Degradation Trend Prediction of Nuclear-level Electric Valve Based on Hilbert-Huang Transform and BP Neural Network

-

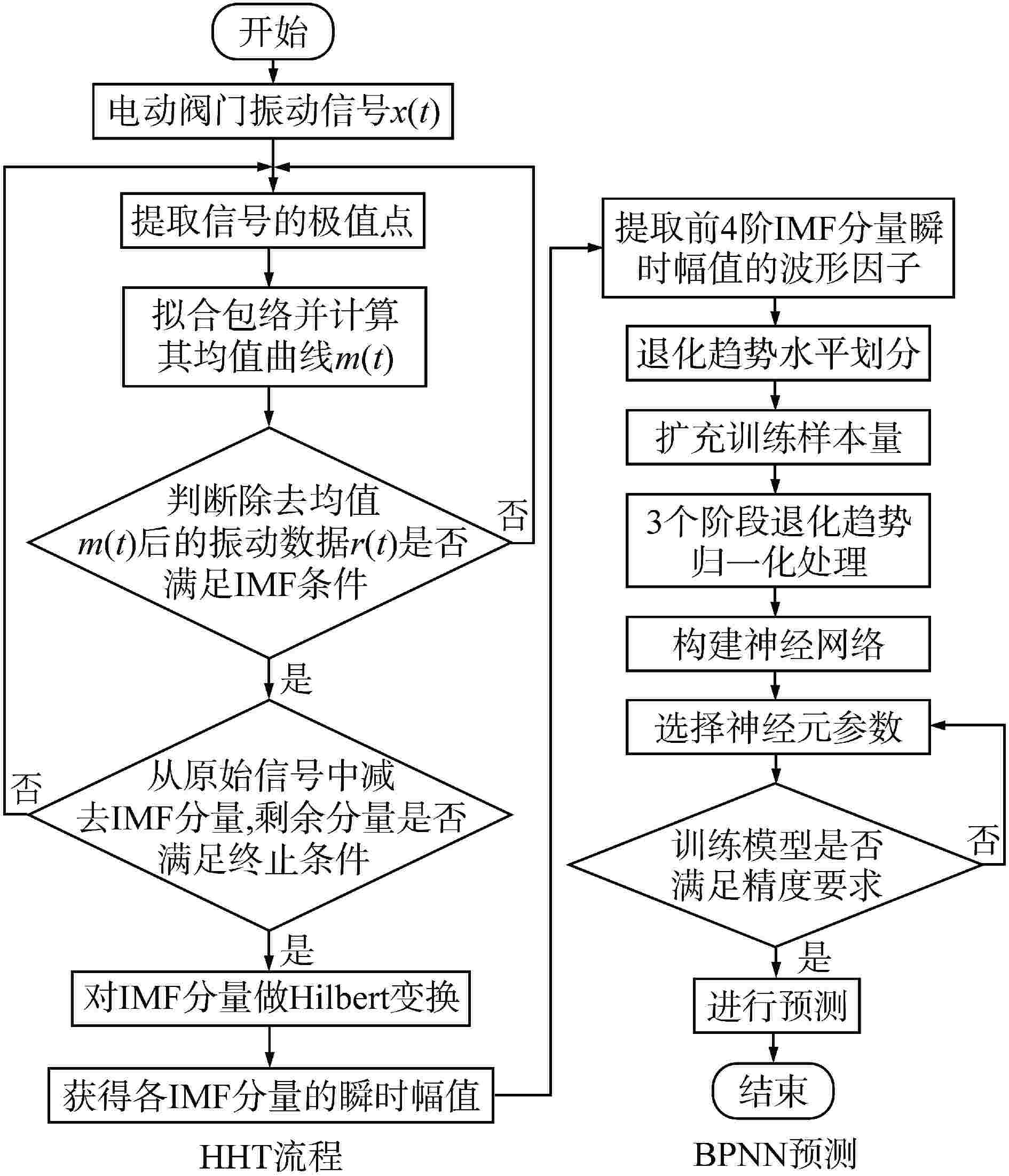

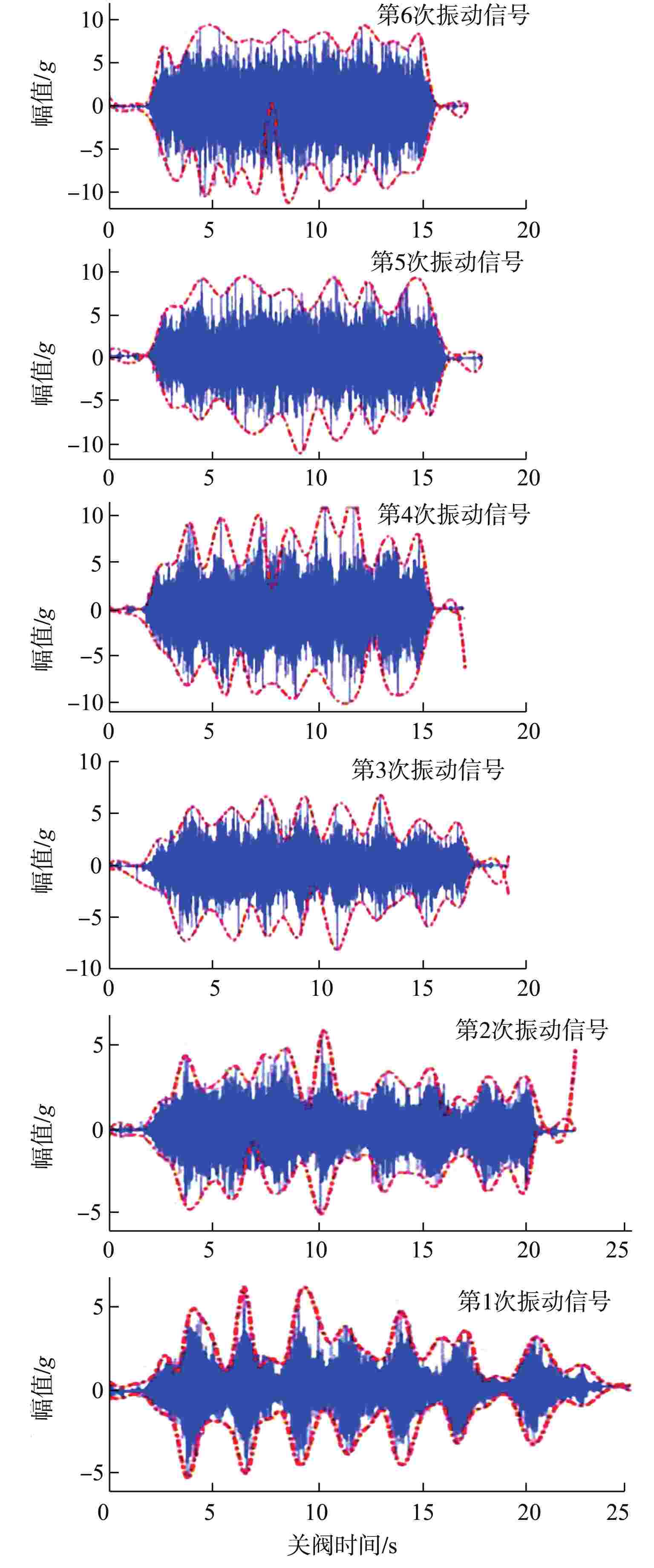

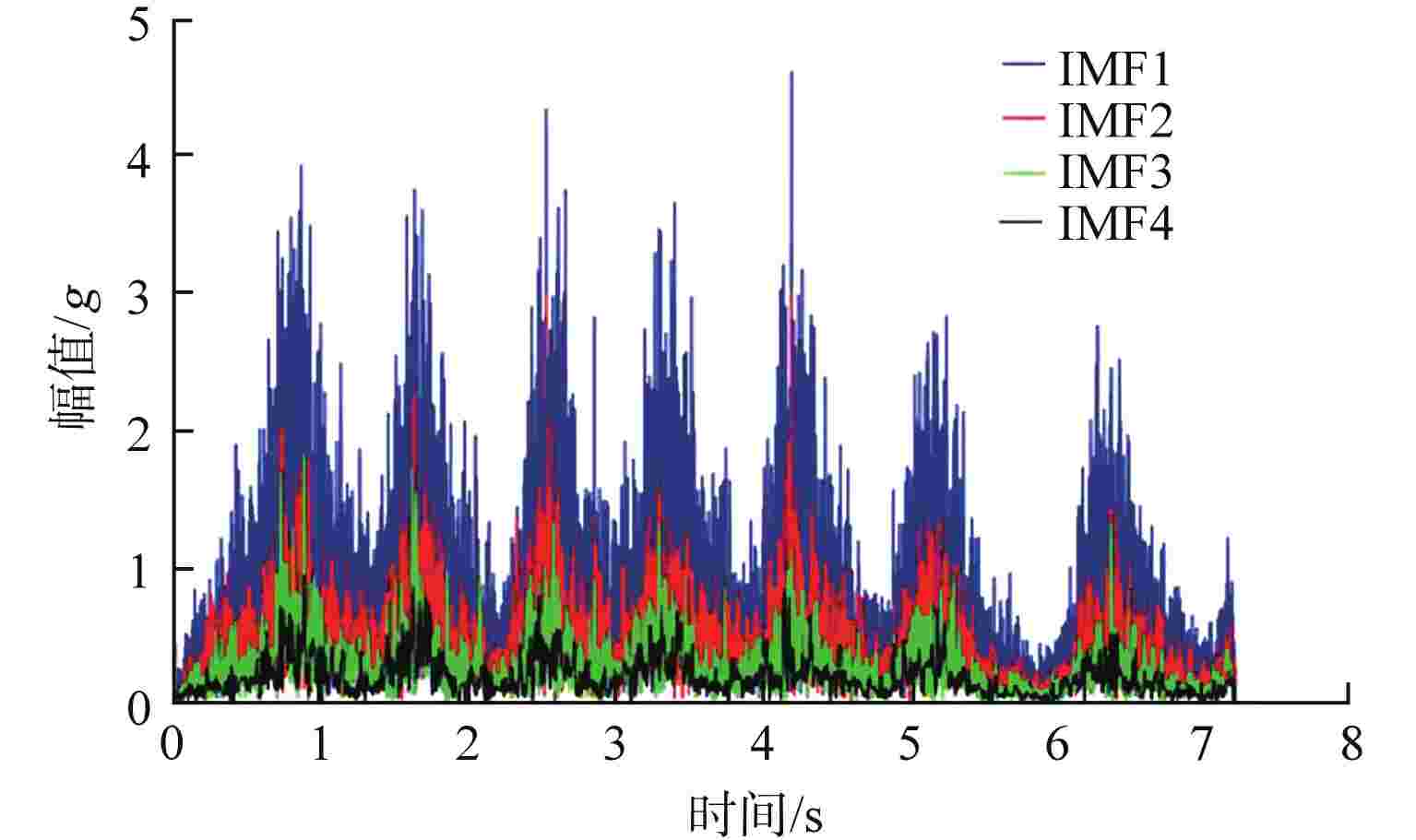

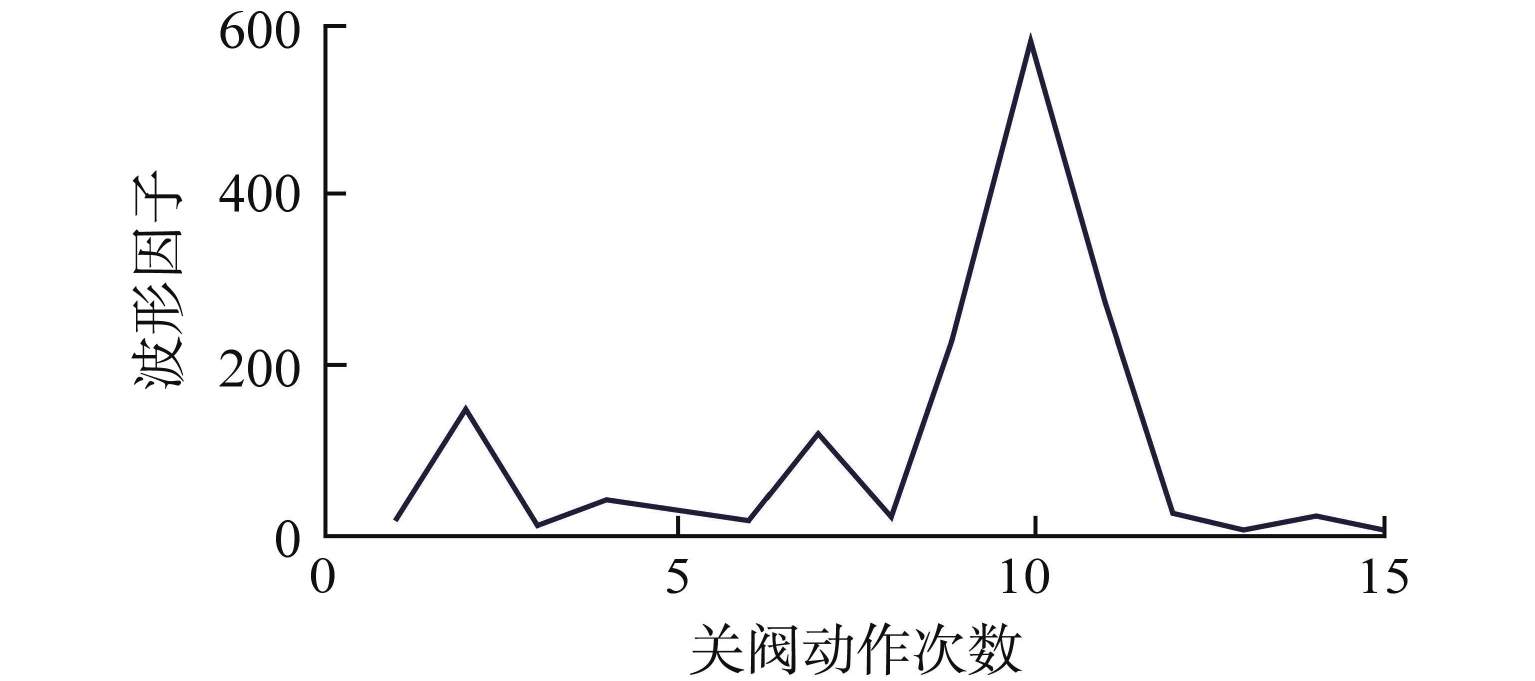

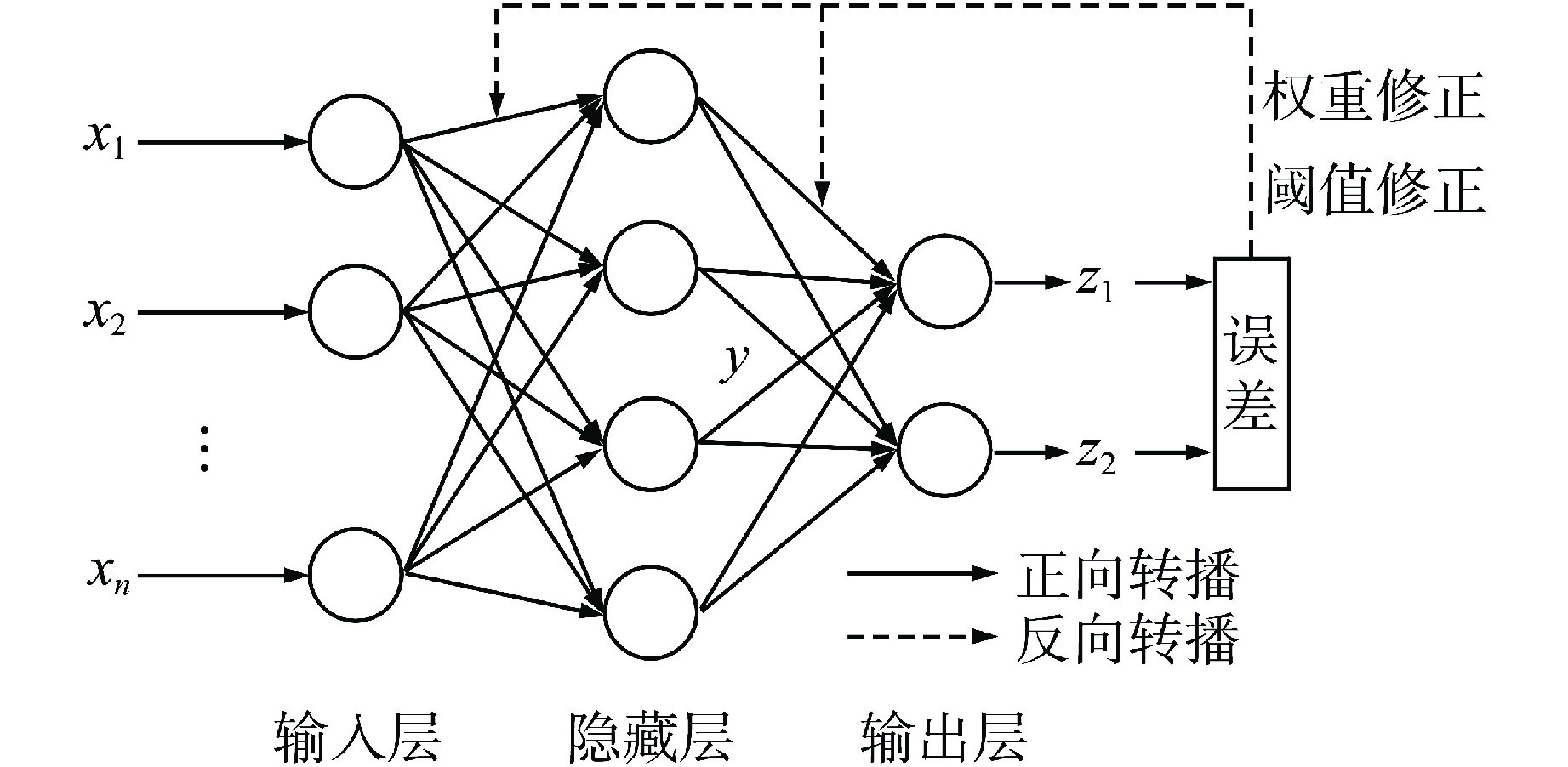

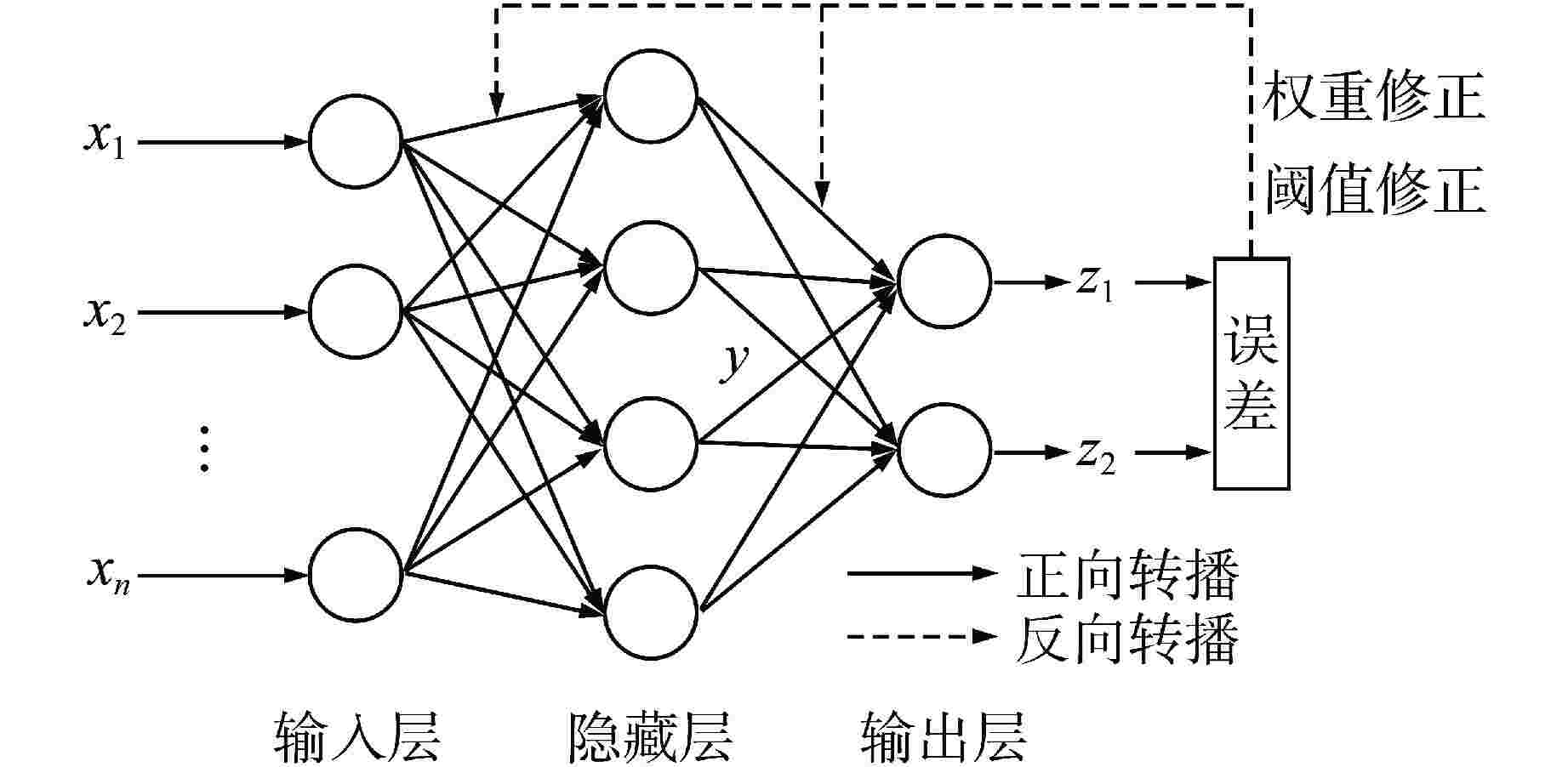

摘要: 核级电动阀门服役环境恶劣,极易发生退化失效。为准确预测核级电动阀门性能退化趋势,采用Hilbert-Huang变换(HHT)和反向传播神经网络(BPNN)相结合的方法(HHT-BPNN)对核级电动阀门的退化状态进行预测。本文采用某次核级电动阀门可靠性试验的振动信号对电动阀门退化趋势进行预测,结果显示该方法能准确预测出核级电动阀门的3种退化状态,且其相对误差在可接受范围内。研究表明HHT能够有效提取信号的退化信息,BPNN能够准确预测核级电动阀门的退化趋势,HHT-BPNN预测方法能有效解决核级电动阀门性能退化预测困难的问题。

-

关键词:

- 核级电动阀门 /

- Hilbert-Huang变换(HHT) /

- 反向传播神经网络(BPNN) /

- 退化预测

Abstract: Due to the harsh service environment of nuclear-level electric valves, degradation and failure are easy to occur. Therefore, in order to accurately predict the performance degradation trend of nuclear-level electric valves, this study adopts a method based on Hilbert-Huang transform (HHT) and BP neural network (BPNN) combined method (HHT-BPNN) to predict the degradation state of nuclear-level electric valve. In this paper, the vibration signal of a nuclear-level electric valve reliability test is used to predict the degradation trend of the electric valve. The results show that the method can accurately predict the three degradation states of the nuclear-level electric valve, and the relative error is within the acceptable range. The analysis and research results show that HHT can effectively extract the degradation information of the signal, and BPNN can accurately predict the degradation trend of nuclear-level electric valves. The HHT-BPNN prediction method can effectively solve the difficulty of predicting the performance degradation of nuclear-level electric valves. -

表 1 优化后BPNN网络参数设置情况

Table 1. BPNN Network Parameter Setting after Optimization

表 2 基于HHT-BPNN方法预测结果

Table 2. Prediction Results Based on HHT-BPNN Method

阀门失效前动作次数 验证指标值 预测输出值 相对误差/% 15 1 0.9991 0.09 14 1 1.0000 0 13 1 0.9984 0.16 12 1 1.0033 0.33 11 1 1.0001 0.01 10 1 0.9985 0.15 9 1 1.0024 0.24 8 1 0.9974 0.26 7 1 1.0005 0.05 6 1 0.9956 0.44 5 1 0.9860 1.40 4 2 1.7032 14.84 3 2 1.9986 0.07 2 2 1.9420 2.90 1 3 3.0004 0.01 -

[1] DUTTON D M, CONROY G V. A review of machine learning[J]. The Knowledge Engineering Review, 1997, 12(4): 341-367. doi: 10.1017/S026988899700101X [2] DU X D, CAI Y H, WANG S, et al. Overview of deep learning[C]//Proceedings of the 31st Youth Academic Annual Conference of Chinese Association of Automation (YAC). Wuhan: IEEE, 2016: 159-164. [3] JIA Z Y, MA J W, WANG F J, et al. Hybrid of simulated annealing and SVM for hydraulic valve characteristics prediction[J]. Expert Systems with Applications, 2011, 38(7): 8030-8036. doi: 10.1016/j.eswa.2010.12.132 [4] 贾春玉,康凯旋,高伟,等. 基于CNN+LSTM神经网络的电液伺服阀故障预测[J]. 液压与气动,2020(12): 173-181. doi: 10.11832/j.issn.1000-4858.2020.12.027 [5] 肖凯,黎婧,赵梦薇,等. 小型压水堆功率神经网络预测控制研究[J]. 核动力工程,2020, 41(S2): 50-53. [6] 曾聿赟,刘井泉,杨春振,等. 基于机器学习的小型核反应堆系统状态预测方法[J]. 核动力工程,2018, 39(1): 117-121. [7] HUANG H E, SHEN Z, LONG S R, et al. The empirical mode decomposition and the Hilbert spectrum for nonlinear and non-stationary time series analysis[J]. Proceedings of the Royal Society A:Mathematical, Physical and Engineering Sciences, 1998, 454(1971): 903-995. doi: 10.1098/rspa.1998.0193 [8] HUANG N E, SHEN Z, LONG S R. A new view of nonlinear water waves: the Hilbert spectrum[J]. Annual Review of Fluid Mechanics, 1999, 31: 417-457. doi: 10.1146/annurev.fluid.31.1.417 [9] CHEN D S, JAIN R C. A robust backpropagation learning algorithm for function approximation[J]. IEEE Transactions on Neural Networks, 1994, 5(3): 467-479. doi: 10.1109/72.286917 [10] SADEGHI B H M. A BP-neural network predictor model for plastic injection molding process[J]. Journal of Materials Processing Technology, 2000, 103(3): 411-416. doi: 10.1016/S0924-0136(00)00498-2 [11] 雷亚国. 基于改进Hilbert-Huang变换的机械故障诊断[J]. 机械工程学报,2011, 47(5): 71-77. [12] LIU B, RIEMENSCHNEIDER S, XU Y. Gearbox fault diagnosis using empirical mode decomposition and Hilbert spectrum[J]. Mechanical Systems and Signal Processing, 2006, 20(3): 718-734. doi: 10.1016/j.ymssp.2005.02.003 -

下载:

下载: