Research on Corrosion Behavior of Stainless Steel Cladding Welding Simulator in Nuclear Power Plant

-

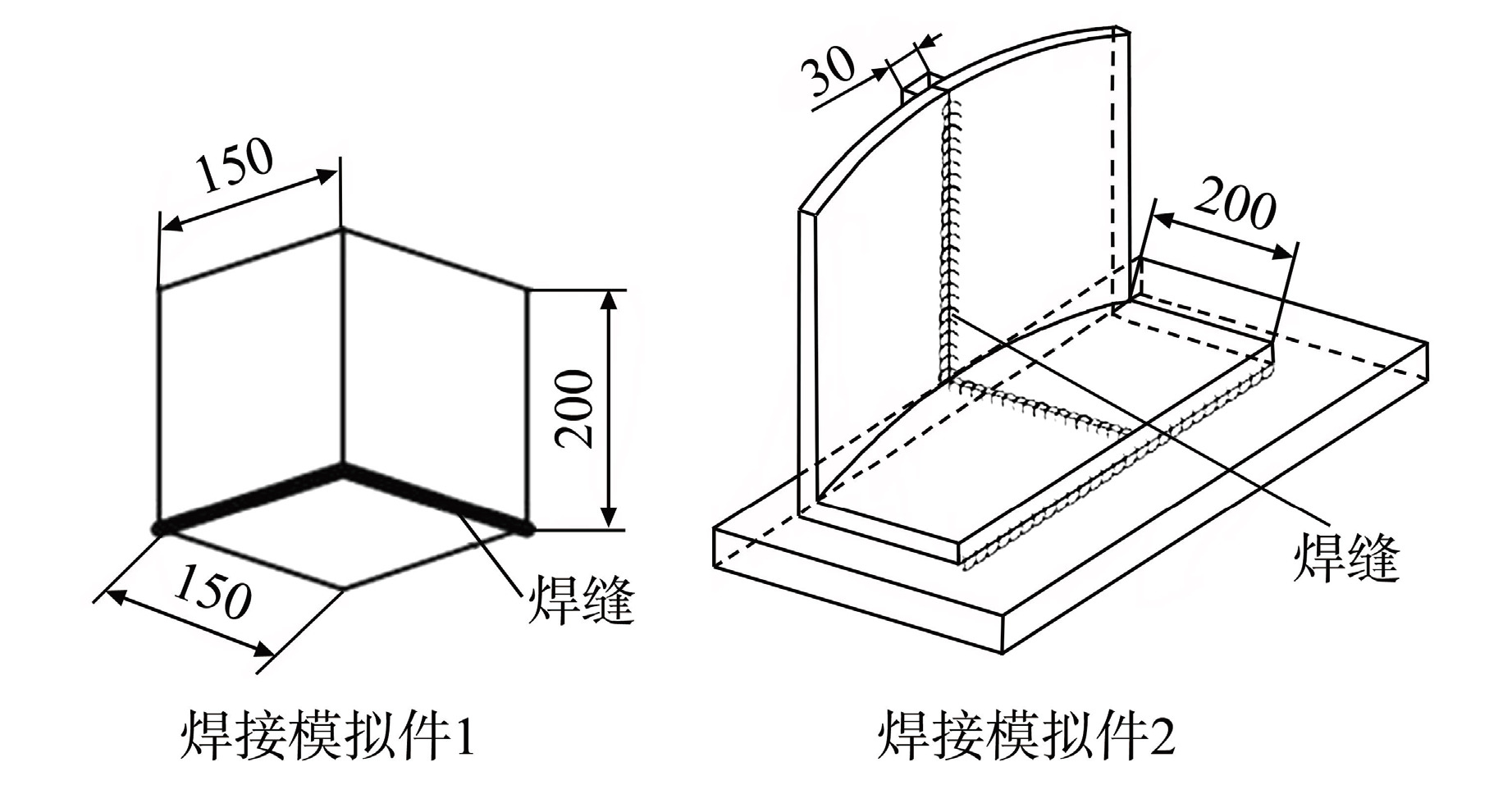

摘要: 对3种核电厂乏燃料水池不锈钢覆面材料S32205、S32101和S30403的焊接模拟件,在H3BO3浓度2500 mg/L、SO42−浓度1500 mg/L、Cl−浓度5%、pH值5.0、温度80℃、饱和氧的条件下浸泡6个月,对比研究其腐蚀行为。结果发现:S30403焊接模拟件在焊接节点和缝隙附近出现了大量的氯致应力腐蚀裂纹;S32101焊接模拟件出现了腐蚀坑,在焊接节点和缝隙附近腐蚀尤其严重;S32205焊接模拟件腐蚀最轻,试件表面未发现腐蚀坑及裂纹。研究表明:3种材料模拟件的耐腐蚀性规律为:S32205>S32101>S30403。S32205具有良好的综合力学性能和耐腐蚀性能,是一种理想的改进型水池覆面材料。Abstract: The corrosion behavior of the welding simulators of three stainless steel cladding materials S32205, S32101 and S30403 in spent fuel pool of nuclear power plant was studied by soaking them for 6 months under the conditions of H3BO3 concentration of 2500 mg/L, SO42− concentration of 1500 mg/L, Cl− concentration of 5%, pH value of 5.0, temperature of 80 ℃ and saturated oxygen. The results show that a large number of chlorine induced stress corrosion cracks appear near the welding joints and gaps of S30403 welding simulator; S32101 welding simulator has corrosion pits, especially near the welding joints and gaps; S32205 welding simulator has the lightest corrosion, and no corrosion pits and cracks are found on the surface of the test piece. The research shows that the corrosion resistance law of the three material simulator is: S32205>S32101>S30403. S32205 has good comprehensive mechanical properties and corrosion resistance, is an ideal improved pool cladding material.

-

Key words:

- Stainless steel cladding /

- Welding simulator /

- Corrosion behavior /

- S32205

-

表 1 化学成分结果

Table 1. Test Result of Chemical Composition

牌号 化学成分(质量分数)/% C Mn Si S P Cr Ni Mo Cu Co 铁素体 S32205 0.020 1.50 0.57 0.0040 0.017 22.20 8.8 3.10 0.03 0.02 46.0 S32101 0.020 1.90 0.57 0.0050 0.016 22.50 8.10 2.70 0.06 0.02 45.0 S30403 0.012 1.92 0.51 0.0038 0.018 19.44 12.97 2.86 0.018 0.03 7.6 表 2 力学性能及残余应力测试结果

Table 2. Test Result of Mechanical Properties and Residual Stress

牌号 S32205 S32101 S30403 力学性能 抗拉强度/MPa 790/800 735/730 565/570 屈服强度/MPa 457/453 665/672 674/682 夏比冲击功/ J

(焊缝区,−40℃)256/158/254 40/42/44 — 残余应力 横向/MPa 206/205 398/48 413/480 纵向/MPa 190/198 287/295 231/378 “—”表示无数据 -

[1] 胡月飞, 张鑫, 张洪军, 等. 不锈钢覆面总则: 1188JT0401[Z]. 北京: 中国核电工程有限公司, 2012: 5 [2] 皮丹, 李博, 于沛, 等. 反应堆换料水池和乏燃料水池冷却和处理系统手册: CP03XRFTXTS02[Z]. 北京: 中国核电工程有限公司, 2018: 7-11. [3] 尹开锯, 洪晓峰, 唐睿, 等. 秦山第二核电厂1号机组换料水池钢覆面失效分析[C]//中国核动力研究设计院科学技术年报. 成都, 2012: 247-249. [4] 王宇欣,白林,张洪军,等. 核电站不锈钢覆面焊接接头的点蚀行为及设计改进[J]. 腐蚀与防护,2021, 42(7): 59-65. doi: 10.11973/fsyfh-202107012 [5] 姚琳,郑越,张洪军,等. 核电厂水池覆面钢板在硼酸溶液中的腐蚀行为[J]. 腐蚀与防护,2018, 39(7): 525-529. doi: 10.11973/fsyfh-201807008 [6] MOSER R D, SINGH P M, KAHN L F. Chloride-induced corrosion resistance of high-strength stainless steels in simulated alkaline and carbonated concrete pore solutions[J]. Corrosion Science, 2012, 57: 241-253. doi: 10.1016/j.corsci.2011.12.012 -

下载:

下载: