Study on Decarburization and Oxidation Corrosion Behavior of T-22 Alloy in Impure Helium of High-temperature Gas-cooled Reactor

-

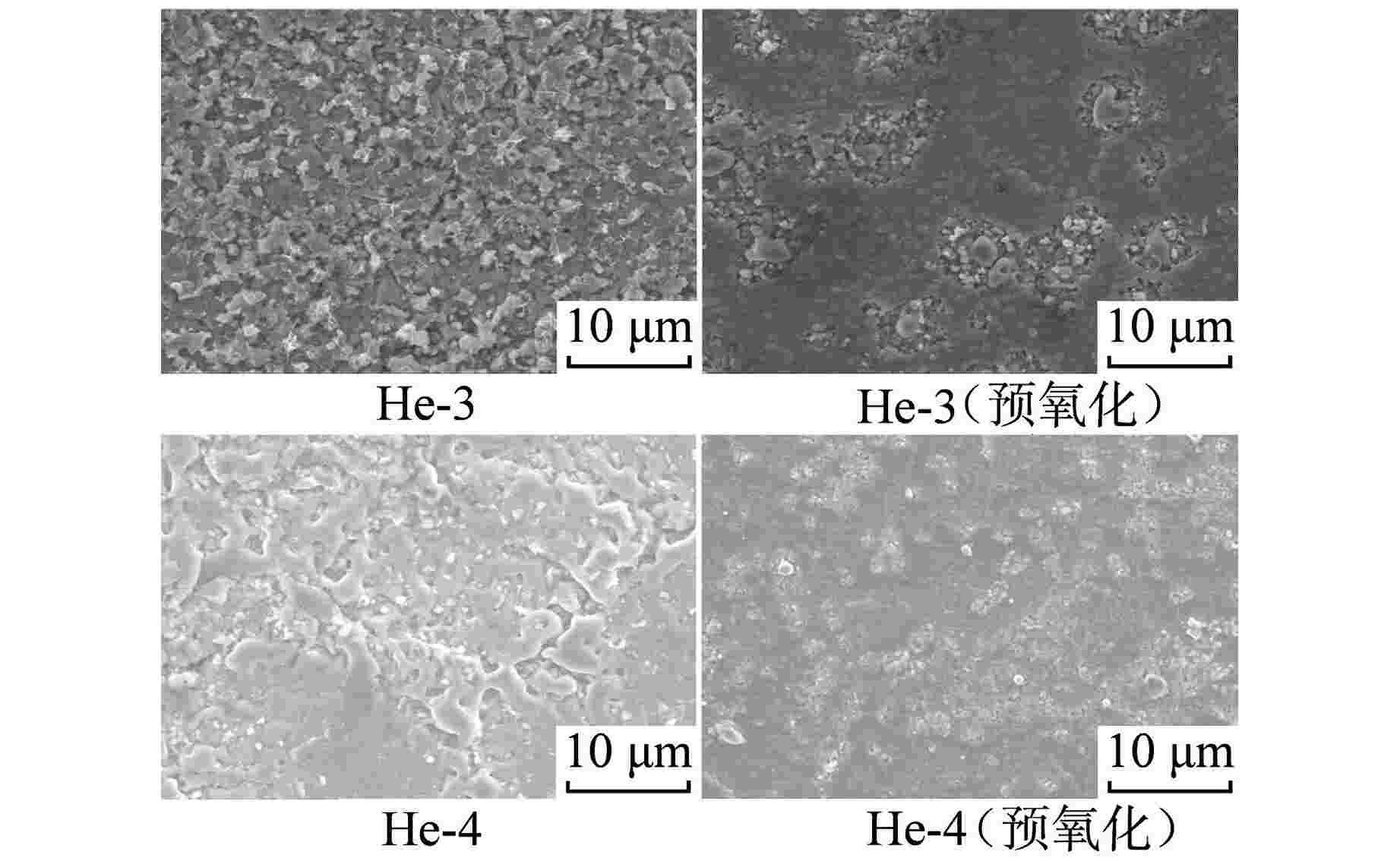

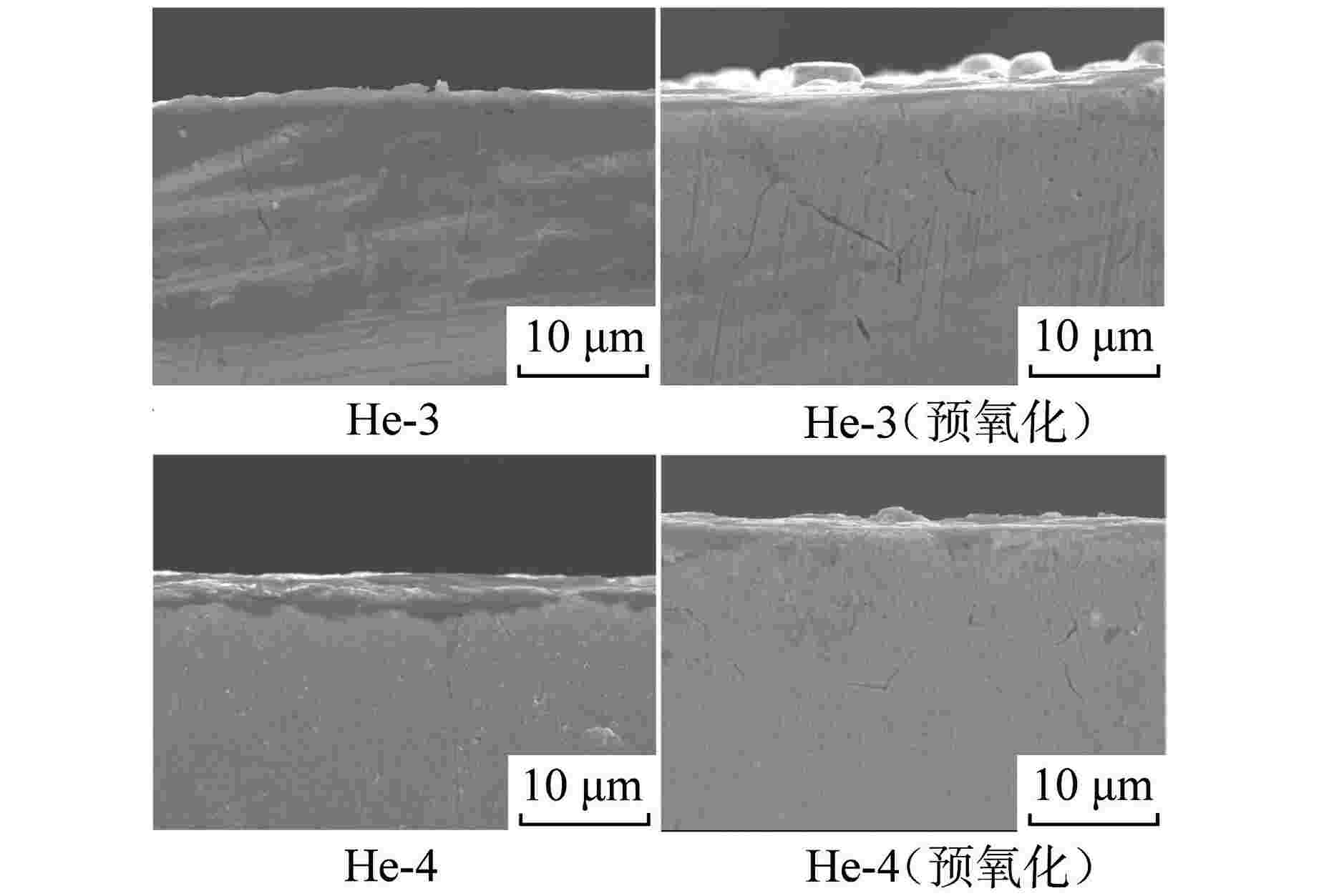

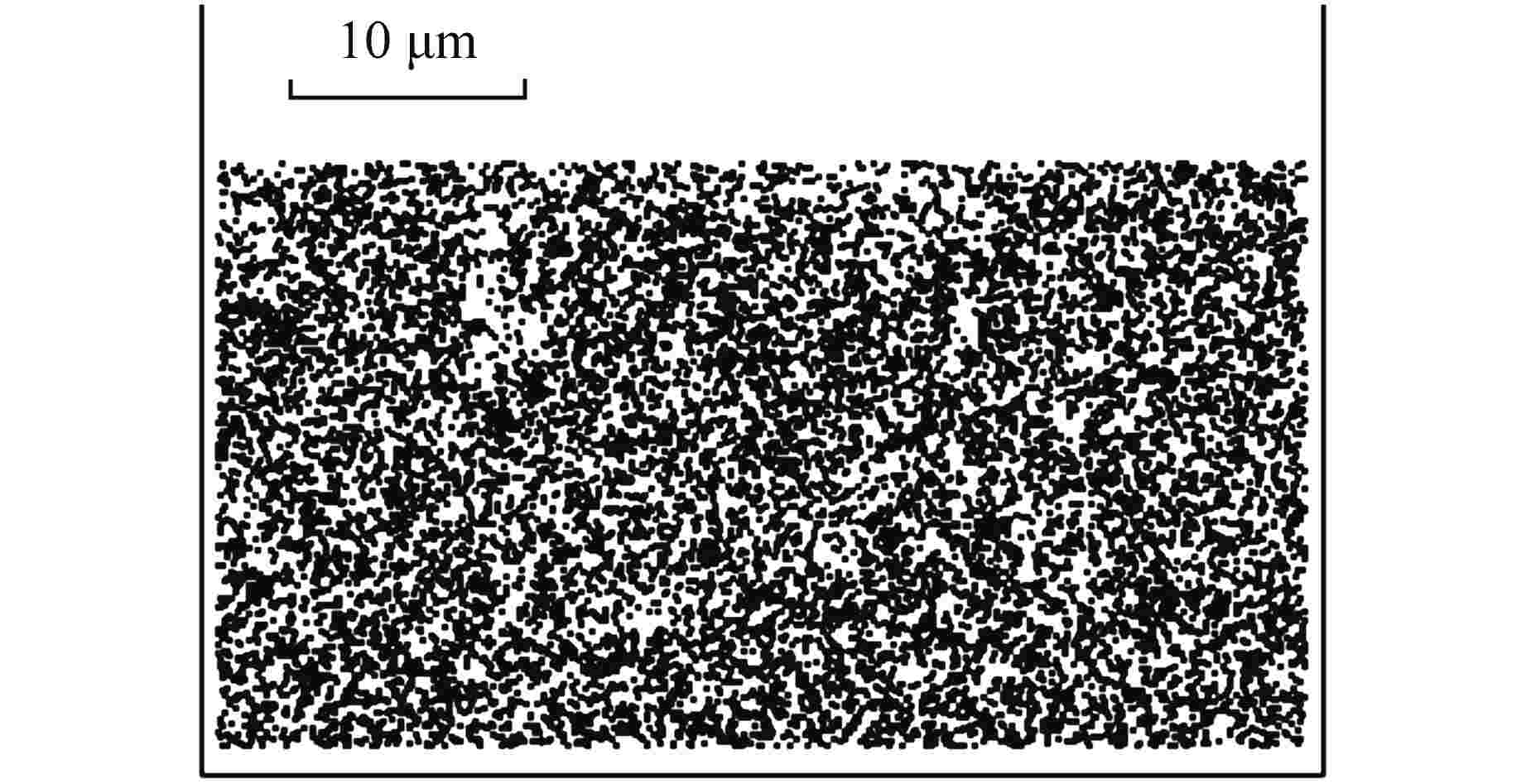

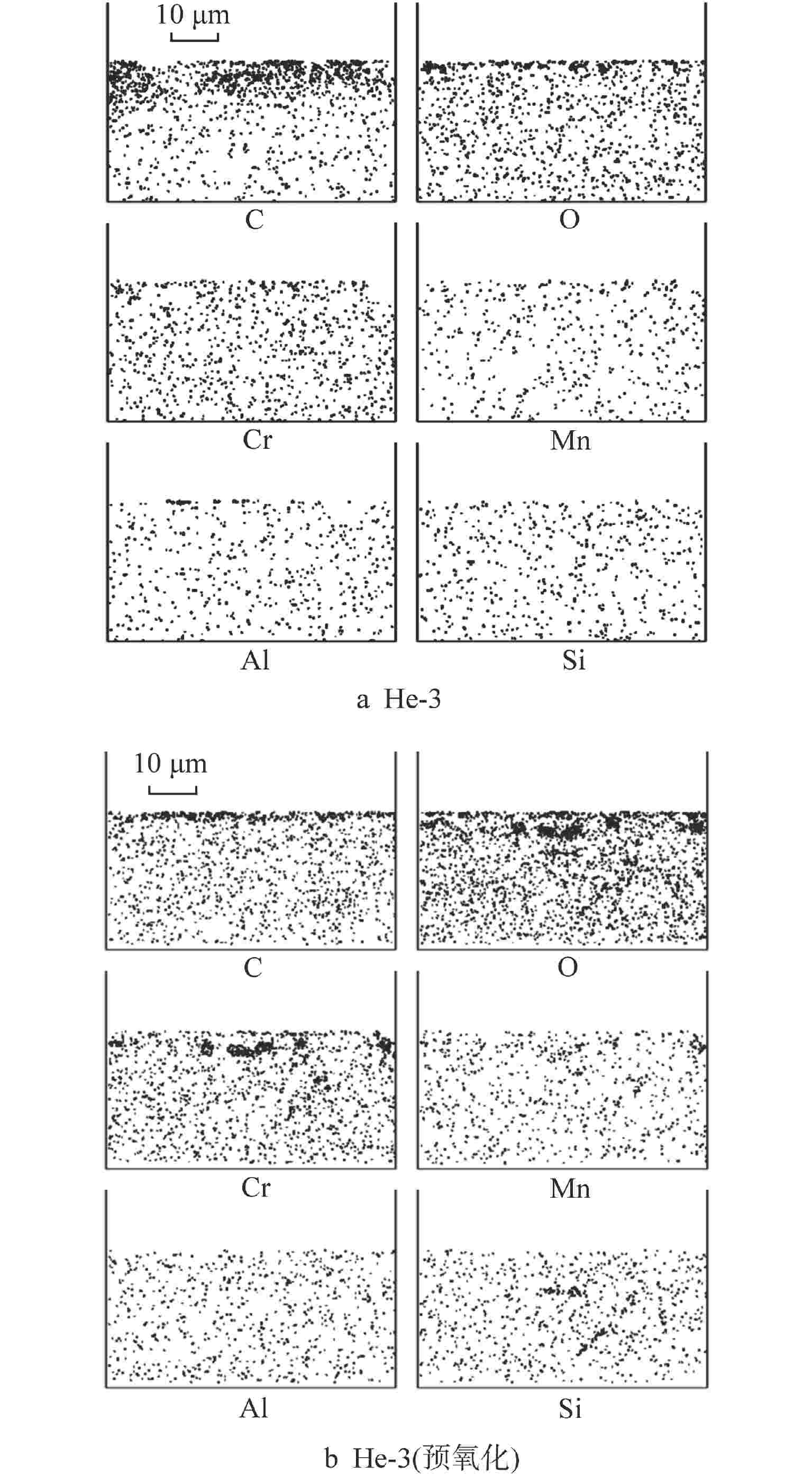

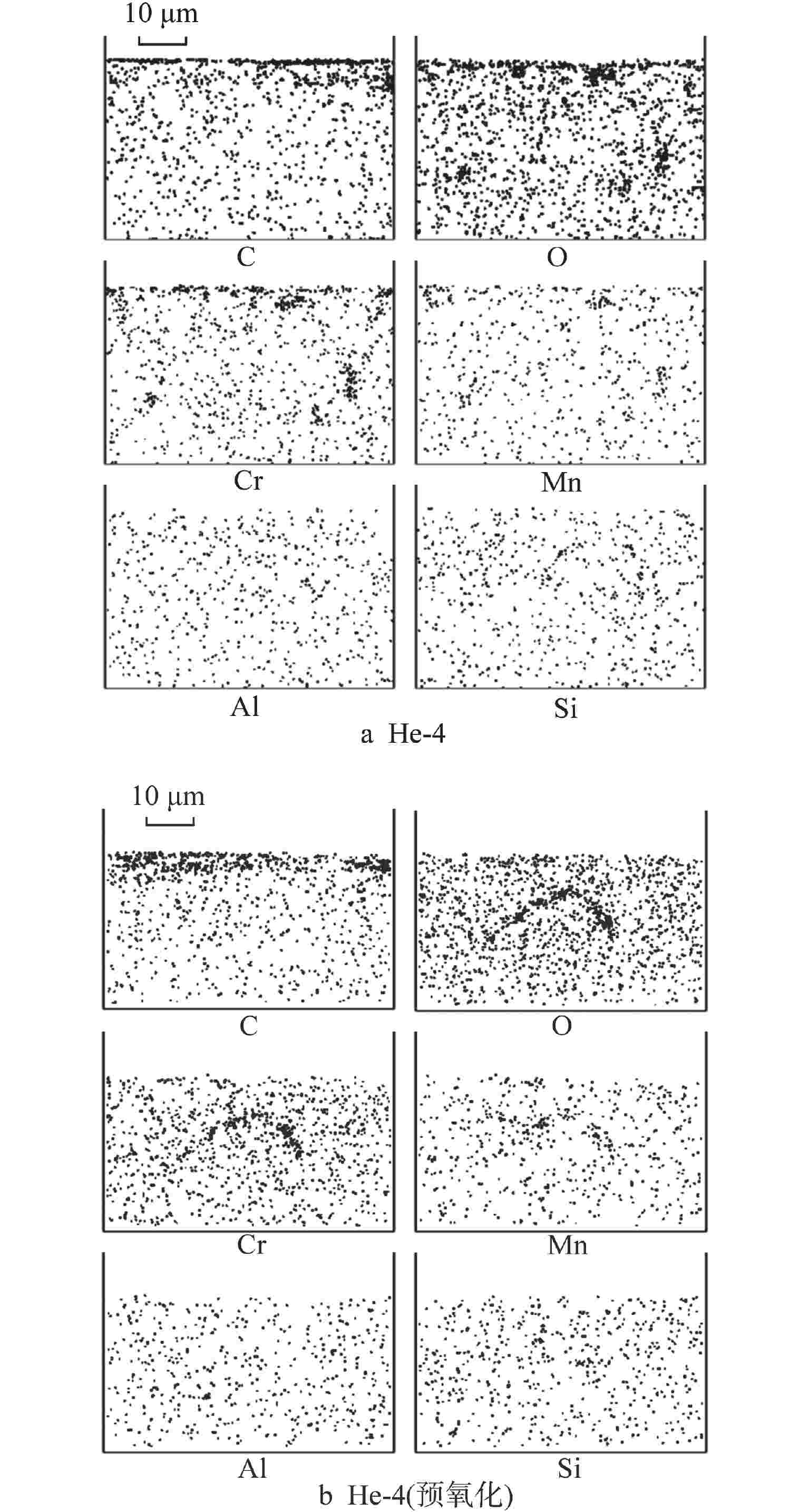

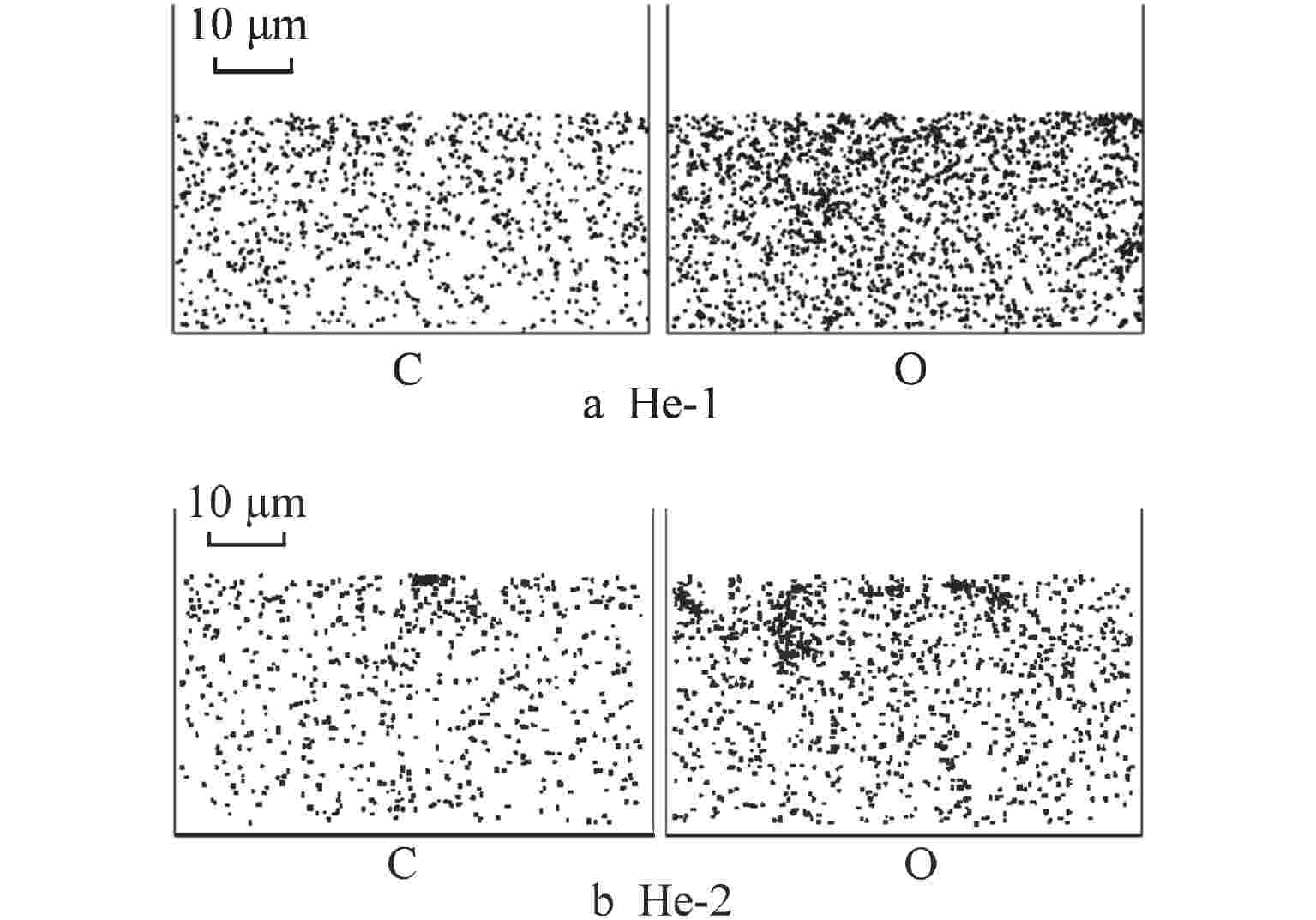

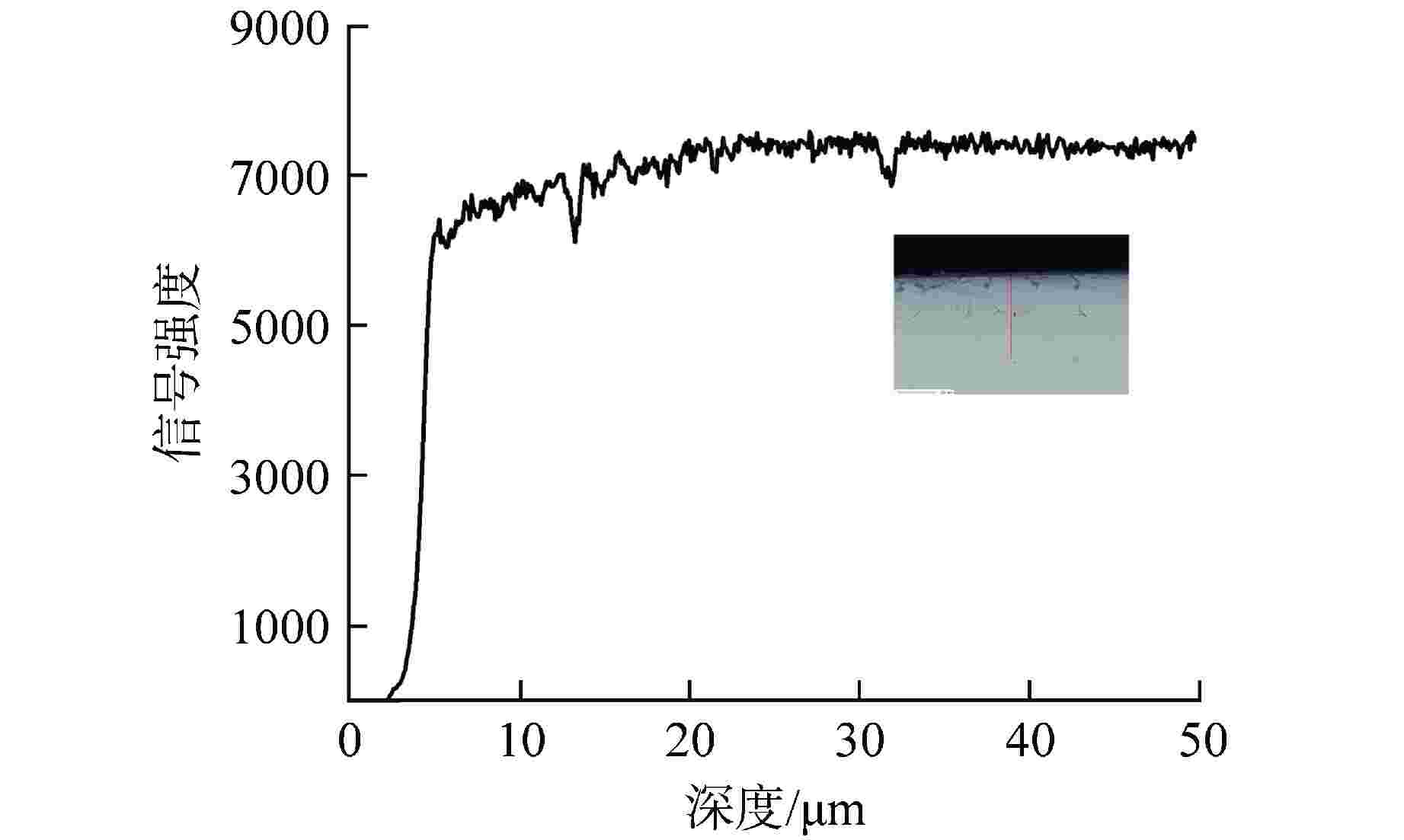

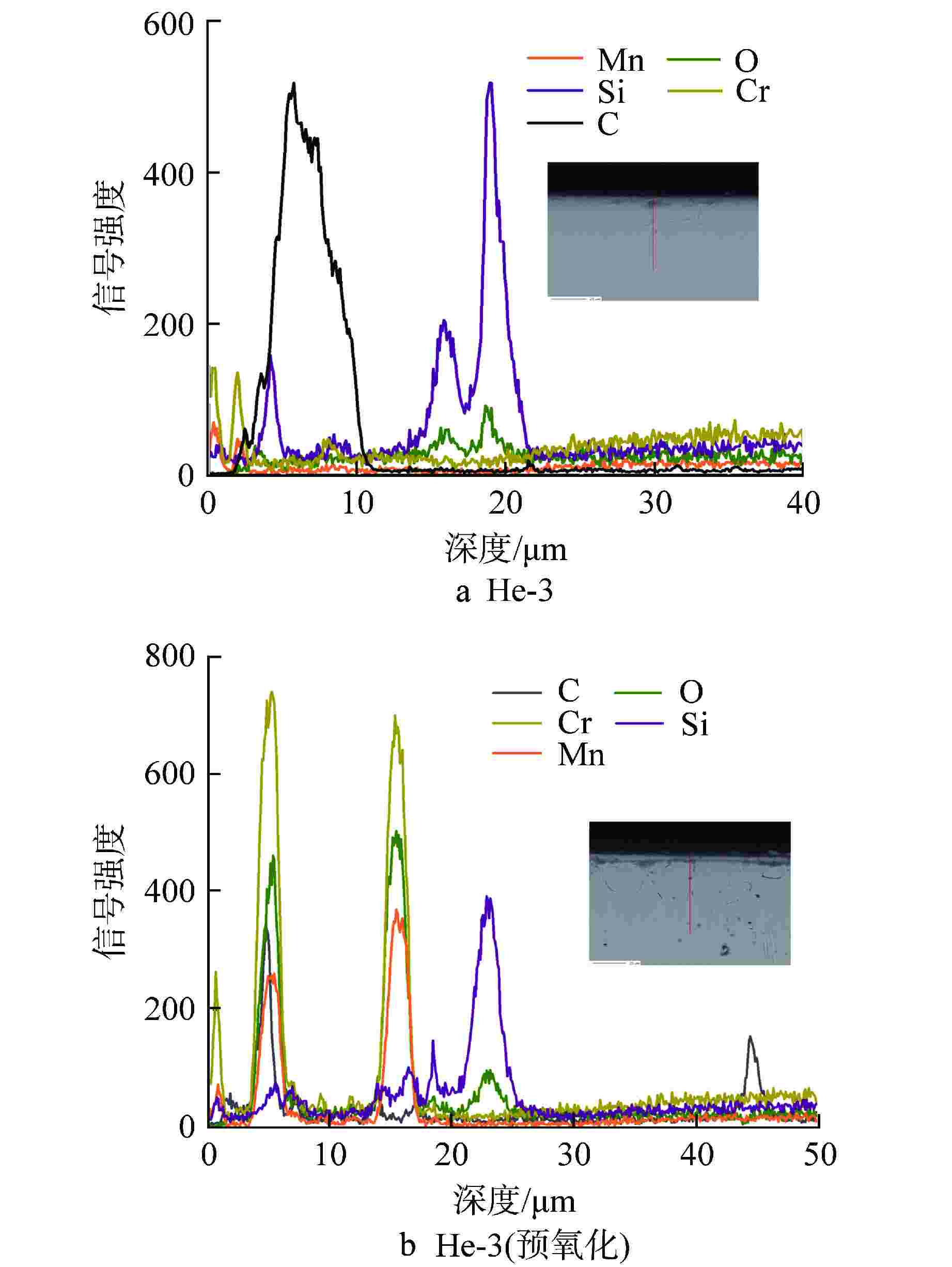

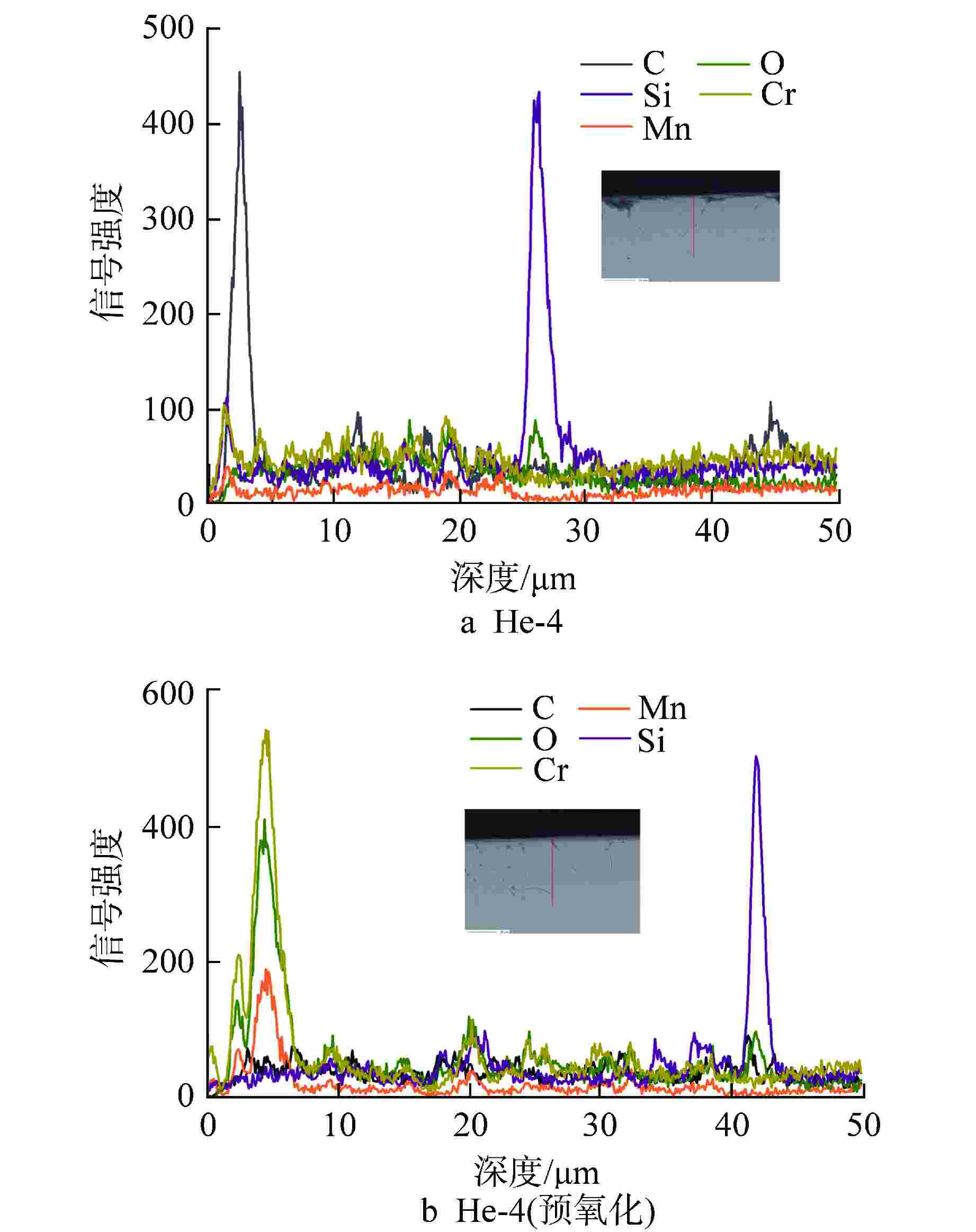

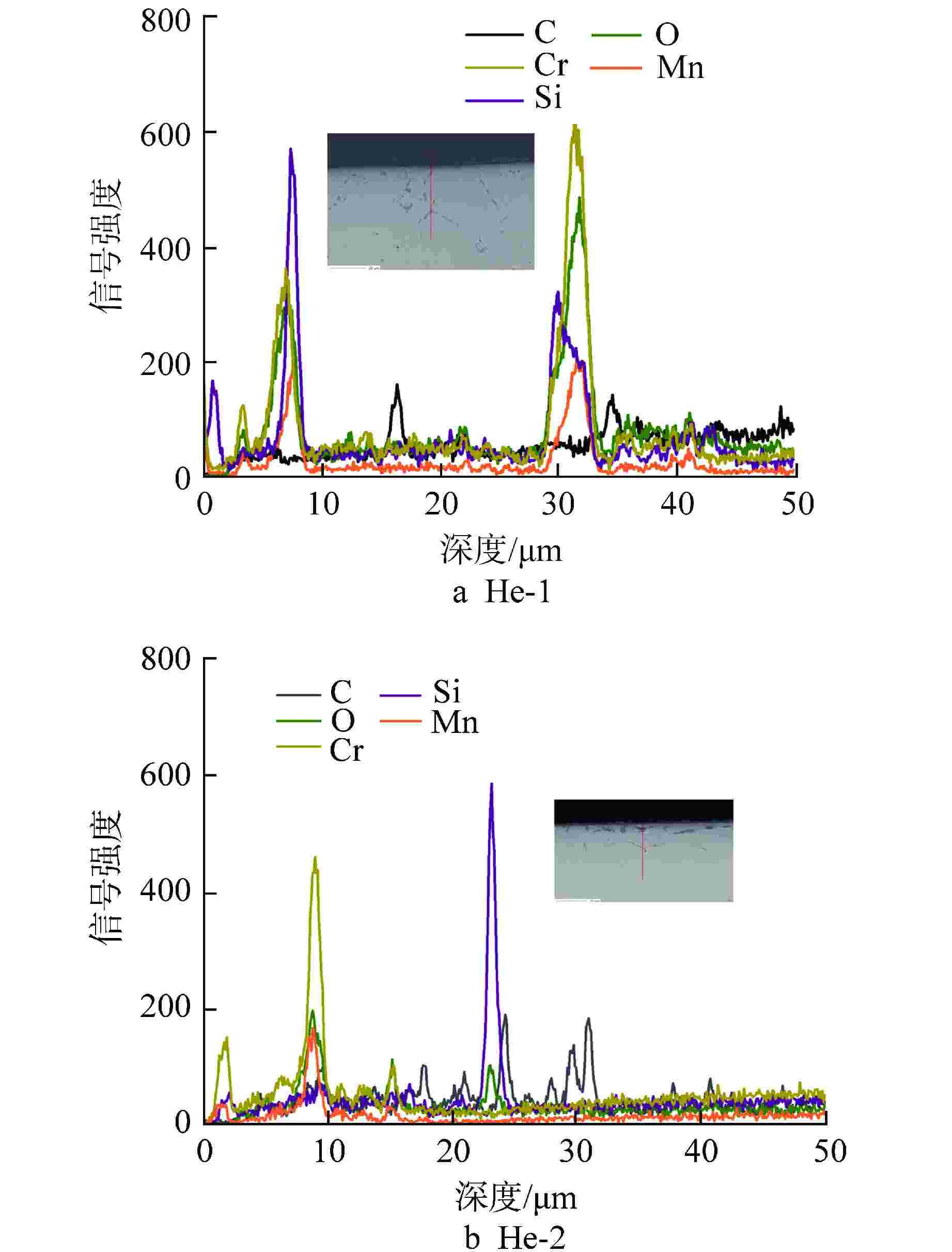

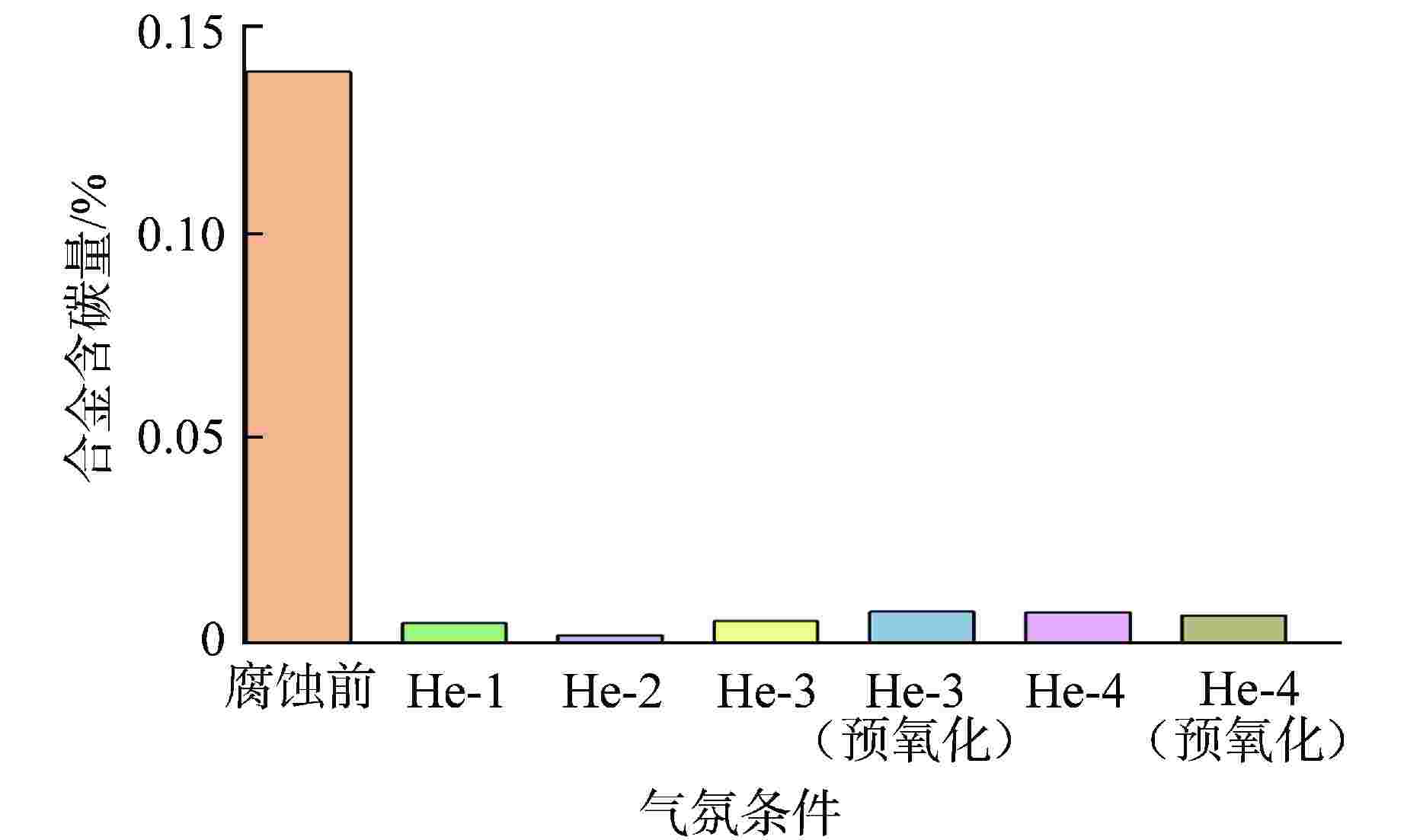

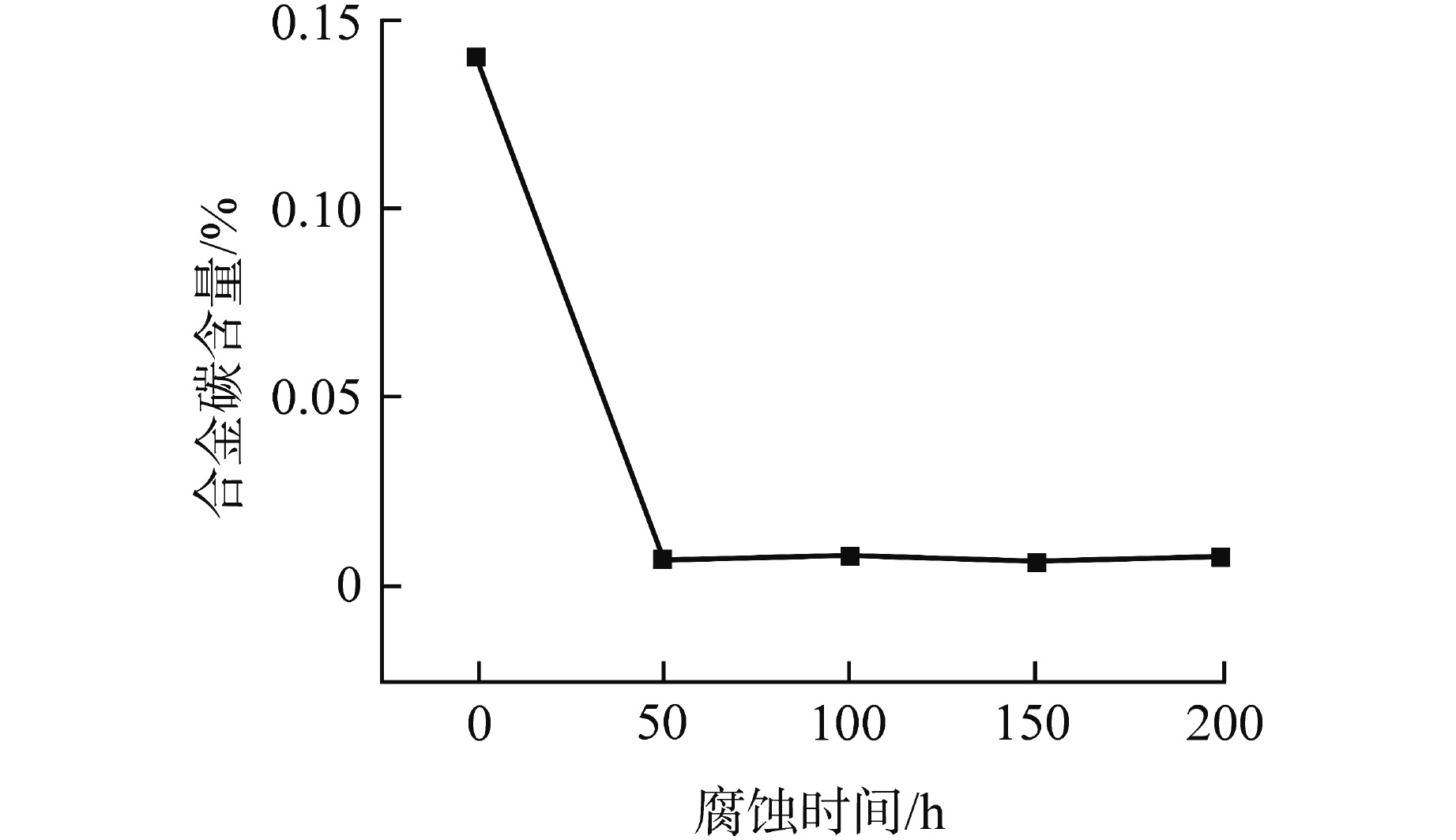

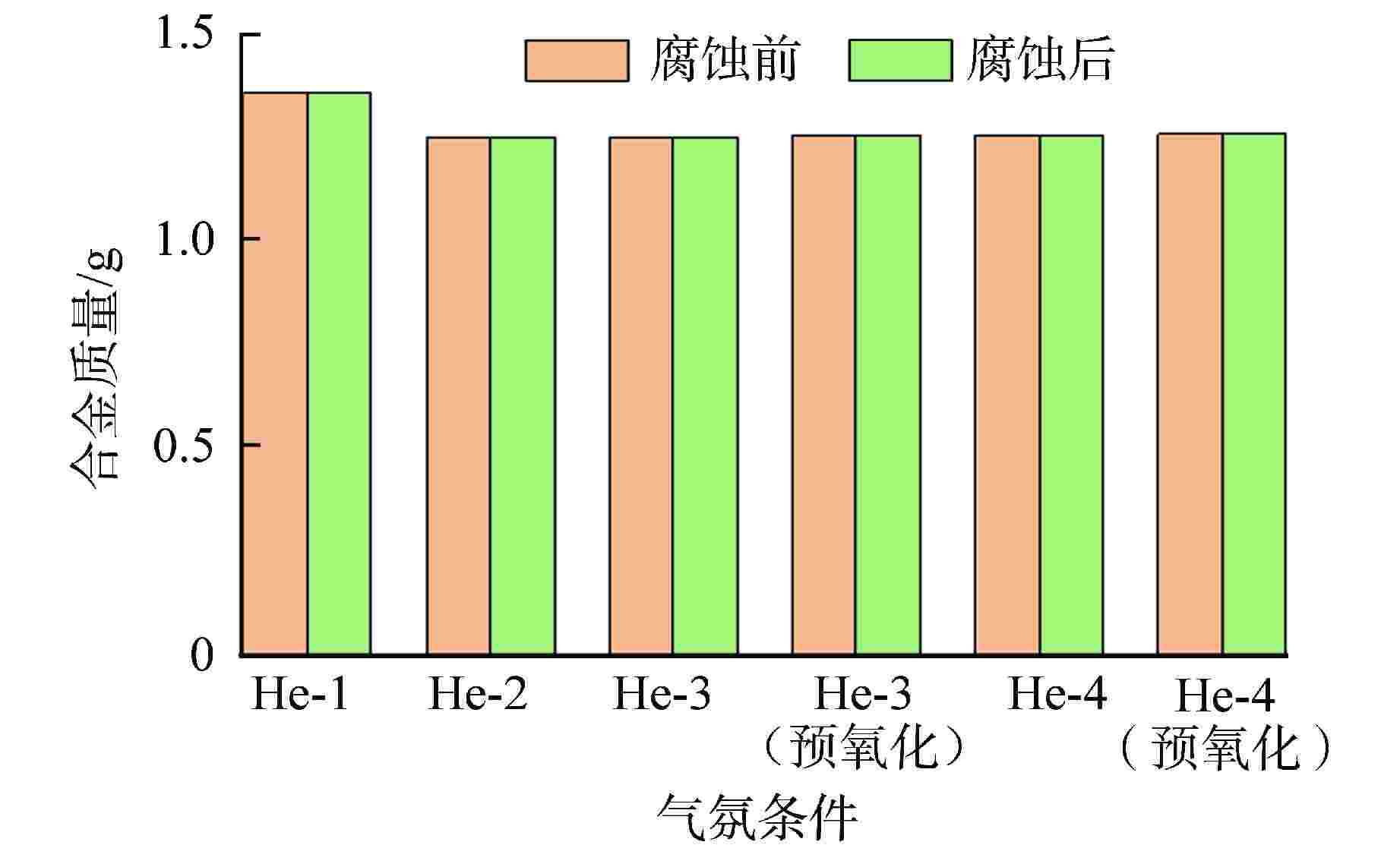

摘要: 高温气冷堆的主冷却剂氦气中含有痕量杂质,其在高温环境下会与设备的合金材料发生反应从而造成材料腐蚀。在950℃、4种非纯氦气中开展高温气冷堆蒸汽发生器备选材料T-22合金的腐蚀试验,腐蚀时间为50 h,然后通过称重、扫描电镜、X射线能谱、电子探针显微分析仪以及碳硫分析仪对腐蚀后的T-22合金进行表征分析。研究表明,T-22合金在6种腐蚀情况下均未形成连续致密氧化层,合金内部均出现内氧化现象且均近乎发生完全脱碳,脱碳量达92.86%;腐蚀后的T-22合金的质量变化均很小,腐蚀50 h时合金已发生充分脱碳。Abstract: Helium in the main coolant of high-temperature gas-cooled reactor (HTGR) contains trace impurities, which reacts with the alloy materials of the equipment at high temperature and cause corrosion of the materials. The corrosion test of T-22 alloy, an alternative material for high-temperature gas-cooled reactor steam generator, is carried out in four kinds of impure helium at 950 ℃, and the corrosion time is 50 h. Then the corroded T-22 alloy is characterized by weighing, scanning electron microscope, X-ray energy spectrum, electron probe microanalyzer and carbon sulfur analyzer. The results show that T-22 alloy does not form a continuous dense oxide layer under six corrosion conditions, internal oxidation occurs in the alloy and complete decarburization occurs, and the amount of decarburization is up to 92.86%. The mass change of T-22 alloy after corrosion is very small, and the alloy has been fully decarburized after corrosion for 50 h.

-

Key words:

- High-temperature gas-cooled reactor /

- T-22 alloy /

- Decarbonization /

- Oxidation /

- Mass gain

-

表 1 T-22合金主要元素含量 %

Table 1. Contents of Main Elements in T-22 Alloy

元素 C Cr Fe Ni Mn Al Si Mo Ti 含量 0.14 2.25 Base − 0.45 − <0.05 1.00 − Base—合金基底元素;“−”—低于检测值,可认为含量为0 表 2 腐蚀试验气氛杂质的成分含量(Ptot=0.1 MPa) ppm

Table 2. Composition Content of Impurities in Corrosion Test Atmosphere (Ptot=0.1 MPa)

气氛条件 H2 H2O CO CO2 CH4 O2 He-1 − 6 − − − 1.00 He-2 490 0.83 490 70 2 0.58 He-3 490 1.52 490 70 210 0.50 He-4 490 1.52 5 70 2 0.50 Ptot—恒定试验压力 -

[1] KUGELER K, ZHANG Z. Modular high-temperature gas cooled reactor power plant[M]. Beijing: Tsinghua University, 2019: 1-21. [2] ZHANG Z Y, WU Z X, WANG D Z, et al. Development strategy of high temperature gas cooled reactor in China[J]. Strategic Study of CAE, 2019, 21(1): 12-19. [3] ZIERMANN E. Review of 21 years of power operation at the AVR experimental nuclear power station in Jülich[J]. Nuclear Engineering and Design, 1990, 121(2): 135-142. doi: 10.1016/0029-5493(90)90098-I [4] QUADAKKERS W J. High temperature corrosion in the service environments of a nuclear process heat plant[J]. Materials Science and Engineering, 1987, 87: 107-112. doi: 10.1016/0025-5416(87)90366-1 [5] FUJIKAWA S, HAYASHI H, NAKAZAWA T, et al. Achievement of reactor-outlet coolant temperature of 950℃ in HTTR[J]. Journal of Nuclear Science and Technology, 2004, 41(12): 1245-1254. doi: 10.1080/18811248.2004.9726354 [6] PAN F, YAN Y F, XU B S, et al. Research on heat treatment of T22 steel high-pressure boiler pipe[J]. Steel Pipe, 2010, 39(1): 60-66. [7] MANNA G, CASTELLO P, HARSKAMP F, et al. Testing of welded 2.25CrMo steel, in hot, high-pressure hydrogen under creep conditions[J]. Engineering Fracture Mechanics, 2007, 74(6): 956-968. doi: 10.1016/j.engfracmech.2006.08.021 [8] MORO L, GONZALEZ G, BRIZUELA G, et al. Influence of chromium and vanadium in the mechanical resistance of steels[J]. Materials Chemistry and Physics, 2008, 109(2-3): 212-216. doi: 10.1016/j.matchemphys.2007.11.030 [9] LI J F, YU X B, DUAN H W, et al. Study on Localization of SA213 T-22 transfer heat tube for nuclear safety class one[J]. Hot Working Technology, 2016, 45(8): 82-84. [10] GU B S, LU Q, FU J Y, et al. Influence of oxidation temperature on the high-temperature oxide film forming behavior of T22 heat-exchange tubes[C]//The 2nd International Conference on Materials Science and Engineering Technology (MSET 2015). Shanghai: Shanghai Xiaoyu Culture Communication Co., Ltd., 2015: 72-78. [11] ZHENG W, LI H X, WANG Q H, et al. Oxidation behaviors of the high temperature alloys in the impure helium and argon[C]// International Conference on Nuclear Engineering. U.S. : American Society of Mechanical Engineers, 2021 [12] LI H X, DU B, ZHENG W, et al. Corrosion behavior of superalloys in high temperature gas cooled reactor in impure helium with corrosion time[C]//International Conference on Nuclear Engineering. U.S. : American Society of Mechanical, 2021 [13] 王秋豪,李昊翔,郑伟,等. 高温气冷堆冷却剂杂质对高温合金材料高温性能影响的研究模型分析[J]. 核技术,2020, 43(4): 37-42. [14] 朱江, 李智慧. 10 MW高温气冷堆一回路氦气品质研究[J]. 原子能科学技术,2010, 44(S1): 274-278. doi: 10.3969/j.issn.0258-0926.2005.01.011 [15] 李昊翔, 郑伟, 银华强, 等. 高温堆非纯氦气中预氧化对3种高温合金的腐蚀行为影响研究[J/OL]. 原子能科学技术: 1-9. [2021-11-25]. http://kns.cnki.net/kcms/detail/11.2044.TL.20211112.1608.006.html. [16] 池成忠,贺志勇,高原,等. 表面渗铬T8钢中碳迁移的热力学分析[J]. 中国表面工程,2004, 17(4): 38-41. doi: 10.3321/j.issn:1007-9289.2004.04.010 -

下载:

下载: