Research on the Thermal-Mechanical Performance of Hollow Hexagonal Fuel Element

-

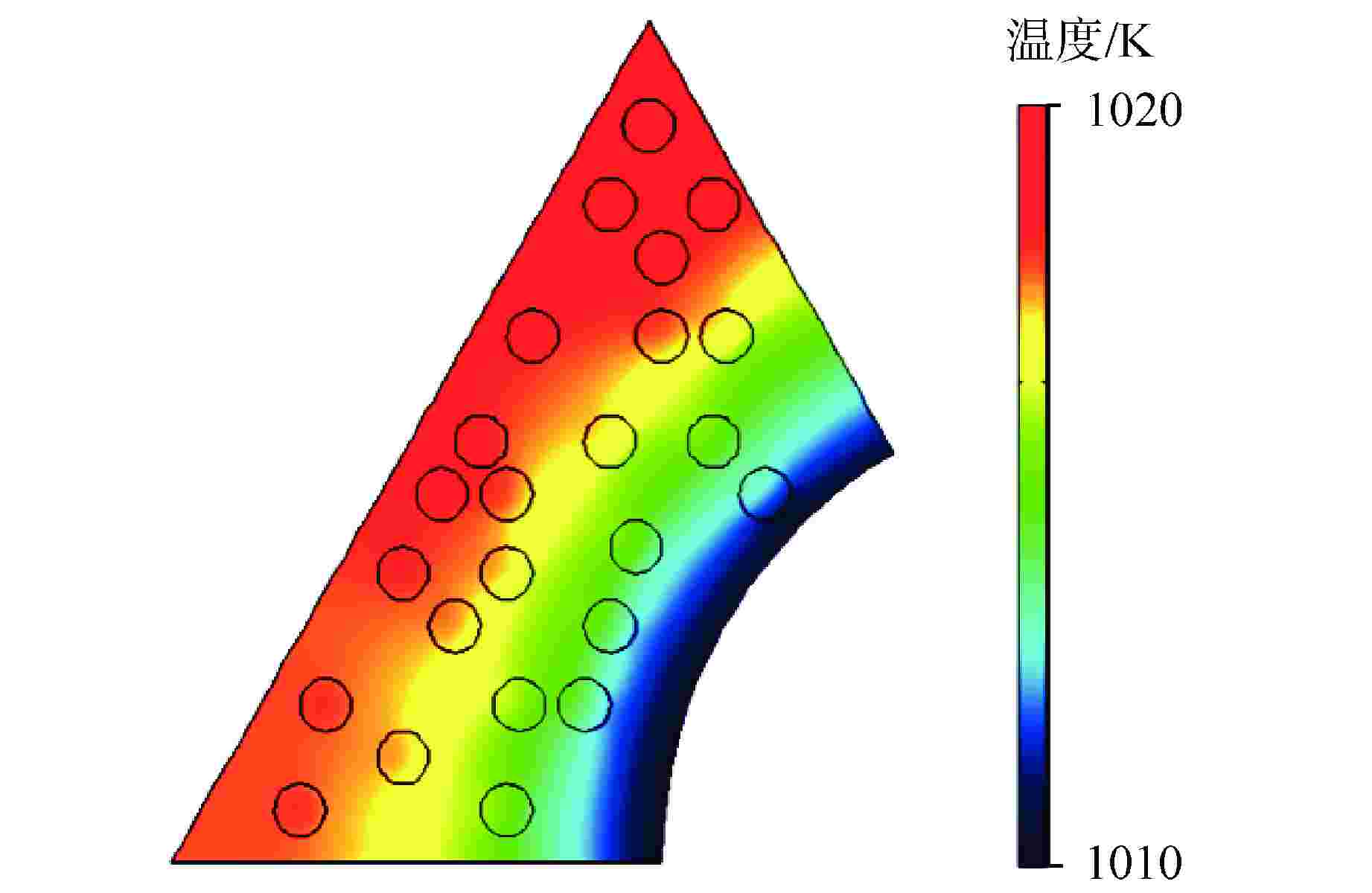

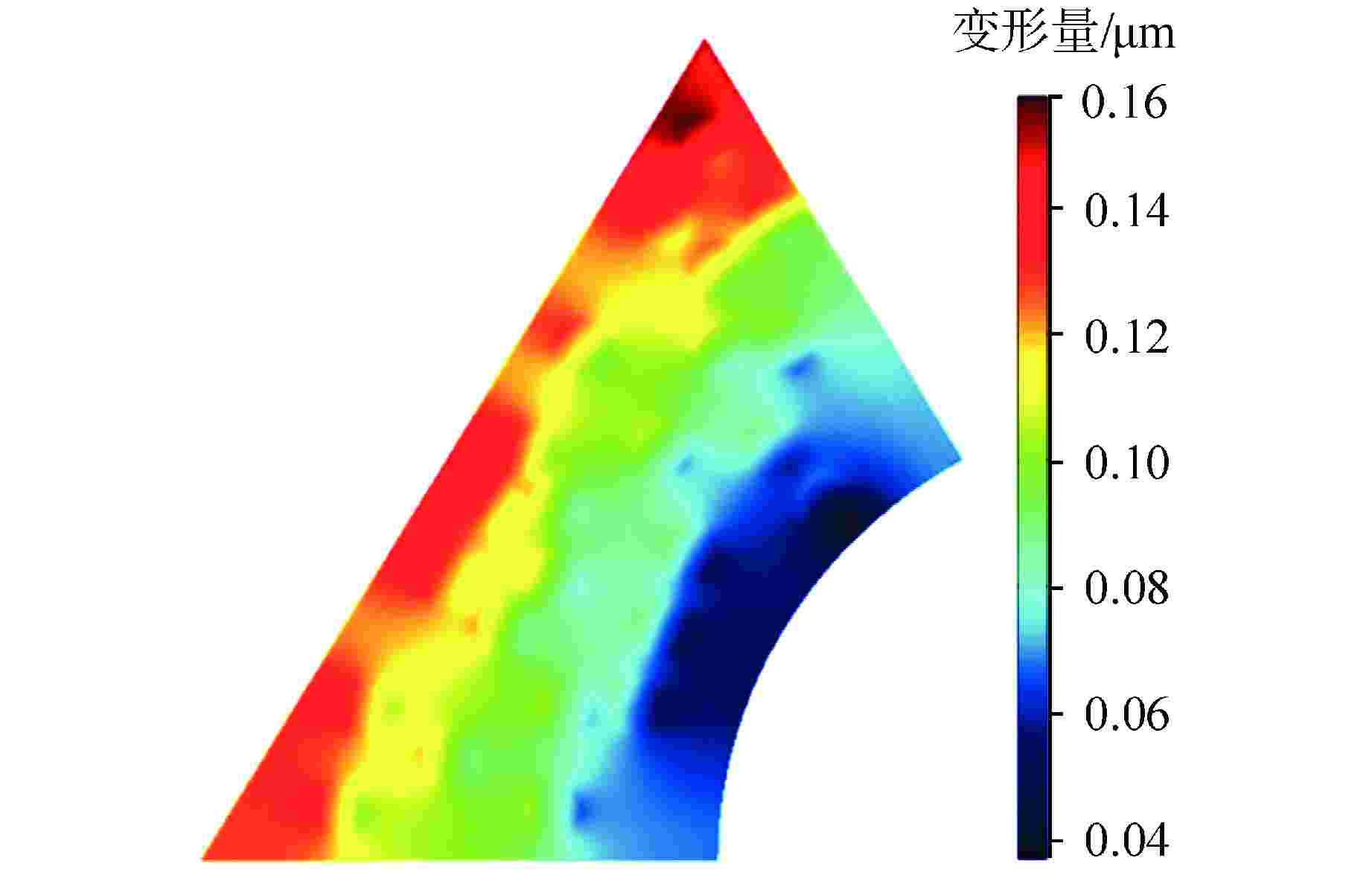

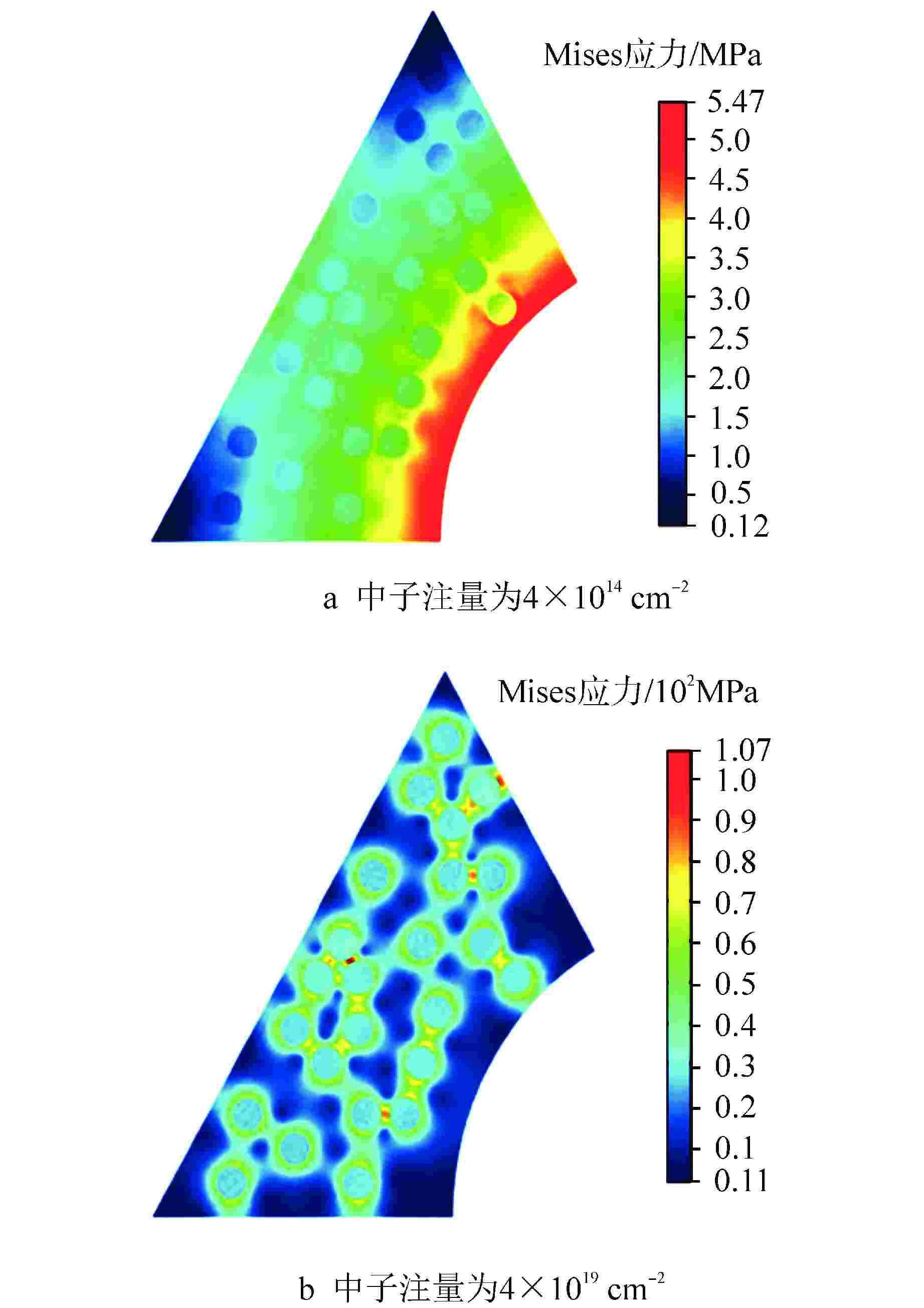

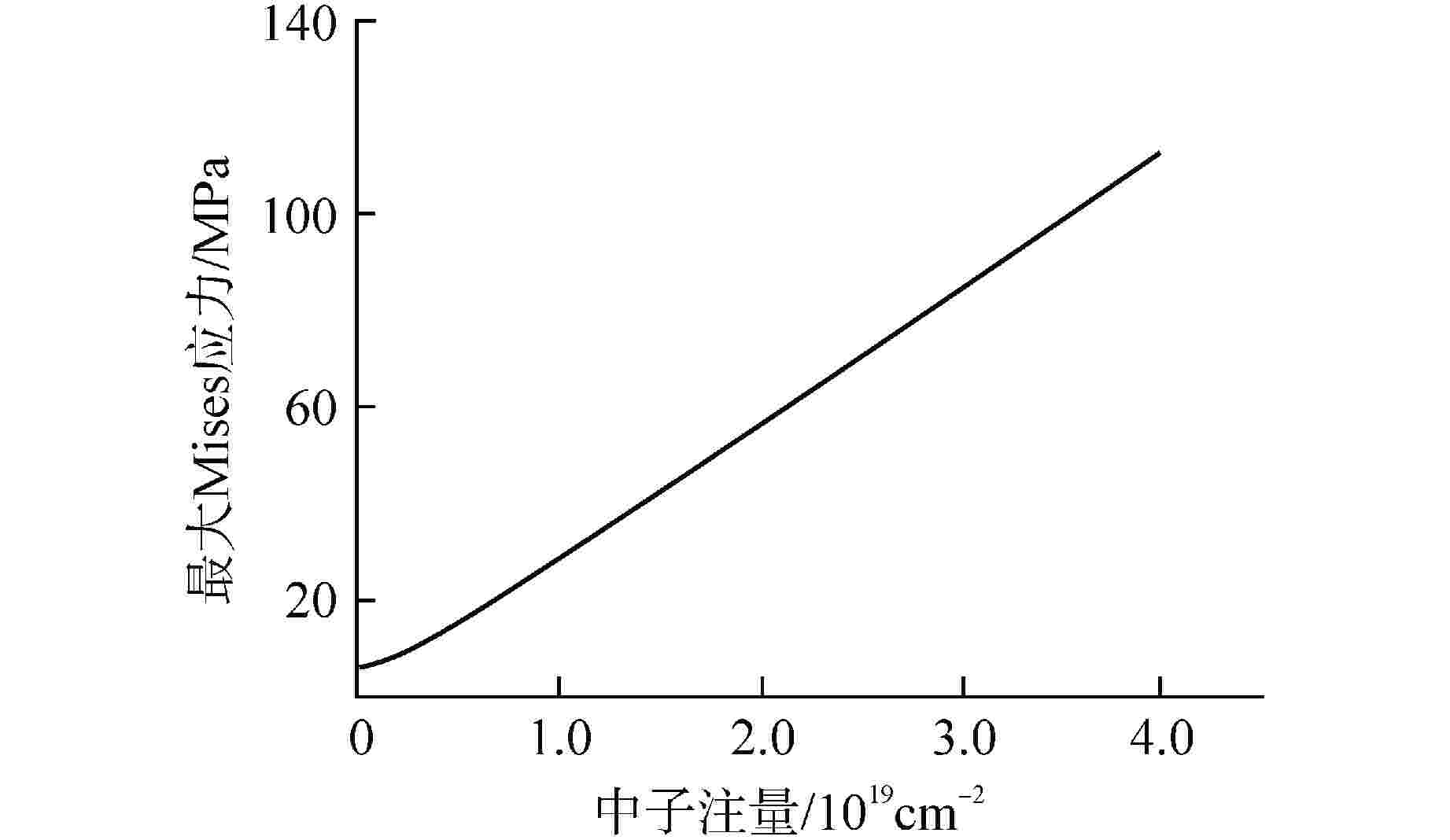

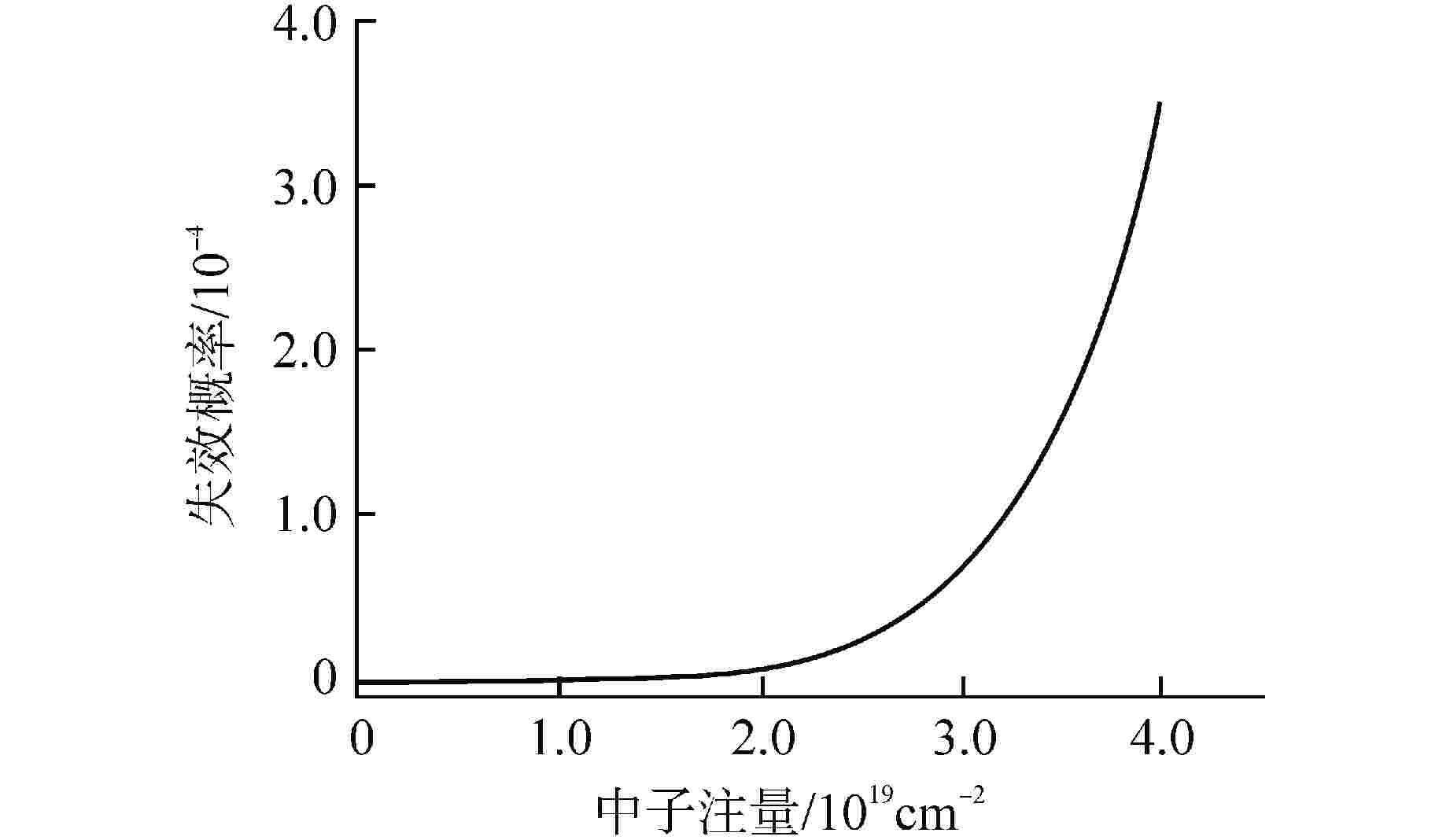

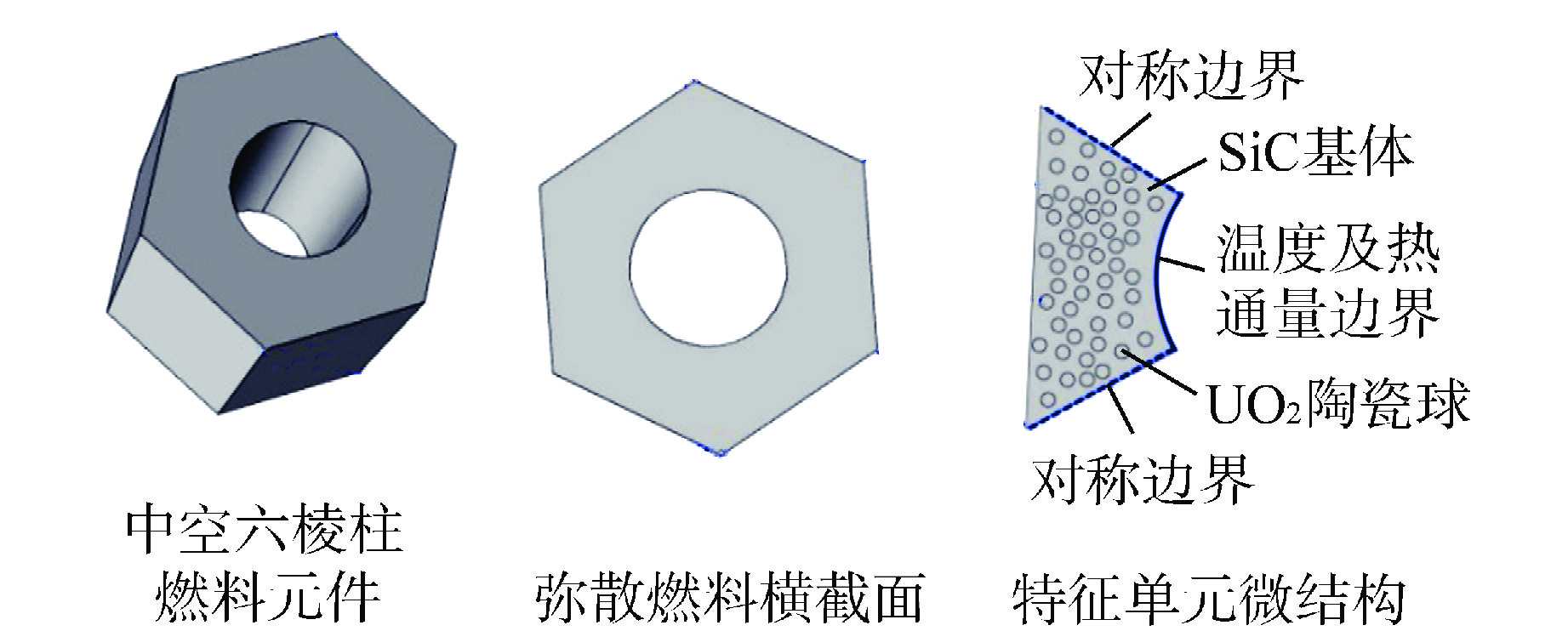

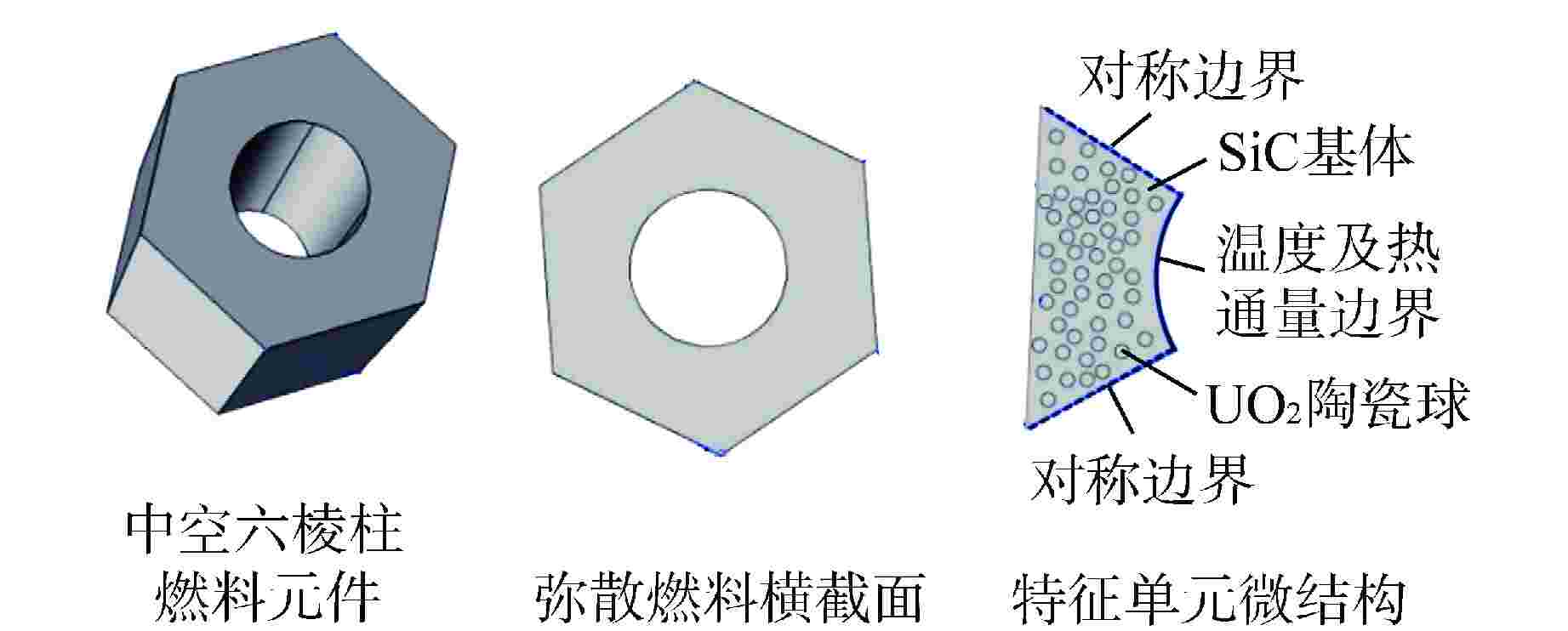

摘要: 中空六棱柱燃料元件在高温气冷堆方面有广泛应用,为研究中空六棱柱燃料元件的堆内性能,评价其失效概率,针对高温气冷堆用中空六棱柱燃料元件进行了热-力学行为分析,采用多物理场耦合的方法计算了中空六棱柱燃料元件的热-力学行为,分析了中空六棱柱燃料元件在较低中子注量条件下的温度场、变形、应力分布以及失效概率。结果表明,中空六棱柱燃料元件的最高运行温度约为1020 K,SiC基体的最大应力约为107.32 MPa、失效概率为3.52×10−4,SiC基体较低的失效概率保证了燃料元件的结构完整性。在较低中子注量下,中空六棱柱燃料元件的运行温度和应力均较低并且可以保证结构完整,具有良好的堆内运行状态。Abstract: Hollow hexagonal fuel elements are widely used in high temperature gas-cooled reactor. In order to study the in-reactor performance of the hollow hexagonal fuel element and evaluate its failure probability, the thermo-mechanical behavior analysis of the hollow hexagonal fuel element for high temperature gas-cooled reactor is carried out. The thermal-mechanical behavior of the hollow hexagonal fuel element is calculated by using the multi-physical field coupling method, and the temperature field, deformation, stress distribution and failure probability of the hollow hexagonal fuel element under the condition of low neutron fluence are analyzed. The results show that the maximum operating temperature of the hollow hexagonal fuel element is about 1020 K, the maximum stress of SiC matrix is about 107.32 MPa, and the failure probability is 3.52×10−4. The low failure probability of SiC matrix ensures the structural integrity of fuel elements. Under the lower neutron fluence, the operating temperature and stress of the hollow hexagonal fuel element are lower, the structural integrity can be ensured, and the fuel element has a good operating state in the reactor.

-

-

[1] MILLER G K, PETTI D A, VARACALLE D J JR, et al. Statistical approach and benchmarking for modeling of multi-dimensional behavior in TRISO-coated fuel particles[J]. Journal of Nuclear Materials, 2003, 317(1): 69-82. doi: 10.1016/S0022-3115(02)01702-6 [2] SEN R S, POPE M A, OUGOUAG A M, et al. Assessment of possible cycle lengths for fully encapsulated microstructure fueled light water reactor concepts[J]. Nuclear Engineering and Design, 2013, 255: 310-320. doi: 10.1016/j.nucengdes.2012.11.007 [3] THORNTON G, ROTHSTEIN A J. Comprehensive technical report, general electric direct-air-cycle aircraft nuclear propulsion program, program summary and references[R]. Oak Ridge, USA: Office of Scientific and Technical Information, 1962: 89-132. [4] BETZLER B R, ADE B J, WYSOCKI A J, et al. Transformational Challenge Reactor preconceptual core design studies[J]. Nuclear Engineering and Design, 2020, 367: 110781. doi: 10.1016/j.nucengdes.2020.110781 [5] 辛勇,李垣明,唐昌兵,等. 金属基弥散微封装燃料中TRISO燃料颗粒的尺寸优化设计[J]. 核动力工程,2019, 40(2): 176-179. doi: 10.13832/j.jnpe.2019.02.0176 [6] CHUN J H, LIM S W, CHUNG B D, et al. Safety evaluation of accident-tolerant FCM fueled core with SiC-coated zircalloy cladding for design-basis-accidents and beyond DBAs[J]. Nuclear Engineering and Design, 2015, 289: 287-295. doi: 10.1016/j.nucengdes.2015.04.021 [7] STONE J G, SCHLEICHER R, DECK C P, et al. Stress analysis and probabilistic assessment of multi-layer SiC-based accident tolerant nuclear fuel cladding[J]. Journal of Nuclear Materials, 2015, 466: 682-697. doi: 10.1016/j.jnucmat.2015.08.001 [8] KATOH Y, OZAWA K, SHIH C, et al. Continuous SiC fiber, CVI SiC matrix composites for nuclear applications: properties and irradiation effects[J]. Journal of Nuclear Materials, 2014, 448(1-3): 448-476. doi: 10.1016/j.jnucmat.2013.06.040 -

下载:

下载: