Numerical Study of Spacer Effects on Convective Heat Transfer at Low Flow Rates

-

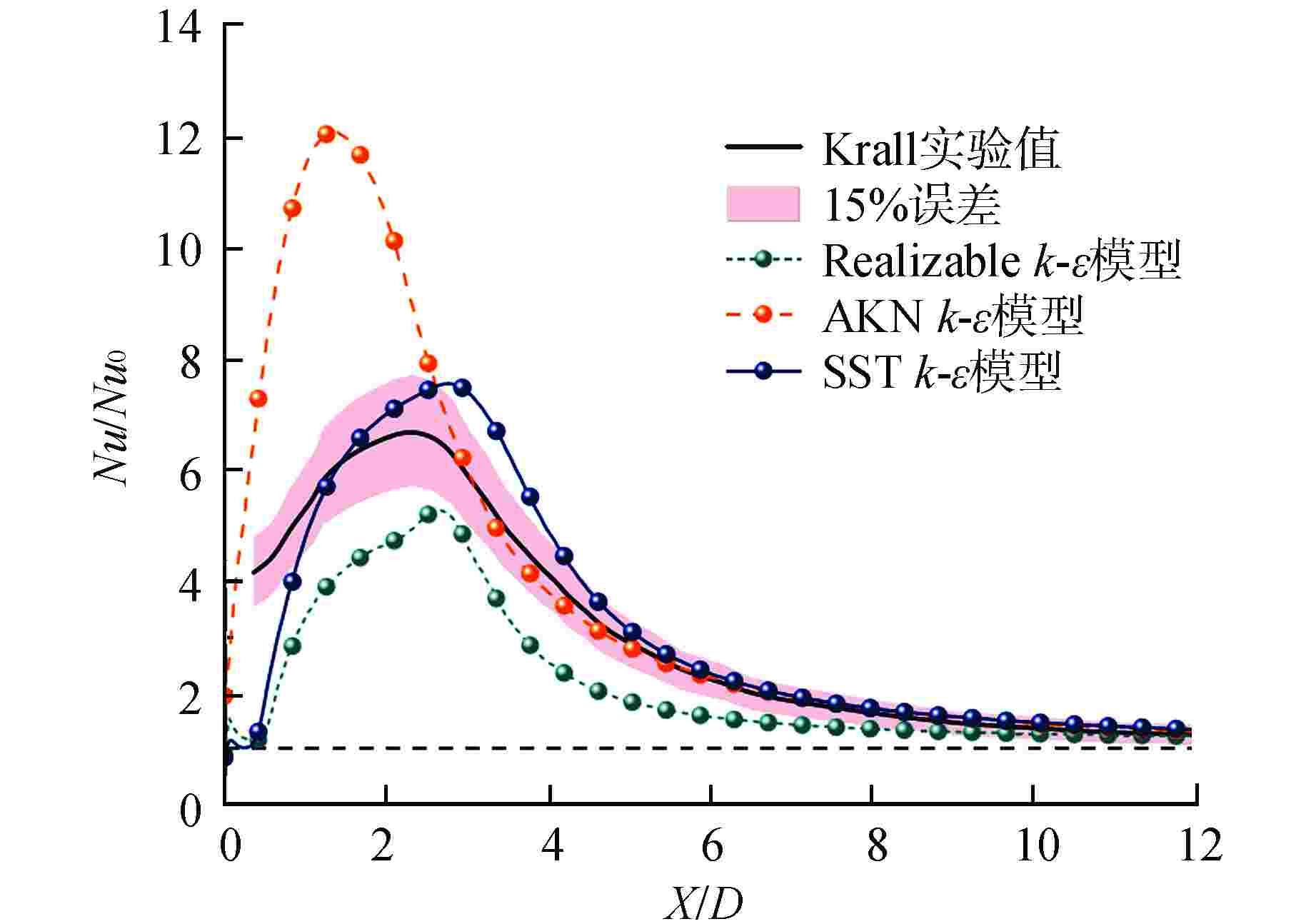

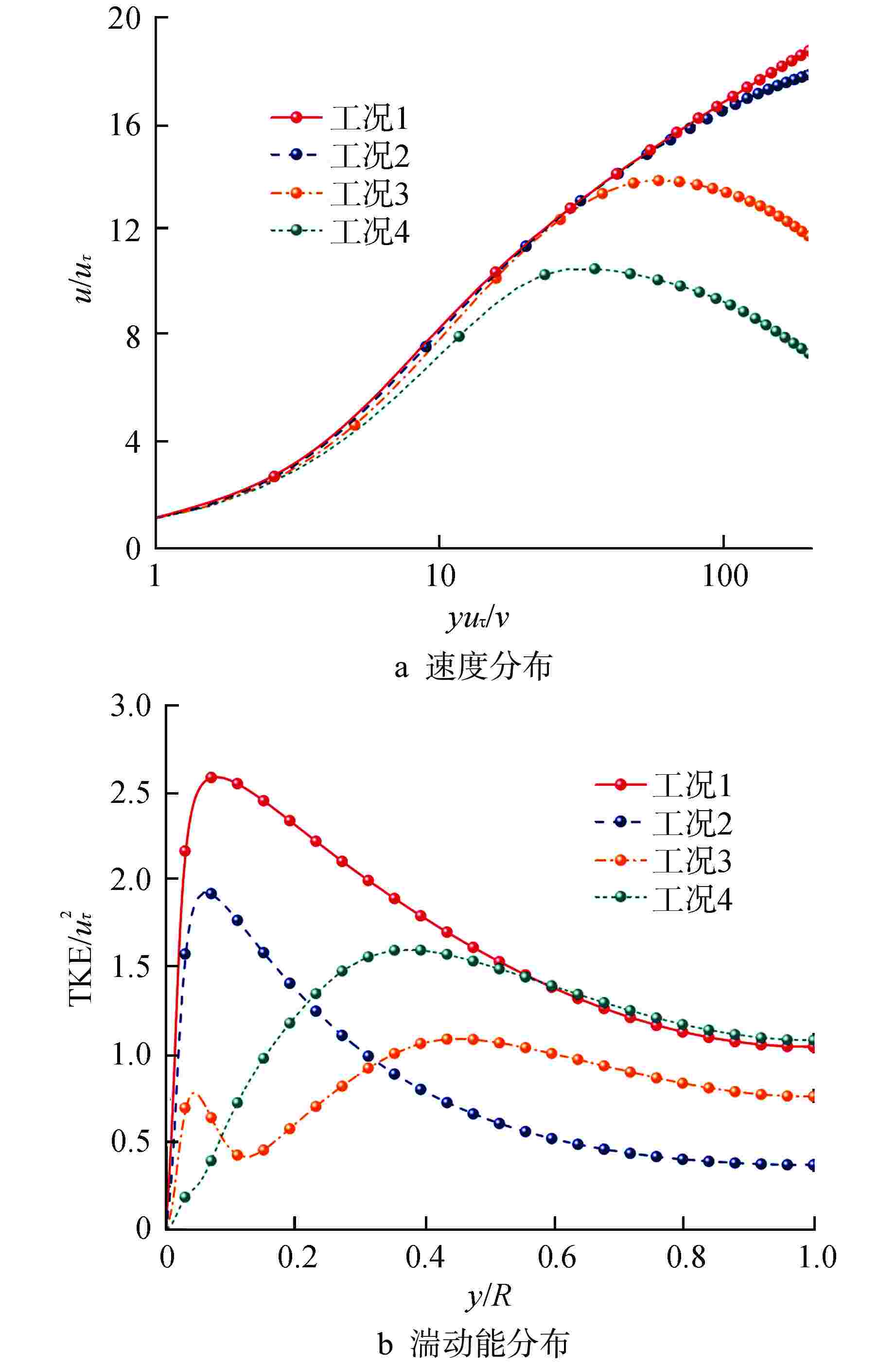

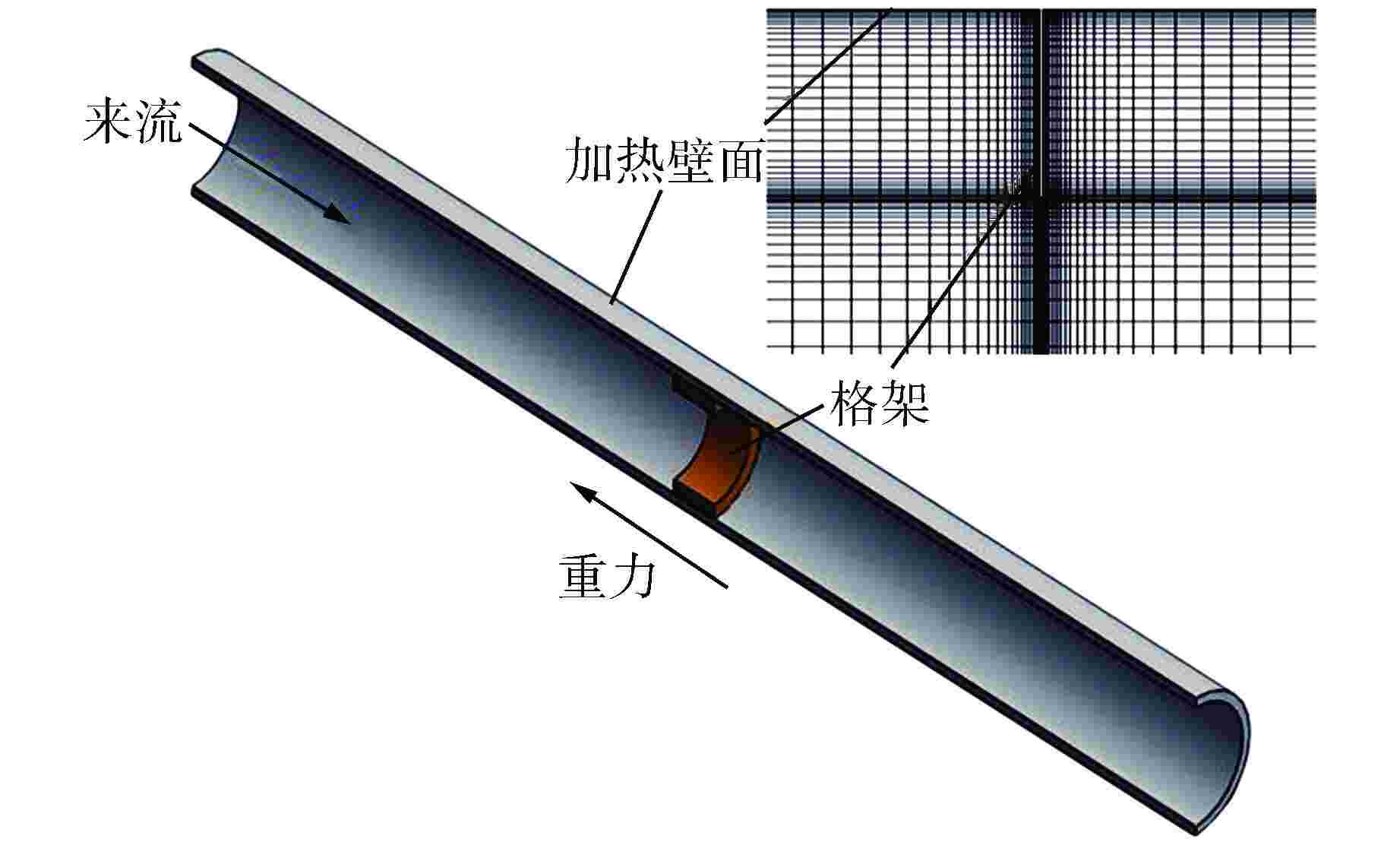

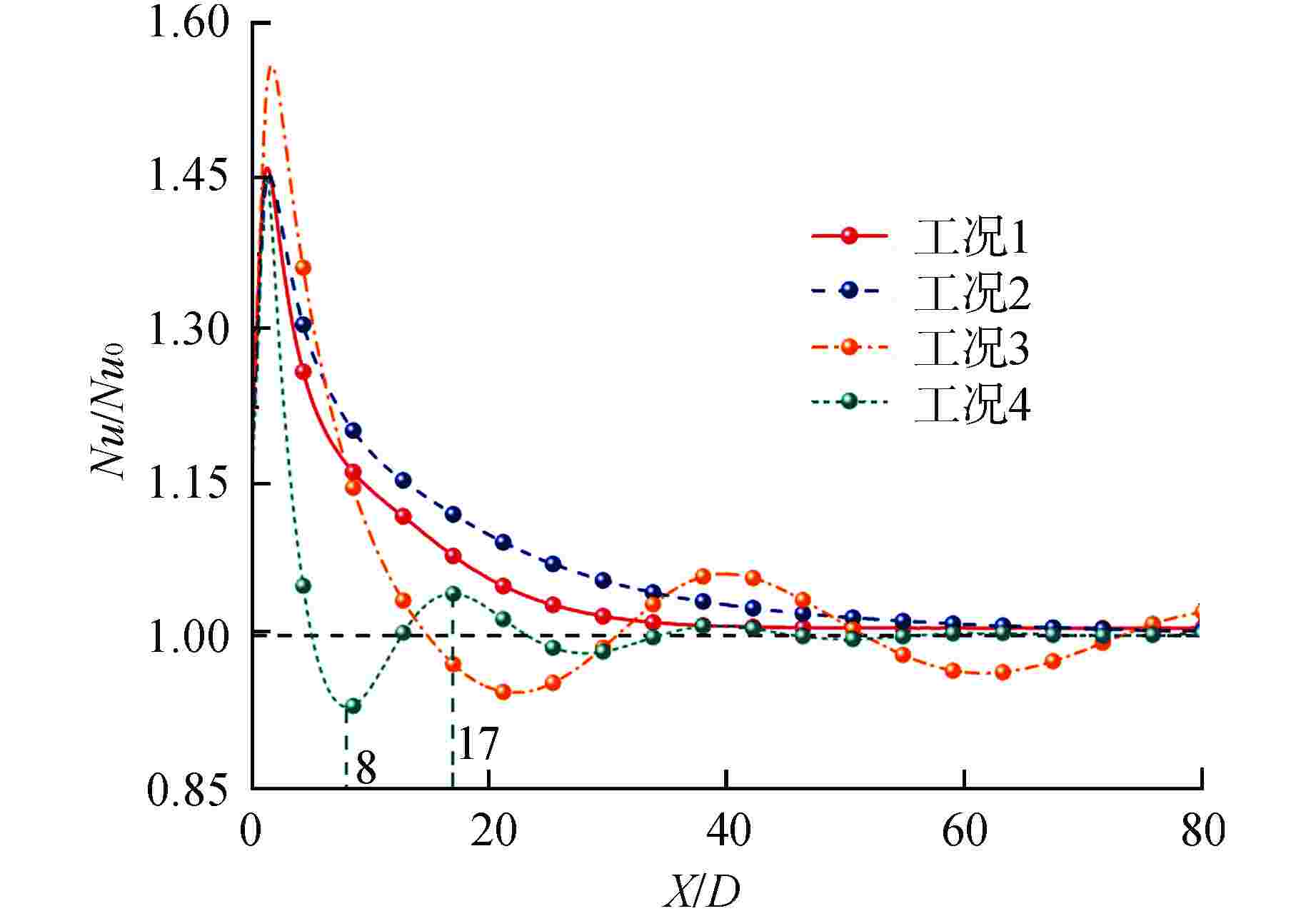

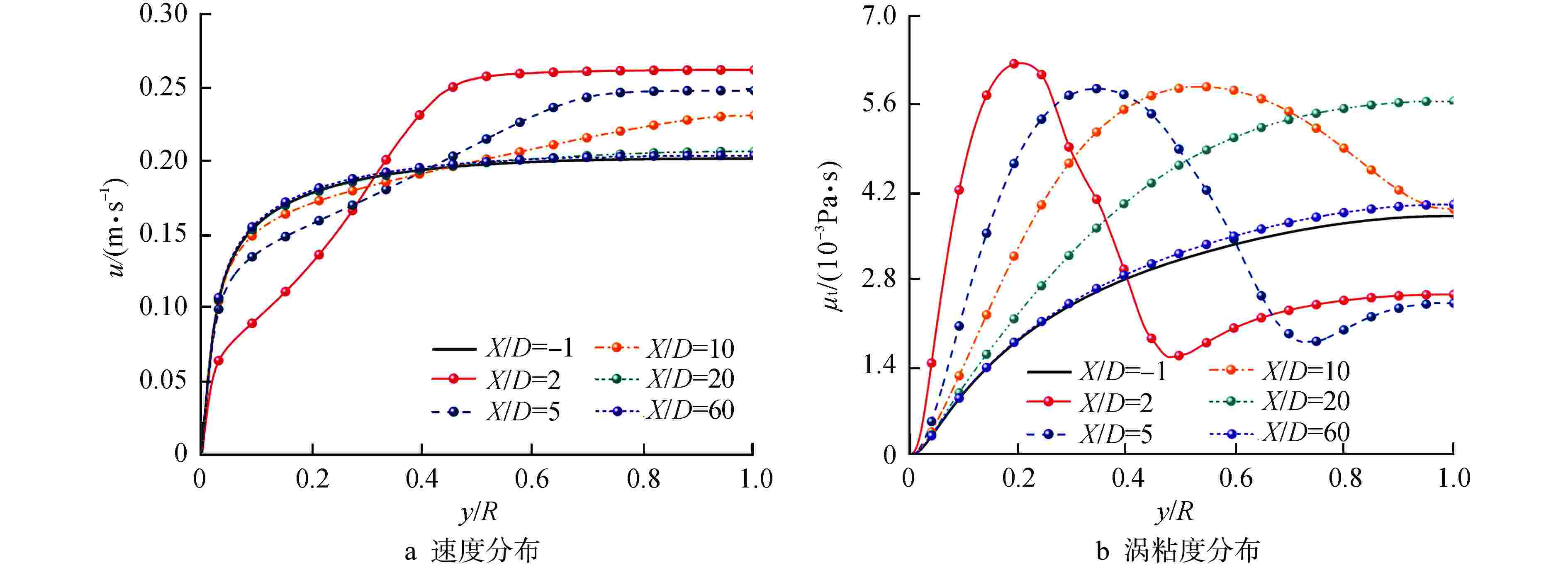

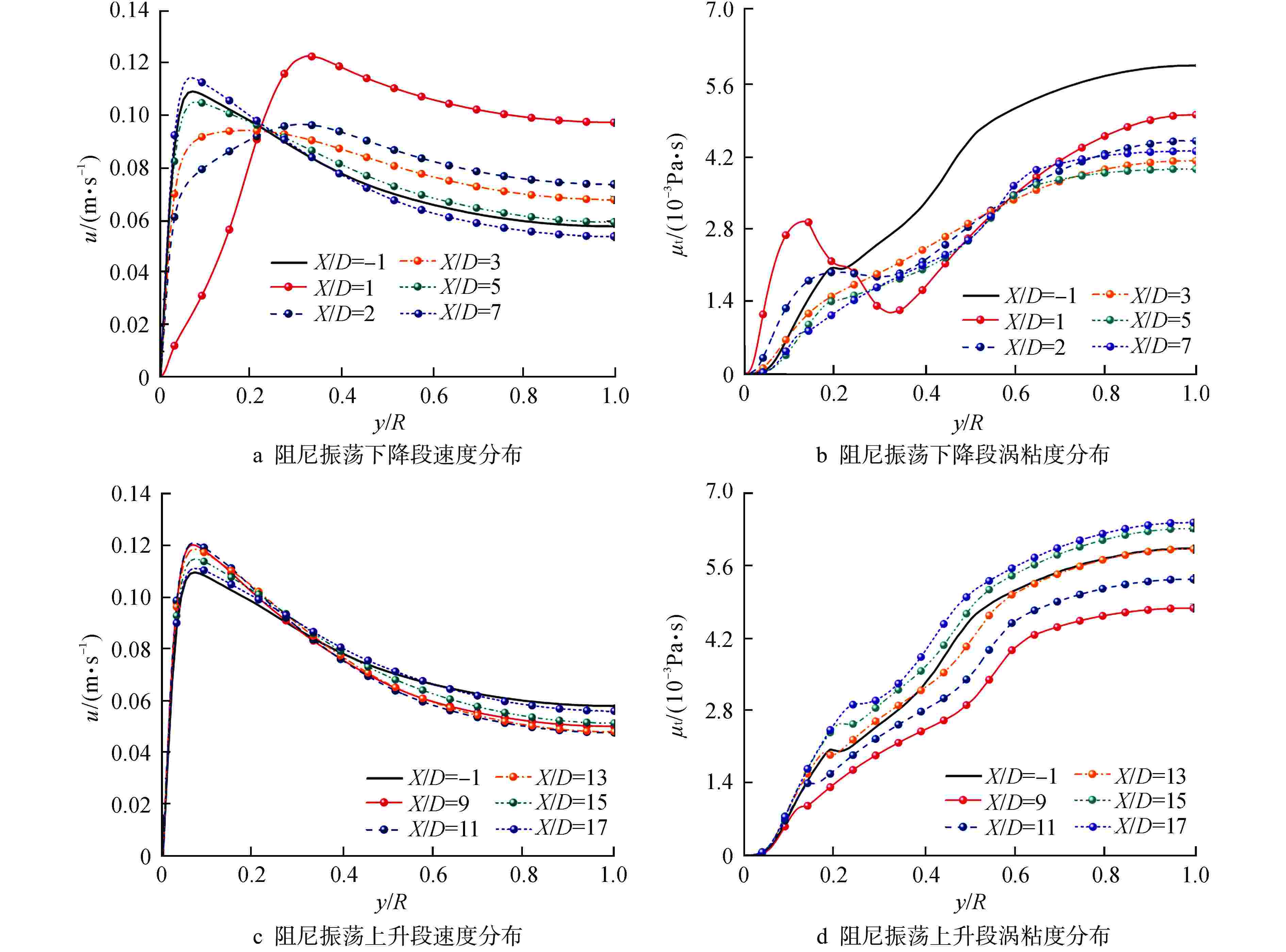

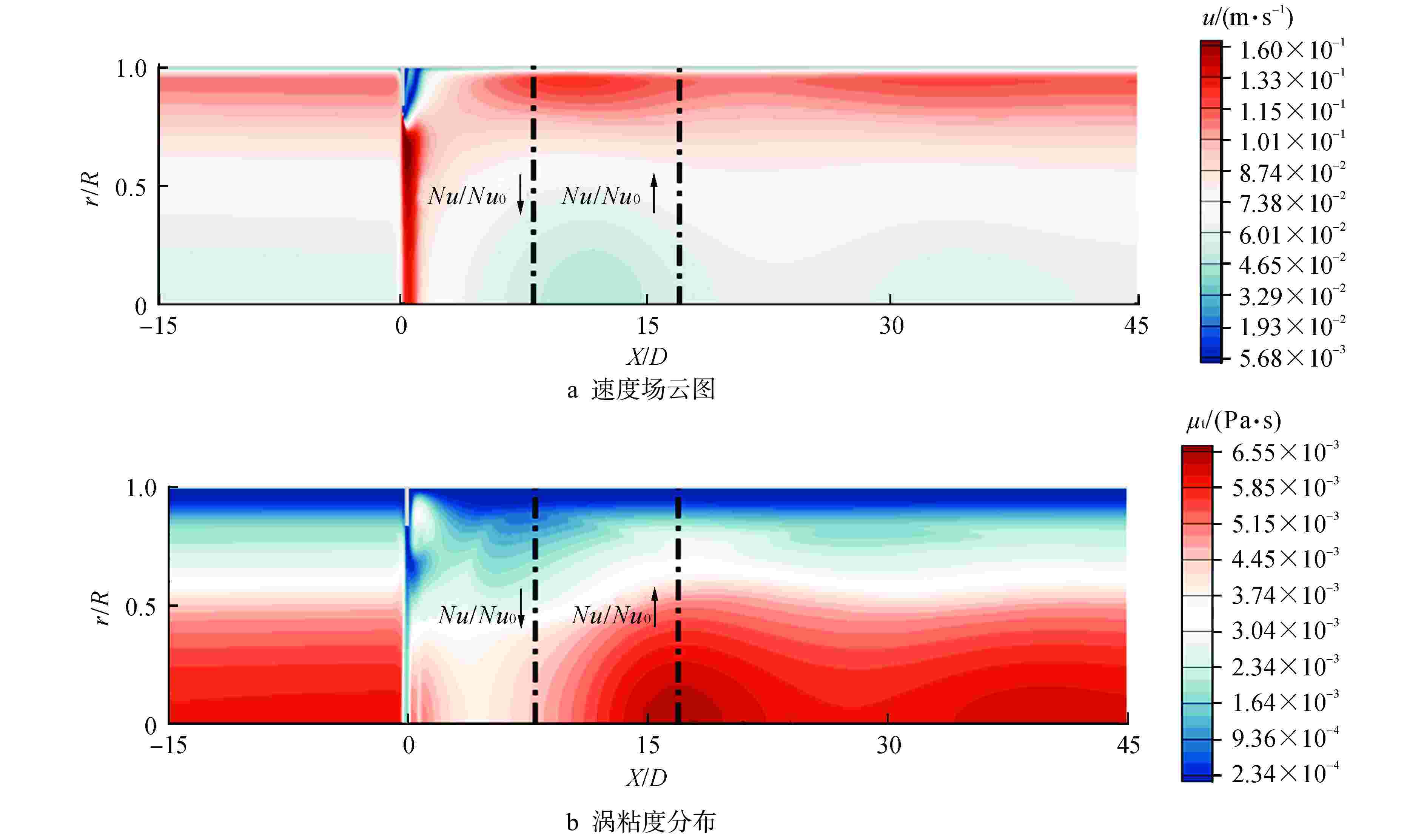

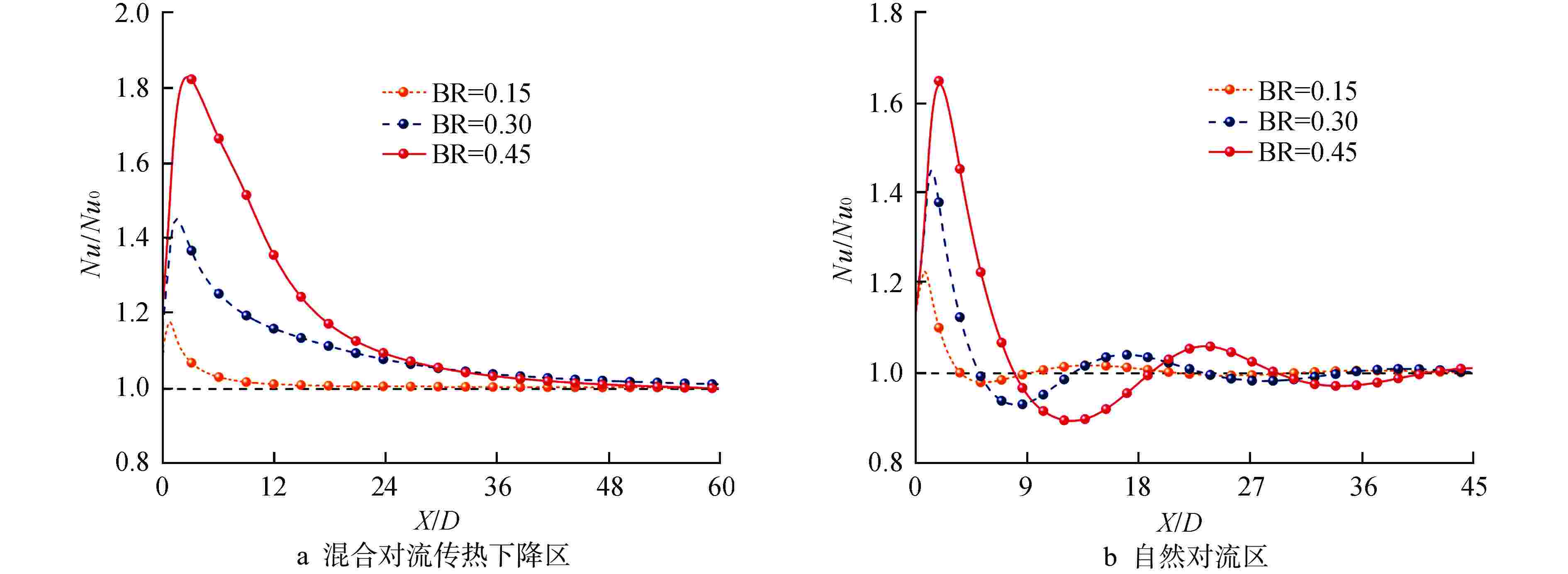

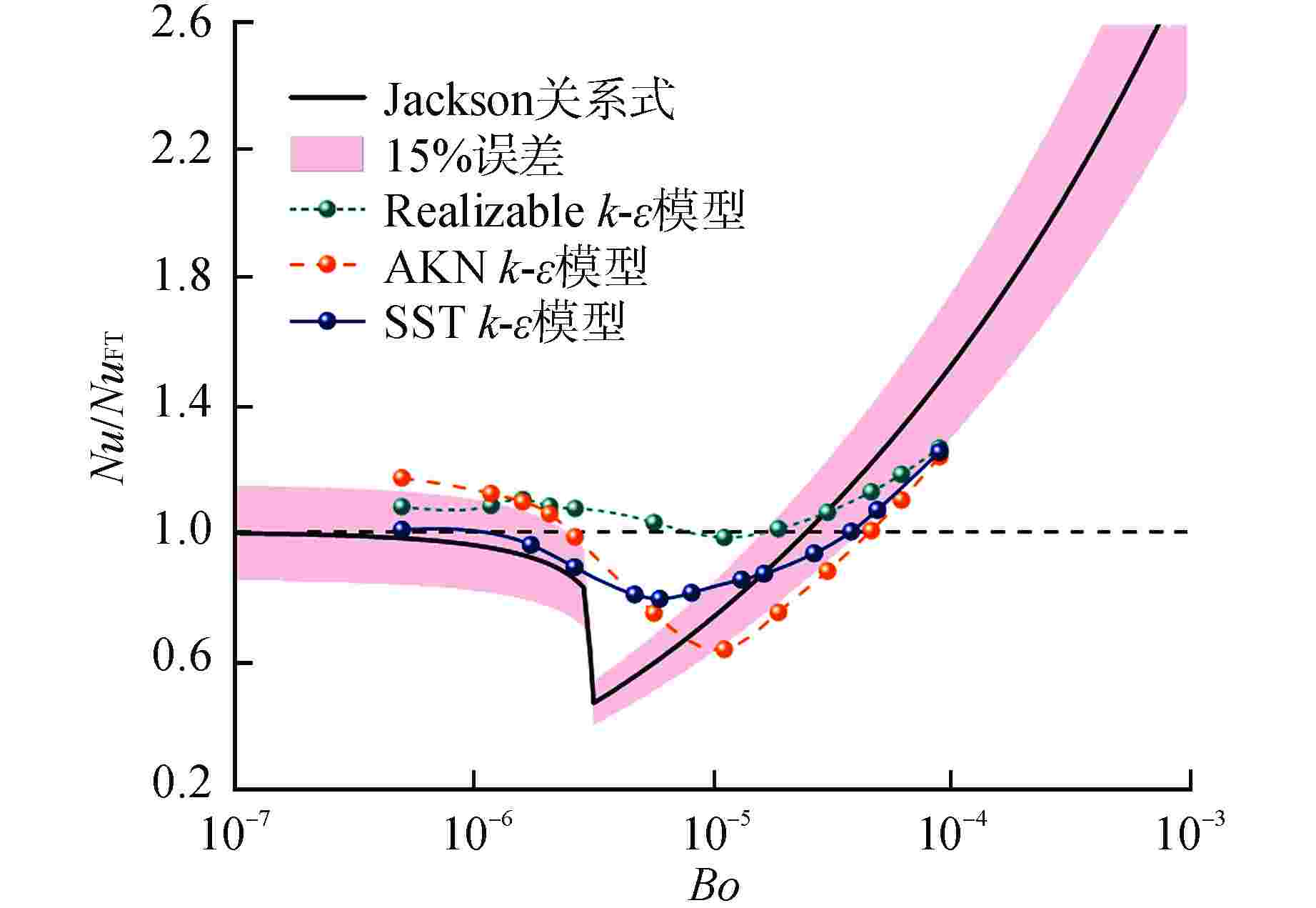

摘要: 针对带格架圆管在低流量高热流密度下的热工水力特性开展了数值研究。通过经验关联式与实验数据分别对光滑圆管内单相水低流量对流传热与格架效应进行标定,确立了基于SST k-ω模型的计算流体动力学(CFD)方法。模拟结果表明,格架下游传热特性取决于浮升力参数大小。强迫对流区与混合对流传热下降区,格架下游传热始终增强,努塞尔数呈指数衰减;混合对流传热恢复区与自然对流区,由于流场与传热的耦合作用,格架下游传热存在恶化现象,努塞尔数呈阻尼振荡。格架下游传热影响范围随着浮升力参数的增加先增大后减小。格架阻塞比越大,传热振荡越剧烈,格架致传热恶化的程度提高。该研究可为低流量堆芯内格架设计提供参考。Abstract: A numerical study is carried out for the thermal-hydraulic characteristics of a circular tube with spacer at low flow rates and high heat flux. The convective heat transfer of single-phase water in a smooth circular tube at low flow rates and the spacer effects are calibrated by the empirical correlation and experimental data. A CFD method based on the SST k-ω model is established. The simulation results show that the heat transfer characteristics downstream of the spacer depend on the buoyancy lift parameter. For the forced convection zone and mixed convection heat transfer decreasing zone, the heat transfer downstream of the spacer is always enhanced and the Nussel number decays exponentially. For the mixed convection heat transfer recovery zone and natural convection zone, due to the coupling effect of flow field and heat transfer, the heat transfer downstream of the spacer deteriorates and the Nussel number oscillates with damping. The influence range of heat transfer at the downstream of the spacer first increases and then decreases with the increase of buoyancy lift parameters. The larger the spacer blocking ratio is, the more severe the heat transfer oscillation is, and the worse the heat transfer caused by the spacer is. This study can provide a reference for the design of core in a low-flow core.

-

图 1 光滑圆管内数值模拟值与Jackson关系式[2]对比

Figure 1. Comparison of Numerical Simulation with Jackson’s Correlation in a Smooth Circular Tube

表 1 几何参数与边界条件设置

Table 1. Setting of Geometric Parameters and Boundary Conditions

参数名 参数值 圆形通道内径(D)/mm 11.9 圆形通道长度(L)/m 3(约252D) 采样点位置(X)/m 1.5(约126D,充分发展段) 工作介质与物性参数 单相水和美国国家标准与技术研究院(NIST) Real Gas模型 运行压力(P)/MPa 15.5 质量流速(G)/(kg·m−2·s−1) 70~200 热流密度(q)/(kW·m−2) 10~50 入口温度(Tin)/℃ 150~200 表 2 计算工况参数

Table 2. Parameters of Calculation Conditions

工况 区域 G/

(kg·m−2·s−1)q/

(kW·m−2)Tin/℃ Bo 1 强迫对流区 200 10 200 5.02×10−7 2 混合对流传热下降区 150 20 200 2.67×10−6 3 混合对流传热恢复区 100 25 200 1.33×10−5 4 自然对流区 70 50 150 9.04×10−5 表中G、q、Tin为本文推荐值,工况仅依据Bo进行划分 -

[1] WIBISONO A F, AHN Y, WILLIAMS W C, et al. Studies of various single phase natural circulation systems for small and medium sized reactor design[J]. Nuclear Engineering and Design, 2013, 262: 390-403. doi: 10.1016/j.nucengdes.2013.04.031 [2] JACKSON J D, COTTON M A, AXCELL B P. Studies of mixed convection in vertical tubes[J]. International Journal of Heat and Fluid Flow, 1989, 10(1): 2-15. doi: 10.1016/0142-727X(89)90049-0 [3] CARR A D, CONNOR M A, BUHR H O. Velocity, temperature, and turbulence measurements in air for pipe flow with combined free and forced convection[J]. Journal of Heat Transfer, 1973, 95(4): 445-452. doi: 10.1115/1.3450087 [4] PARLATAN Y, TODREAS N E, DRISCOLL M J. Buoyancy and property variation effects in turbulent mixed convection of water in vertical tubes[J]. Journal of Heat Transfer, 1996, 118(2): 381-387. doi: 10.1115/1.2825855 [5] KESHMIRI A, COTTON M A, ADDAD Y, et al. Turbulence models and large eddy simulations applied to ascending mixed convection flows[J]. Flow, Turbulence and Combustion, 2012, 89(3): 407-434. doi: 10.1007/s10494-012-9401-4 [6] WU T H, XU Z Y, JACKSON J D. Mixed convection heat transfer to water flowing through a vertical passage of annular cross section: part 2[J]. Chemical Engineering Research and Design, 2002, 80(3): 246-251. doi: 10.1205/026387602753582006 [7] FOROOGHI P, ABDI I A, DAHARI M, et al. Buoyancy induced heat transfer deterioration in vertical concentric and eccentric annuli[J]. International Journal of Heat and Mass Transfer, 2015, 81: 222-233. doi: 10.1016/j.ijheatmasstransfer.2014.10.009 [8] LIU D, GU H Y. Mixed convection heat transfer in a 5 × 5 rod bundles[J]. International Journal of Heat and Mass Transfer, 2017, 113: 914-921. doi: 10.1016/j.ijheatmasstransfer.2017.05.113 [9] LI J L, XIAO Y, GU H Y, et al. Development of a correlation for mixed convection heat transfer in rod bundles[J]. Annals of Nuclear Energy, 2021, 155: 108151. doi: 10.1016/j.anucene.2021.108151 [10] YAO S C, HOCHREITER L E, LEECH W J. Heat-transfer augmentation in rod bundles near grid spacers[J]. Journal of Heat Transfer, 1982, 104(1): 76-81. doi: 10.1115/1.3245071 [11] KRALL K M, SPARROW E M. Turbulent heat transfer in the separated, reattached, and redevelopment regions of a circular tube[J]. Journal of Heat Transfer, 1966, 88(1): 131-136. doi: 10.1115/1.3691456 [12] TANASE A, GROENEVELD D C. An experimental investigation on the effects of flow obstacles on single phase heat transfer[J]. Nuclear Engineering and Design, 2015, 288: 195-207. doi: 10.1016/j.nucengdes.2015.04.004 [13] LIU D, GU H Y. Study on heat transfer behavior in rod bundles with spacer grid[J]. International Journal of Heat and Mass Transfer, 2018, 120: 1065-1075. doi: 10.1016/j.ijheatmasstransfer.2017.12.121 [14] MENTER F R. Two-equation eddy-viscosity turbulence models for engineering applications[J]. AIAA Journal, 1994, 32(8): 1598-1605. doi: 10.2514/3.12149 [15] KAYS W M. Turbulent Prandtl number-Where are we?[J]. Journal of Heat Transfer, 1994, 116(2): 284-295. doi: 10.1115/1.2911398 [16] PIORO I L, GROENEVELD D C, DOERFFER S S, et al. Effects of flow obstacles on the critical heat flux in a vertical tube cooled with upward flow of R-134a[J]. International Journal of Heat and Mass Transfer, 2002, 45(22): 4417-4433. doi: 10.1016/S0017-9310(02)00150-3 [17] XIAO Y, PAN J S, GU H Y. Numerical investigation of spacer effects on heat transfer of supercritical fluid flow in an annular channel[J]. International Journal of Heat and Mass Transfer, 2018, 121: 343-353. doi: 10.1016/j.ijheatmasstransfer.2018.01.030 [18] EZE C, WONG K W, GSCHNAIDTNE T, et al. Numerical study of effects of vortex generators on heat transfer deterioration of supercritical water upward flow[J]. International Journal of Heat and Mass Transfer, 2019, 137: 489-505. doi: 10.1016/j.ijheatmasstransfer.2019.03.145 [19] TIAN R, WEI M S, DAI X Y, et al. Buoyancy effect on the mixed convection flow and heat transfer of supercritical R134a in heated horizontal tubes[J]. International Journal of Heat and Mass Transfer, 2019, 144: 118607. doi: 10.1016/j.ijheatmasstransfer.2019.118607 [20] MILLER D J, CHEUNG F B, BAJOREK S M. On the development of a grid-enhanced single-phase convective heat transfer correlation[J]. Nuclear Engineering and Design, 2013, 264: 56-60. doi: 10.1016/j.nucengdes.2012.11.023 -

下载:

下载: