Analysis and Research on the Influence of Closed Loop Structure on Main Pump Performance Based on Source Term Method

-

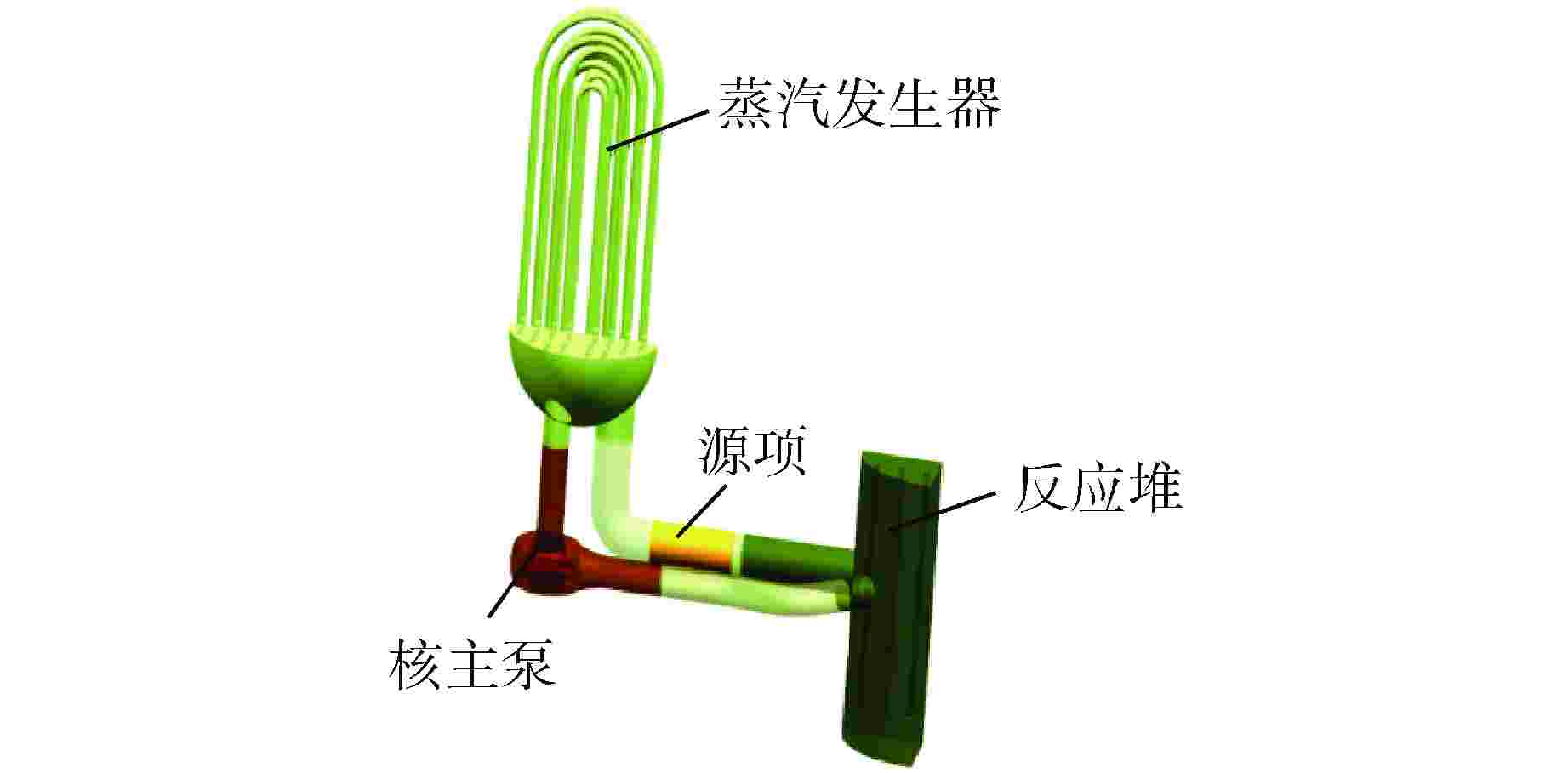

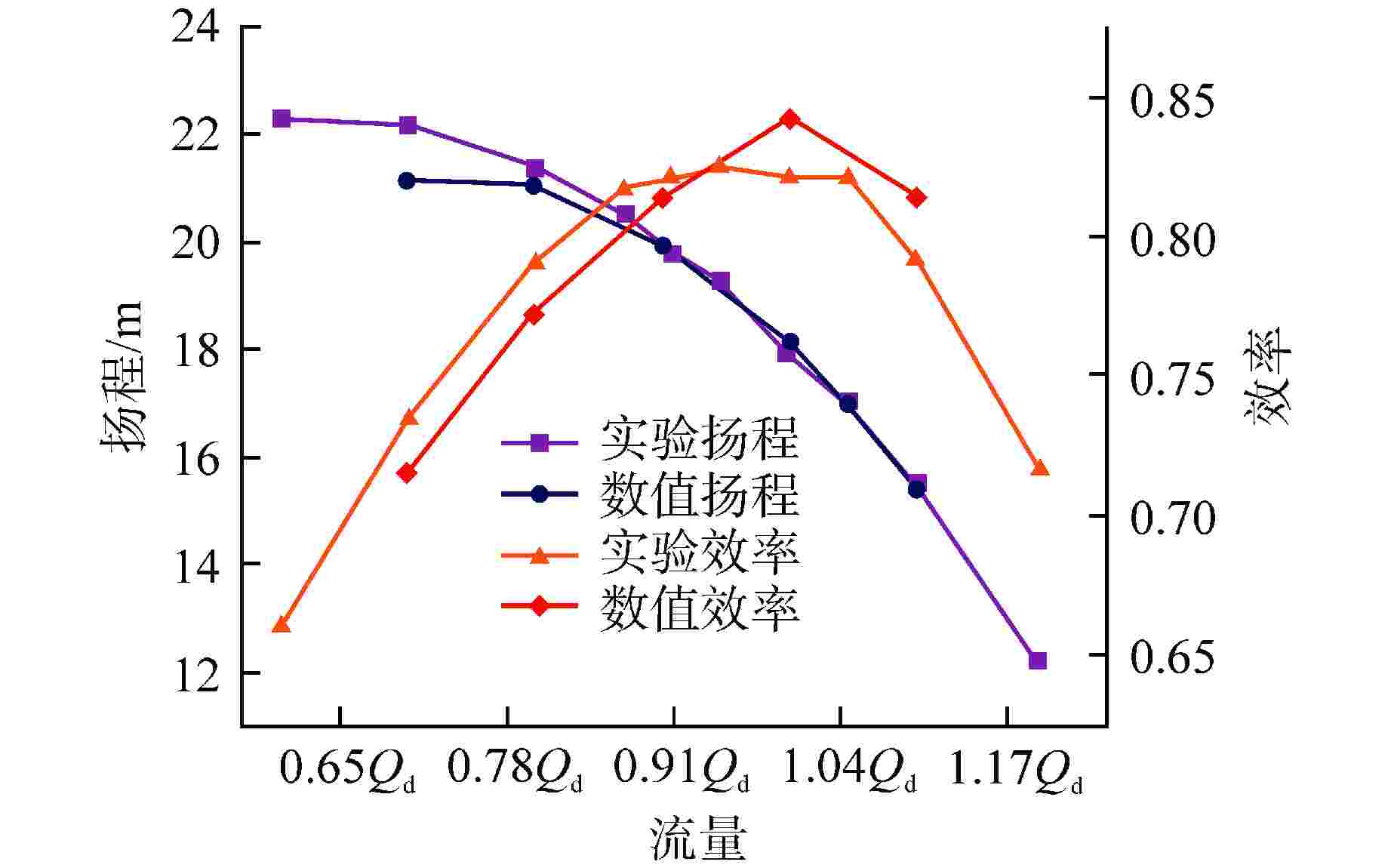

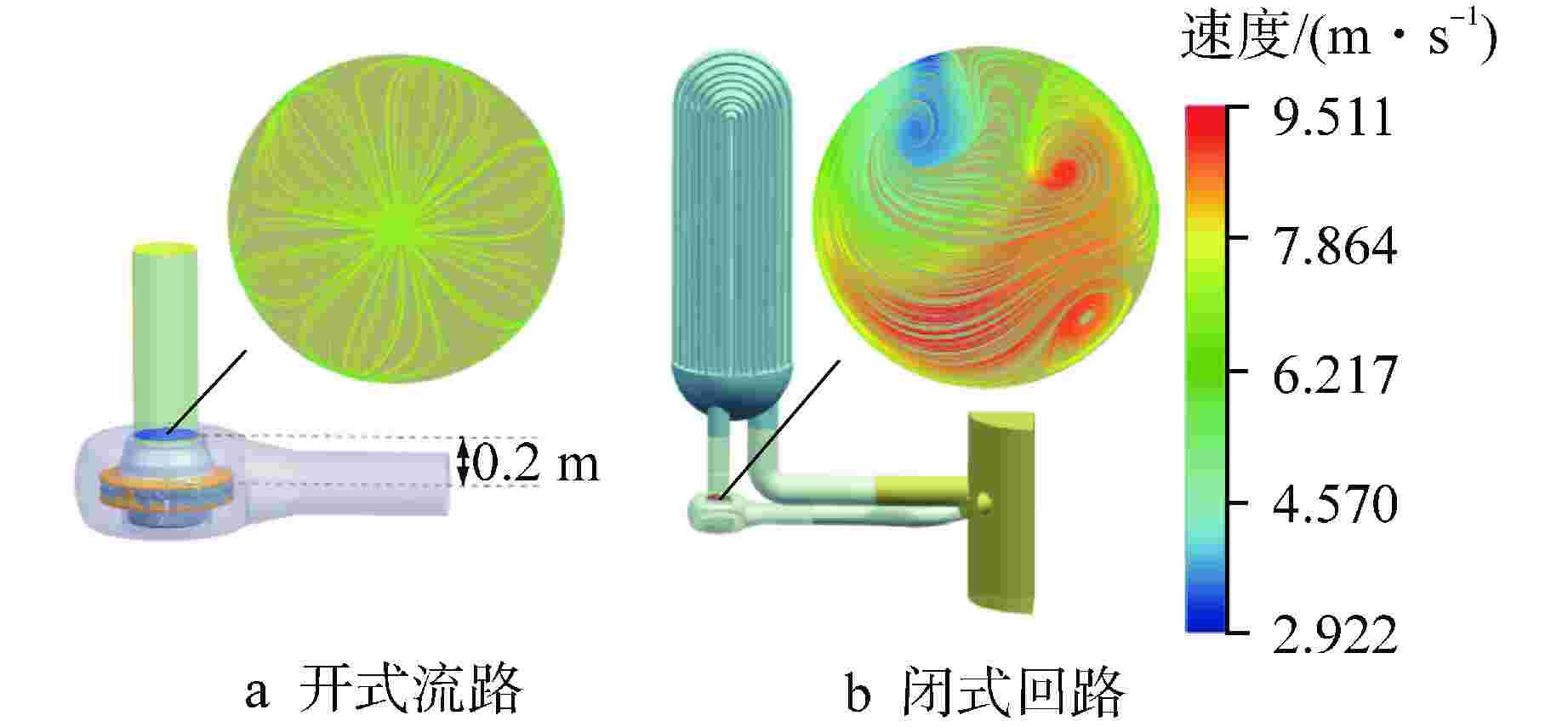

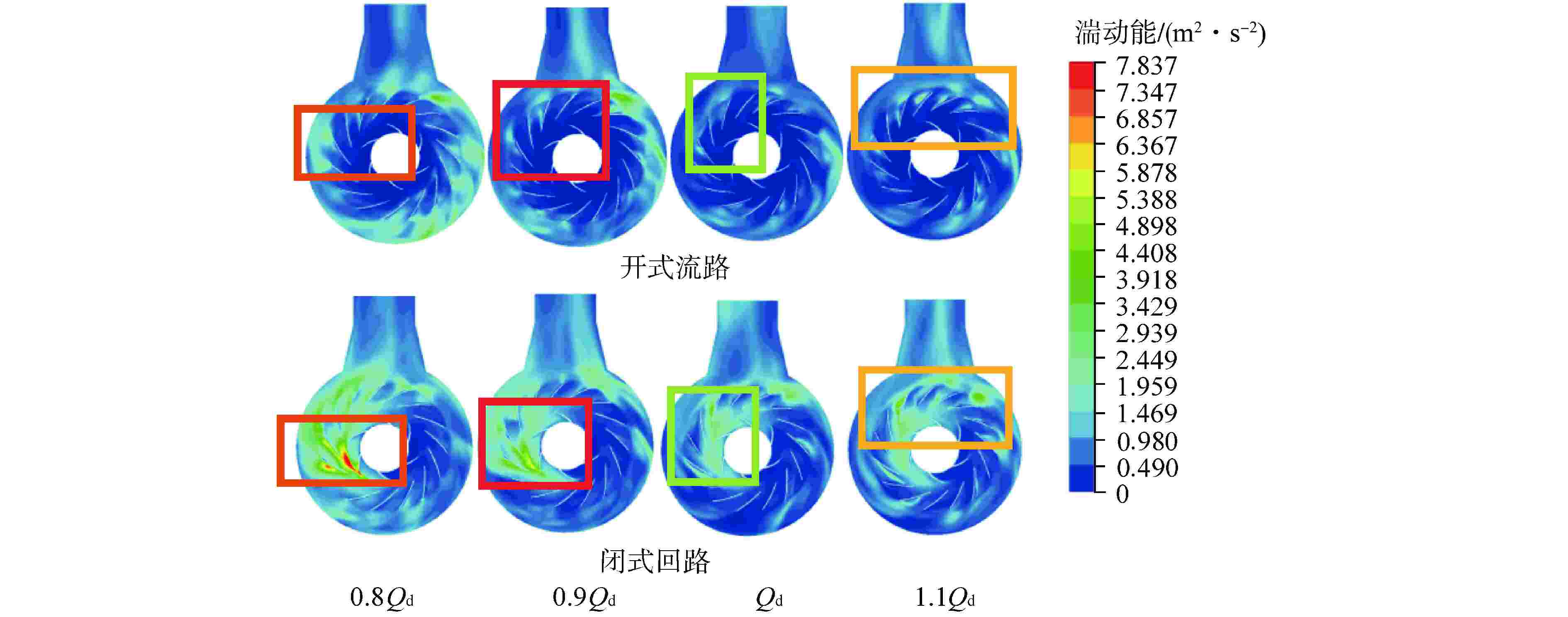

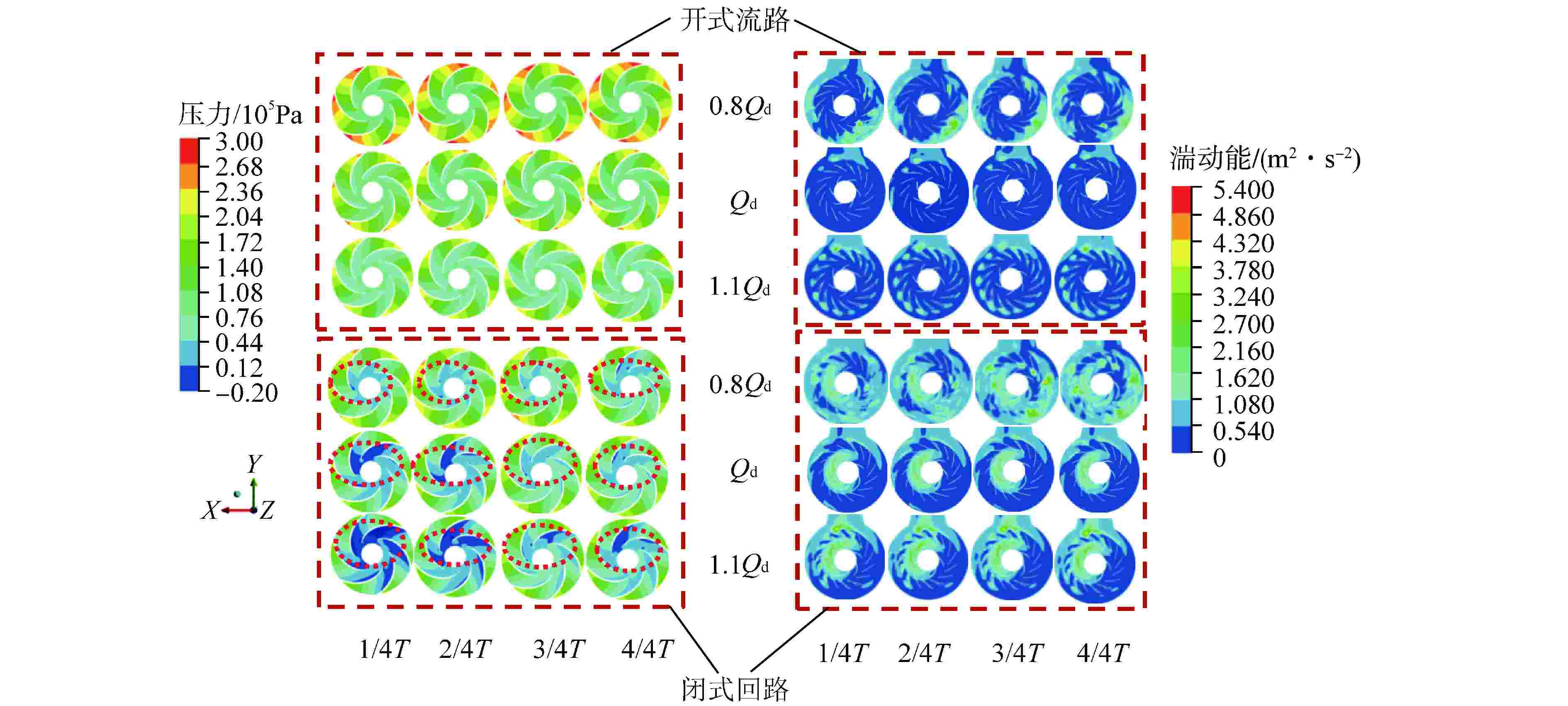

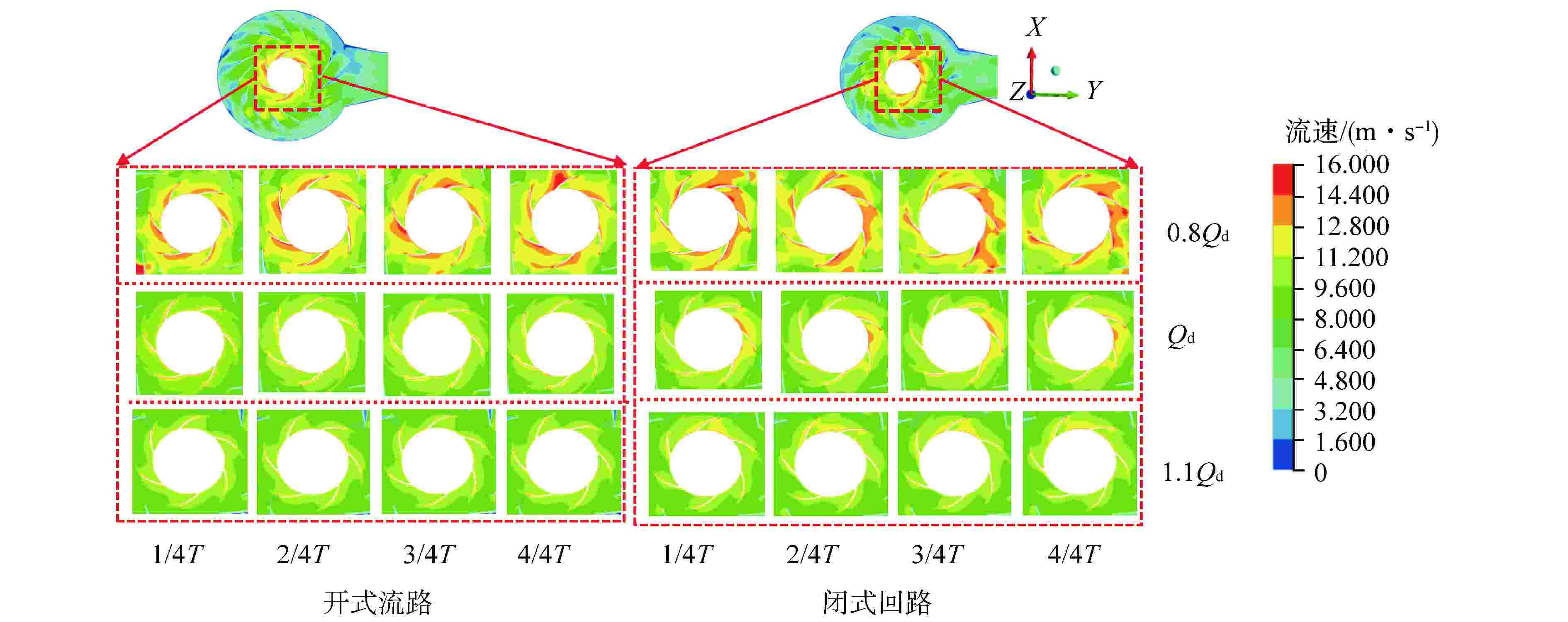

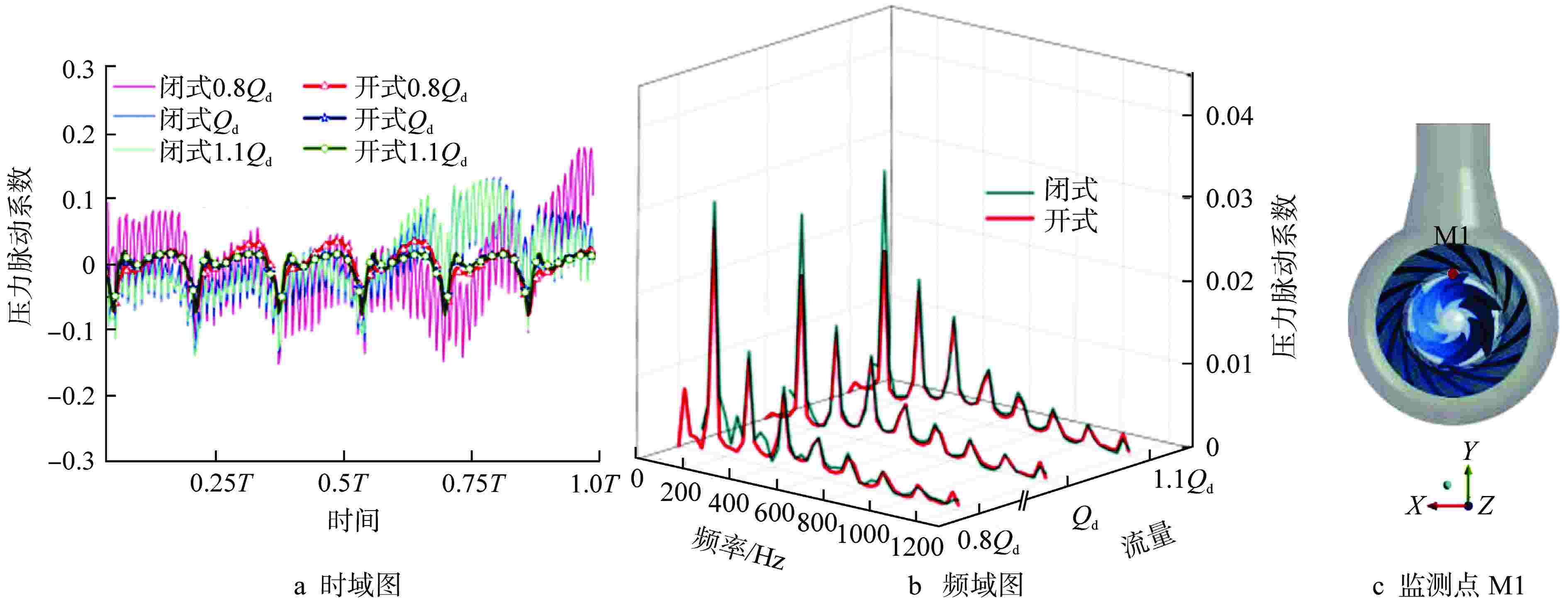

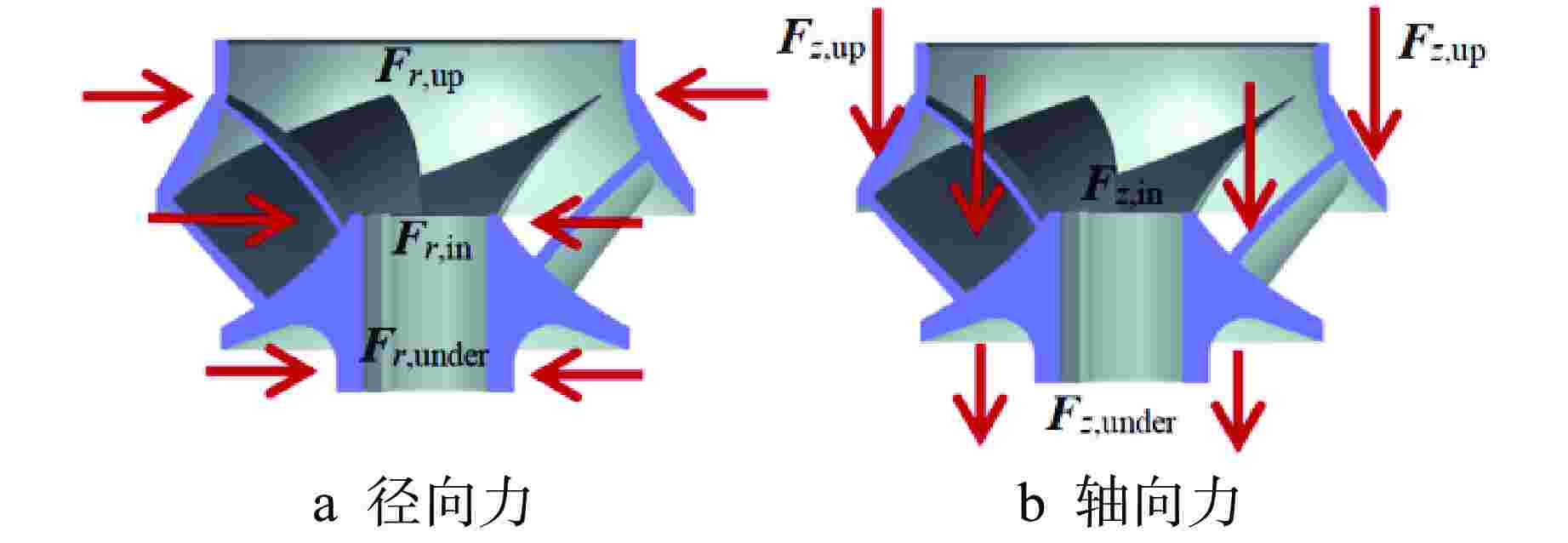

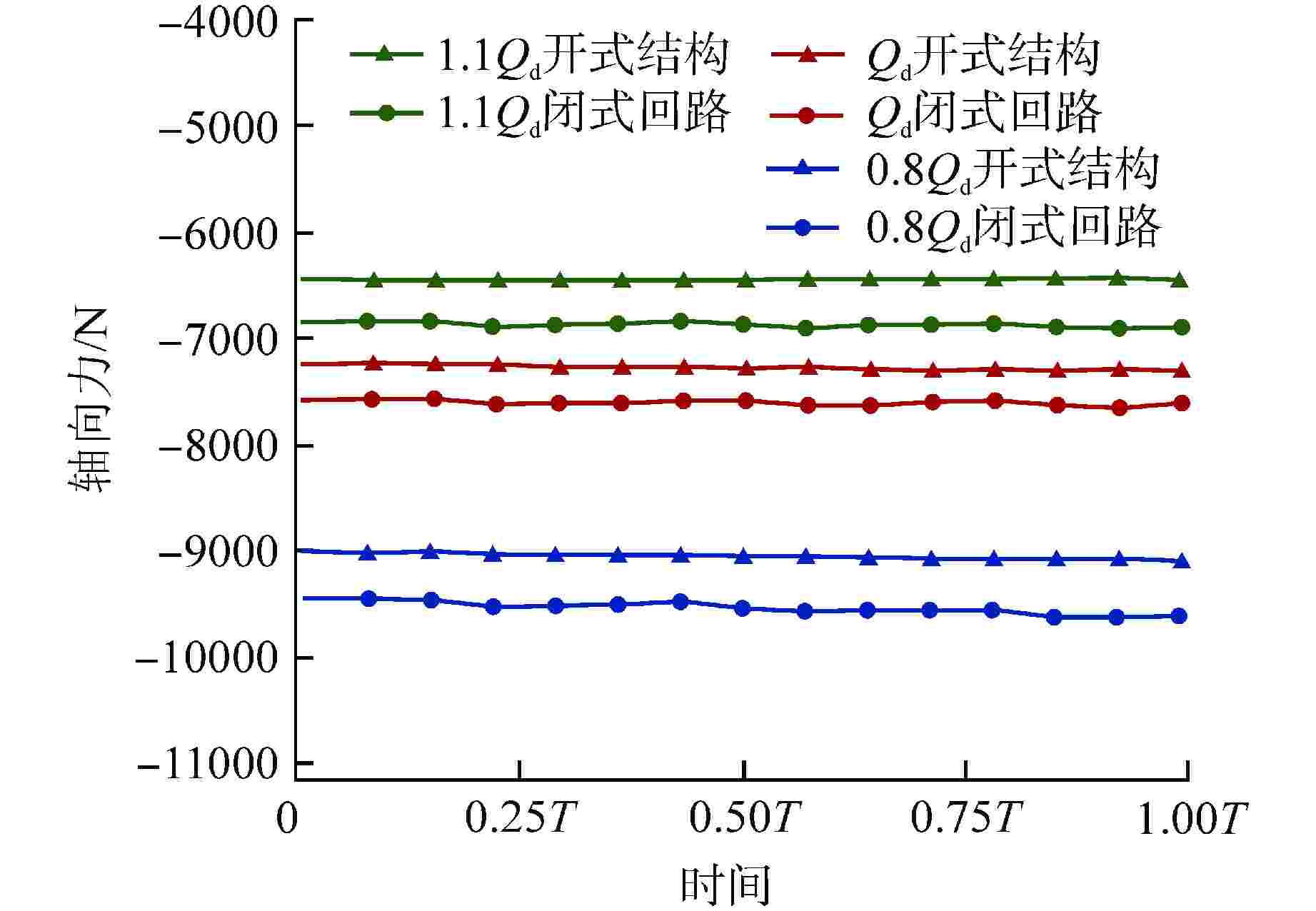

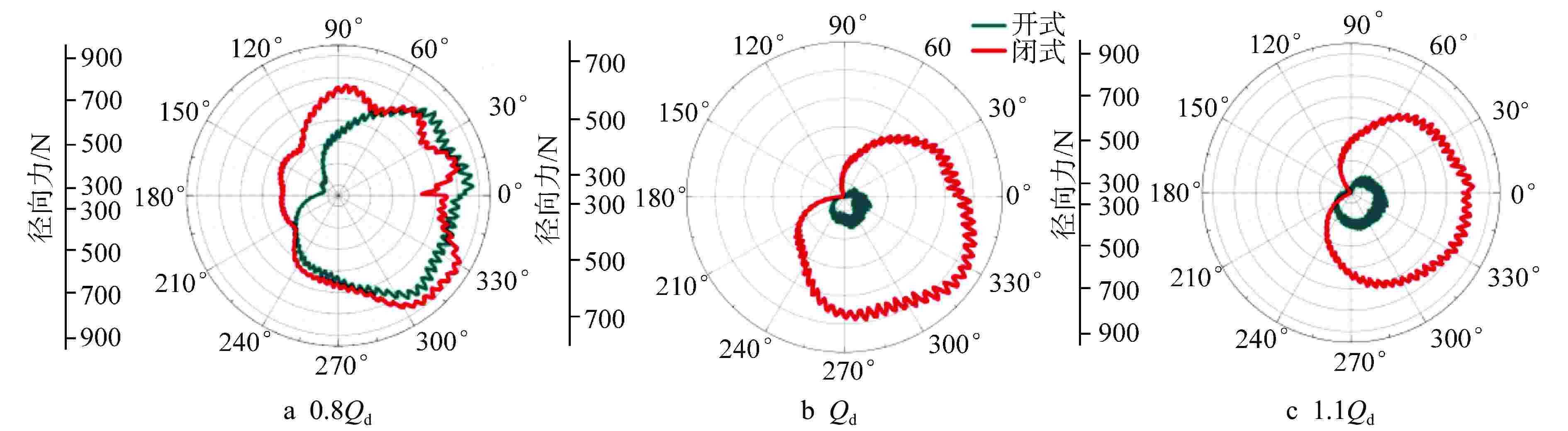

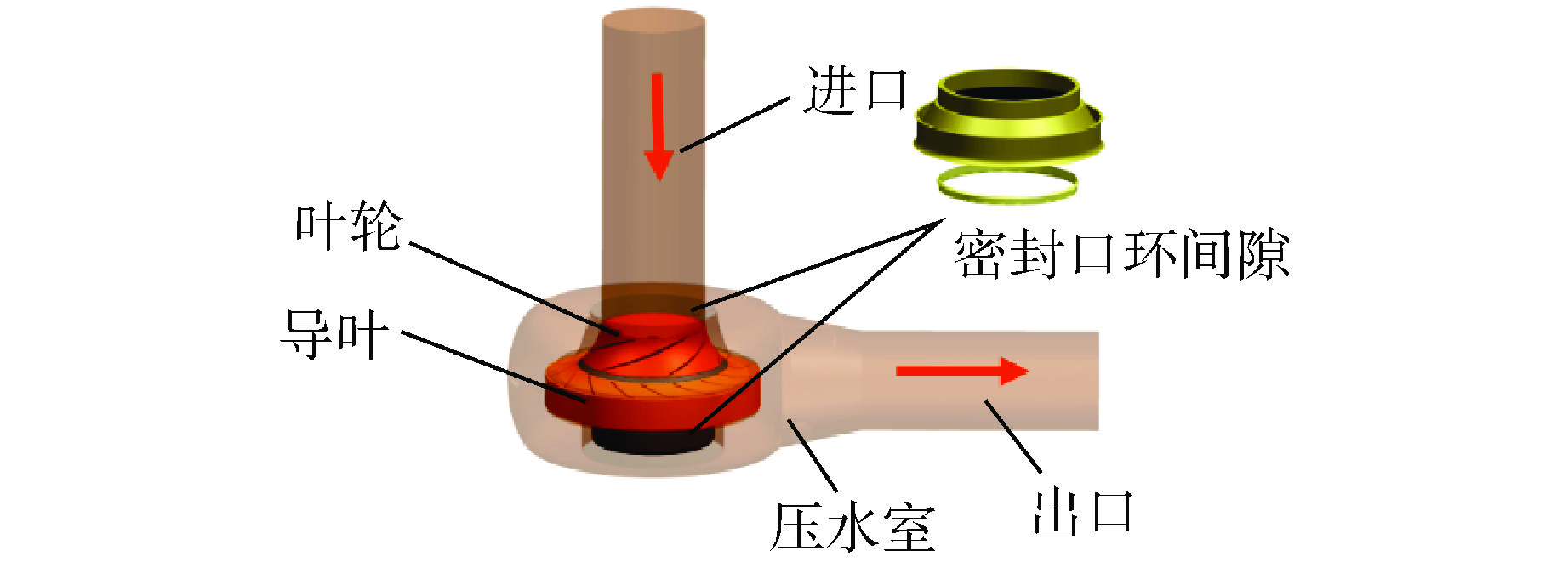

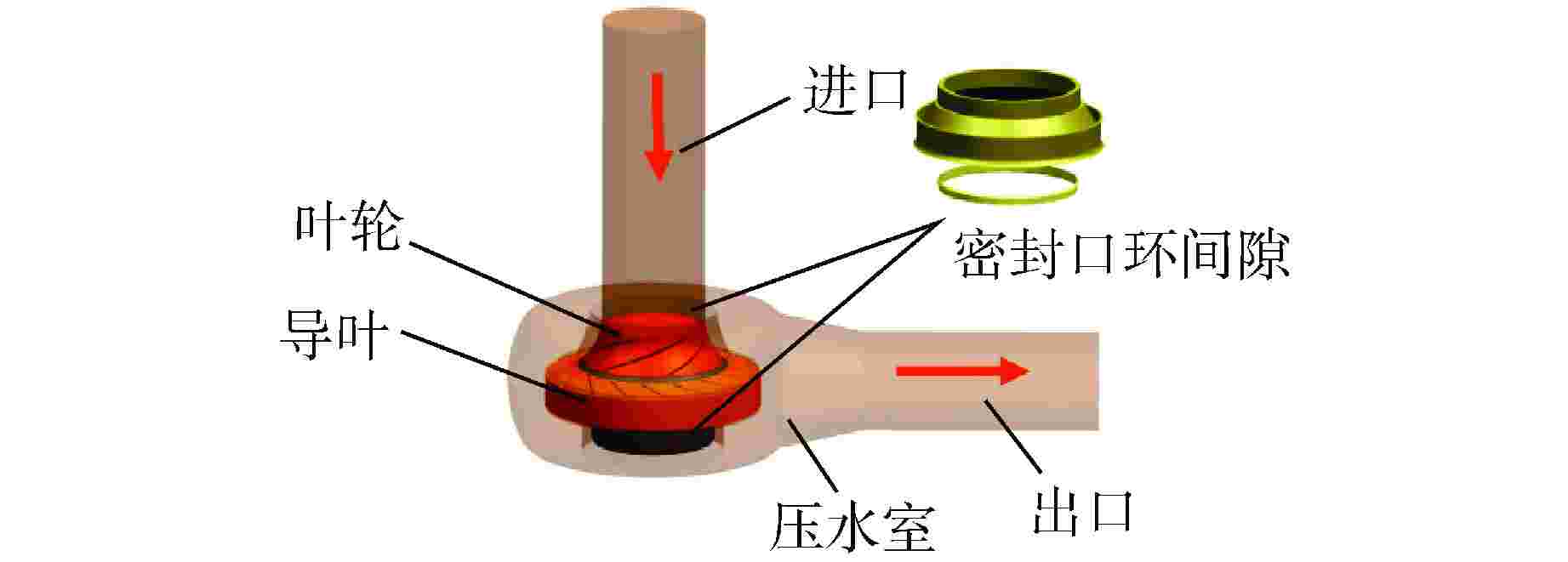

摘要: 传统的主泵流动分析平台多为简化的开式流路,与真实闭式回路运行工况存有较大差异。为探究主泵在真实回路中的流动特性与机理,以包含密封口环间隙的主泵全通道水力模型为研究对象,采用源项法进行稳态、瞬态计算分析研究。稳态计算结果表明:闭式循环回路中形成漩涡流态,致使主泵进口处发生预旋,产生入流畸变,导致湍动能有所增加,能量分布不均匀;瞬态计算结果表明:相较于开式流路,闭式回路入流畸变带来流场压力、速度、湍动能、压力脉动等特性的变化,导致泵体扬程、效率均有所下降,所受径向力、轴向力增大。闭式循环回路架构针对主泵流动性能的分析更接近真实流动。Abstract: The traditional main pump flow analysis platform is mostly a simplified open flow path, which is quite different from the real closed loop operation conditions. In order to explore the flow characteristics and mechanism of the main pump in the real loop, this paper takes the full-channel hydraulic model of the main pump with seal ring clearance as the research object, and uses the source term method for steady-state and transient calculation and analysis. The steady-state calculation results show that the vortex flow pattern is formed in the closed circulation loop, which leads to pre-swirl at the inlet of the main pump and inflow distortion, resulting in the increase of turbulent kinetic energy and uneven energy distribution. The transient calculation results show that compared with the open flow path, the inflow distortion of the closed loop brings changes in the characteristics of flow field pressure, velocity, turbulent kinetic energy and pressure fluctuation, which leads to the decrease of pump head and efficiency and the increase of radial force and axial force. The analysis of the flow performance of the main pump based on the closed loop structure is closer to the real flow.

-

Key words:

- Nuclear main pump /

- Closed circulation /

- Source term method /

- Inflow distortion /

- Numerical simulation

-

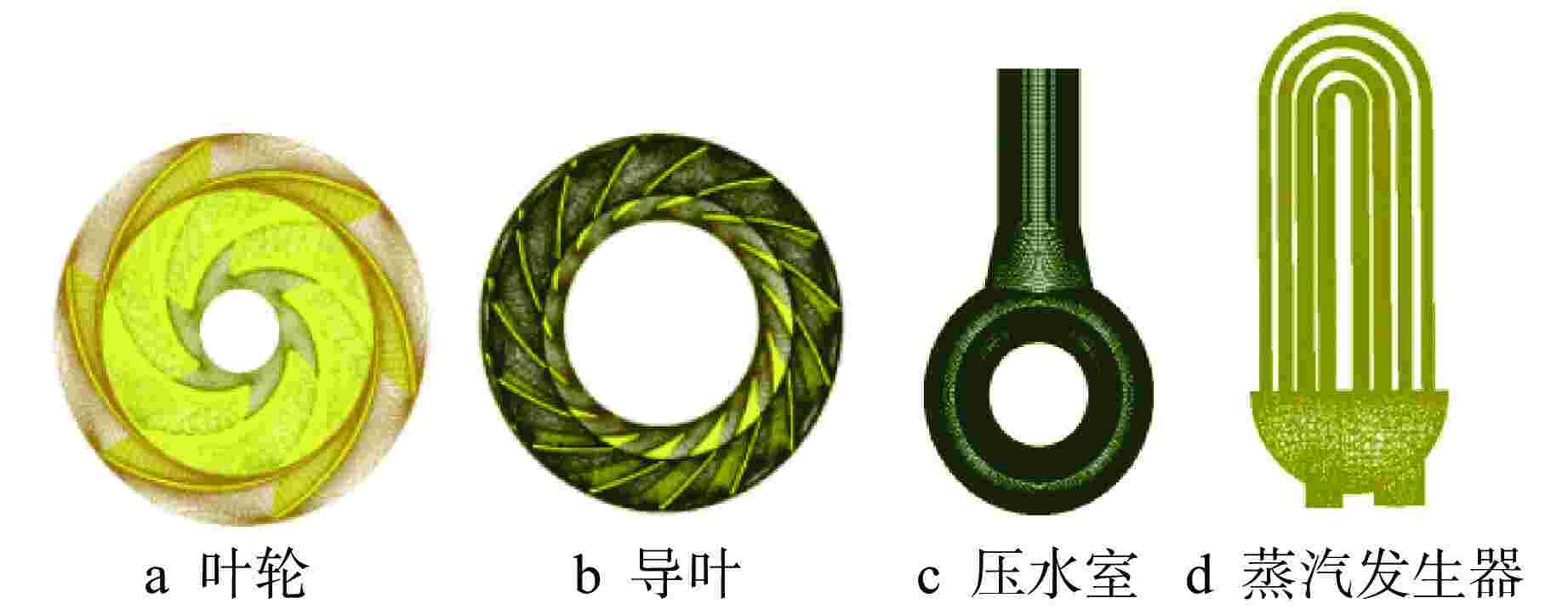

表 1 网格信息汇总表

Table 1. Grid Information Summary

方案 网格总

数/万叶轮网

格数/万导叶网

格数/万压水室网

格数/万蒸汽发生

器网格数/万扬程/m 效率/% 1 455.59 79.96 150.89 90.59 100.98 16.38 79.02 2 625.88 157.89 180.98 135.99 120.78 17.14 80.13 3 826.59 192.45 200.65 160.29 189.75 17.25 80.28 -

[1] 龙茂雄. 世界核电发展现状与展望[N]. 中国能源报, 2019-09-16(011). [2] 王强磊,赖喜德,叶道星. 叶轮叶片厚度对混流式核主泵能量性能的影响[J]. 核动力工程,2020, 41(1): 28-32. [3] 韩自强,顾林生. 核能的公众接受度与影响因素分析[J]. 中国人口·资源与环境,2015, 25(6): 107-113. [4] 夏栓,冯斌,张海军. AP1000核岛主泵流场数值模拟[J]. 核技术,2013, 36(4): 104-110. [5] 乔翼飞. 不同入流条件对核主泵压力脉动和振动特性影响研究[D]. 上海: 上海交通大学, 2018. [6] 侯向陶,王鹏飞,许忠斌,等. 蒸汽发生器下封头对核主泵入口流场影响[J]. 排灌机械工程学报,2016, 34(4): 277-282. [7] 王悦荟,刘聪,王鹏飞,等. 蒸汽发生器致畸变入流对核主泵流动性能的影响[J]. 浙江大学学报:工学版,2019, 53(11): 2076-2084. [8] 宋煜,顾希垚,刘迎圆,等. 不同边界条件下核主泵压力脉动性能的数值模拟[J]. 排灌机械工程学报,2019, 37(8): 645-649,667. [9] 周方明. 大功率屏蔽式核主泵高效低轴向力低脉动水力设计研究[D]. 大连: 大连理工大学, 2017. [10] 范兆京. 核主泵入口畸变流模型及其性能影响机理研究[D]. 兰州: 兰州理工大学, 2020. [11] 宋长红,林永峰,陈文轩,等. 基于动量源方法的涵道尾桨CFD分析[J]. 直升机技术,2009(1): 6-11. [12] 杨从新,刘满,王秀勇,等. 动静叶栅间隙对钠冷快堆二回路泵压力脉动特性的影响[J]. 核动力工程,2020, 41(1): 127-133. [13] 王春林,杨晓勇,李长军,等. 混流式主泵模型泵内部流场压力脉动特性研究[J]. 核动力工程,2013, 34(4): 47-52. [14] LU Y M, WANG X F, LIU H R, et al. Investigation of the effects of the impeller blades and vane blades on the CAP1400 nuclear coolant pump's performances with a united optimal design technology[J]. Progress in Nuclear Energy, 2020, 126: 103426. doi: 10.1016/j.pnucene.2020.103426 [15] 程效锐,贾程莉,杨从新,等. 导叶周向布置位置对核主泵压力脉动的影响[J]. 机械工程学报,2016, 52(16): 197-204. [16] ZHOU W J, QIU N, WANG L Q, et al. Dynamic analysis of a planar multi-stage centrifugal pump rotor system based on a novel coupled model[J]. Journal of Sound and Vibration, 2018, 434: 237-260. doi: 10.1016/j.jsv.2018.07.041 [17] ZHOU W J, QIU N, ZHANG N, et al. Research on steady-state characteristics of centrifugal pump rotor system with weak nonlinear stiffness[J]. Transactions of FAMENA, 2018, 42(3): 87-102. doi: 10.21278/TOF.42306 [18] KANG C, ZHAO H X, ZHANG Y C, et al. Effects of upstream deflector on flow characteristics and startup performance of a drag-type hydrokinetic rotor[J]. Renewable Energy, 2021, 172: 290-303. doi: 10.1016/j.renene.2021.03.043 -

下载:

下载: