Design Optimization of Retention Coil for 2 MWt Liquid Fuel Thorium-based Molten Salt Experimental Reactor

-

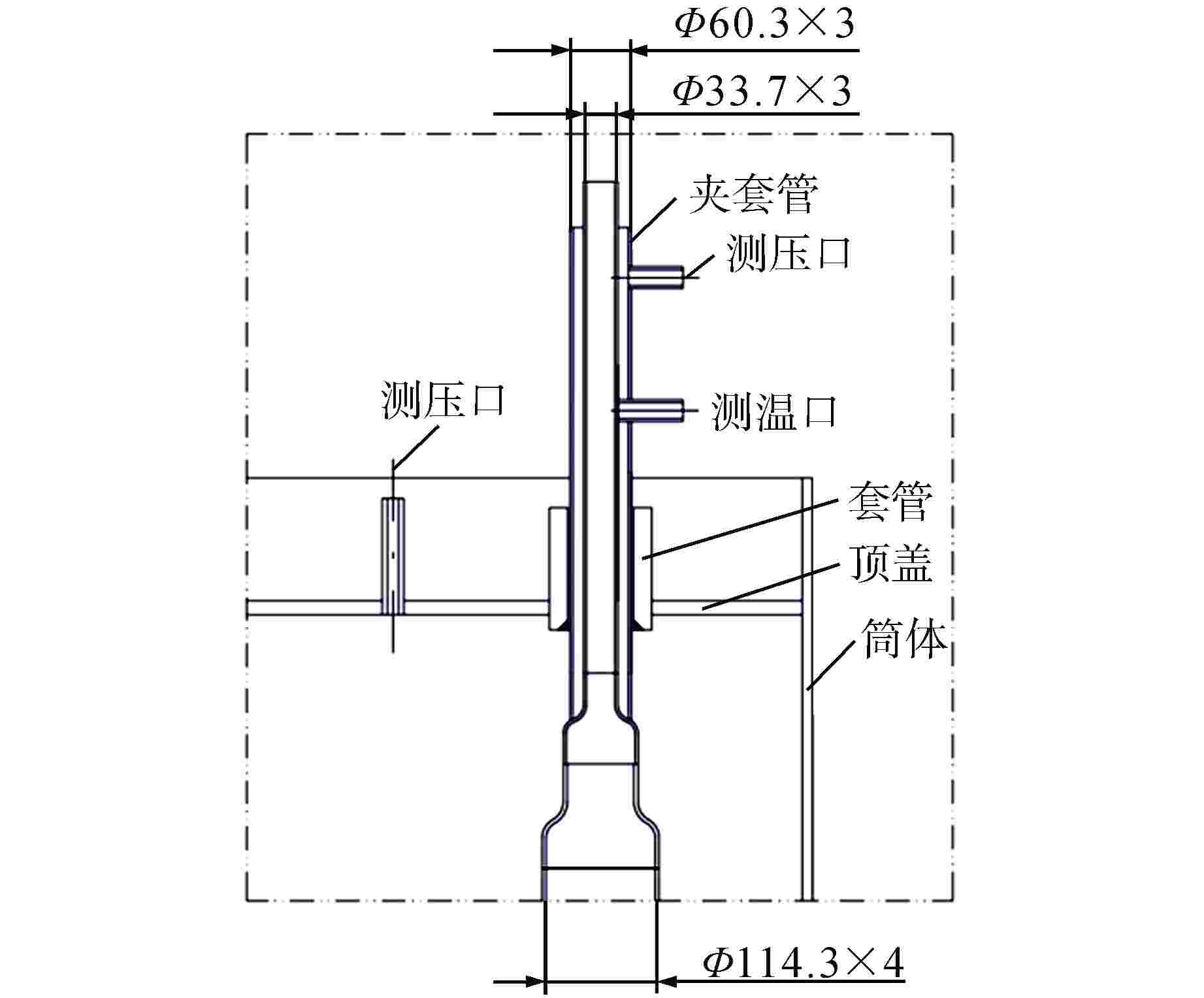

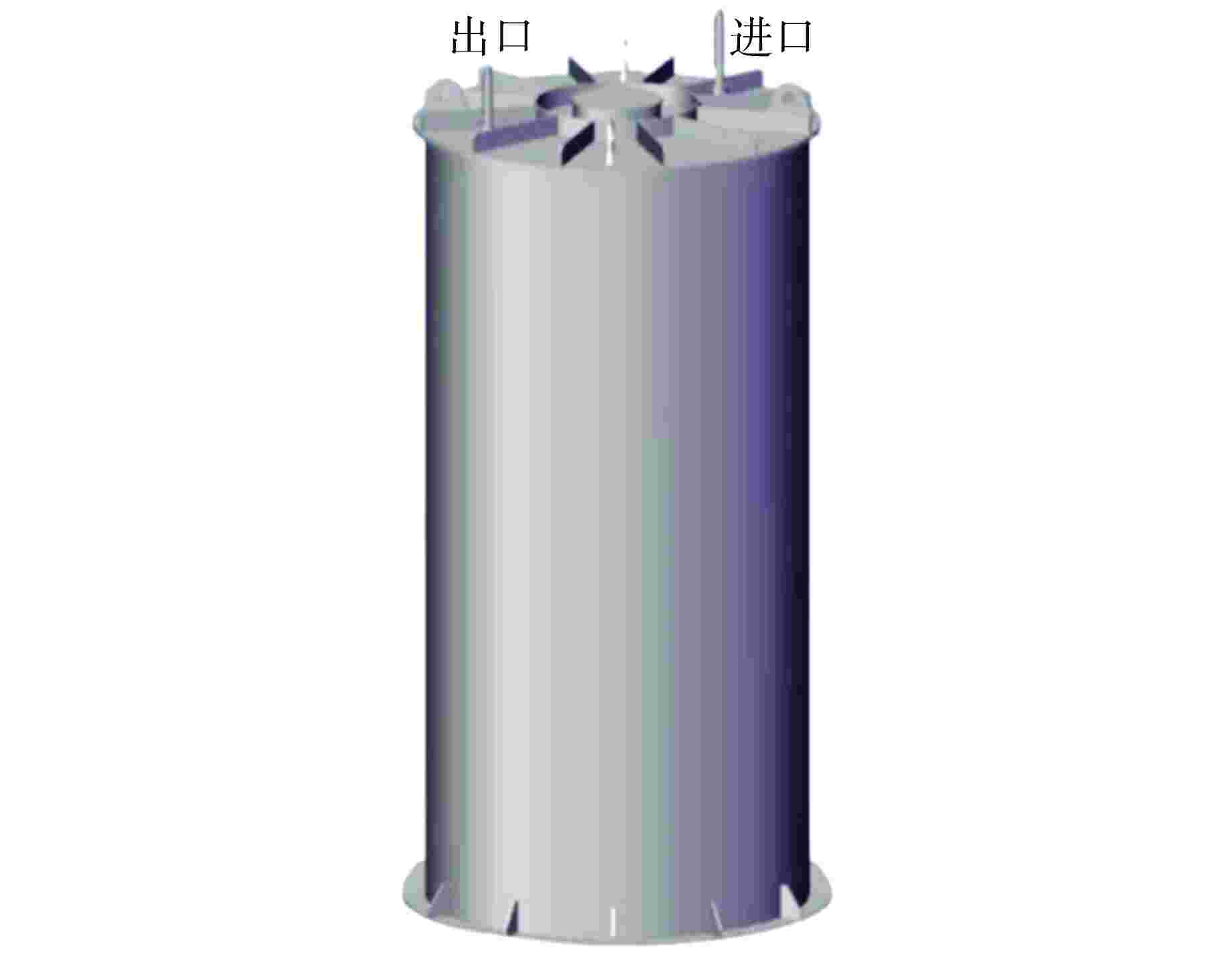

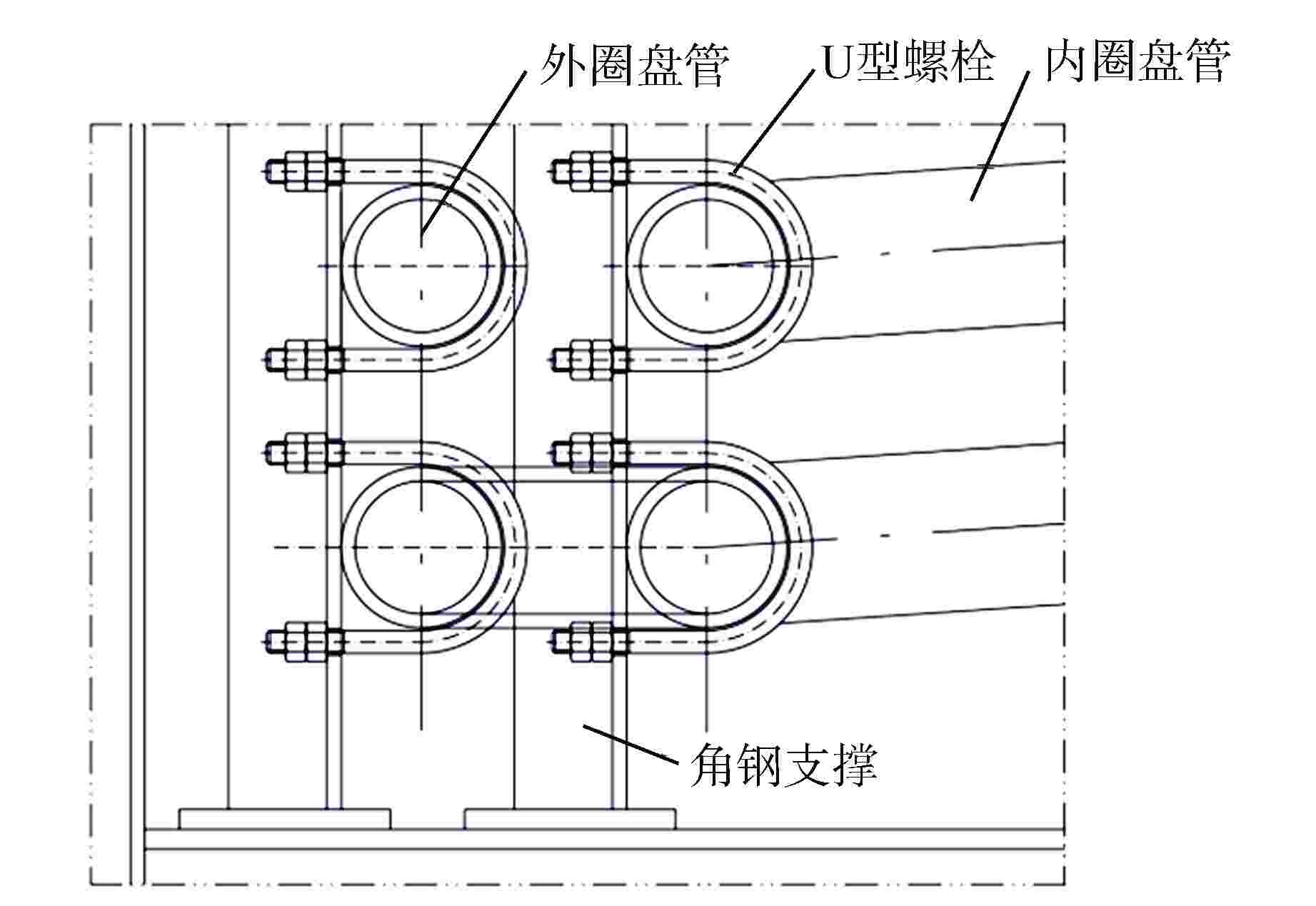

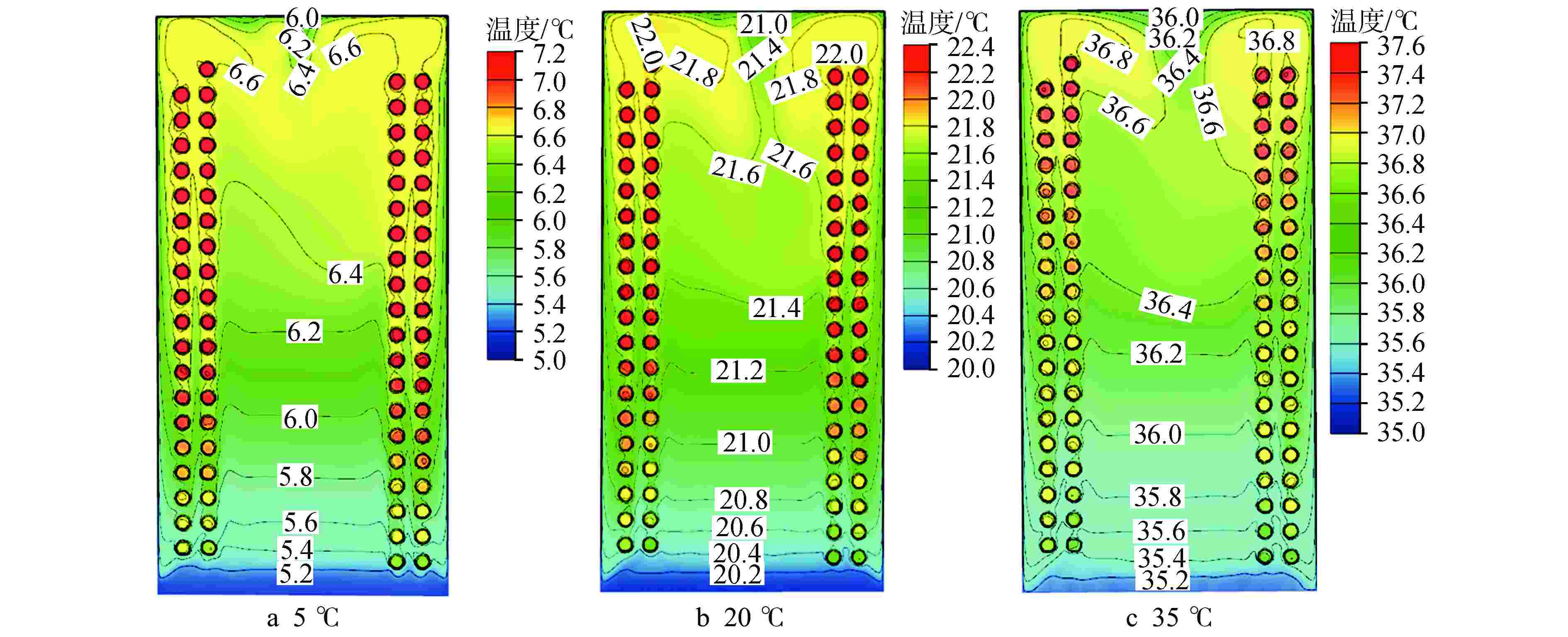

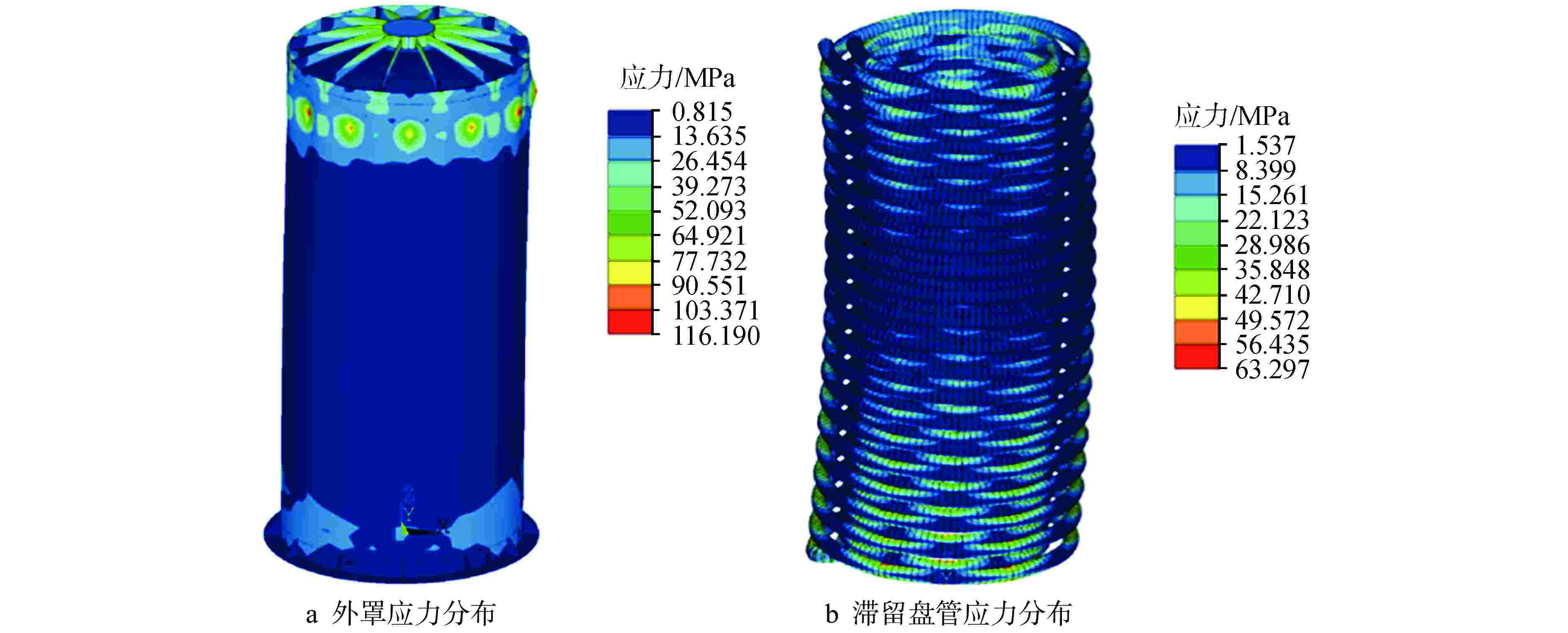

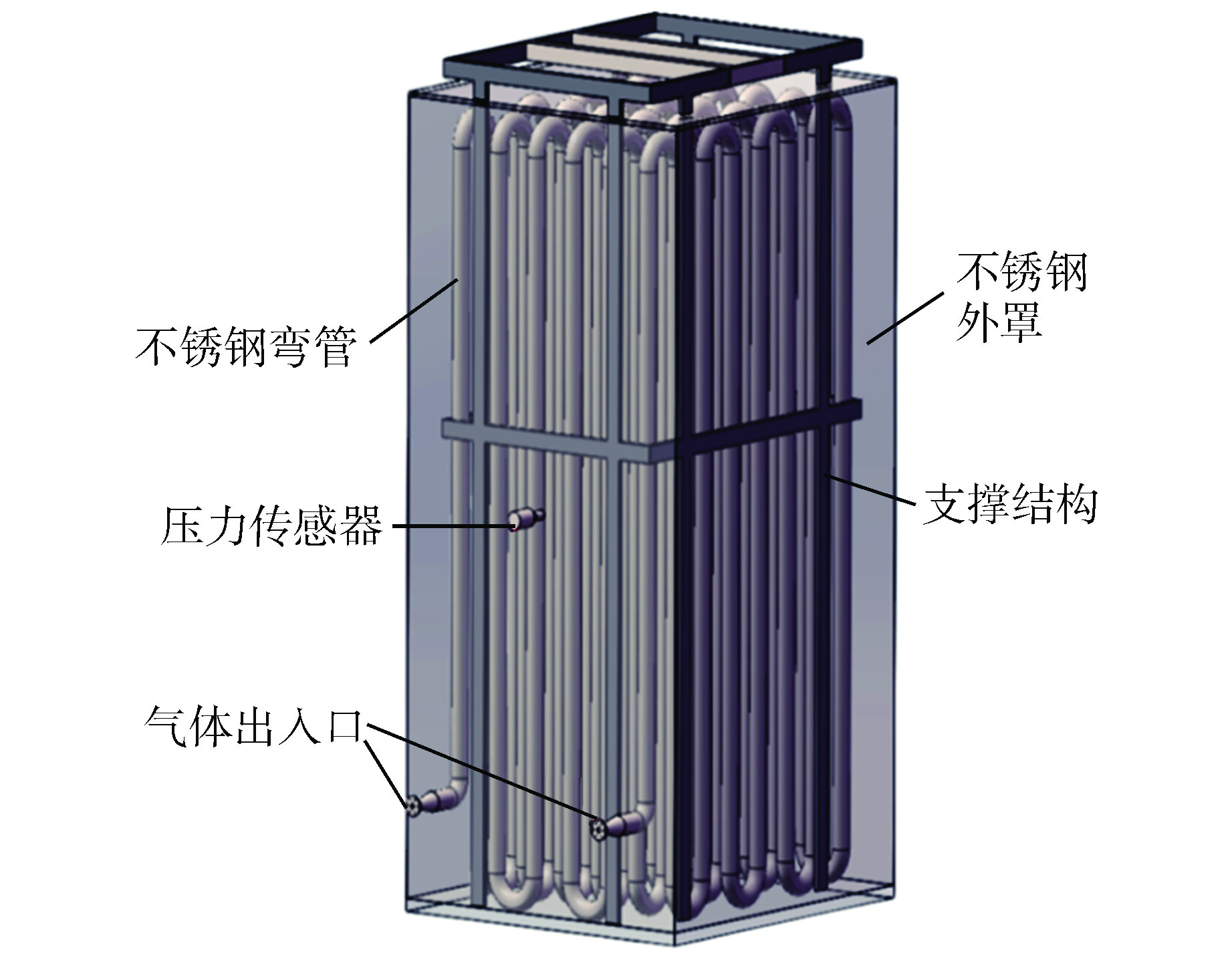

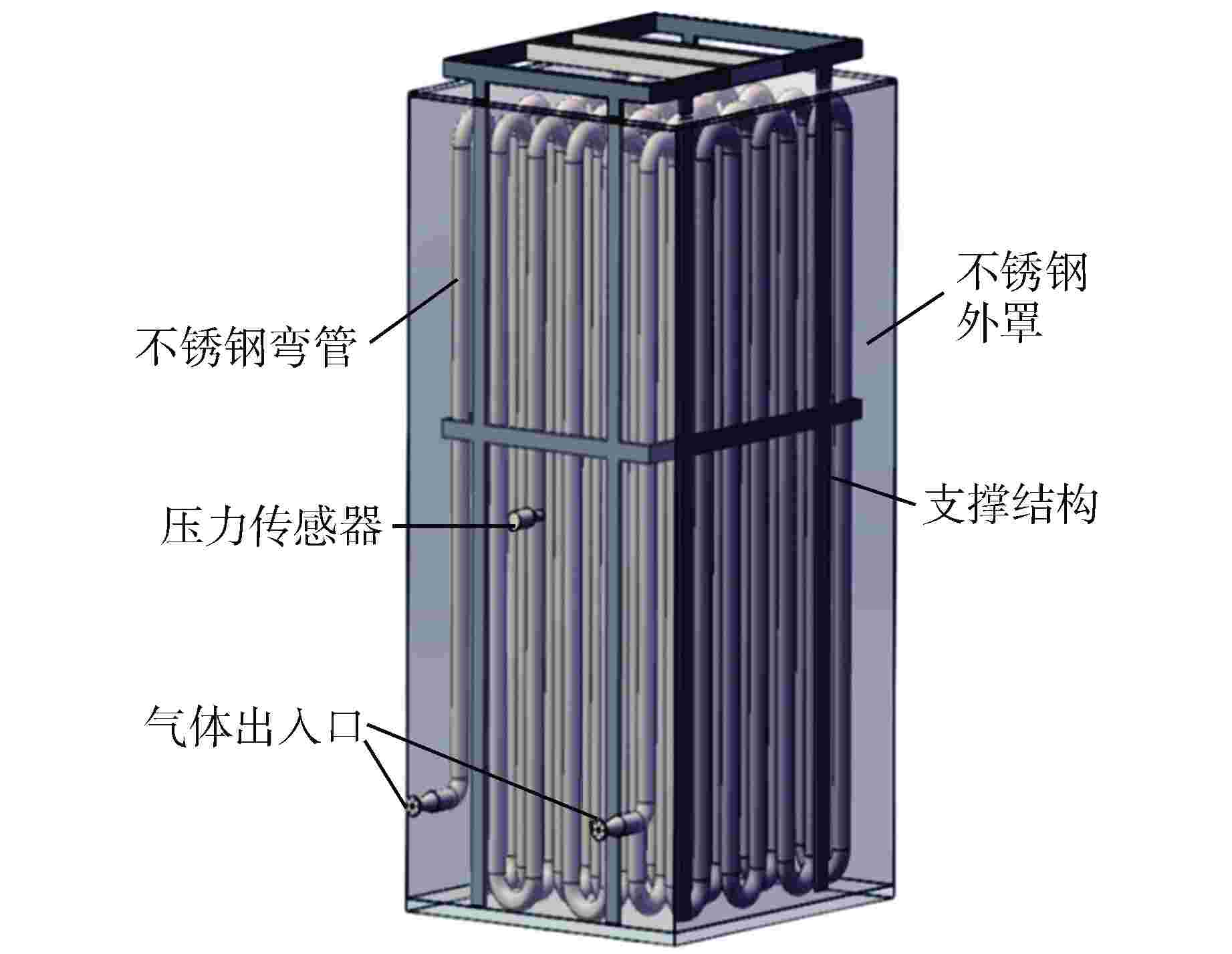

摘要: 液态燃料钍基熔盐实验堆滞留盘管是熔盐堆尾气处理系统的重要核安全级设备,为尾气中短寿命核素衰变提供封闭环境,同时去除衰变热,降低其后碘吸附床和活性炭吸附床的温度。本文介绍了业主提供的2 MWt液态燃料钍基熔盐实验堆滞留盘管原设计方案中存在的问题及结构优化后的新设计方案。优化后的滞留盘管设计方案具有散热性好、泄漏点少(焊缝少)、容易施焊、便于检测监控维修、用材少等优点,具有较好的可靠性和经济性。Abstract: The retention coil of liquid fuel thorium-based molten salt experimental reactor is an important nuclear safety equipment in the tail gas treatment system of molten salt reactor, which provides a closed environment for the decay of short-lived nuclides in the tail gas, removes the decay heat at the same time, and reduces the temperature of the iodine adsorption bed and the activated carbon adsorption bed downstream it. This paper introduces the problems existing in the original design scheme of the retention coil of the 2 MWt liquid fuel thorium-based molten salt experimental reactor provided by the owner and the new design scheme after structural optimization. The optimized design scheme of retention coil has the advantages of good heat dissipation, few leakage points (few welds), easy welding, easy inspection, monitoring and maintenance, less materials, etc., and has good reliability and economy.

-

Key words:

- Thorium-based molten salt reactor /

- Retention coil /

- Outer housing /

- Design optimization

-

表 1 滞留盘管技术参数

Table 1. Technical Parameters of Retention Coil

参数 数值或描述 流经气体类型 反应堆尾气

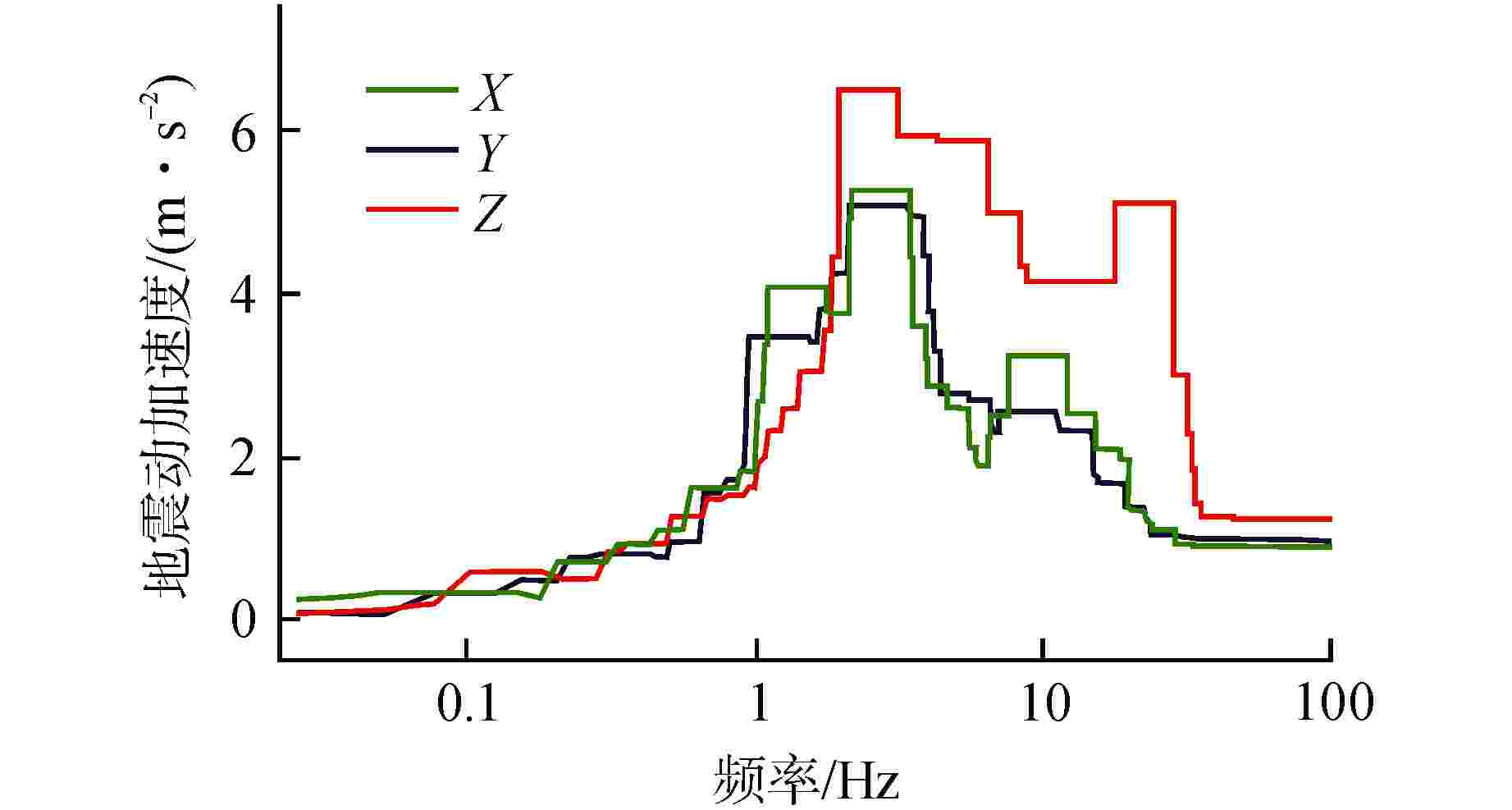

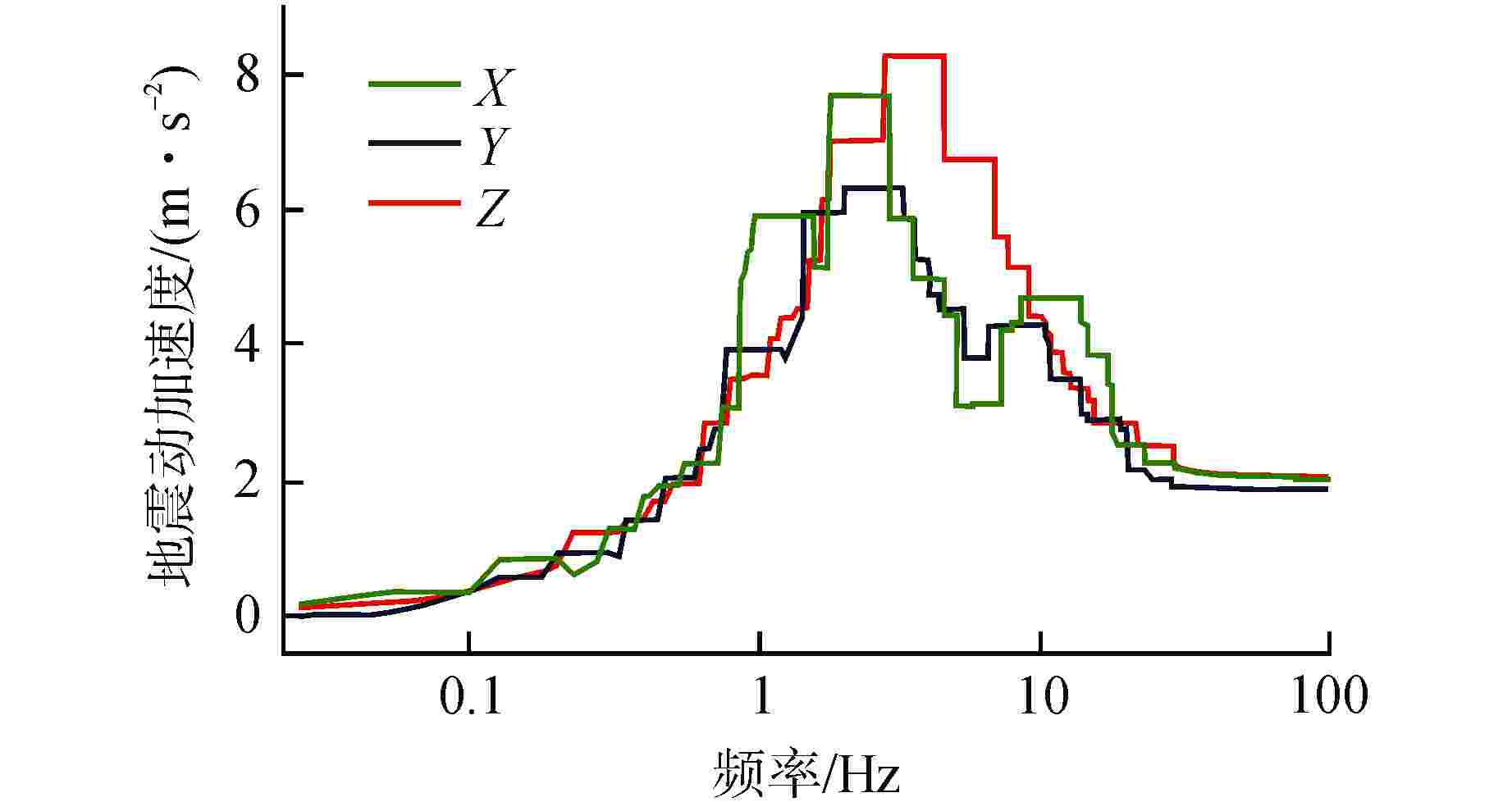

(氩气+少量放射性气体)气体流量/(L·min–1) 10 滞留时间/h 3 衰变热/W 100 管道壁厚/mm 4 外罩外形最大尺寸 2.4 m×2.4 m×5 m 滞留盘管内正常运行压力/MPa 0.05(表压) 滞留盘管进口温度/℃ 25~80 滞留盘管出口温度/℃ ≤50 罩外环境介质 大气 环境温度/℃ 5~35 环境大气压力 常压 相对湿度/% ≤30 滞留盘管泄漏率/(Pa·m3·s–1) ≤10−9 使用寿命(金属部件)/a 10 气体进出管接口 DN25 密封 焊接 安装地点 甘肃省武威市民勤县红沙岗镇 抗震要求 特殊抗震要求 表 2 新方案与原方案对比

Table 2. Comparison between the New Scheme and the Original Scheme

项目 原方案 新方案 结构设计 管道形式 直管+弯头 双层螺旋盘管 外罩形式 矩形 圆筒形 泄漏检测 无 进/出口增设测压口 外罩增设检漏仪表口 检修孔 无 增设人孔 滞留盘管 焊缝长度/m 18 13.6 弯头数量/个 50 1 成本 新方案节约弯头49个,采购成本降低74.4

万元,焊缝长度减少4.4 m外罩 外罩重量/t 13.3 4.7 焊缝长度/m 242.8 75.6 成本 新方案材料直接成本降低12.6万元,焊缝

总长度减少167.2 m设备材料费/万元 138 50.6 -

[1] FORSBERG C W, TERRANI K A, SNEAD L L, et al. Fluoride-salt-cooled high-temperature reactor (FHR) with silicon-carbide-matrix coated-particle fuel[Z]. Oak Ridge: Oak Ridge National Lab., 2012. [2] 江绵恒,徐洪杰,戴志敏. 未来先进核裂变能−TMSR核能系统[J]. 中国科学院院刊,2012, 27(3): 366-374. doi: 10.3969/j.issn.1000-3045.2012.03.016 [3] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 钢制对焊管件 类型与参数: GB/T 12459−2017[S]. 北京: 中国标准出版社, 2017: 7 [4] The American Society of Mechanical Engineers. Rules for construction of nuclear facility components: ASME BPV code section III division 1 subsection ND class 3 components[S]. New York: The American Society of Mechanical Engineers, 2019: 37-41 -

下载:

下载: