Research on Structural Response Characteristics of Research Reactor Fuel Assembly During Collision

-

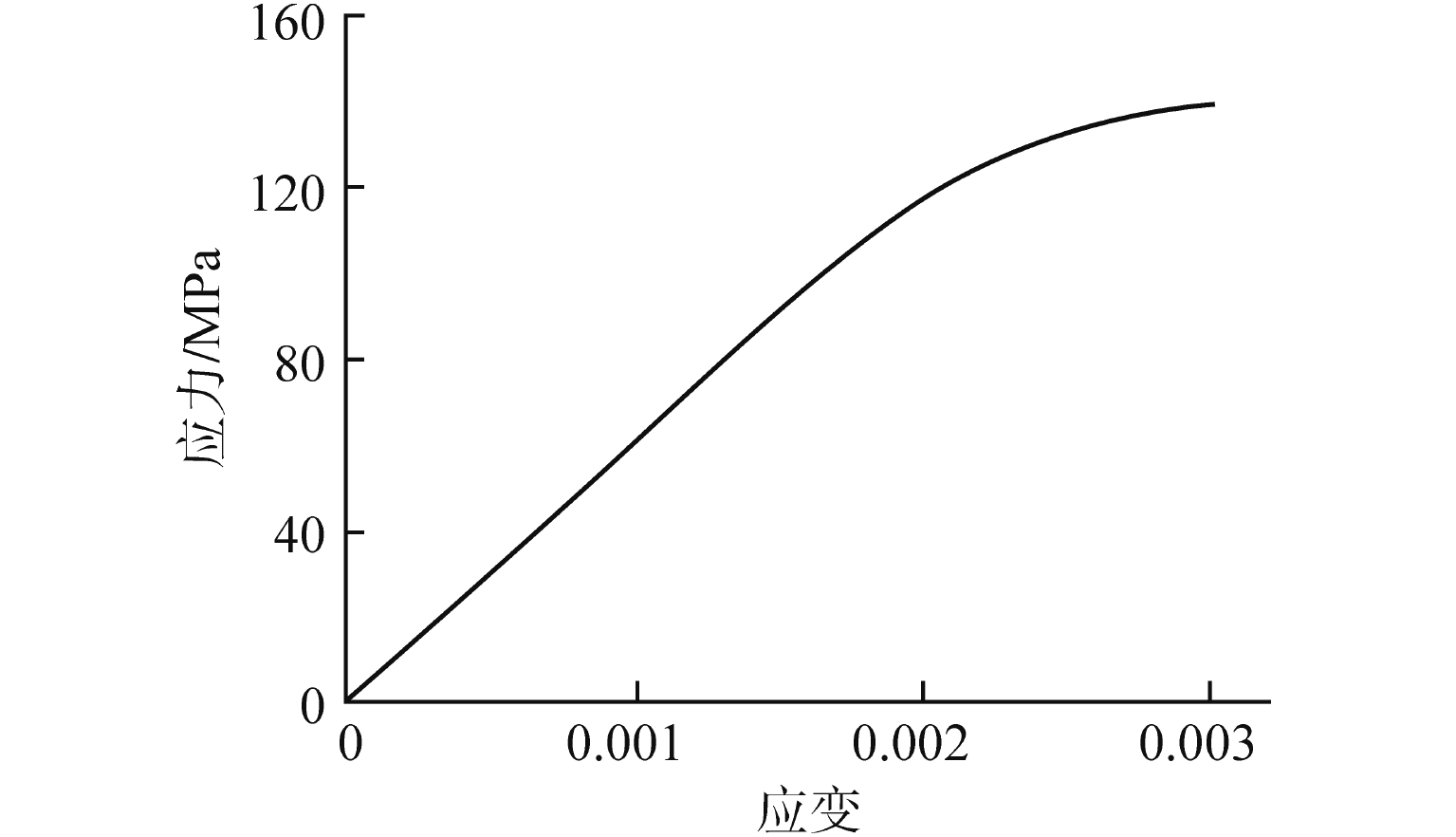

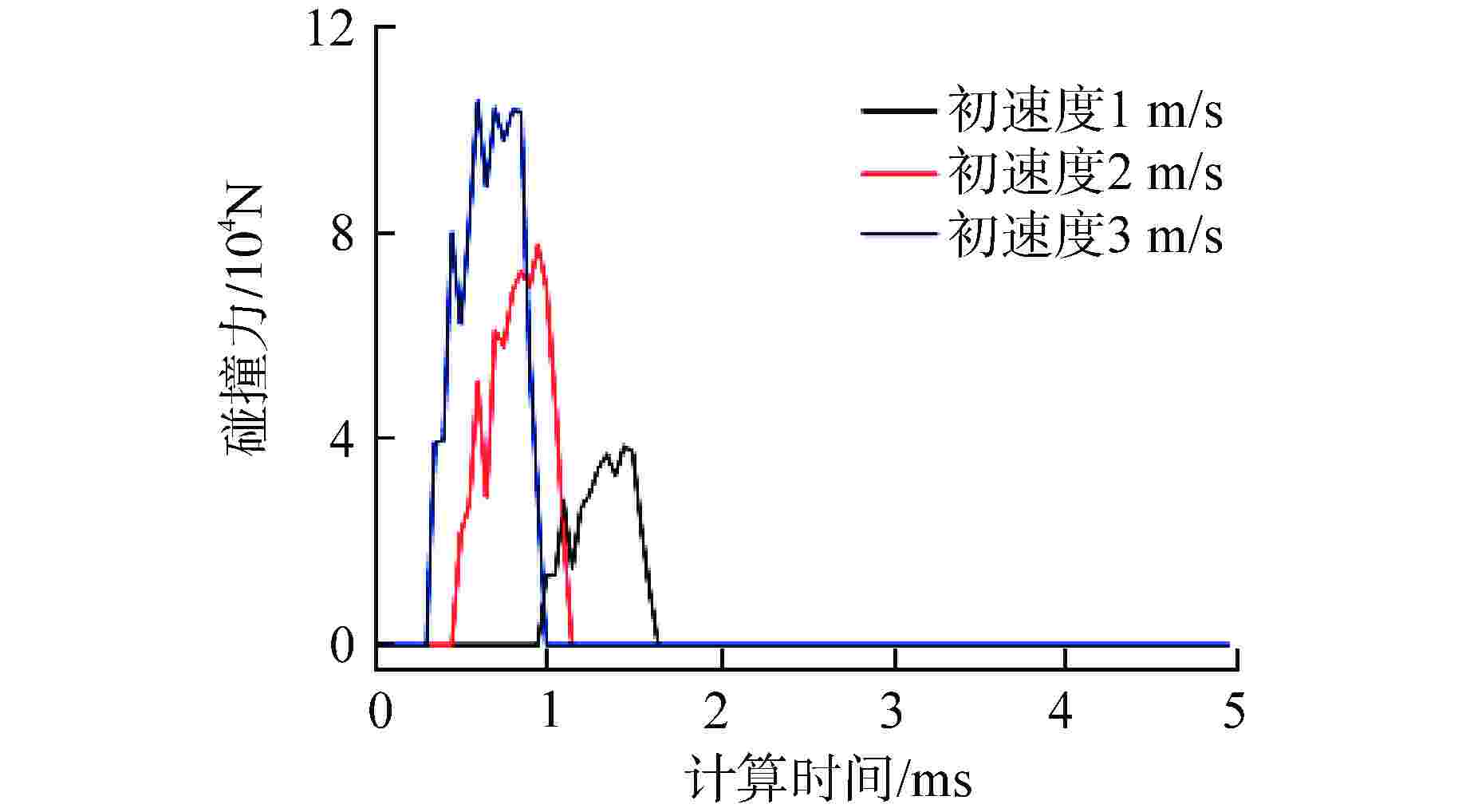

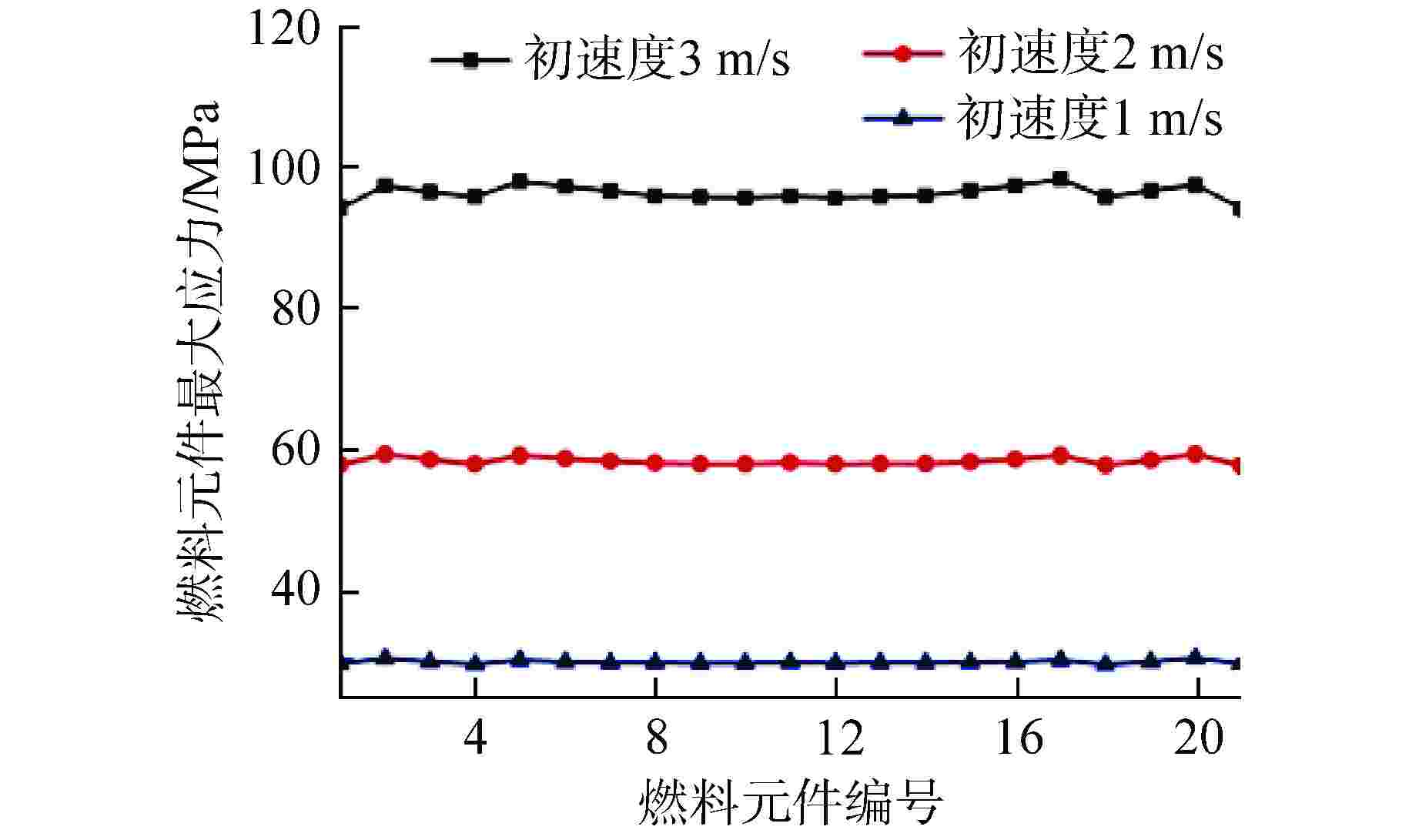

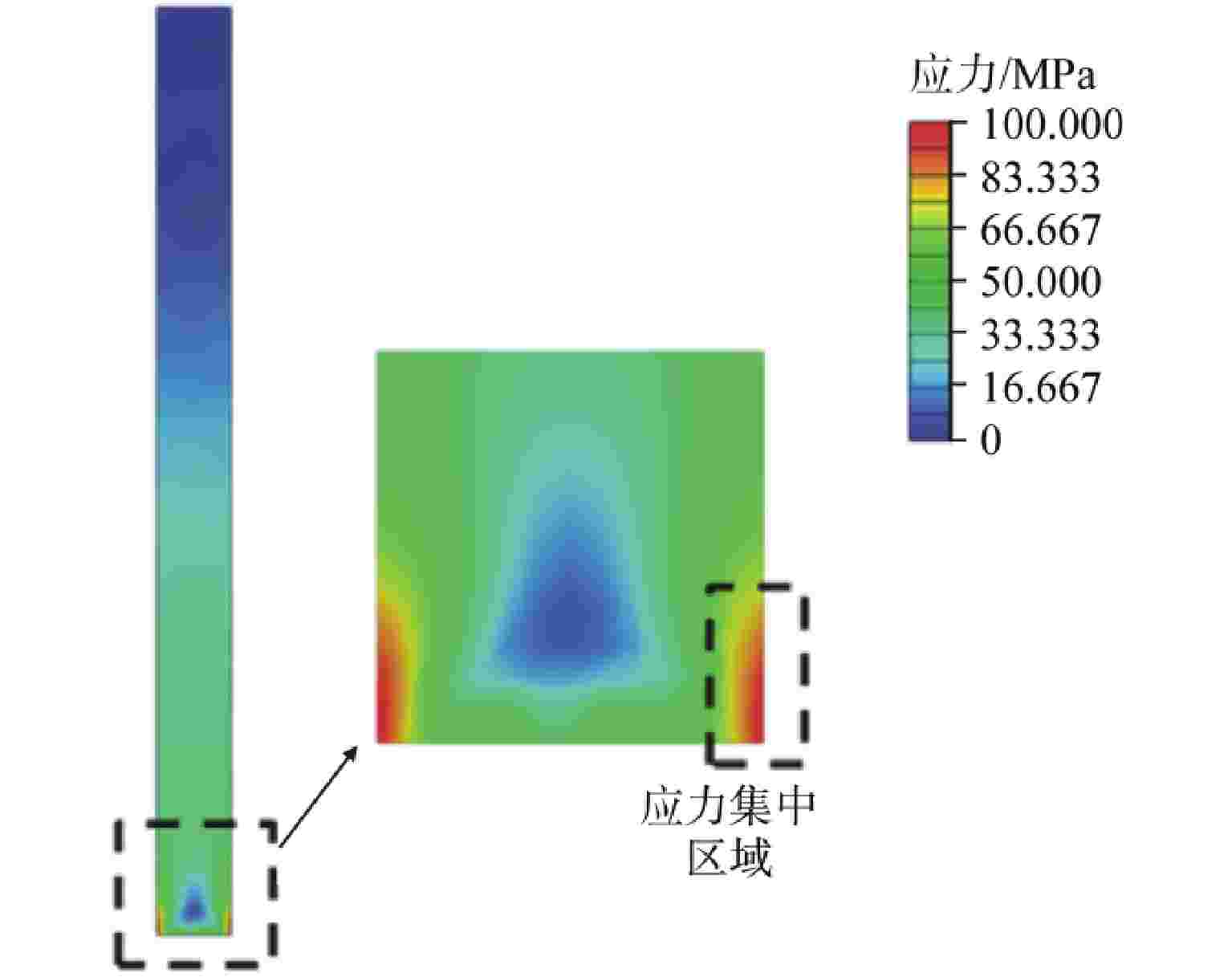

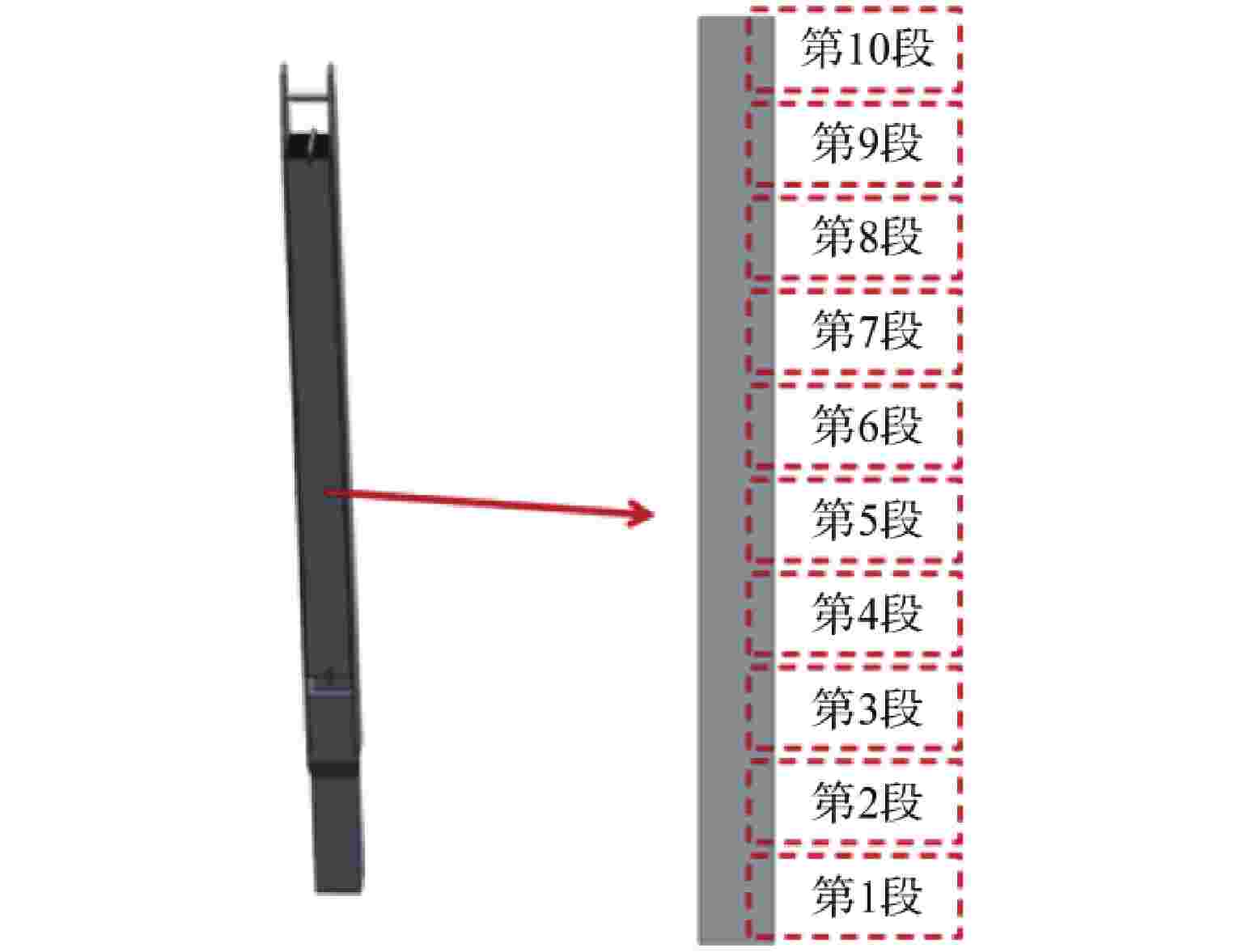

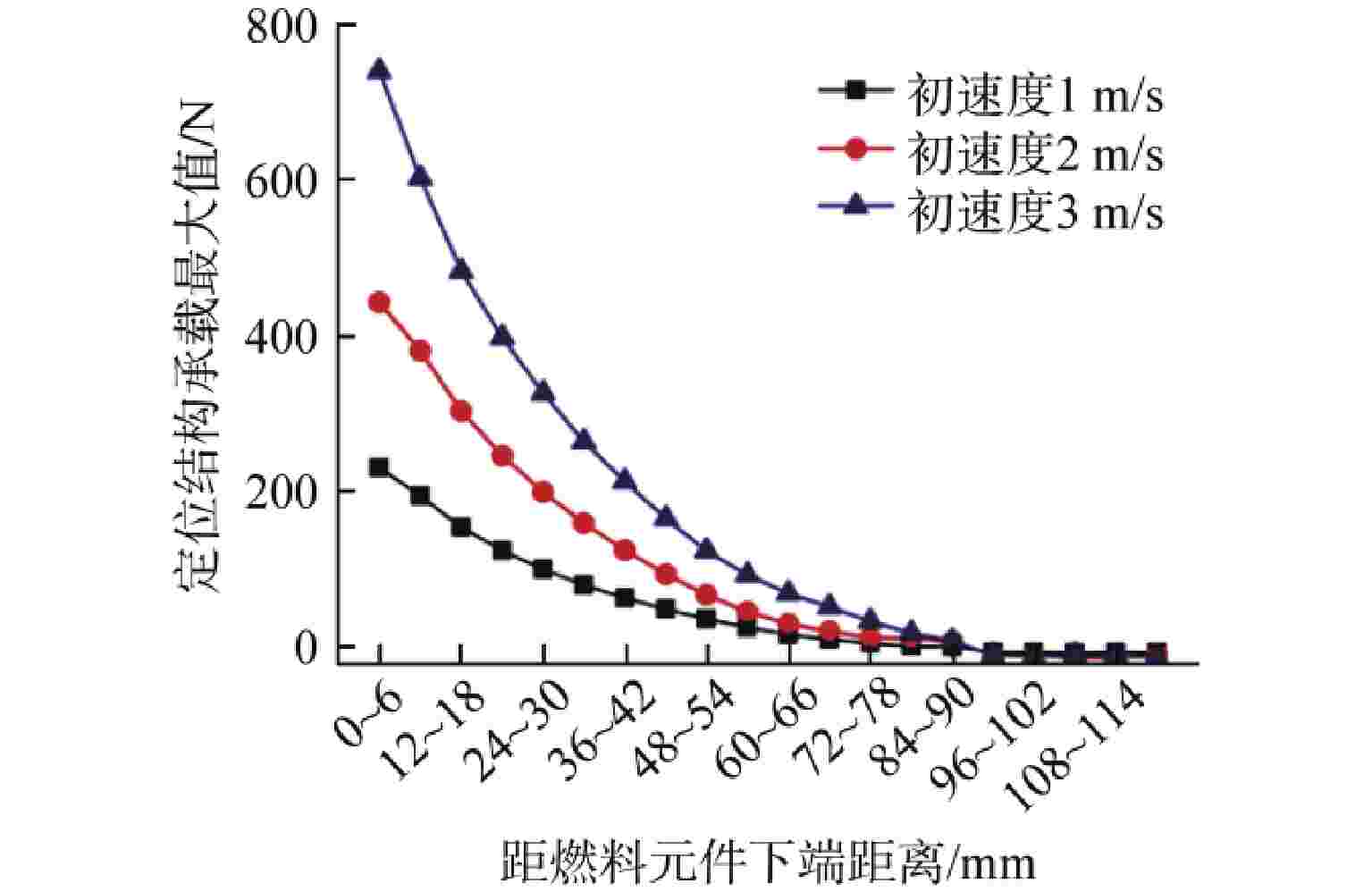

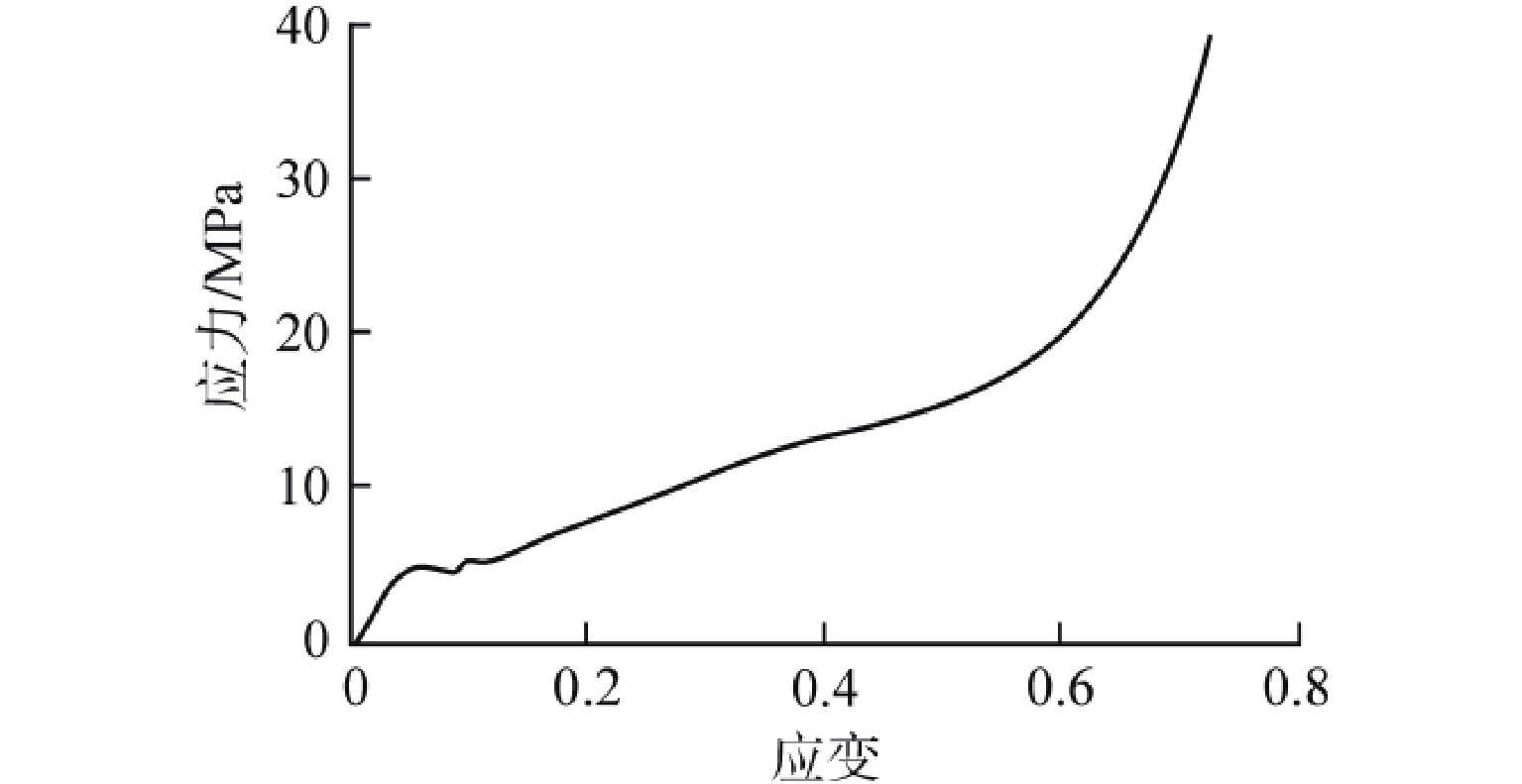

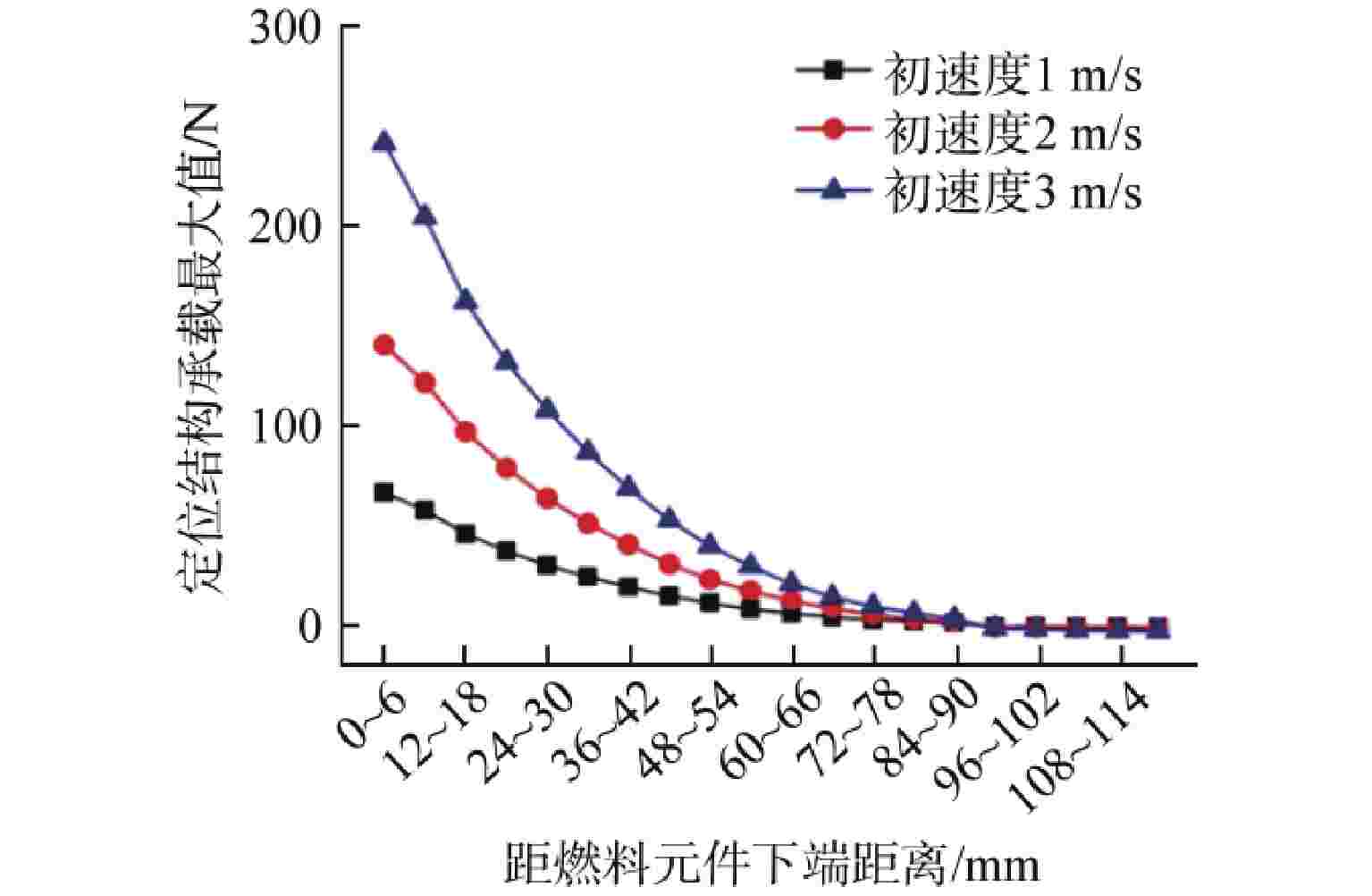

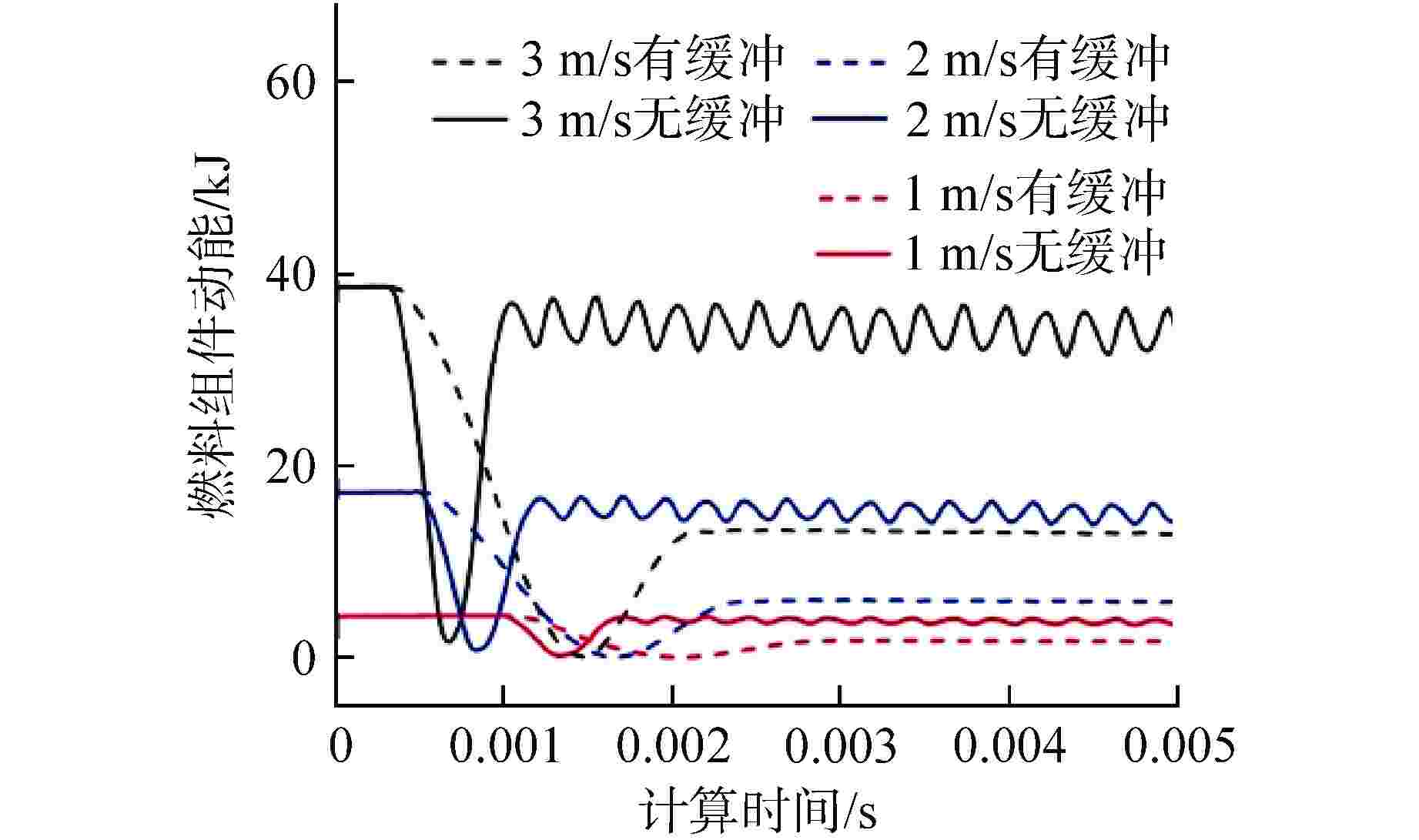

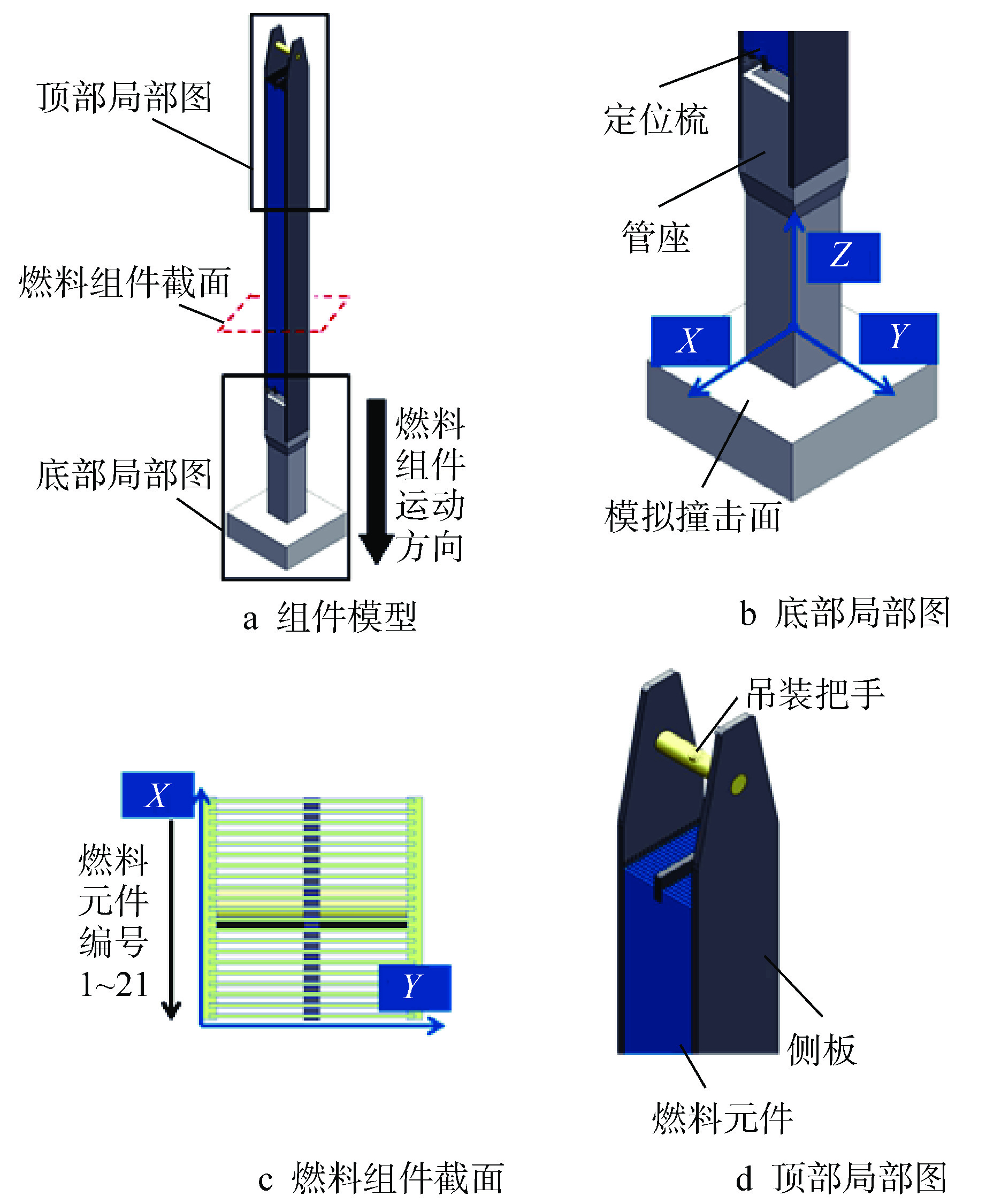

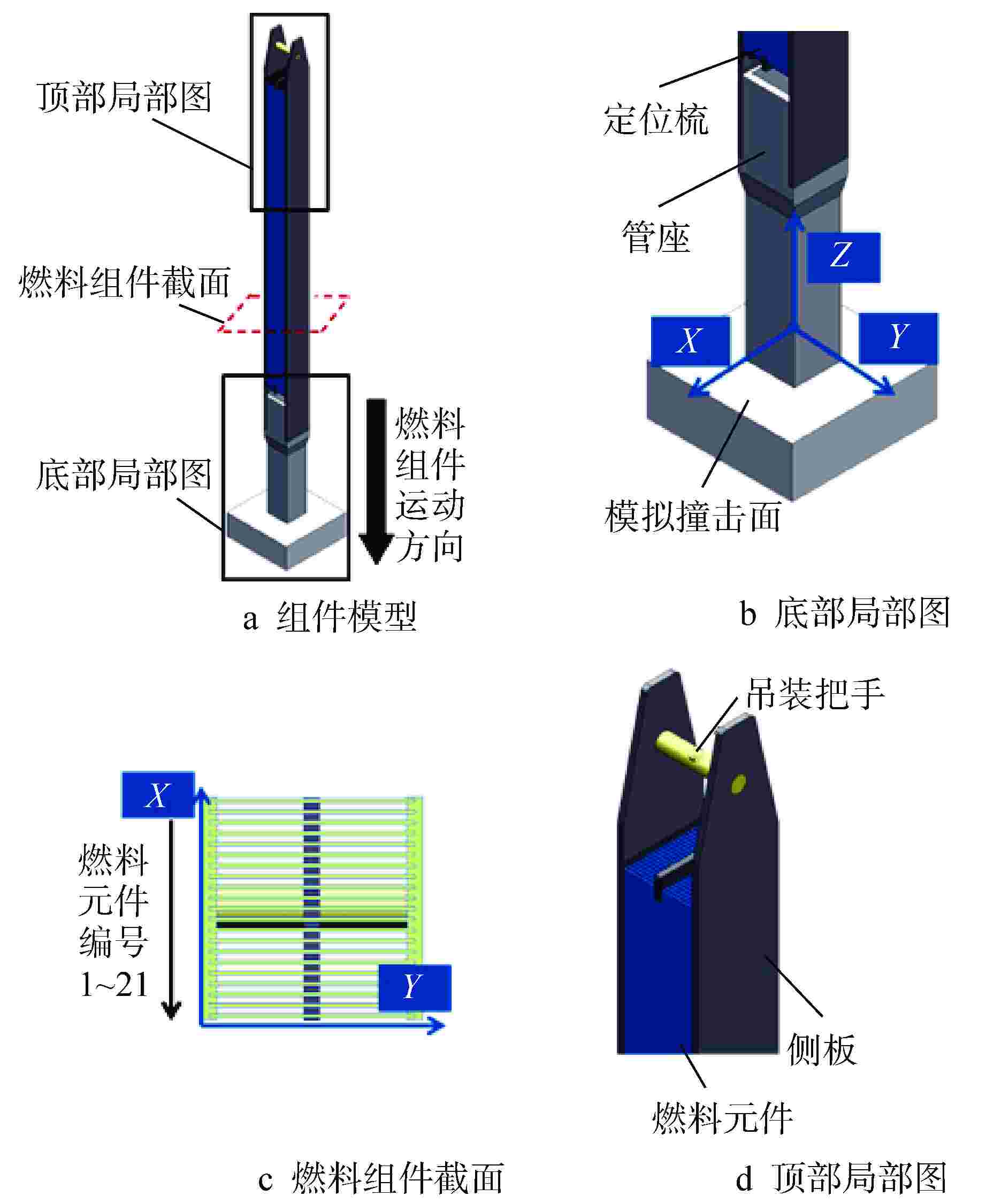

摘要: 对典型的研究堆燃料组件碰撞过程结构响应特性进行了数值模拟研究,分析了在碰撞过程中燃料组件应力响应特性、燃料元件定位结构的承载特征以及填充缓冲材料对燃料组件碰撞的保护效果。研究发现:在碰撞过程中燃料元件端部附近有明显的应力集中现象,增加燃料元件端部包壳长度可避免应力集中对芯体产生影响;燃料元件端部定位结构承受的载荷显著大于中部,加强端部定位结构的强度可提升燃料组件承载能力;缓冲材料在碰撞过程中对燃料组件具有良好的吸能保护功能,同时能平缓碰撞中的动能变化以及碰撞后的结构振动。Abstract: The structural response characteristics of typical research reactor fuel assembly collision process are numerically simulated. The stress response characteristics of the fuel assembly, the bearing characteristics of the positioning structure of the fuel element and the protective effect of the filling cushion material on the collision of the fuel assembly during the collision are analyzed. It is found that there is an obvious stress concentration near the end of the fuel element during the collision, and increasing the cladding length at the end of the fuel element can avoid the effect of stress concentration on the core. The load borne by the end positioning structure of the fuel element is significantly greater than that in the middle, and strengthening the strength of the end positioning structure can improve the bearing capacity of the fuel assembly; the cushion material has a good energy absorption and protection function for the fuel assembly during the collision, and can smooth the change of kinetic energy in the collision and the structural vibration after the collision.

-

Key words:

- Fuel assembly /

- Collision analysis /

- Research reactor /

- Positioning structure /

- Cushion material

-

材料 密度/(kg·m−3) 弹性模量/GPa 泊松比 6061铝合金 2800 71 0.33 304不锈钢 7850 199 0.28 燃料元件材料 4240 60.5 0.33 材料 A/MPa B/MPa n m C 6061铝合金 324 114 0.42 1.34 0.002 304不锈钢 454 1962 0.75 0.69 0.173 表 3 1号燃料元件最大应力

Table 3. Maximum Stress of Fuel Element No.1

参数 初速度 1 m/s 2 m/s 3 m/s 碰撞中最大应力/MPa 30.08 58.76 94.84 碰撞后最大应力/MPa 15.42 30.63 42.91 相对偏差/% −49 −48 −55 表 4 有无缓冲层有限元分析结果对比

Table 4. Comparison of FEA Results with or without Cushion

工况 最大碰撞

击力/N定位结构最

大应力/MPa燃料元件最

大应力/MPa3 m/s 无缓冲 106219 191.2 98.1 有缓冲 39582 134.6 26.8 偏差/% −63 −30 −73 2 m/s 无缓冲 78189 114.67 59.16 有缓冲 24835 81.23 15.00 偏差/% −68 −29 −75 1 m/s 无缓冲 38897 58.6 30.3 有缓冲 12781 42.79 8.91 偏差/% −67 −27 −71 -

[1] WIT H J, TSENG C C, CHENG S C. A Numerical analysis for a BWR fuel assembly drop event[J]. Journal of Nuclear Science and Technology, 2006, 43(9): 1068-1073. doi: 10.1080/18811248.2006.9711196 [2] KIM H J, YIM J S, LEE B H, et al. Drop impact analysis of plate-type fuel assembly in research reactor[J]. Nuclear Engineering and Technology, 2014, 46(4): 529-540. doi: 10.5516/NET.09.2013.103 [3] KIM H J, YIM J S, TAHK Y W, et al. Drop behaviors of a plate-type fuel assembly used in research reactor for a drop accident[J]. Progress in Nuclear Energy, 2019, 113: 255-262. doi: 10.1016/j.pnucene.2019.01.020 [4] HANIFEHZADEH M, GENCTURK B, MOUSAVI R. A numerical study of spent nuclear fuel dry storage systems under extreme impact loading[J]. Engineering Structures, 2018, 161: 68-81. doi: 10.1016/j.engstruct.2018.01.068 [5] KALININA E, AMMERMAN D, GREY C, et al. Full-scale assembly 30 cm drop test[J]. MRS Advances, 2020, 5(5): 265-274. [6] PETKEVICH P, ABRAMOV V, YUREMENKO V, et al. Simulation of the nuclear fuel assembly drop test with LS-Dyna[J]. Nuclear Engineering and Design, 2014, 269: 136-141. doi: 10.1016/j.nucengdes.2013.08.019 [7] 胡神阳. 6061铝合金试件的超声冲击表面强化及其组织性能基础研究[D]. 南京: 南京航空航天大学, 2019: 26-35. [8] 李星星. 304不锈钢本构模型参数识别研究[D]. 武汉: 华中科技大学, 2012: 15-27. [9] WANG X S, XU Y. Mechanical characterizations of the dispersion U3Si2-Al fuel plate with sandwich structure[J]. Applied Composite Materials, 2003, 10(3): 159-167. doi: 10.1023/A:1023978413329 [10] OHAIL S, OHAIL S H I, KHAN M, et al. Numerical and experimental investigation of Johnson–Cook material models for aluminum (Al 6061-T6) alloy using orthogonal machining approach[J]. Advances in Mechanical Engineering, 2018, 10(9): 1-14. [11] 袁上钦,王志豪,李江,等. 基于激光烧结纳米复材的高效吸能超材料[J]. 航空制造技术,2021, 64(15): 42-51. -

下载:

下载: