Study on Slug Characteristics of Air-water Two-phase Flow in Horizontal Narrow Rectangular Channel

-

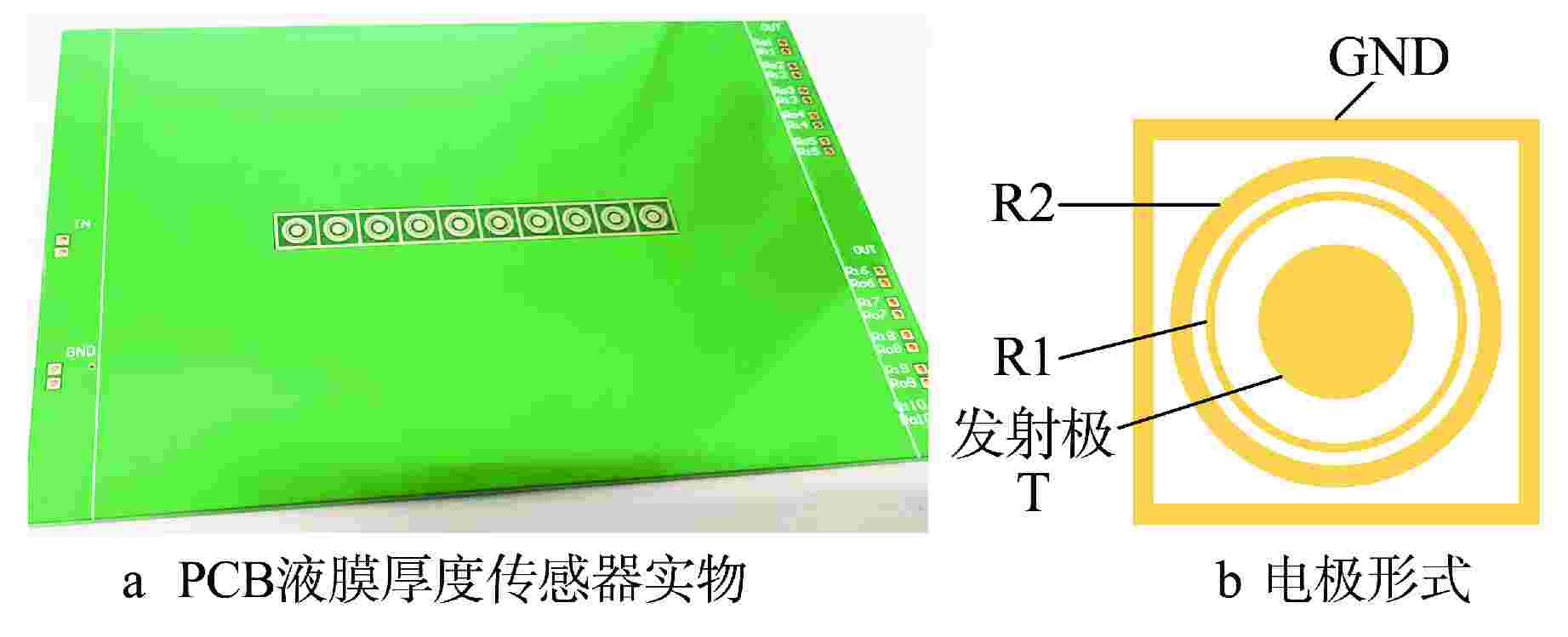

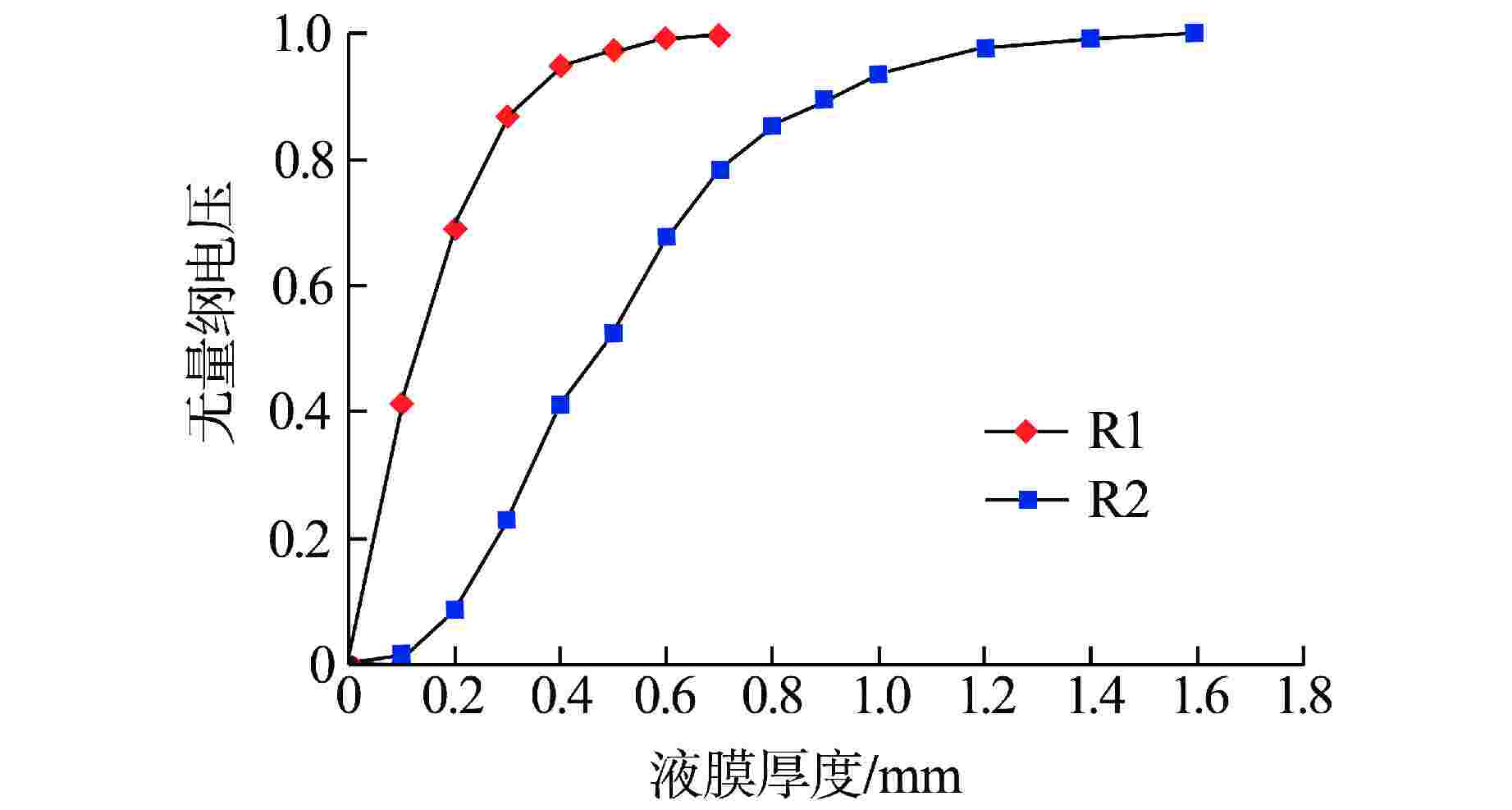

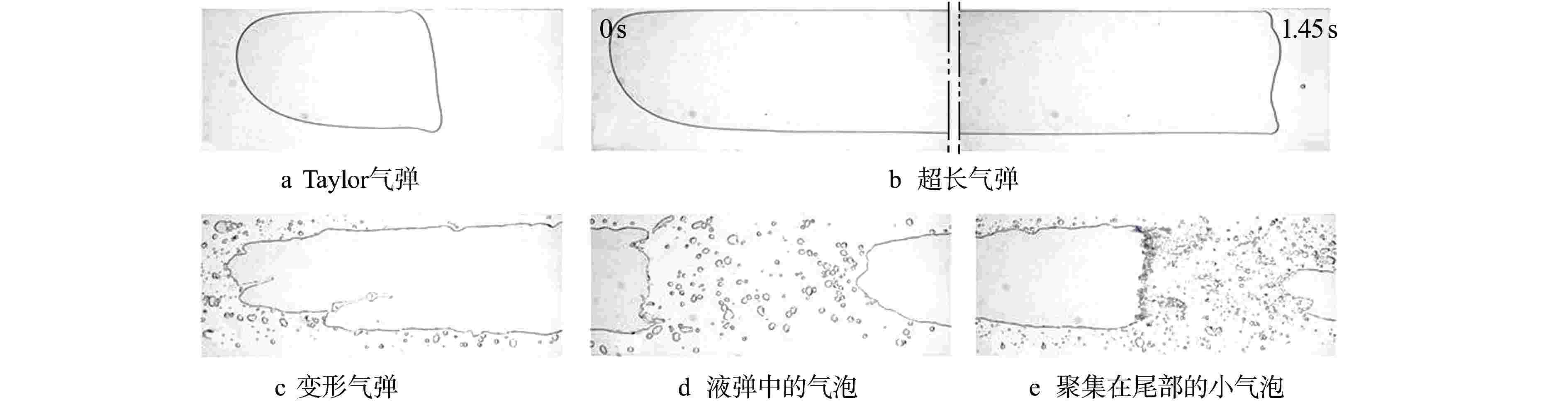

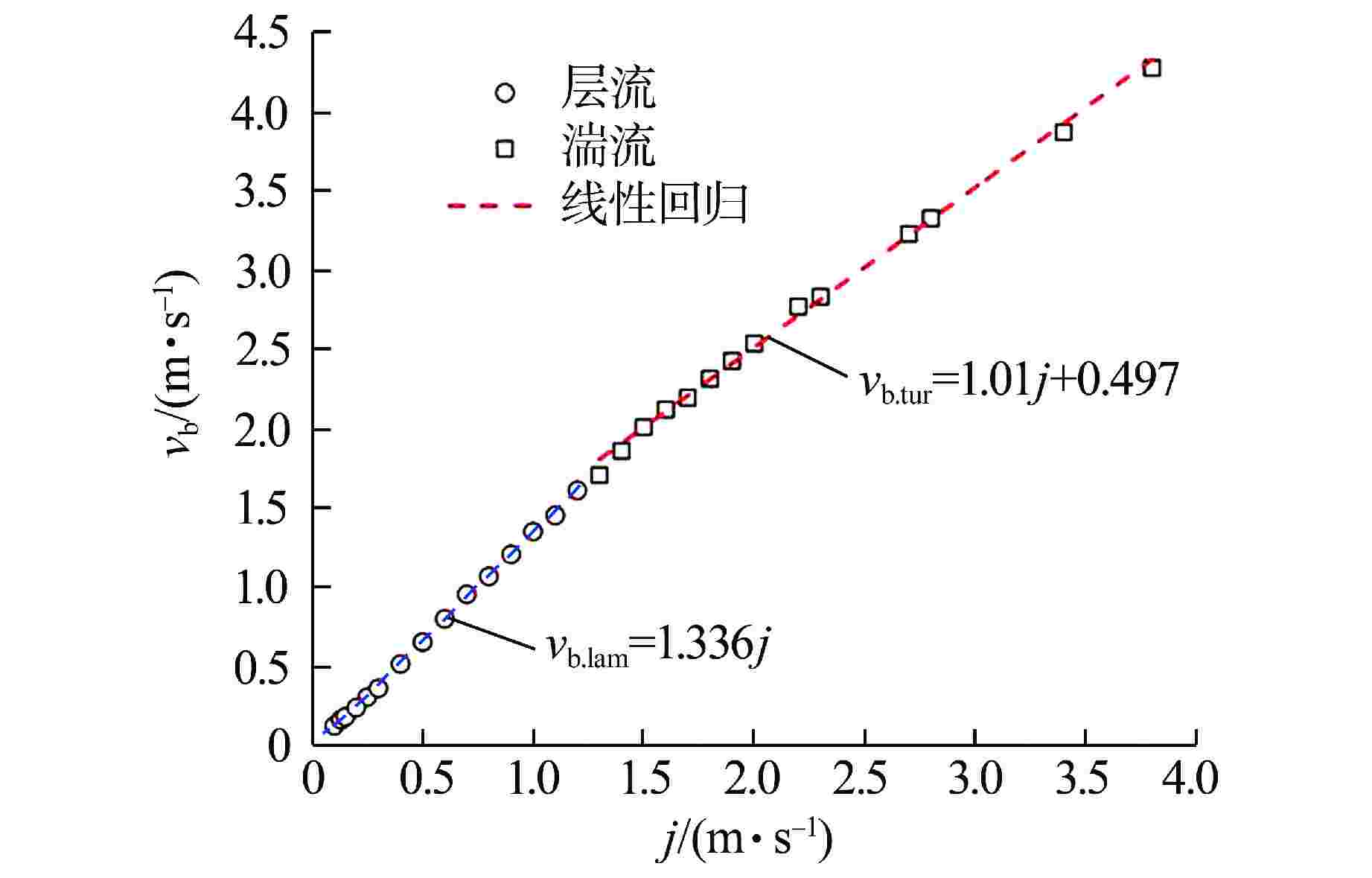

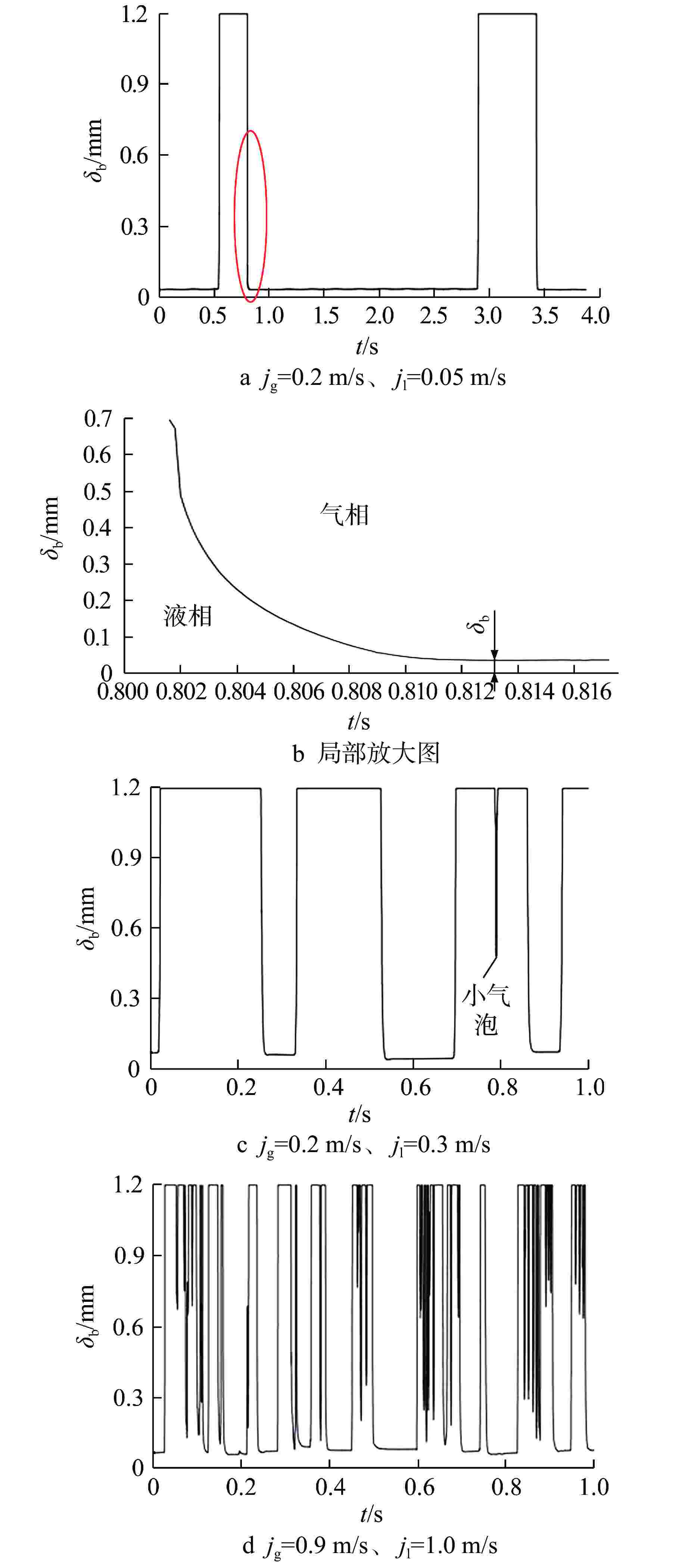

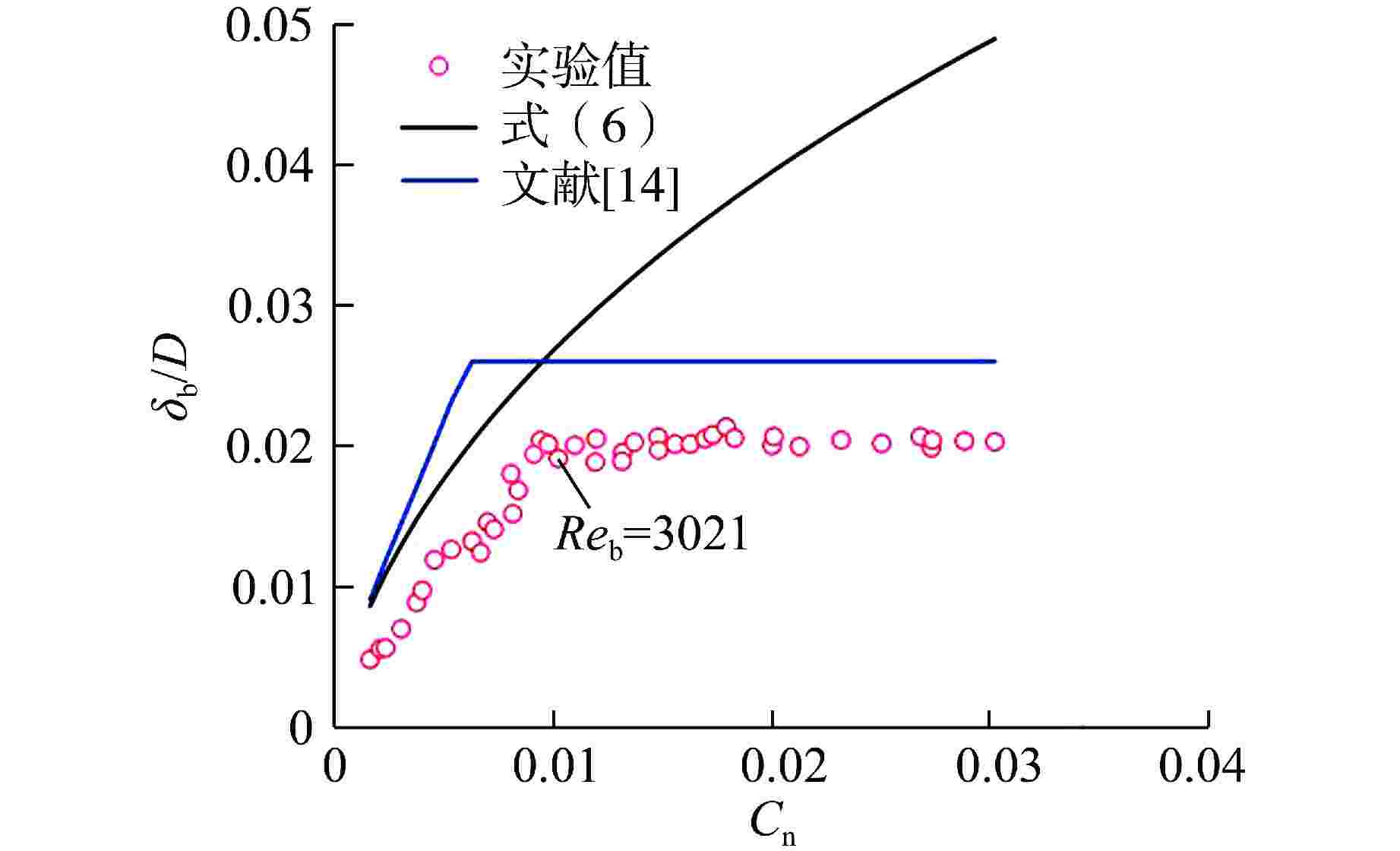

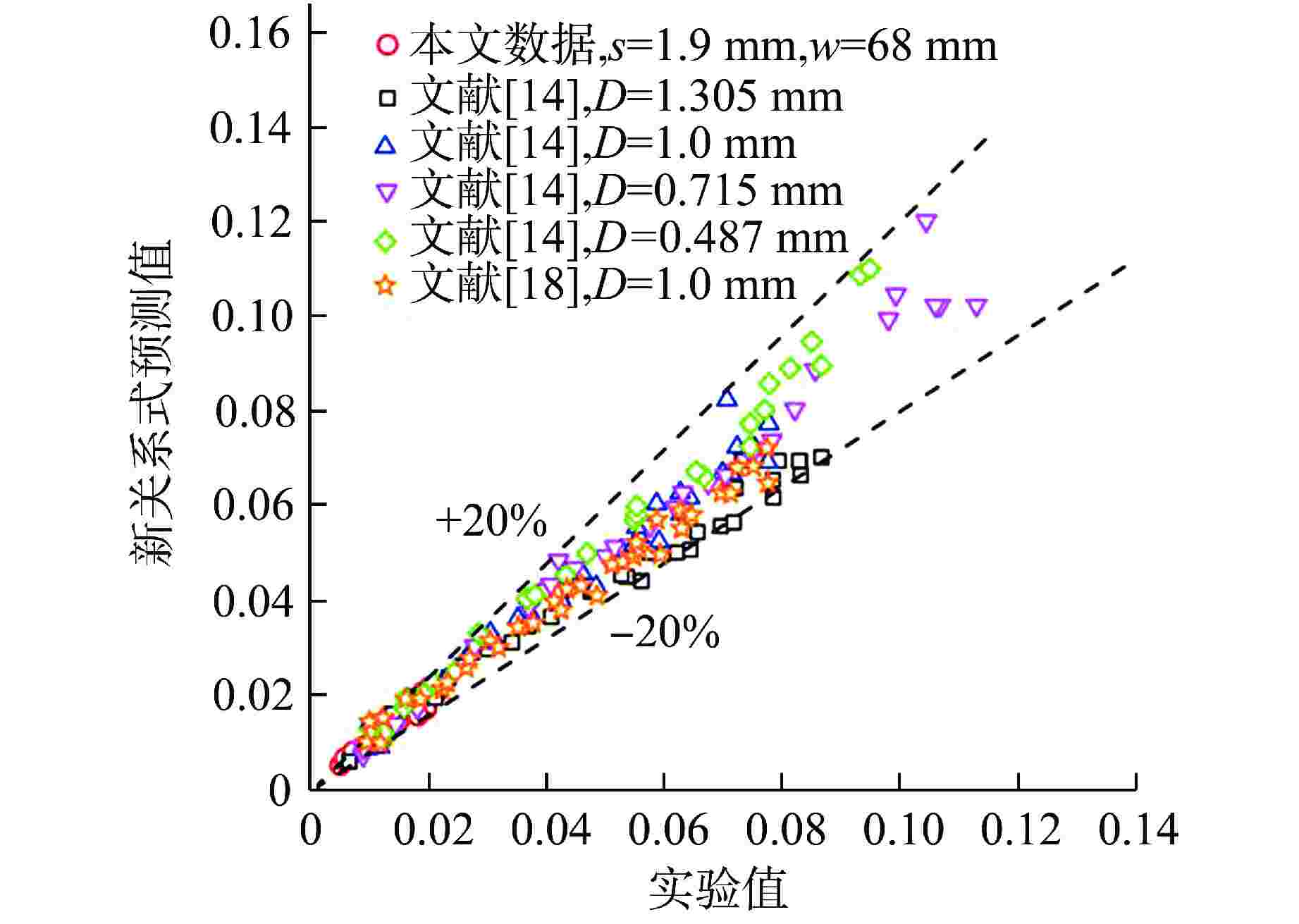

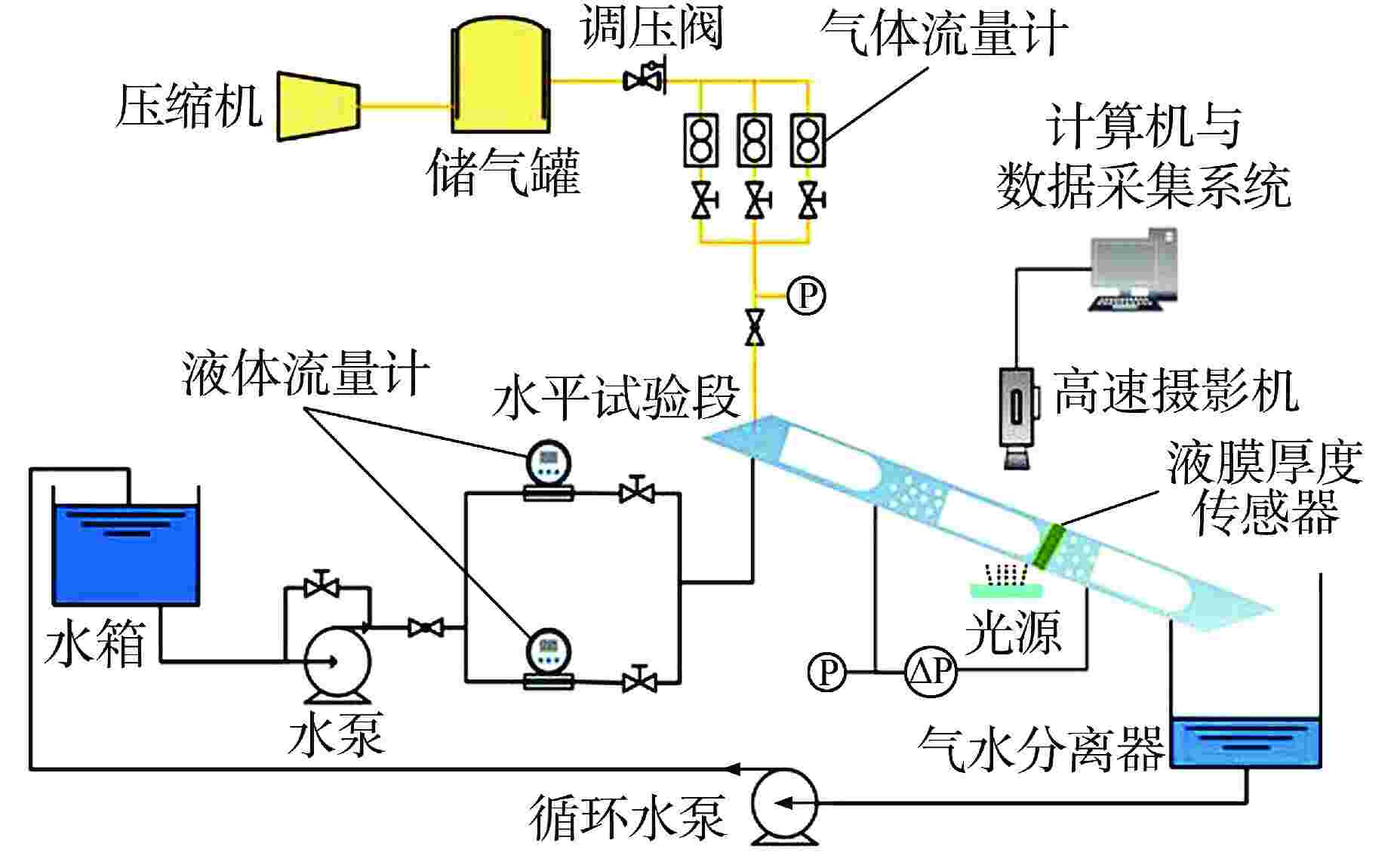

摘要: 气弹速度和液膜厚度作为弹状流工况下的关键参数,在传热分析和力学分析中具有重要意义。本文以空气-水为介质,采用高速摄影机和印刷电路板式(PCB)液膜厚度传感器,对高1.9 mm×宽68 mm的水平窄矩形通道内气弹运动特性进行研究。液相雷诺数(Rel)<2500,矩形通道内为层流区;Rel≥2500,矩形通道内为湍流区,基于气-液两相混合速度分别拟合了气弹运动速度的预测关系式,结果表明,层流区分布系数(C0)可采用Ishii 关系式计算且漂移速度为0;而湍流区C0为1.0。当气弹雷诺数(Reb)<3100时,气弹底部液膜厚度(δb)随毛细管数的增大而增大;而在Reb≥3100时,δb表现出波动性。现有的δb预测关系式不适用于窄矩形通道,在考虑通道高宽比的影响下提出了一个新的δb预测关系式,对文献中210个数据进行了验证,预测误差均在±20%内。Abstract: As the key parameters of slug flow, slug velocity and liquid film thickness are of great significance in heat transfer analysis and mechanical analysis. In this paper, the characteristics of slug in a horizontal narrow rectangular channel with 1.9 mm×68 mm are studied by using high-speed camera and PCB liquid film sensor. For liquid Reynolds number

${{Re}}_{\text{l}}\text{ < 2500}$ ) , the rectangular channel is a laminar area; For Rel≥2500, the rectangular channel is a turbulent area. Based on the gas-liquid two-phase mixing velocity, the predictive relation of slug velocity is fitted respectively. The results show that the laminar area distribution coefficient (C0) can be calculated by Ishii equation and the drift velocity is 0; the turbulent area C0 is 1.0. For slug Reynolds number Reb<3100, the liquid film thickness (δb) at the bottom of slug increases with the increase of capillary number; For Reb≥3100, δb shows volatility. Existing δb predictive relation is not applicable to narrow rectangular channels. Considering the influence of channel aspect ratio, a new δb predictive relation is proposed to verify 210 data in the literature, and the prediction errors are all within ±20%. -

[1] 谢清清,阎昌琪,曹夏昕,等. 窄矩形通道内单相水阻力特性实验研究[J]. 原子能科学技术,2012, 46(2): 181-185. [2] 黄豪杰. 窄微通道内液膜厚度特性及其在沸腾传热中的应用[D]. 重庆: 重庆大学, 2018. [3] HIBIKI T, MISHIMA K. Flow regime transition criteria for upward two-phase flow in vertical narrow rectangular channels[J]. Nuclear Engineering and Design, 2001, 203(2-3): 117-131. doi: 10.1016/S0029-5493(00)00306-X [4] YUAN P, DENG J, PAN L M, et al. Air-water two-phase flow regime and transition criteria in vertical upward narrow rectangular channels[J]. Progress in Nuclear Energy, 2021, 136: 103750. doi: 10.1016/j.pnucene.2021.103750 [5] 王洋,阎昌琪,孙立成,等. 竖直窄矩形通道内弹状流中液膜特性研究[J]. 原子能科学技术,2014, 48(1): 33-38. doi: 10.7538/yzk.2014.48.01.0033 [6] 王洋,阎昌琪,孙立成,等. 竖直窄矩形通道内空气-水两相流中气弹运动速度研究[J]. 原子能科学技术,2013, 47(12): 2202-2207. doi: 10.7538/yzk.2013.47.12.2202 [7] 闫超星,阎昌琪,孙立成. 倾斜窄矩形通道内弹状流特性的实验研究[J]. 高校化学工程学报,2015, 29(3): 551-556. doi: 10.3969/j.issn.1003-9015.2015.03.008 [8] LIU A T, YAN C Q, ZHU F Q, et al. Liquid film thickness of vertical upward annular flow in narrow rectangular channel[J]. Chemical Engineering Research and Design, 2021, 175: 10-24. doi: 10.1016/j.cherd.2021.08.011 [9] MISHIMA K, HIBIKI T, NISHIHARA H. Some characteristics of gas-liquid flow in narrow rectangular ducts[J]. International Journal of Multiphase Flow, 1993, 19(1): 115-124. doi: 10.1016/0301-9322(93)90027-R [10] ISHII M. One-dimensional drift-flux model and constitutive equations for relative motion between phases in various two-phase flow regimes: ANL-77-47[R]. USA: ANL, 1977. [11] 夏国栋,周芳德,胡明胜. 倾斜上升弹状流中Taylor气泡运动速度研究[J]. 化学工程,1997, 25(5): 36-41. [12] ZHENG D H, CHE D F. Experimental study on hydrodynamic characteristics of upward gas–liquid slug flow[J]. International Journal of Multiphase Flow, 2006, 32(10-11): 1191-1218. doi: 10.1016/j.ijmultiphaseflow.2006.05.012 [13] WANG X, GUO L J, ZHANG X M. An experimental study of the statistical parameters of gas–liquid two-phase slug flow in horizontal pipeline[J]. International Journal of Heat and Mass Transfer, 2007, 50(11-12): 2439-2443. doi: 10.1016/j.ijheatmasstransfer.2006.12.011 [14] HAN Y, SHIKAZONO N. Measurement of liquid film thickness in micro square channel[J]. International Journal of Multiphase Flow, 2009, 35(10): 896-903. doi: 10.1016/j.ijmultiphaseflow.2009.06.006 [15] BRETHERTON F P. The motion of long bubbles in tubes[J]. Journal of Fluid Mechanics, 1960, 10(2): 166-188. [16] AUSSILLOUS P, QUERE D. Quick deposition of a fluid on the wall of a tube[J]. Physics of Fluids, 2000, 12(10): 2367-2371. doi: 10.1063/1.1289396 [17] TAYLOR G I. Deposition of a viscous fluid on the wall of a tube[J]. Journal of Fluid Mechanics, 1961, 10(2): 161-165. doi: 10.1017/S0022112061000159 [18] YOUN Y J, LEE C K, SHIKAZONO N, et al. Theoretical and experimental study on liquid film thicknesses of unsteady slug flows in a capillary tube[J]. International Journal of Multiphase Flow, 2021, 134: 103470. doi: 10.1016/j.ijmultiphaseflow.2020.103470 -

下载:

下载: