Numerical Study on Heat Transfer Enhancement of Modified Wall in U-tube Steam Generator

-

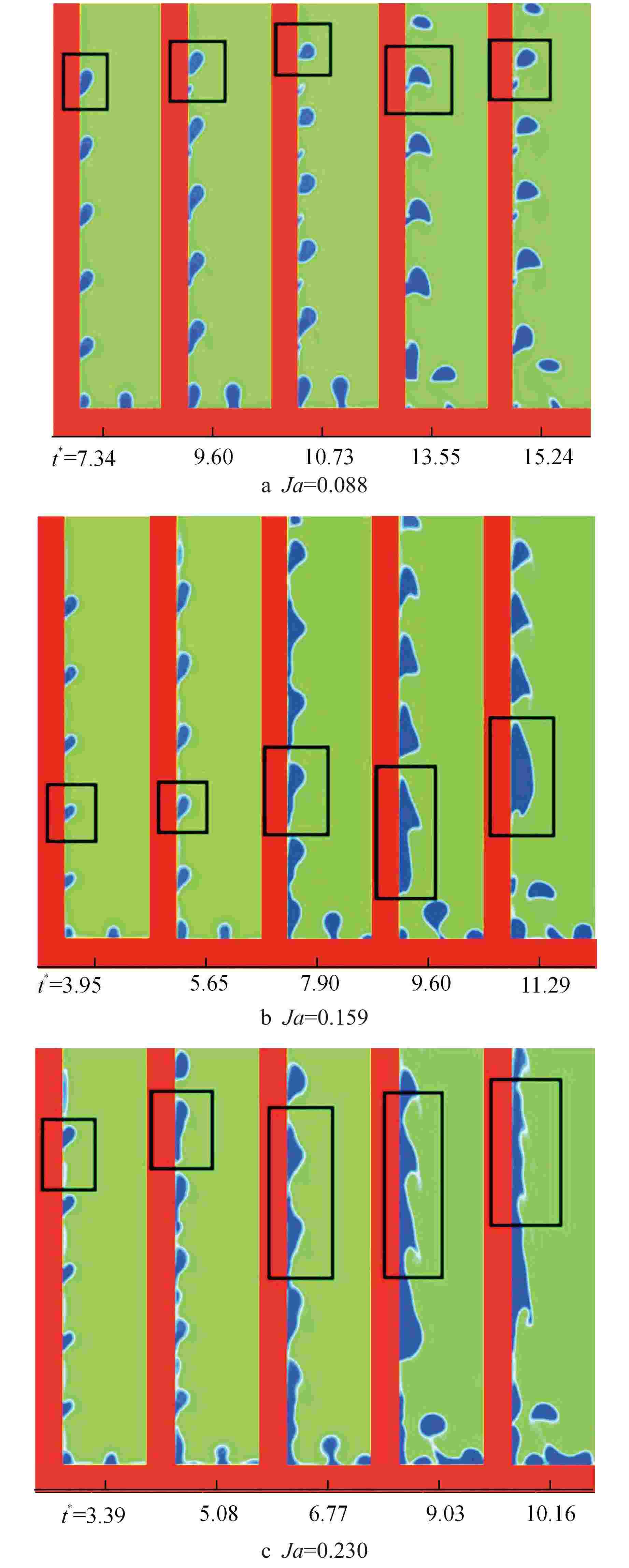

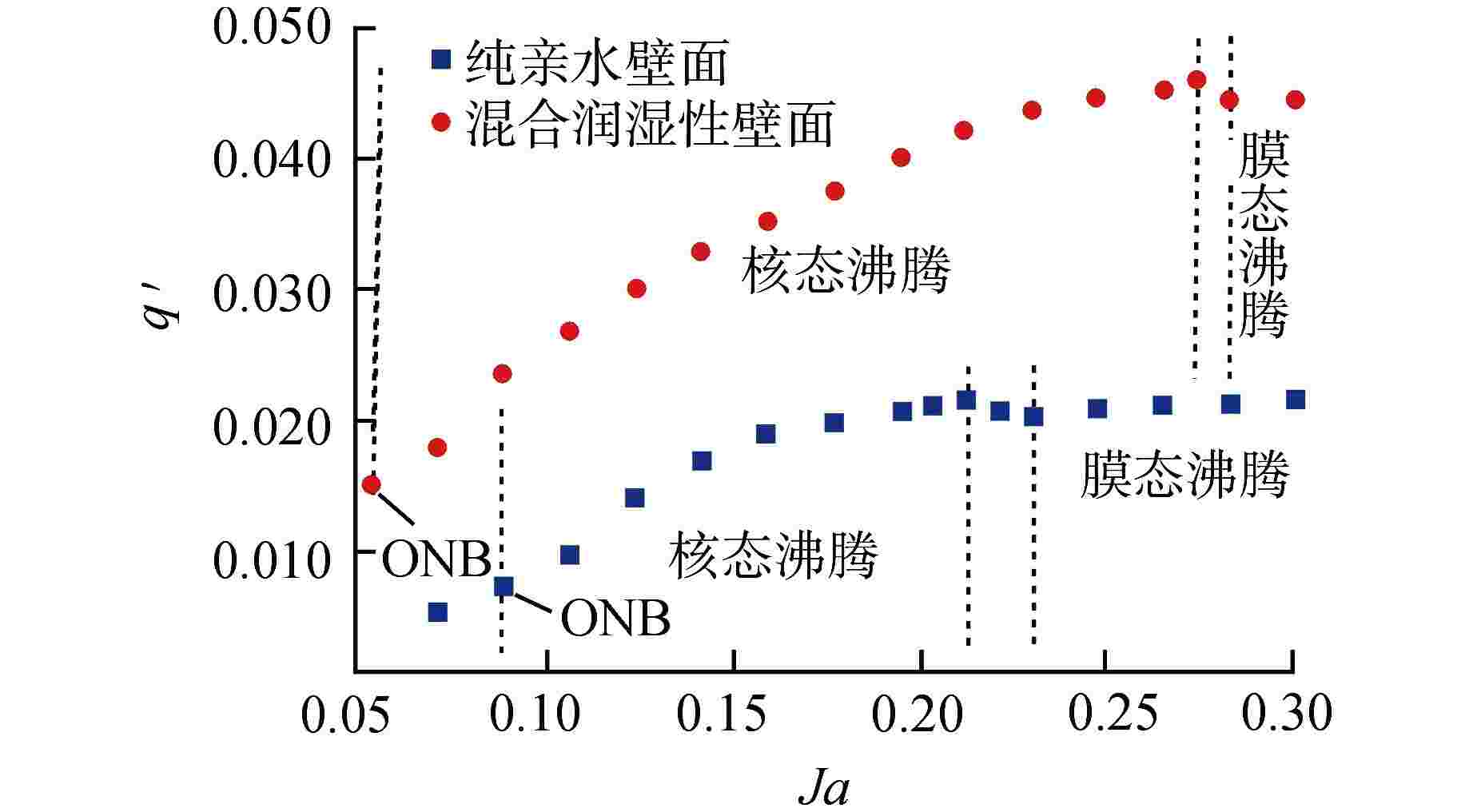

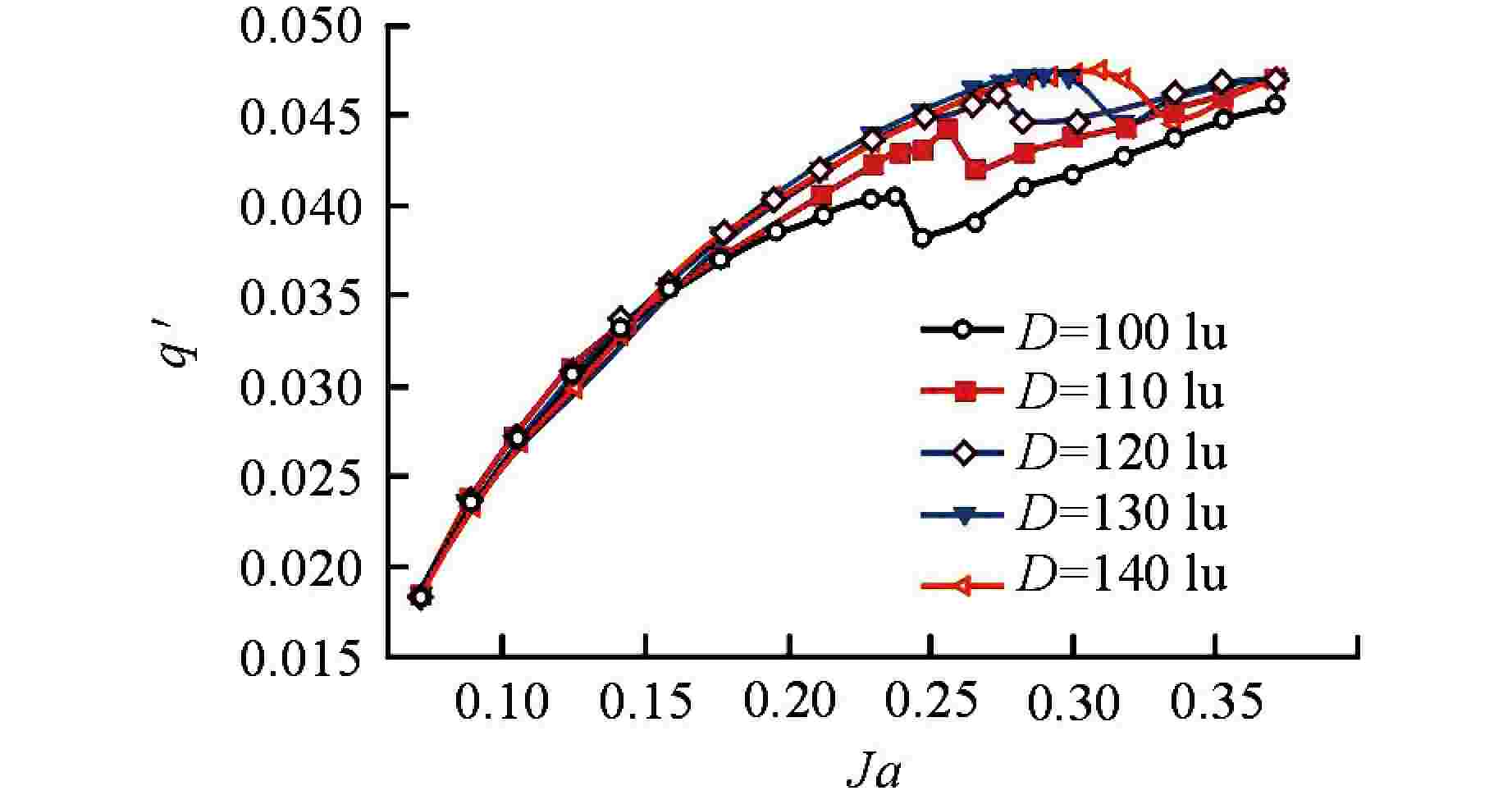

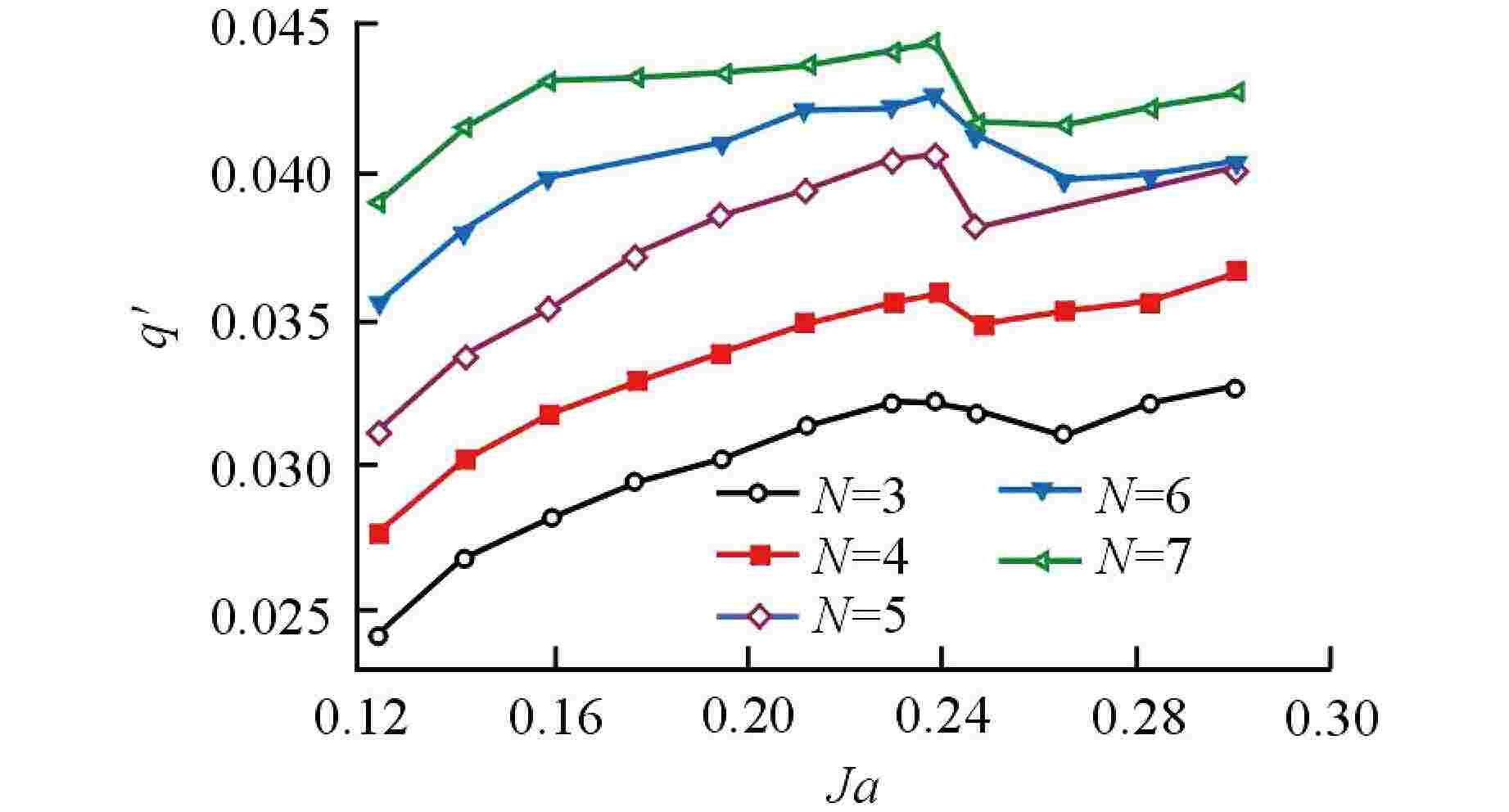

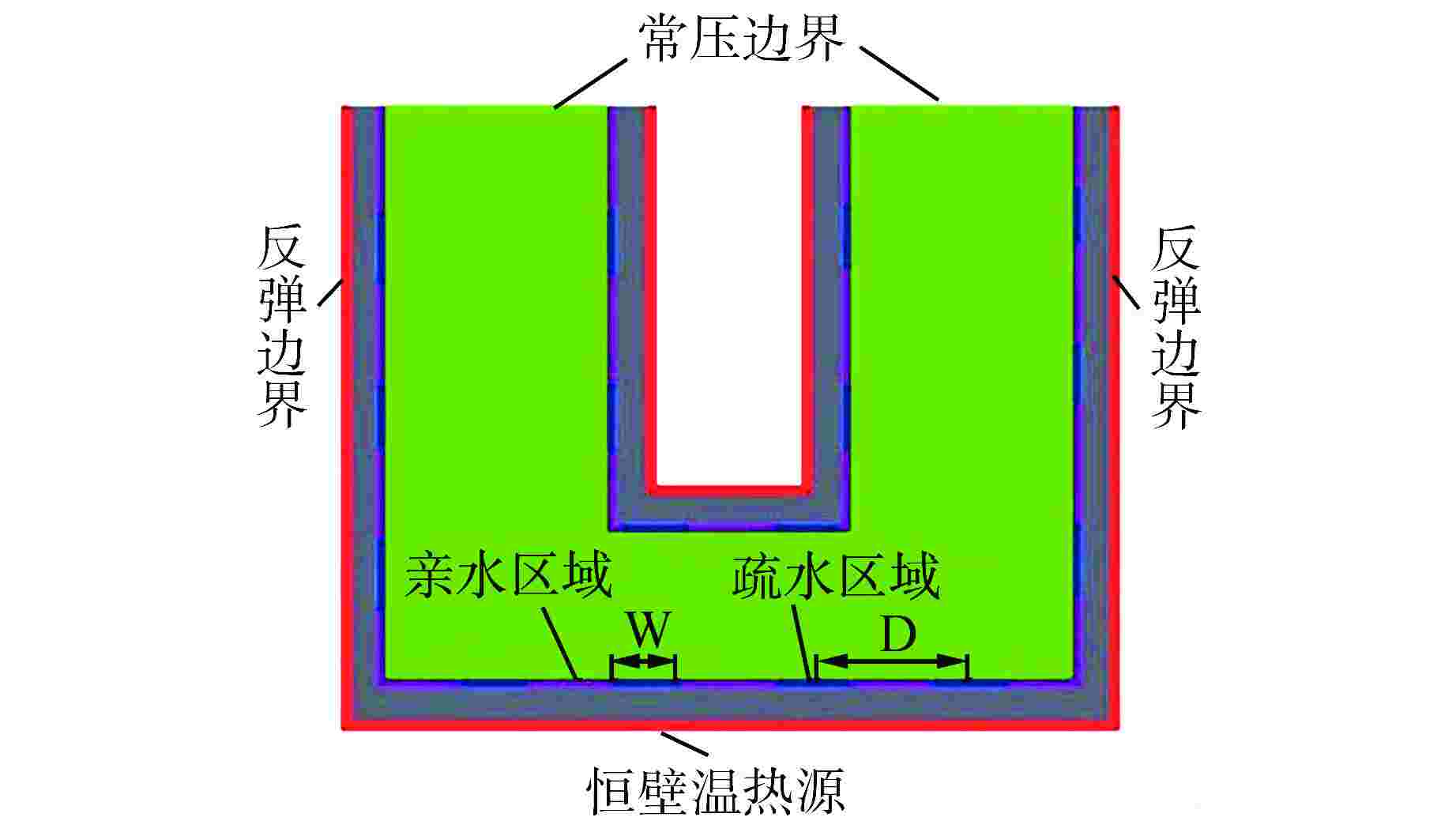

摘要: 为了达到较好的传热效果以及减少传热恶化造成管道破裂等事故的可能,本文基于改进的格子Boltzmann方法(LBM)相变传热模型,对蒸汽发生器U型传热管内工质的气泡动力学行为和壁面的传热性能进行了数值研究。结果表明:与纯亲水壁面相比,疏水区域促进气泡成核,混合润湿性壁面可以显著提高沸腾传热量。混合润湿性壁面可以提高临界热流密度(CHF),并延迟CHF点的出现,可以有效地减小传热恶化的可能。总体上,疏水点间距和个数决定气泡的生长状态,存在一个最佳疏水点设置可以获得最佳沸腾传热性能,选择合适的疏水点间距和个数可以得到理想的传热壁面。

-

关键词:

- 蒸汽发生器U型管 /

- 强化换热 /

- 格子Boltzmann方法(LBM) /

- 混合润湿性

Abstract: In order to achieve better heat transfer effect and reduce the possibility of pipe rupture caused by heat transfer deterioration, based on the improved lattice Boltzmann method (LBM) phase transition heat transfer model, the bubble dynamics behavior and wall heat transfer performance of working medium in U-shaped heat transfer tube of steam generator were studied numerically. The results show that compared with the pure hydrophilic wall, the hydrophobic zone promotes bubble nucleation, and the wall with mixed wettability can significantly increase the boiling heat transfer. The wall with mixed wettability can increase the critical heat flux (CHF) and delay the occurrence of CHF point, which can effectively reduce the possibility of heat transfer deterioration. Generally speaking, the distance and number of hydrophobic points determine the growth state of bubbles, the best boiling heat transfer performance can be obtained if there is an optimal setting of hydrophobic points, and the ideal heat transfer wall can be obtained by selecting appropriate distance and number of hydrophobic points. -

表 1 物性参数设置

Table 1. Physical Parameter Settings

参数名 参数值 参数名 参数值 液体饱和温度(Ts) 0.9Tc 重力加速度(G) 0.00003 饱和液体(ρl) 5.9 饱和蒸汽(ρv) 0.58 动力粘度(μ) 0.354 热扩散系数(α) 0.05 表面张力(σ) 0.088 汽化潜热(hfg) 0.33 润湿性(θ亲水) 60° 润湿性(θ疏水) 100° -

[1] 吴宜灿,柏云清,宋勇,等. 中国铅基研究反应堆概念设计研究[J]. 核科学与工程,2014, 34(2): 201-208. [2] 魏诗颖,王成龙,田文喜,等. 铅基快堆关键热工水力问题研究综述[J]. 原子能科学技术,2019, 53(2): 326-336. doi: 10.7538/yzk.2018.youxian.0335 [3] 张朝东. 蒸汽发生器管道破裂对铅基堆热工安全特性影响分析研究[D]. 合肥: 中国科学技术大学, 2018. [4] SUROTO B J, TASHIRO M, HIRABAYASHI S, et al. Effects of hydrophobic-spot periphery and subcooling on nucleate pool boiling from a mixed-wettability surface[J]. Journal of Thermal Science and Technology, 2013, 8(1): 294-308. doi: 10.1299/jtst.8.294 [5] BETZ A R, JENKINS J, KIM C J, et al. Boiling heat transfer on superhydrophilic, superhydrophobic, and superbiphilic surfaces[J]. International Journal of Heat and Mass Transfer, 2013, 57(2): 733-741. doi: 10.1016/j.ijheatmasstransfer.2012.10.080 [6] JO H, KIM S, PARK H S, et al. Critical heat flux and nucleate boiling on several heterogeneous wetting surfaces: controlled hydrophobic patterns on a hydrophilic substrate[J]. International Journal of Multiphase Flow, 2014, 62: 101-109. doi: 10.1016/j.ijmultiphaseflow.2014.02.006 [7] MOTEZAKKER A R, SADAGHIANI A K, ÇELIK S, et al. Optimum ratio of hydrophobic to hydrophilic areas of biphilic surfaces in thermal fluid systems involving boiling[J]. International Journal of Heat and Mass Transfer, 2019, 135: 164-174. doi: 10.1016/j.ijheatmasstransfer.2019.01.139 [8] LIN Y H, LUO Y, LI J Y, et al. Heat transfer, pressure drop and flow patterns of flow boiling on heterogeneous wetting surface in a vertical narrow microchannel[J]. International Journal of Heat and Mass Transfer, 2021, 172: 121158. doi: 10.1016/j.ijheatmasstransfer.2021.121158 [9] GONG S, CHENG P. Numerical simulation of pool boiling heat transfer on smooth surfaces with mixed wettability by lattice Boltzmann method[J]. International Journal of Heat and Mass Transfer, 2015, 80: 206-216. doi: 10.1016/j.ijheatmasstransfer.2014.08.092 [10] FENG Y, CHANG F C, HU Z T, et al. Investigation of pool boiling heat transfer on hydrophilic-hydrophobic mixed surface with micro-pillars using LBM[J]. International Journal of Thermal Sciences, 2021, 163: 106814. doi: 10.1016/j.ijthermalsci.2020.106814 [11] ZHAO Z C, ZHANG J J, JIA D D, et al. Thermal performance analysis of pool boiling on an enhanced surface modified by the combination of microstructures and wetting properties[J]. Applied Thermal Engineering, 2017, 117: 417-426. doi: 10.1016/j.applthermaleng.2017.02.014 [12] YUAN J J, YE X, SHAN Y G. Modeling of the bubble dynamics and heat flux variations during lateral coalescence of bubbles in nucleate pool boiling[J]. International Journal of Multiphase Flow, 2021, 142: 103701. doi: 10.1016/j.ijmultiphaseflow.2021.103701 [13] YUAN J J, WENG Z H, SHAN Y G. Modelling of double bubbles coalescence behavior on different wettability walls using LBM method[J]. International Journal of Thermal Sciences, 2021, 168: 107037. doi: 10.1016/j.ijthermalsci.2021.107037 [14] GONG S, CHENG P. Lattice Boltzmann simulation of periodic bubble nucleation, growth and departure from a heated surface in pool boiling[J]. International Journal of Heat and Mass Transfer, 2013, 64: 122-132. doi: 10.1016/j.ijheatmasstransfer.2013.03.058 -

下载:

下载: