Study on Earthquake Interaction between Safety-Related and Non-Safety- Related Items in Equipment Cooling Water System Room of Qinshan Nuclear Power Plant

-

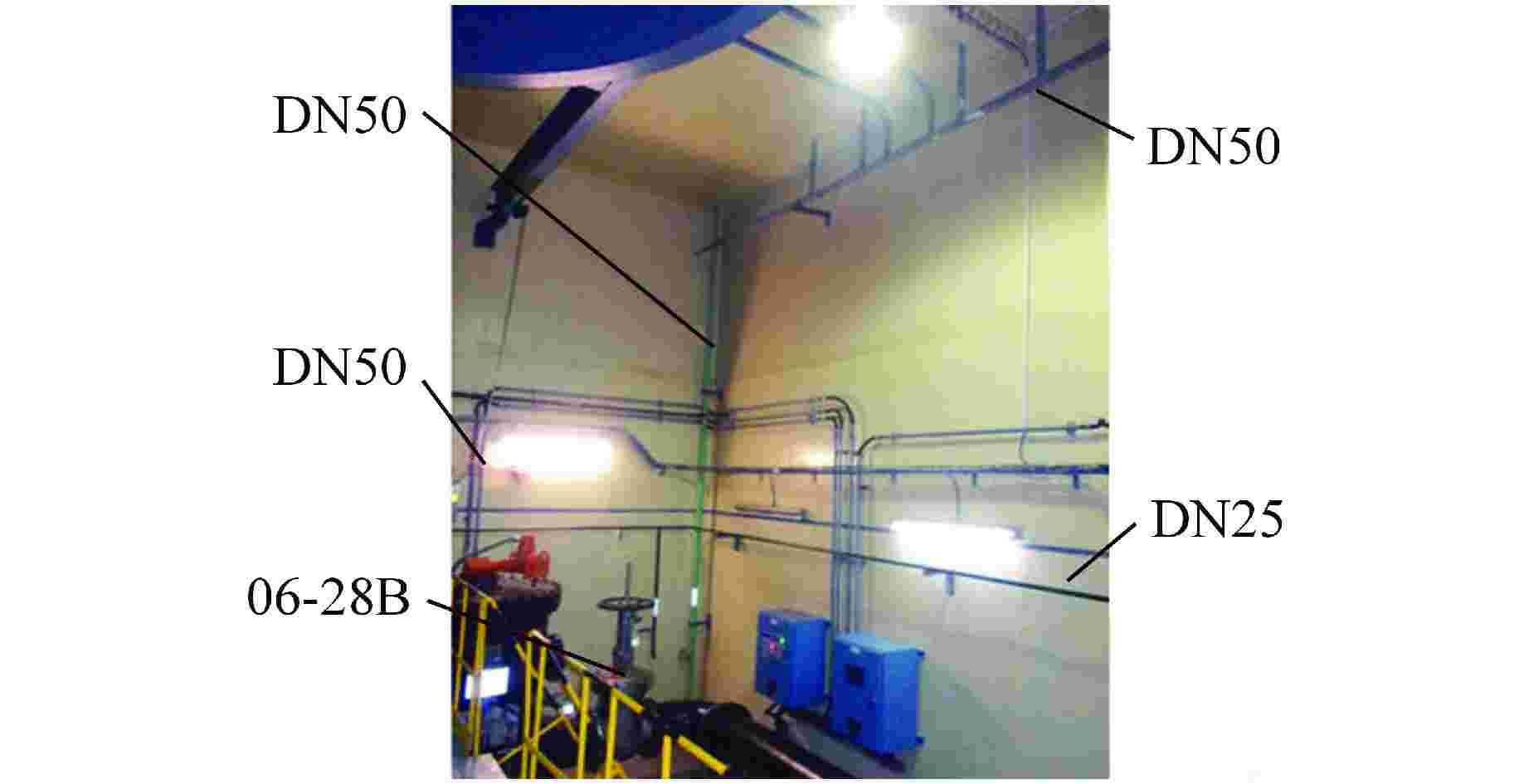

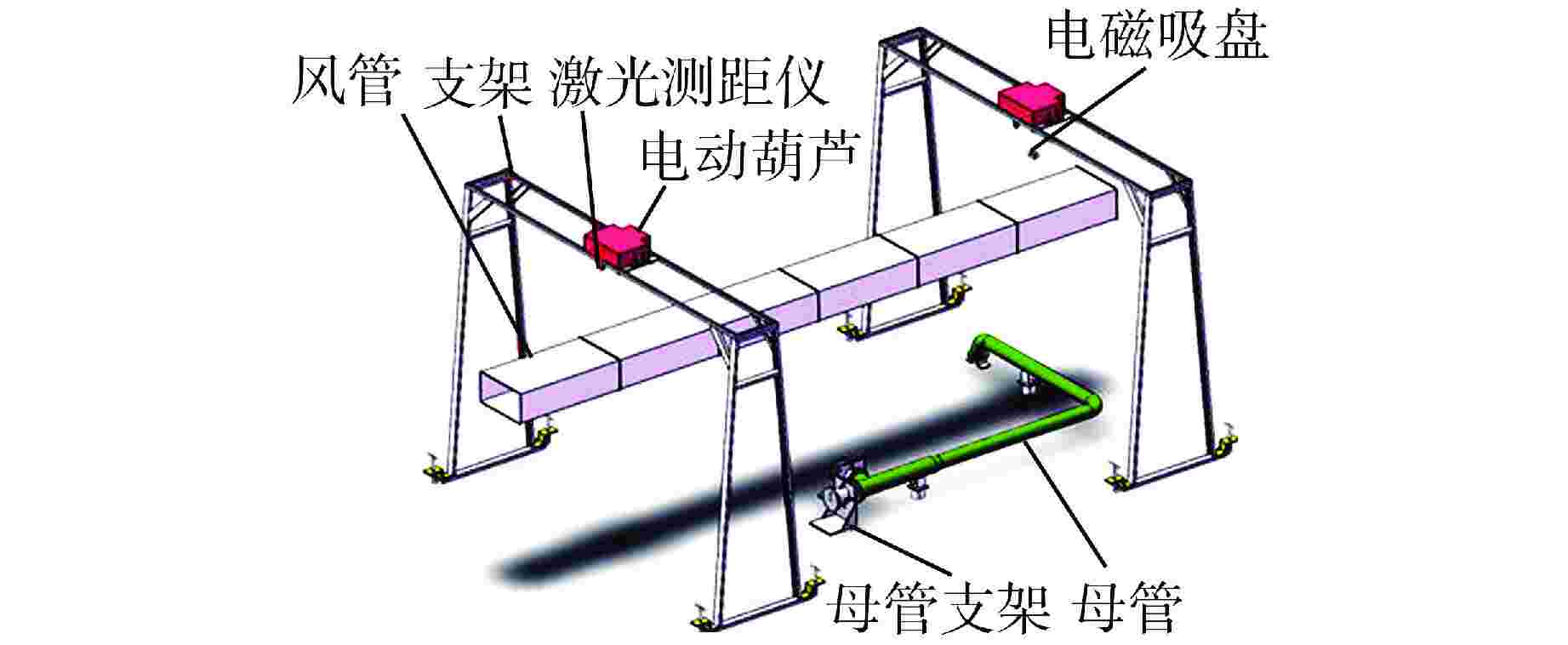

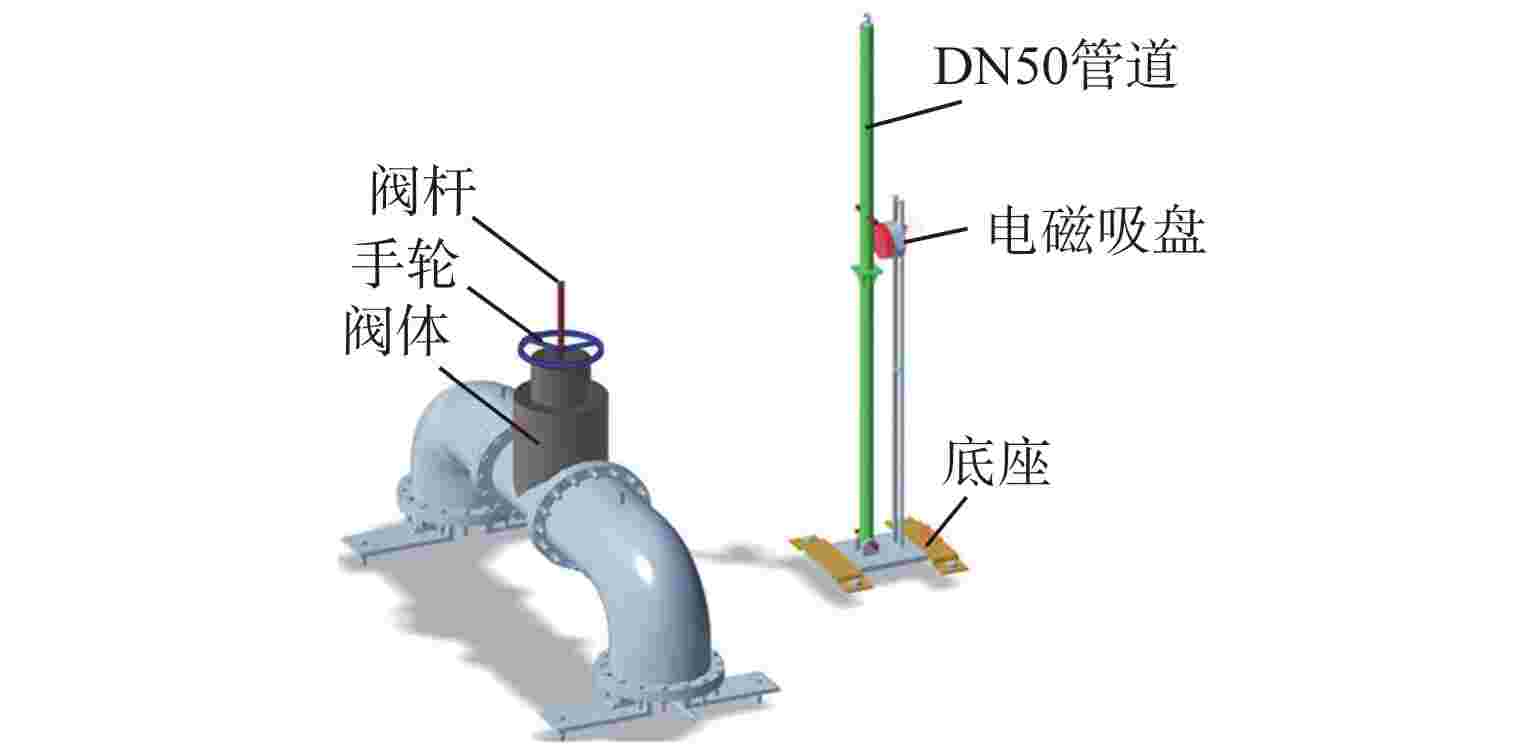

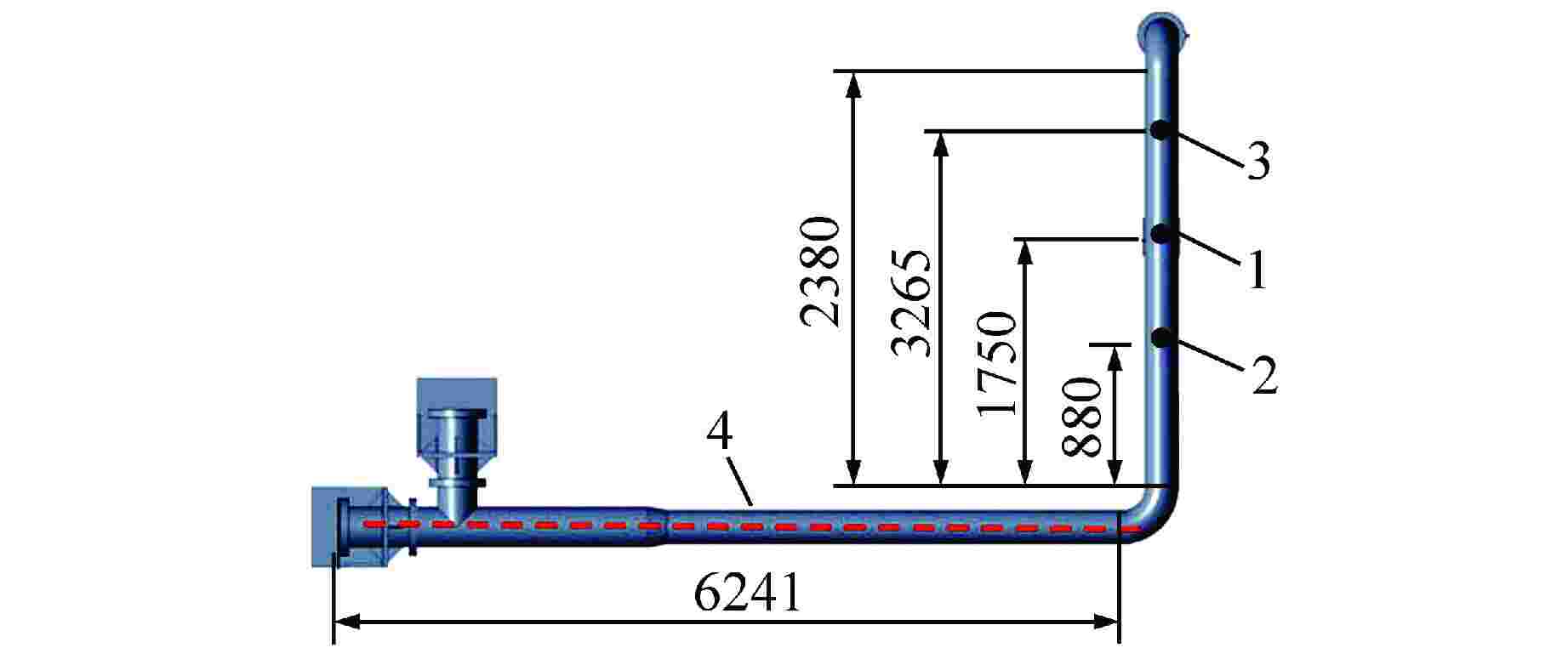

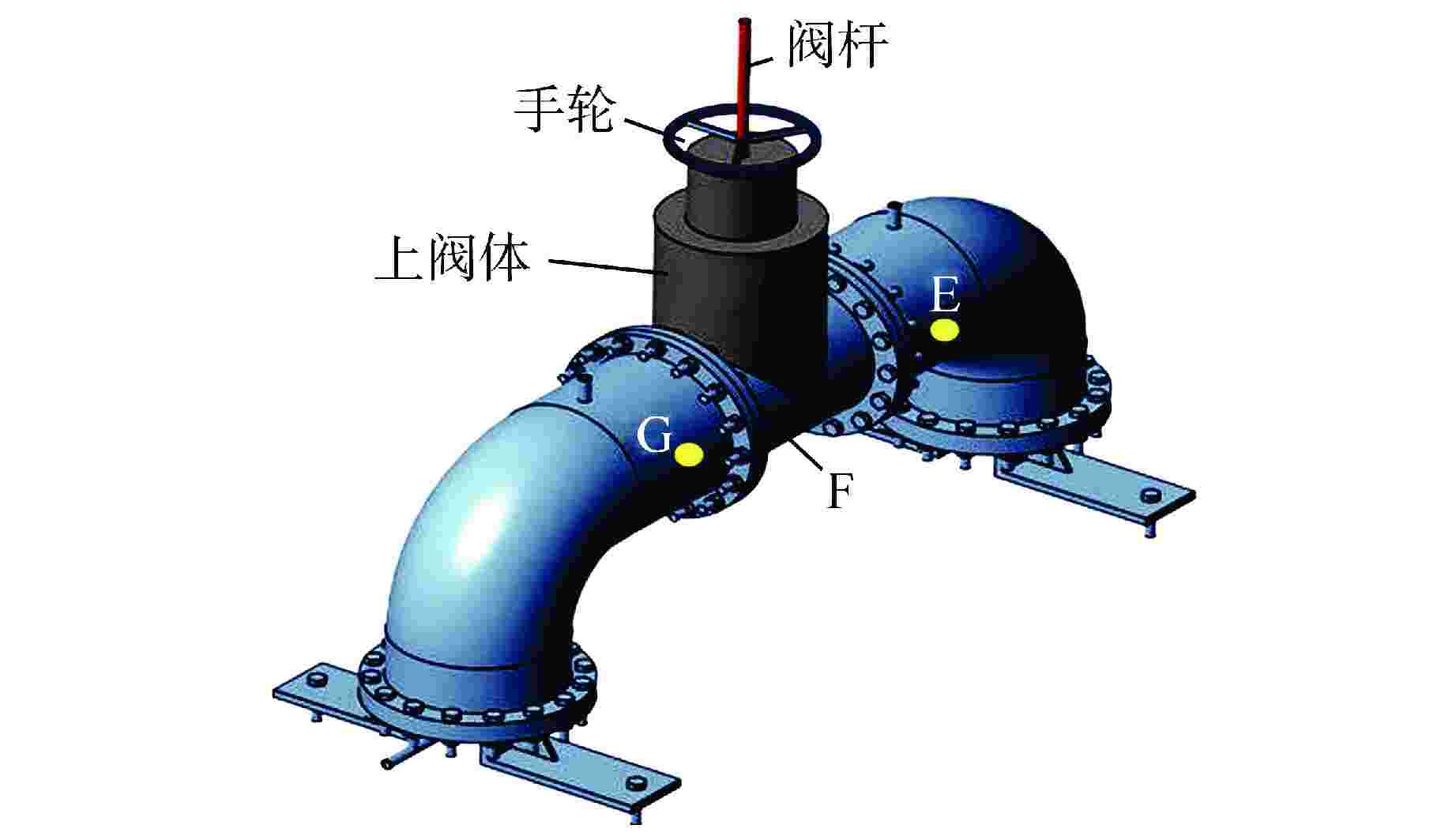

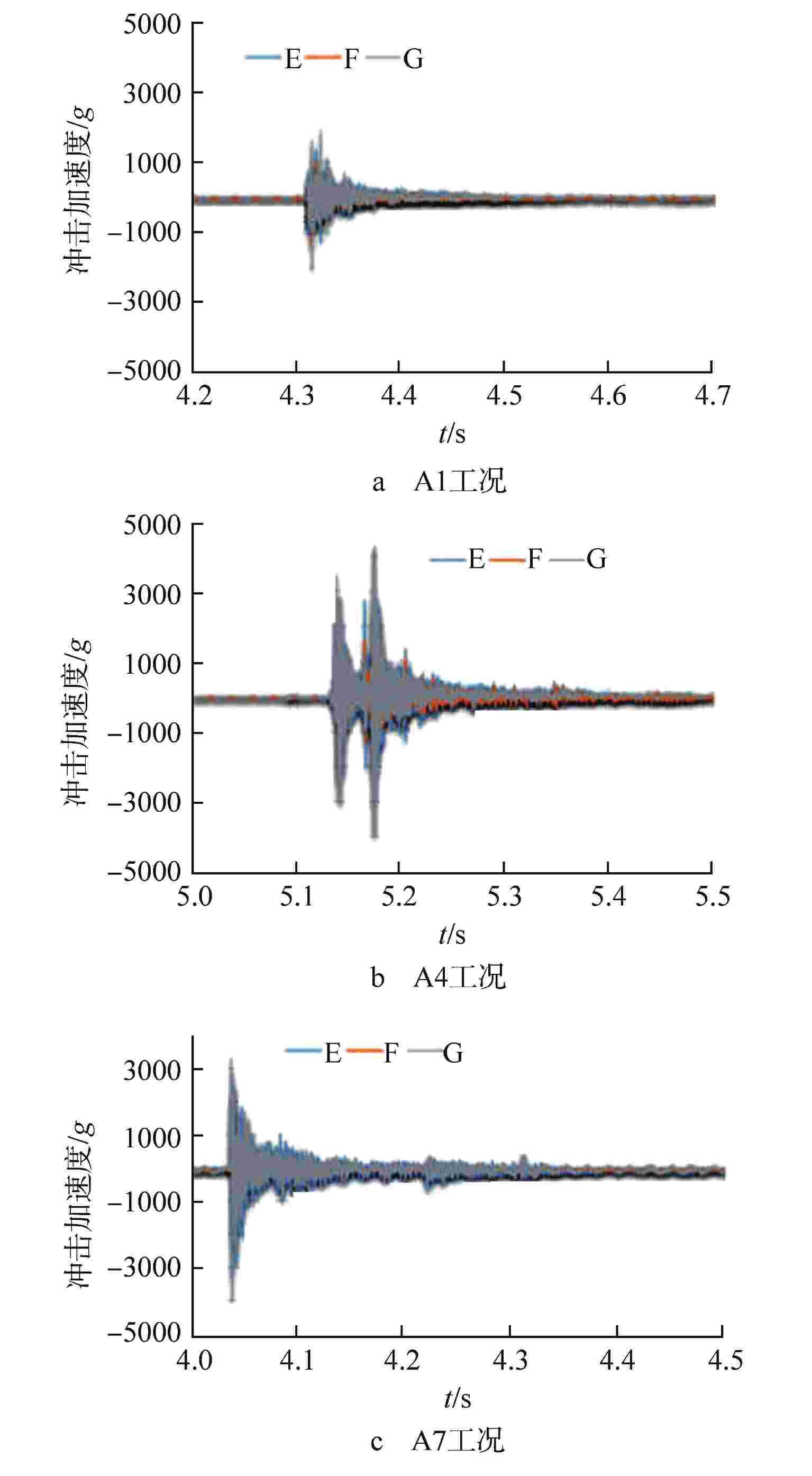

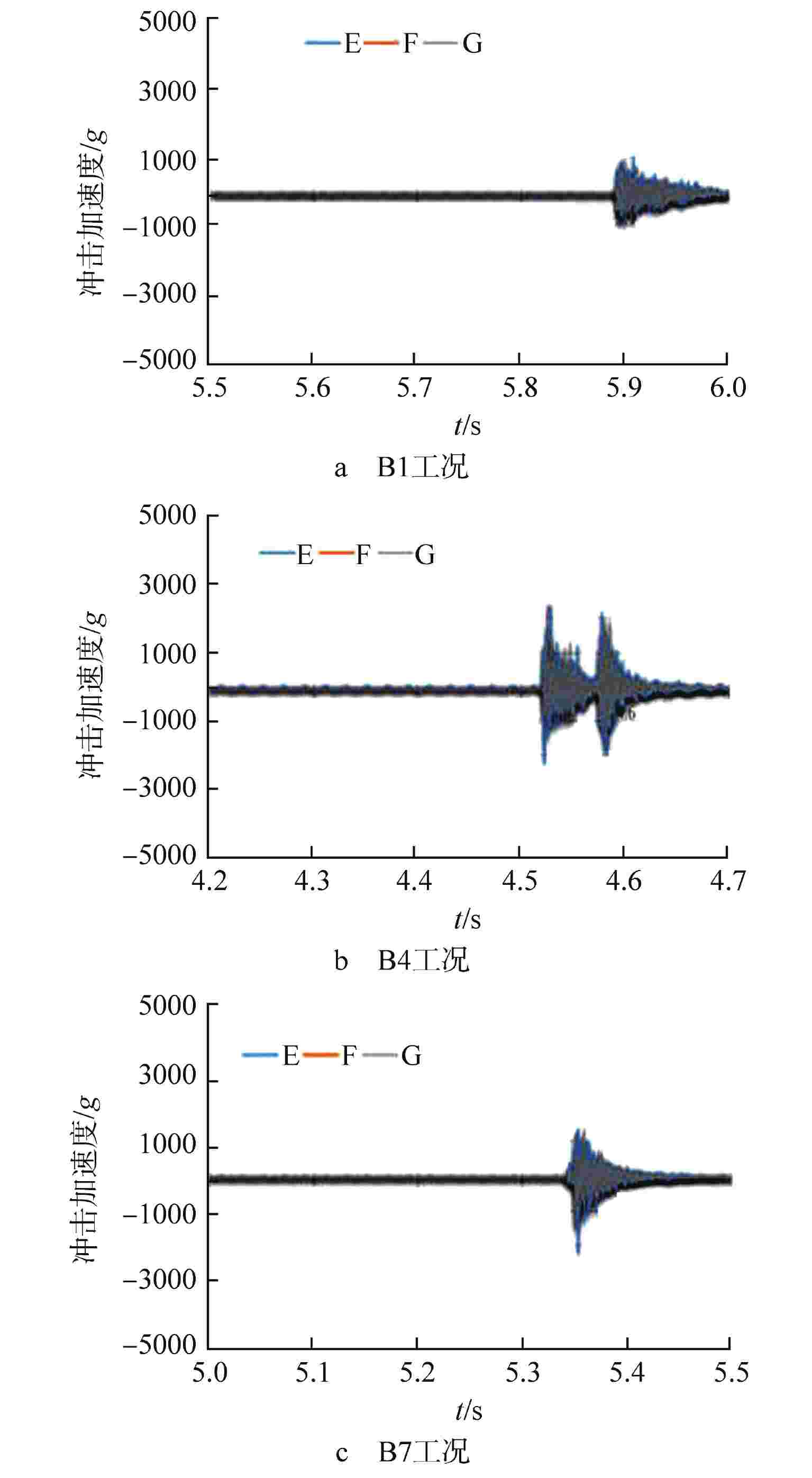

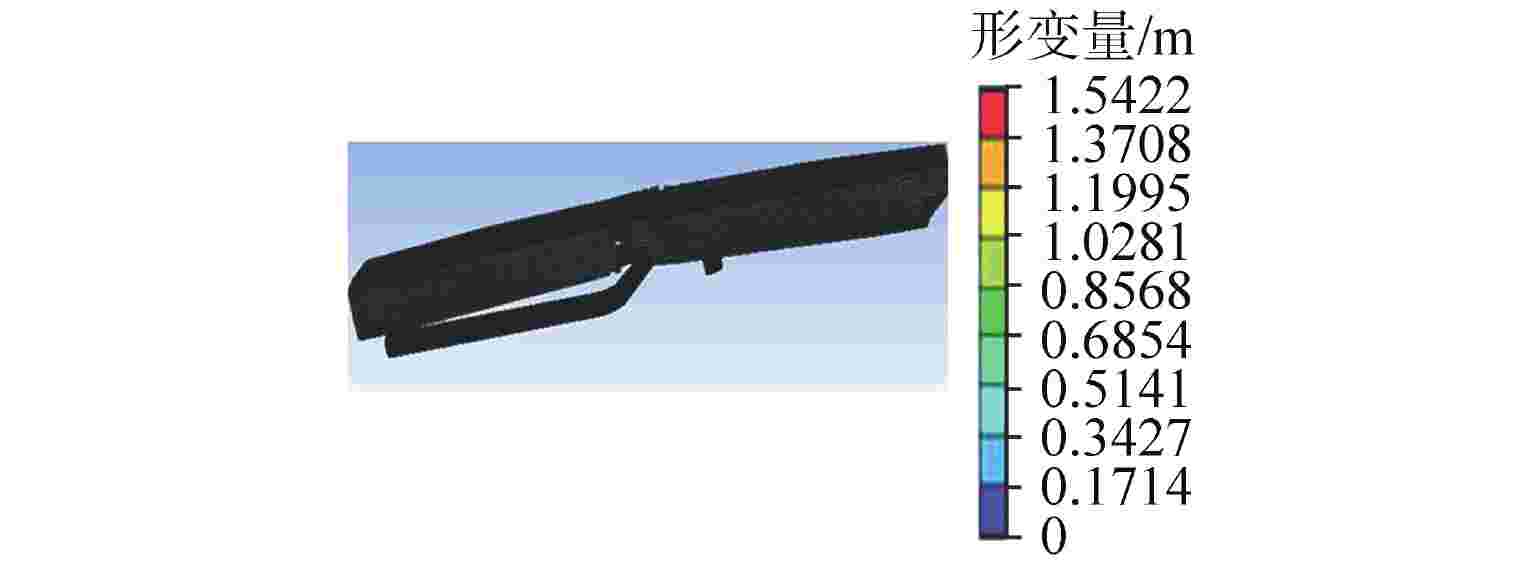

摘要: 为解决秦山核电厂设冷水大厅中安全级与非安全级物项混杂布置、地震工况下可能产生交互作用的问题,采用试验分析方法,对布置在设冷水大厅中的安全级阀门和管道在地震工况下受其他非安全级风管、管道的影响进行研究和分析。试验中1:1复现了秦山核电厂设冷水大厅的物项尺寸和位置高度,通过平落、单摆、倾倒等多种交互方式进行测试,以管道、阀门的保压性能作为破坏准则,并对形变、冲击加速度进行测量和分析。为了验证试验的可靠性,采用数值模拟的方法对风管-管道交互作用的工况进行失效分析和对比,结果与试验方法保持了一致。最终研究结果表明,秦山核电厂设冷水大厅顶部3.6 m高处布置的风管、8 m高处布置的DN50的管道等非安全级物项不会对下方的安全级设冷水母管、阀门的功能和结构完整性产生破坏。Abstract: In order to solve the problems of mixed arrangement of safety-related and non-safety-related items in the equipment cooling water system room of Qinshan Nuclear Power Plant and possible interaction under seismic conditions, by using the method of test and analysis, the safety-related valves and pipes arranged in the equipment cooling water system room are studied and analyzed under the influence of other non-safety-related ducts and pipes under seismic conditions. In the test, the size and height of the items in the equipment cooling water system room of Qinshan Nuclear Power Plant are reproduced 1:1, and the tests are carried out through various interactive methods such as flat fall, single pendulum, and dumping. Taking the pressure retaining performance of pipes and valves as the failure criterion, the deformation and impact acceleration are measured and analyzed. In order to verify the reliability of the test, the numerical simulation method is used to analyze and compare the failure of the duct-pipe interaction conditions, and the results are consistent with the test method. The final research results show that the non-safety-related items such as the duct arranged at 3.6 m above the top of the equipment cooling water system room and the DN50 pipe arranged at 8 m above the top of the equipment cooling water system room in Qinshan Nuclear Power Plant will not damage the function and structural integrity of the safety-related equipment cooling water system header and valve below.

-

Key words:

- Earthquake /

- Interaction /

- Integrity /

- Equipment cooling water system /

- Pipe /

- Valve

-

表 1 交互试验工况表

Table 1. Interactive Test Conditions

交互类型 交互方式 工况序号 交互位置 特征高度/m 风管-安全级母管 单端掉落 A1-A2-A3 1-2-3 3.6 双端掉落 A4-A5-A6-A7 1-2-3-4 管道-安全级阀门 单端掉落 B1-B2-B3 1-2-3 6.83 双端掉落 B4-B5-B6 1-2-3 立管冲击 B7-B8-B9 1-2-3 空格表示“没有高度数据” 表 2 试验用非安全级物项材料及参数表

Table 2. Materials and Parameters of Non-Safety Items for testing

物项类型 风管 DN50管道 材料 DX520D+Z 304L,SMLS 长度/m 8.15 6.83 质量/ kg 692 32.1 高度/m 3.6 6.83 SMLS—处理工艺为无缝钢管 -

[1] 国家质量技术监督局. 核电厂安全重要系统和部件的实体防护: GB/T 13285—1999[S]. 北京: 中国标准出版社, 2004: 4-17. [2] International Atomic Energy Agency. Earthquake experience and seismic qualification by indirect methods in nuclear installations: IAEA-TECDOC-1333[R]. Vienna: IAEA, 2003. [3] JOHNSON J J, GÜRPINAR A, CAMPBELL R D, et al. Seismic design standards and calculational methods in the United States and Japan: NUREG/CR-7230[R]. Washington: U. S. Nuclear Regulatory Commission, 2013 [4] STEVENSON J D. Application of bounding spectra to seismic design of piping based on the performance of above ground piping in power plants subjected to strong motion earthquakes: NUREG/CR-6240[R]. Washington: U. S. Nuclear Regulatory Commission, 1995. [5] Stevenson and Associates. Procedure for seismic evaluation and design of small bore piping (NCIG-14): EPRI NP-6628[R]. Palo Alto: EPRI, 1990. [6] 刘少华. 基于LS-DYNA的轿车保险杠耐撞性研究[D]. 长春: 吉林大学, 2008. [7] 赵海鸥. LS-DYNA动力分析指南[M]. 北京: 兵器工业出版社, 2003, 244-249. [8] 范亚夫,段祝平. Johnson-Cook材料模型参数的实验测定[J]. 力学与实践,2003, 25(5): 40-43. doi: 10.3969/j.issn.1000-0879.2003.05.013 [9] 董菲,GERMAIN G,LEBRUN J L,等. 有限元分析法确定Johson-Cook本构方程材料参数[J]. 上海交通大学学报,2011, 45(11): 1657-1660,1667. [10] Livermore Software Technology Corporation. LS-DYNA® Keyword user’s manual volume II: material models[M]. Livermore: Livermore Software Technology Corporation, 2014, 89-95. -

下载:

下载: