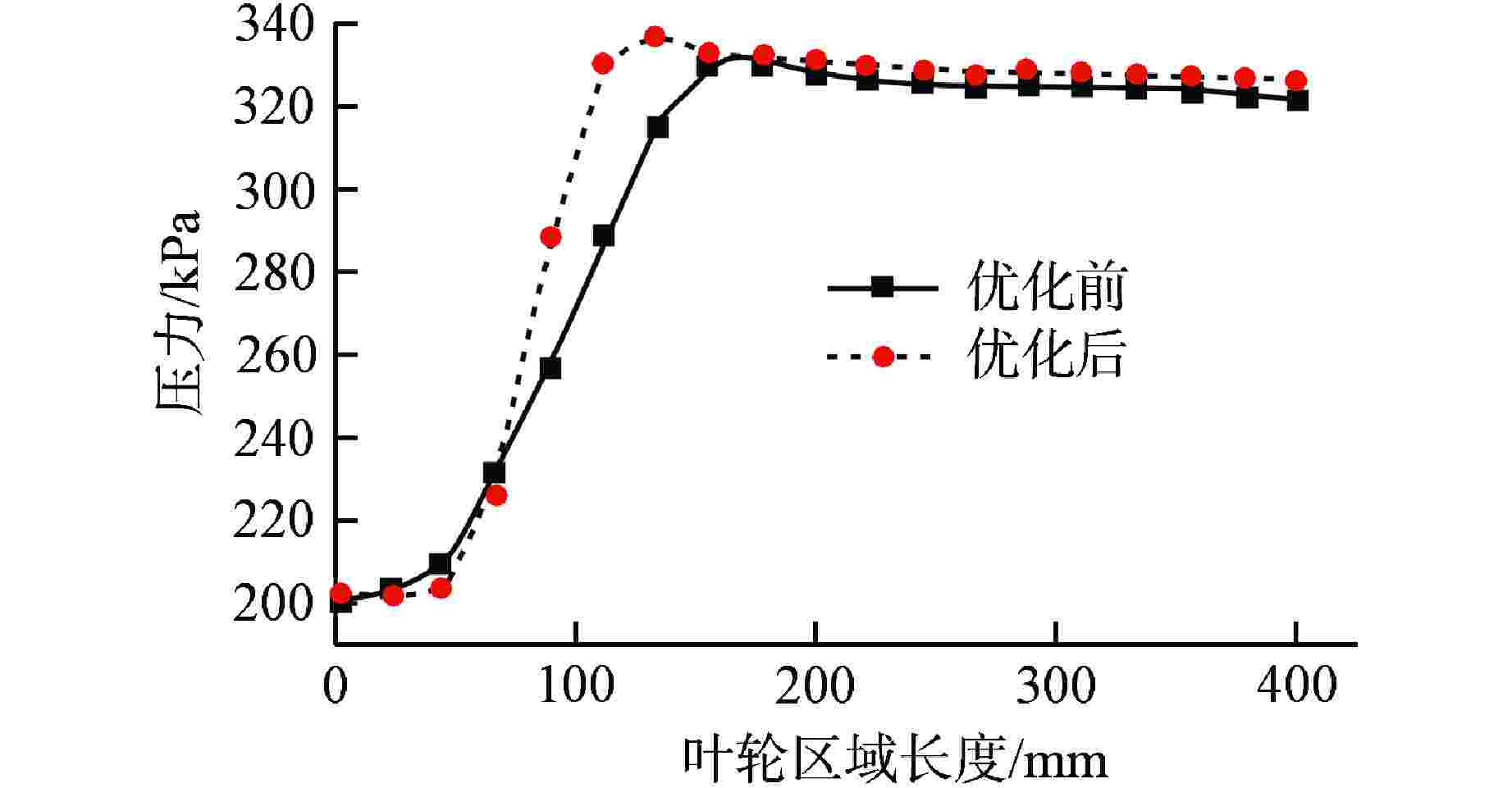

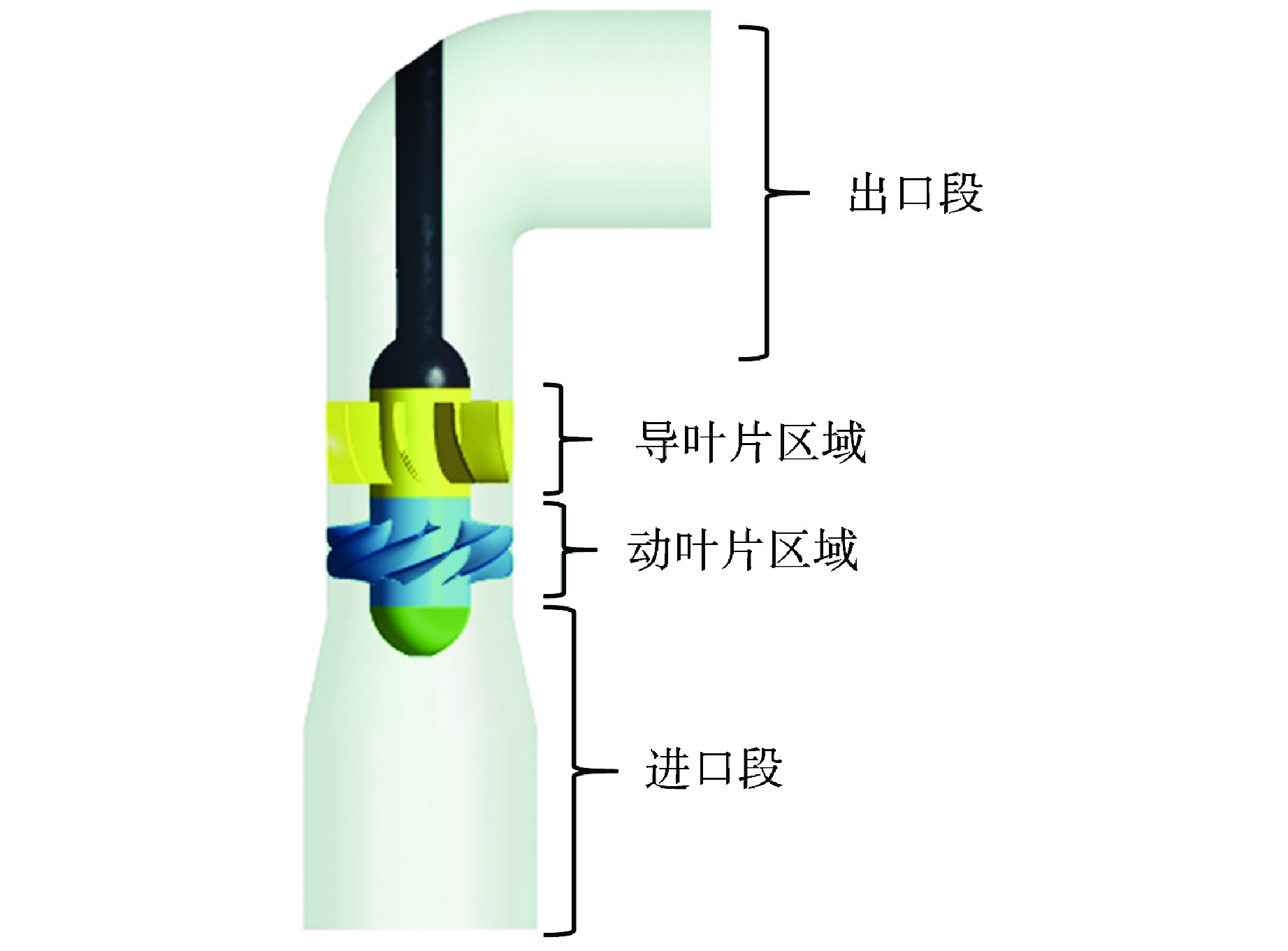

摘要: 铅铋泵作为铅铋冷却快堆一回路的关键输送设备,其安全运行对铅铋冷却快堆的安全至关重要。液态铅铋合金在泵内流动特性对泵的长期安全运行有重要影响,为了研究轴流铅铋泵泵内流场,通过Workbench/BladeGen软件建立了主泵叶轮模型,在ANSYS CFX软件中数值模拟泵内流场,并根据数值模拟结果改进了导叶片厚度,优化了动叶片翼型出口角,从而改善泵内流场。研究结果表明,铅铋泵叶片型线出口附近角度变化过快会导致叶片压力分布不均匀,产生局部高压的现象,进而可能造成更严重的冲蚀。优化导叶片厚度以及动叶片出口液流角后,泵内流场整体迹线较为平稳,导叶片出口处铅铋合金流速可以维持在1.8 m/s左右。Abstract: The lead-bismuth main pump is the key conveying equipment of the primary circuit in a lead- bismuth cooled fast reactor, and its safe operation is essential to the safety of the lead- bismuth cooled fast reactor. The flow characteristics of liquid lead-bismuth alloy in the pump have an important impact on the long-term safe operation of the pump. In order to study the flow field in an axial flow lead-bismuth pump, the impeller model of the main pump is constructed through Workbench/BladeGen software, and the flow field in the pump is simulated and analyzed in ANSYS CFX software. According to the numerical simulation results, the thickness of the guide vane is improved, and the wing outlet angle of the moving vane is optimized, thereby improving the flow field in the pump. The research results show that too fast angle change near the vane pattern outlet of lead- bismuth pump will lead to uneven vane pressure distribution and local high pressure, which may lead to more serious erosion. After optimizing the thickness of the guide vanes and the outlet flow angle of the moving vane, the overall trace of the flow field in the pump is relatively stable and the flow velocity of lead- bismuth at the exit of the guide vane maintained at about 1.8 m/s.

-

表 1 铅铋泵的设计参数

Table 1. Design Parameters of Lead-Bismuth Pump

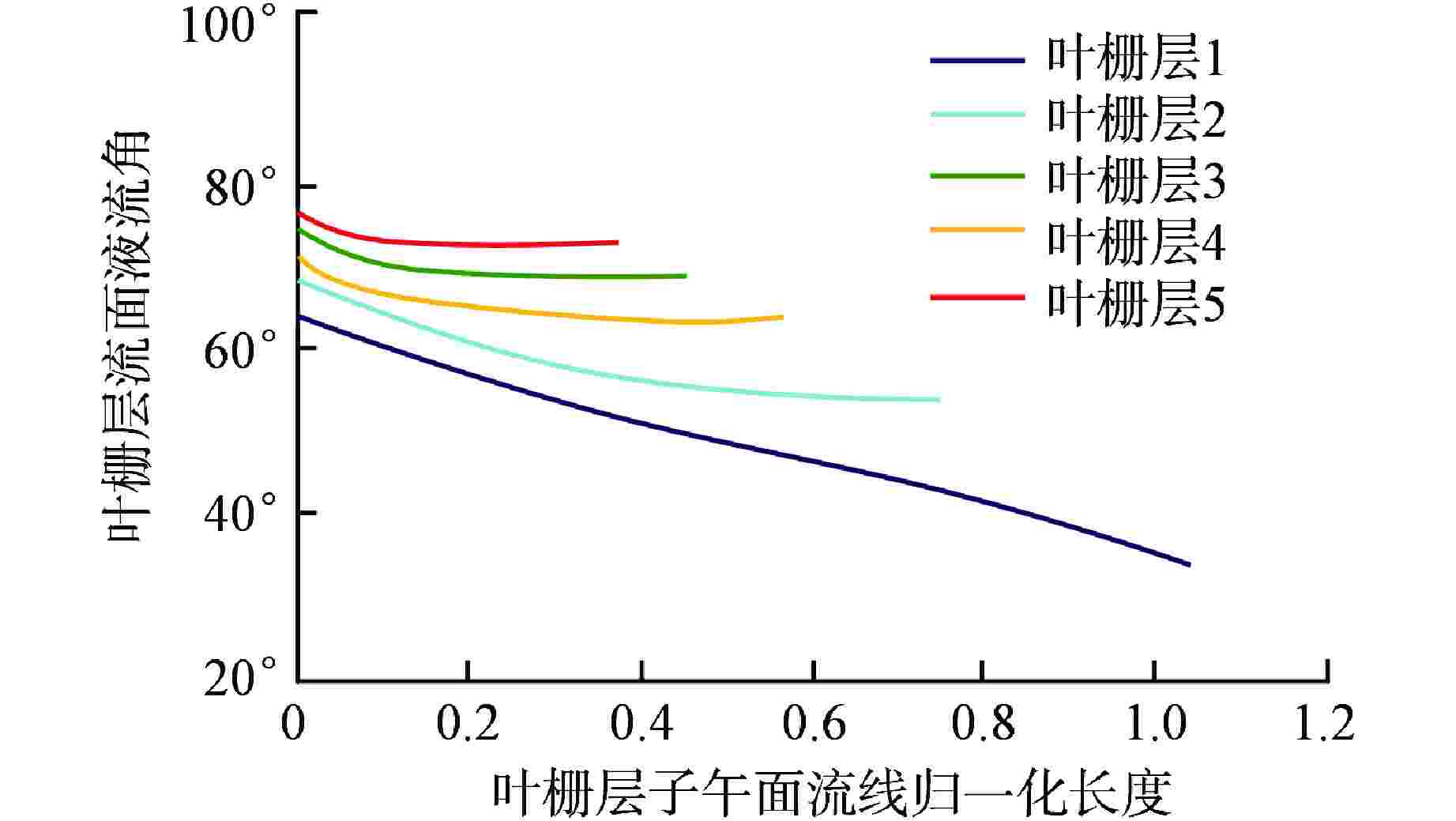

叶栅层层数 β1/rad β2 /rad α3/rad α4/rad u1=u2/(m·s−1) vm1=vm2/(m·s−1) vmax/(m·s−1) lr/m lg/m δp/kPa H/m 叶栅层1 0.461 0.863 0.712 1.57 4.52 2.25 5.05 0.107 0.162 125 1.2 叶栅层2 0.381 0.582 0.798 1.57 5.48 2.2 5.91 0.122 0.160 125 1.2 叶栅层3 0.322 0.435 0.867 1.57 6.45 2.15 6.80 0.137 0.158 125 1.2 叶栅层4 0.276 0.347 0.925 1.57 7.4 2.10 7.69 0.152 0.157 125 1.2 叶栅层5 0.241 0.286 0.973 1.57 8.37 2.06 8.62 0.167 0.67 125 1.2 β1、β2—动叶片进口和出口位置的液流角,在叶栅流面上是相对速度和圆周速度间的夹角;α3、α4——导叶片的进、出口角,表征叶珊流面绝对速度和圆周速度之间的夹角;u1、u2—圆周方向进、出口流速;vm1和vm2—动叶片进口和出口的轴向速度;lr—动叶片翼型长度;H—扬程;lg—导叶片叶型长度;δp—叶轮进出口压差 表 2 叶轮网格无关性分析

Table 2. Independence Analysis of Impeller Grid

网格数量/万 8 30 60 120 理论计算结/kPa 125 125 125 125 CFX模拟计算结果/kPa 115.8 121.4 123.1 123.3 偏差范围/% 7.36 2.88 1.52 1.36 -

[1] DAMIANI L, REVETRIA R. New steam generation system for lead-cooled fast reactors, based on steam re-circulation through ejector[J]. Applied Energy, 2015(137): 292-300. doi: 10.1016/j.apenergy.2014.10.014 [2] DAMIANI L, PRATO A P, REVETRIA R. Innovative steam generation system for the secondary loop of “ALFRED” lead-cooled fast reactor demonstrator[J]. Applied Energy, 2014(121): 207-218. doi: 10.1016/j.apenergy.2014.02.014 [3] HEJZLAR P, TODREAS N E, SHWAGERAUS E, et al. Cross-comparison of fast reactor concepts with various coolants[J]. Nuclear Engineering and Design, 2009, 239(12): 2672-2691. doi: 10.1016/j.nucengdes.2009.07.007 [4] GROMOV B F, ORLOV Y I, MARTYNOV P N, et al. Proceedings of heavy liquid metal coolants in nuclear technology[Z]. HLMC, 1988, 98: 5-9. [5] 潘瑾宜,杨婷,钱虹. 小型模块化反应堆冷却剂平均温度的预测控制方法[J]. 核动力工程,2020, 41(3): 62-67. [6] SHI L T, BING T, WANG C L, et al. Experimental investigation of gas lift pump in a lead-bismuth eutectic loop[J]. Nuclear Engineering and Design, 2018, 330: 516-523. doi: 10.1016/j.nucengdes.2018.01.042 [7] 左娟莉,田文喜,秋穗正,等. 铅铋合金冷却反应堆内气泡提升泵提升自然循环能力的理论研究[J]. 原子能科学技术,2013, 47(7): 1155-1161. doi: 10.7538/yzk.2013.47.07.1155 [8] KWAK J, KIM H R. Development of innovative reactor-integrated coolant system design concept for a small modular lead fast reactor[J]. International Journal of Energy Research, 2018, 42(13): 4197-4205. doi: 10.1002/er.4177 [9] 卢永刚. 铅铋冷却快堆主循环泵优化设计与可靠性分析[D]. 镇江: 江苏大学, 2019. [10] MANGIALARDO A, BORREANI W, LOMONACO G, et al. Numerical investigation on a jet pump evolving liquid lead for GEN-IV reactors[J]. Nuclear Engineering and Design, 2014(280): 608-618. doi: 10.1016/j.nucengdes.2014.09.028 [11] FERRINI M, BORREANI W, LOMONACO G, et al. Design by theoretical and CFD analyses of a multi-blade screw pump evolving liquid lead for a generation IV LFR[J]. Nuclear Engineering and Design, 2016, 297: 276-290. doi: 10.1016/j.nucengdes.2015.12.006 [12] 张勇,何小冬,张杰,等. 铅铋泵原型机水力模型分析验证[J]. 通用机械,2018(11): 63-66. doi: 10.3969/j.issn.1671-7139.2018.11.021 [13] БЕЗНОСОВ А В, АНТОНЕНКОВ М А, БОКОВ П А, et al. Специфика циркуляционных насосов реакторных контуров со свинцовым и свинецвисмутовым теплоносителями[J]. Известия высших учебных заведений. Ядерная энергетика, 2009(4): 155-160. [14] 吴宜灿,王明煌,黄群英,等. 铅基反应堆研究现状与发展前景[J]. 核科学与工程,2015, 35(2): 213-221. doi: 10.3969/j.issn.0258-0918.2015.02.004 [15] 潘中永,李晓俊,袁寿其,等. CFD技术在泵上的应用进展[J]. 水泵技术,2009(1): 1-6. [16] 王凯琳,李良星,张双雷,等. 轴流铅铋泵的设计及其水力性能分析[J]. 西安交通大学学报,2020, 54(11): 166-174. [17] 赵国群,虞松,王广春. 六面体网格自动划分和再划分算法[J]. 机械工程学报,2006, 42(3): 188-192. doi: 10.3321/j.issn:0577-6686.2006.03.033 [18] БЕЗНОСОВ А В, БОКОВА Т А, ЗУДИН А Д, et al. Экспериментальное исследование и отработка насосов для перекачки свинцового и свинец-висмутового теплоносителя для ядерных установок[J]. НГТУ им. Р. Е. Алексеева, 2017, 1(116): 117-128. [19] 沙毅,侯丽艳. 叶片厚度对轴流泵性能影响及内部流场分析[J]. 农业工程学报,2012, 28(18): 75-81. doi: 10.3969/j.issn.1002-6819.2012.18.012 [20] 史缘缘,黄逸哲. 轴流泵流体激励涡旋涡核提取技术研究[J]. 装备制造技术,2018(3): 233-235, 238. doi: 10.3969/j.issn.1672-545X.2018.03.073 [21] 王强磊,赖喜德,叶道星. 叶轮叶片厚度对混流式核主泵能量性能的影响[J]. 核动力工程,2020, 41(1): 28-32. -

下载:

下载: