Temperature Field Calculation of Spherical Fuel Element Based on Online Coupling

-

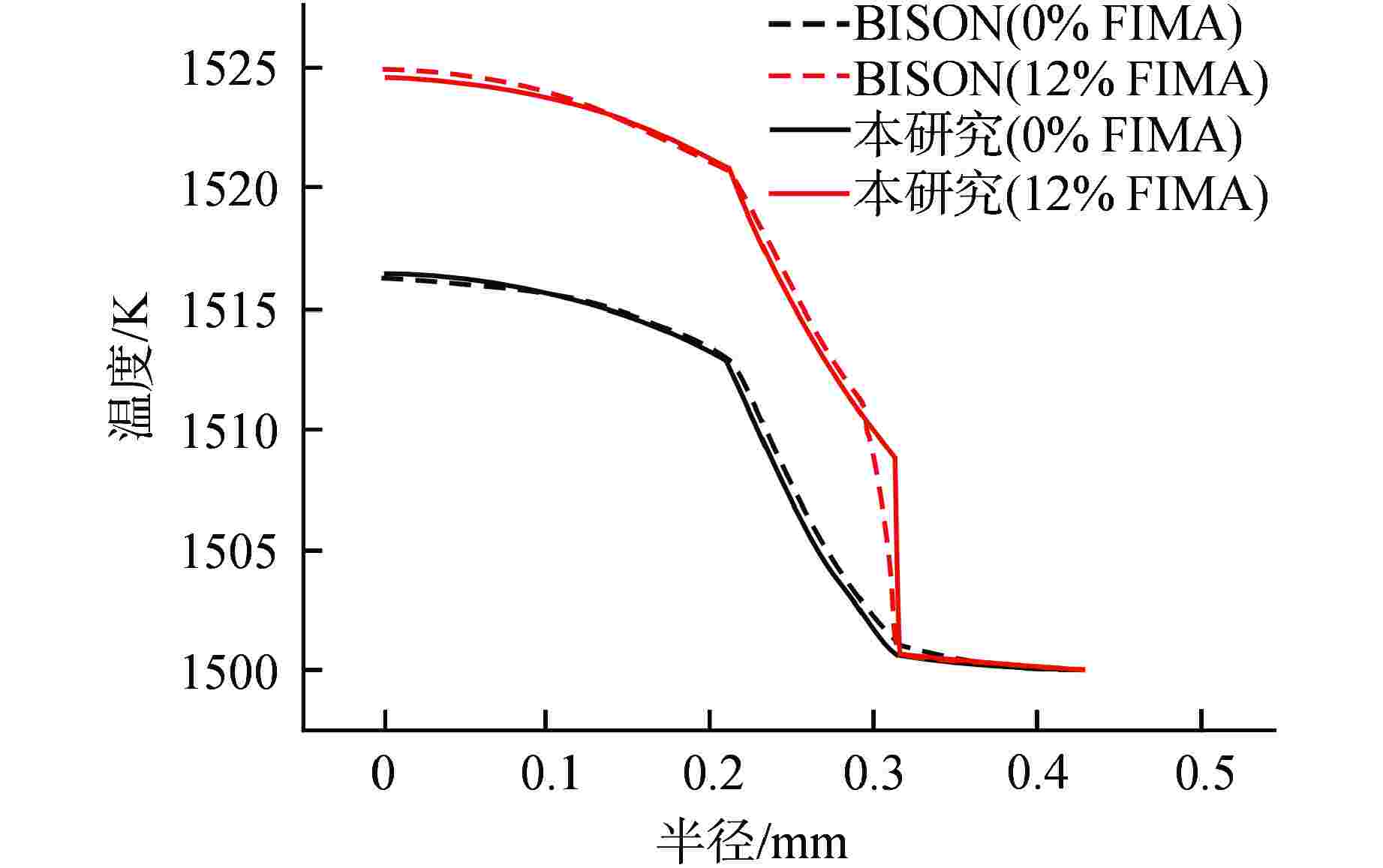

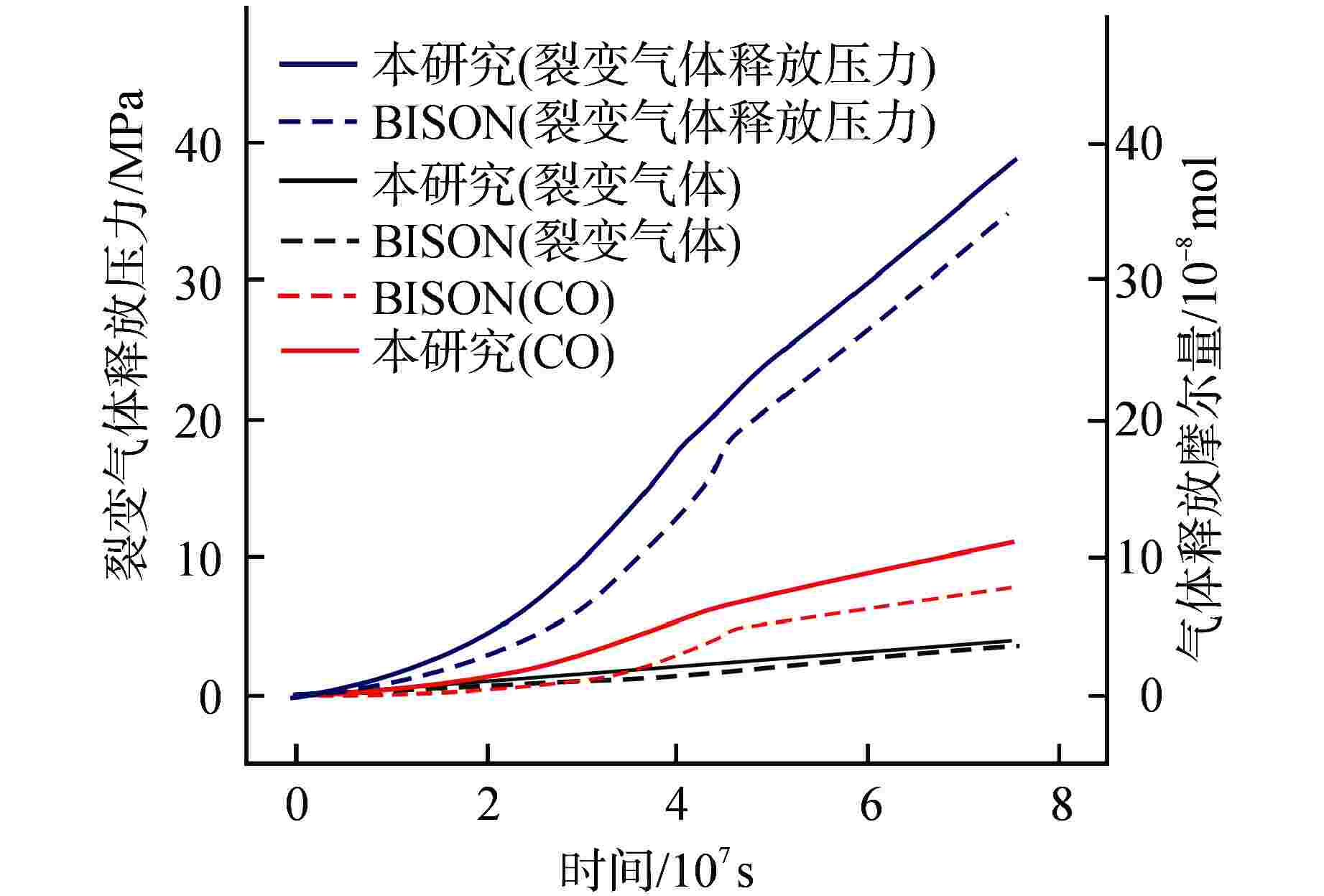

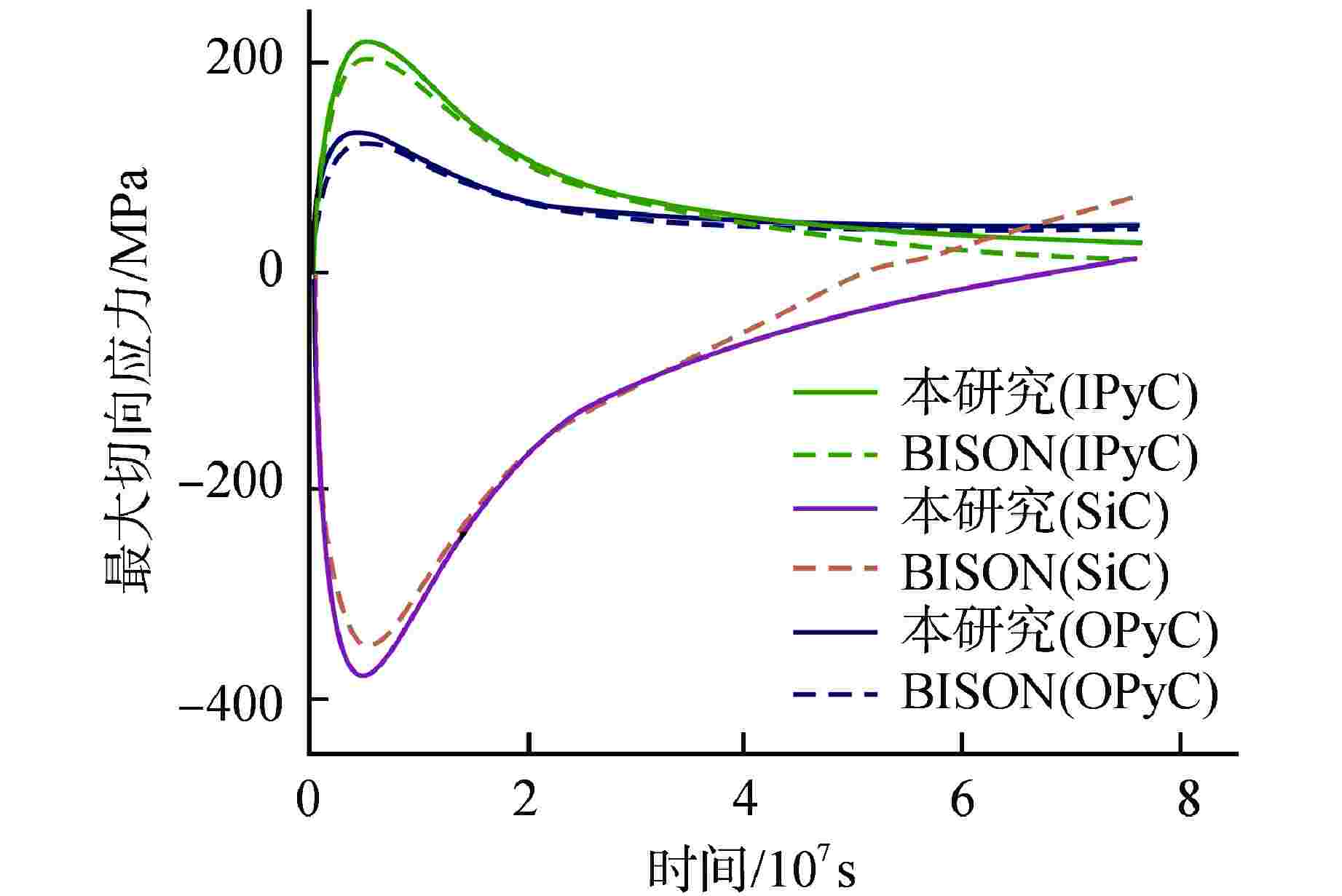

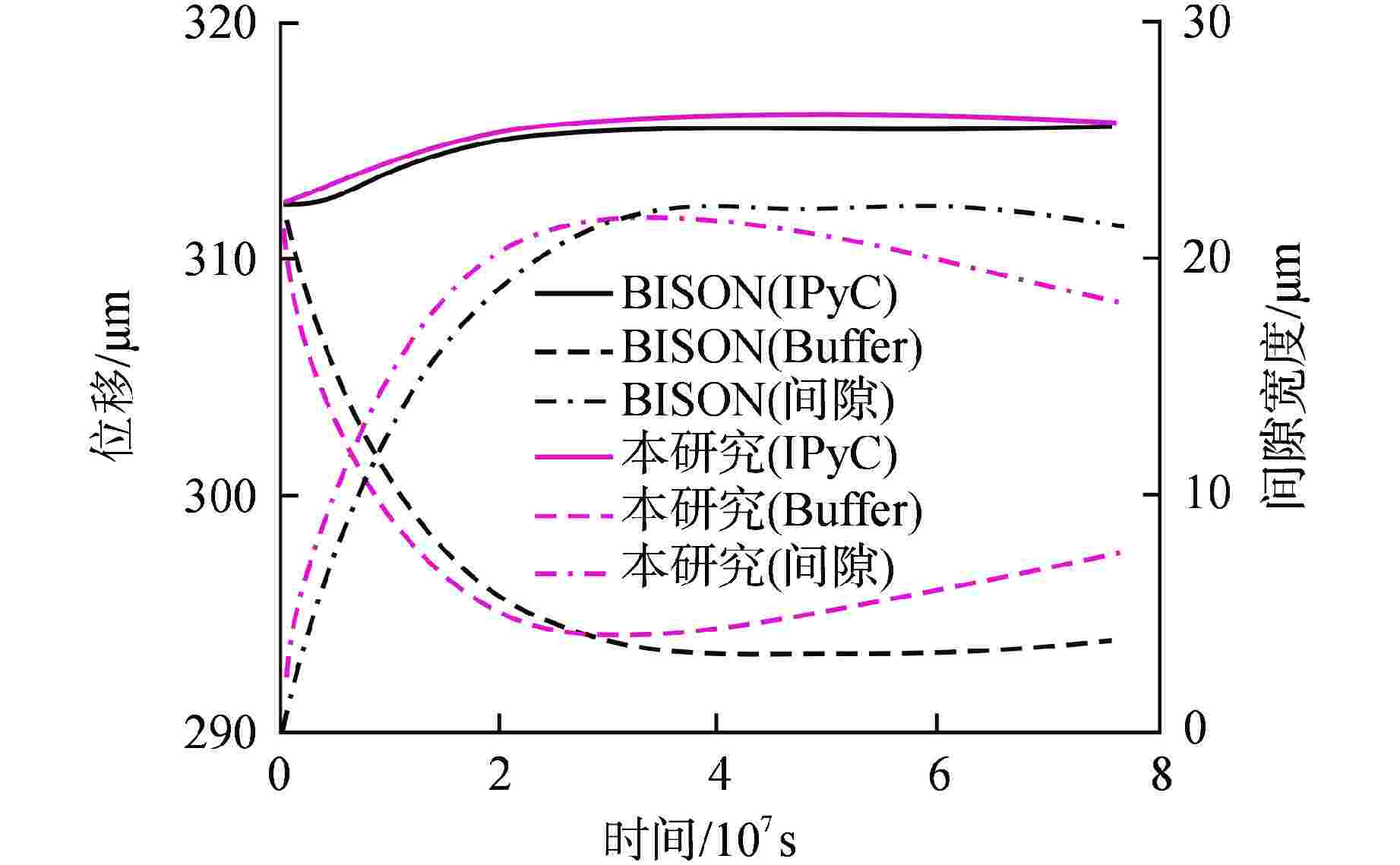

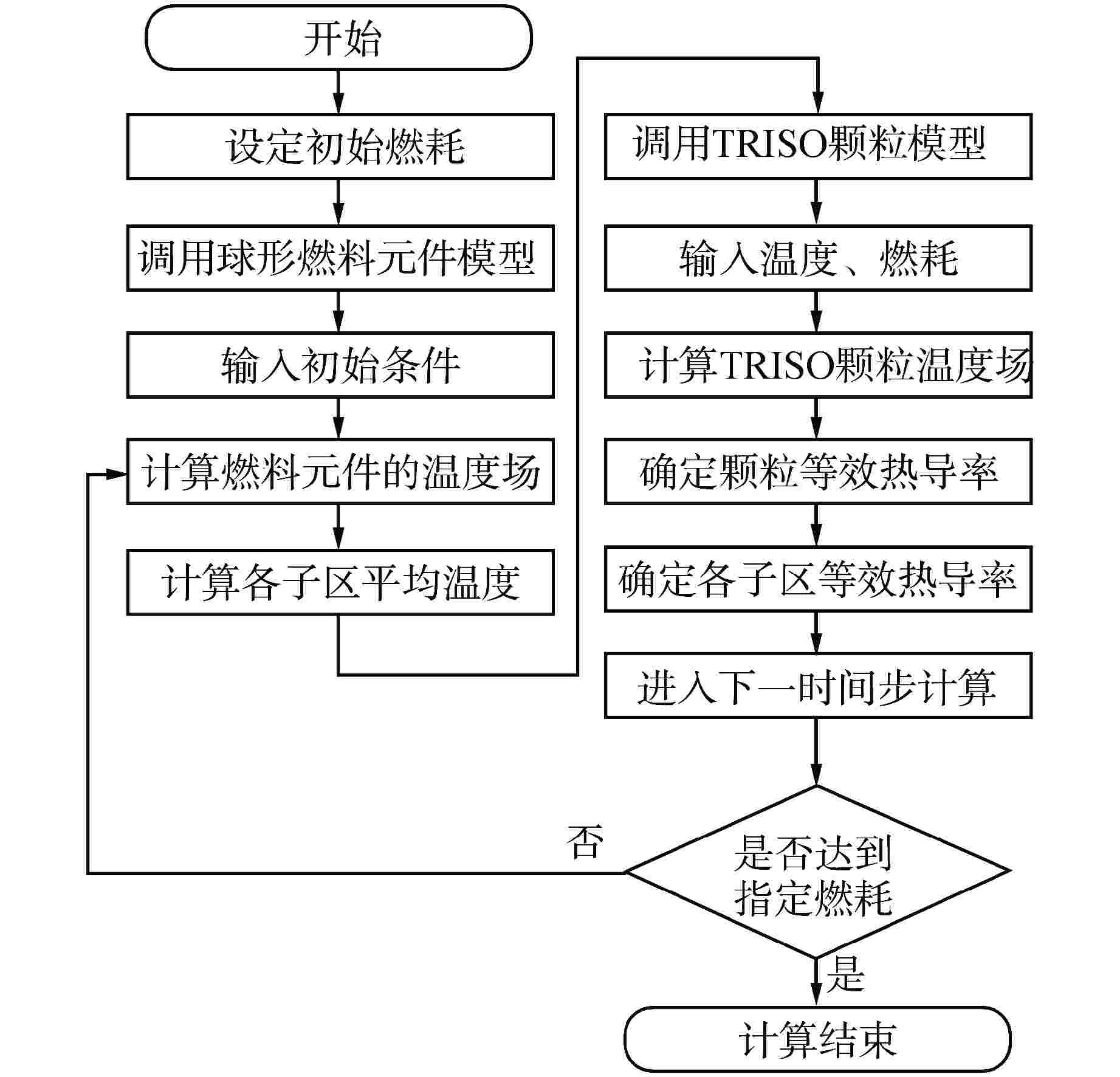

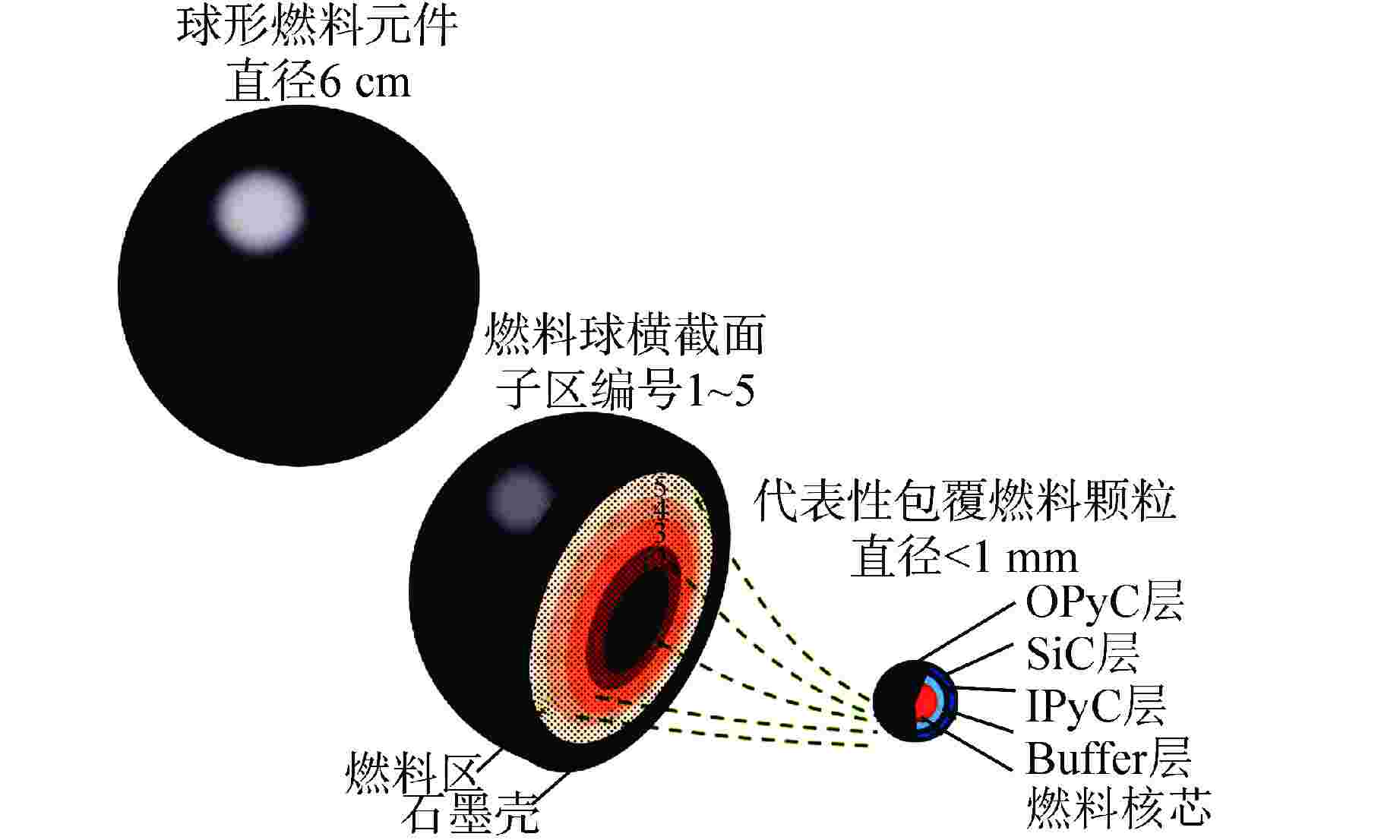

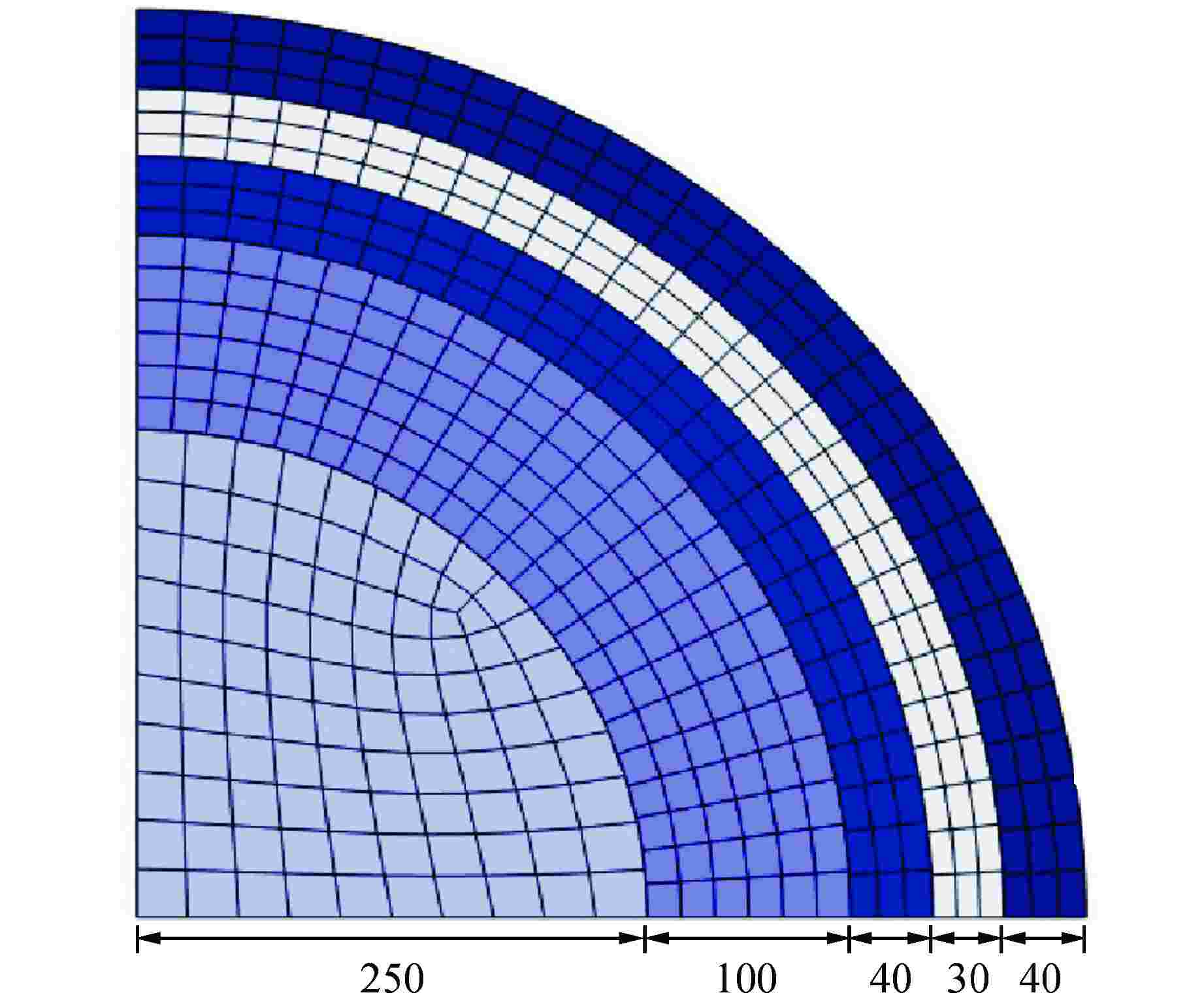

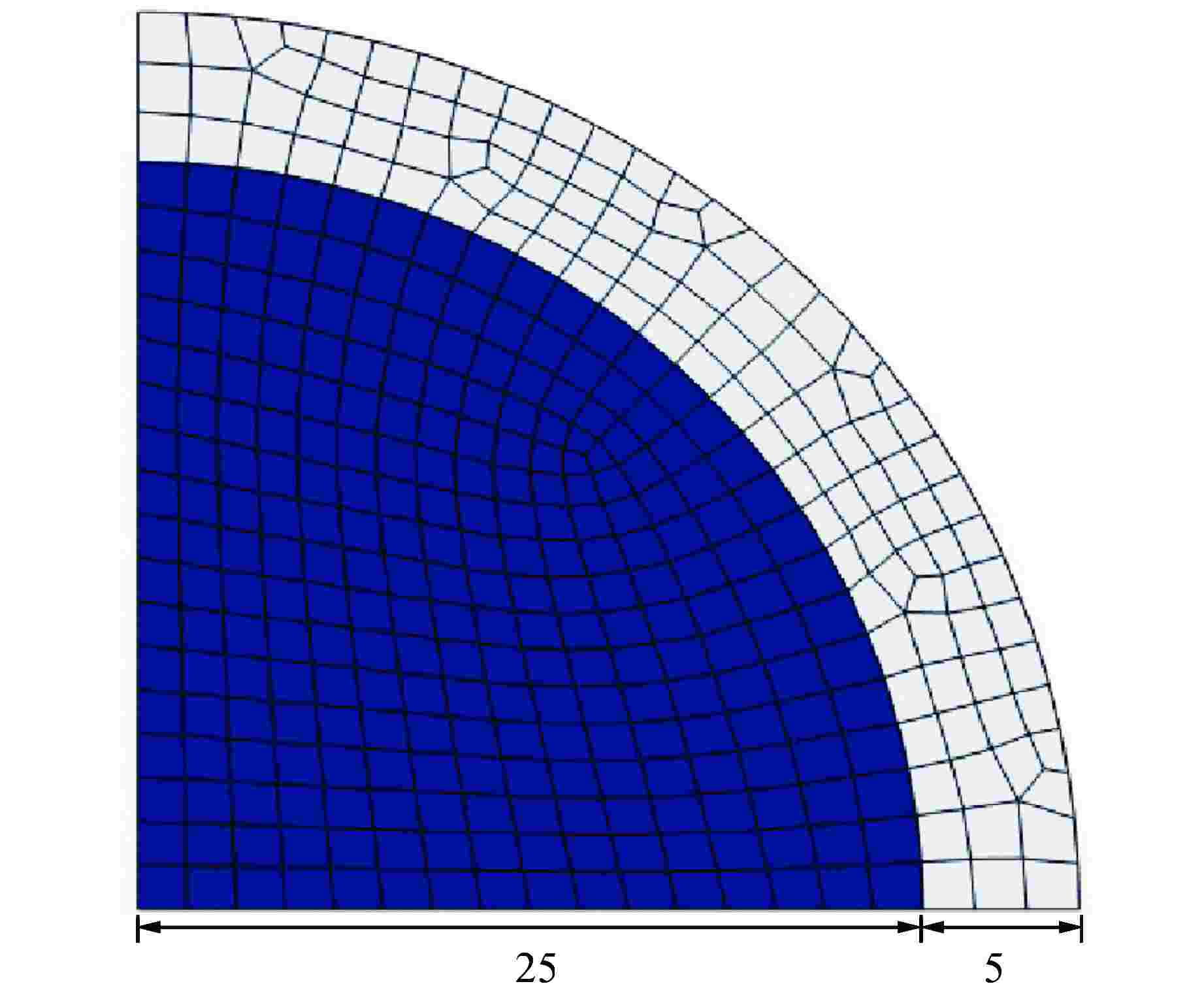

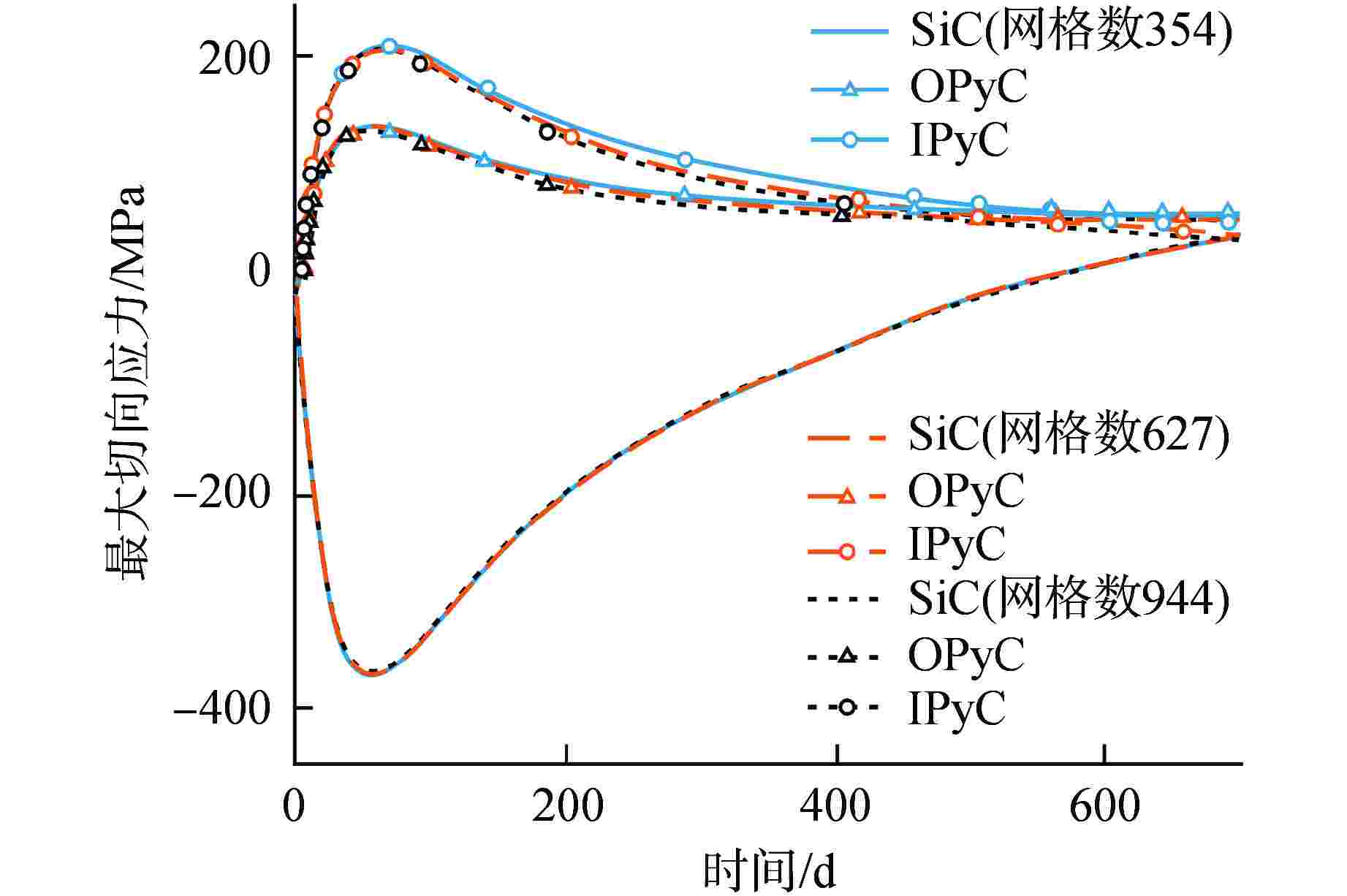

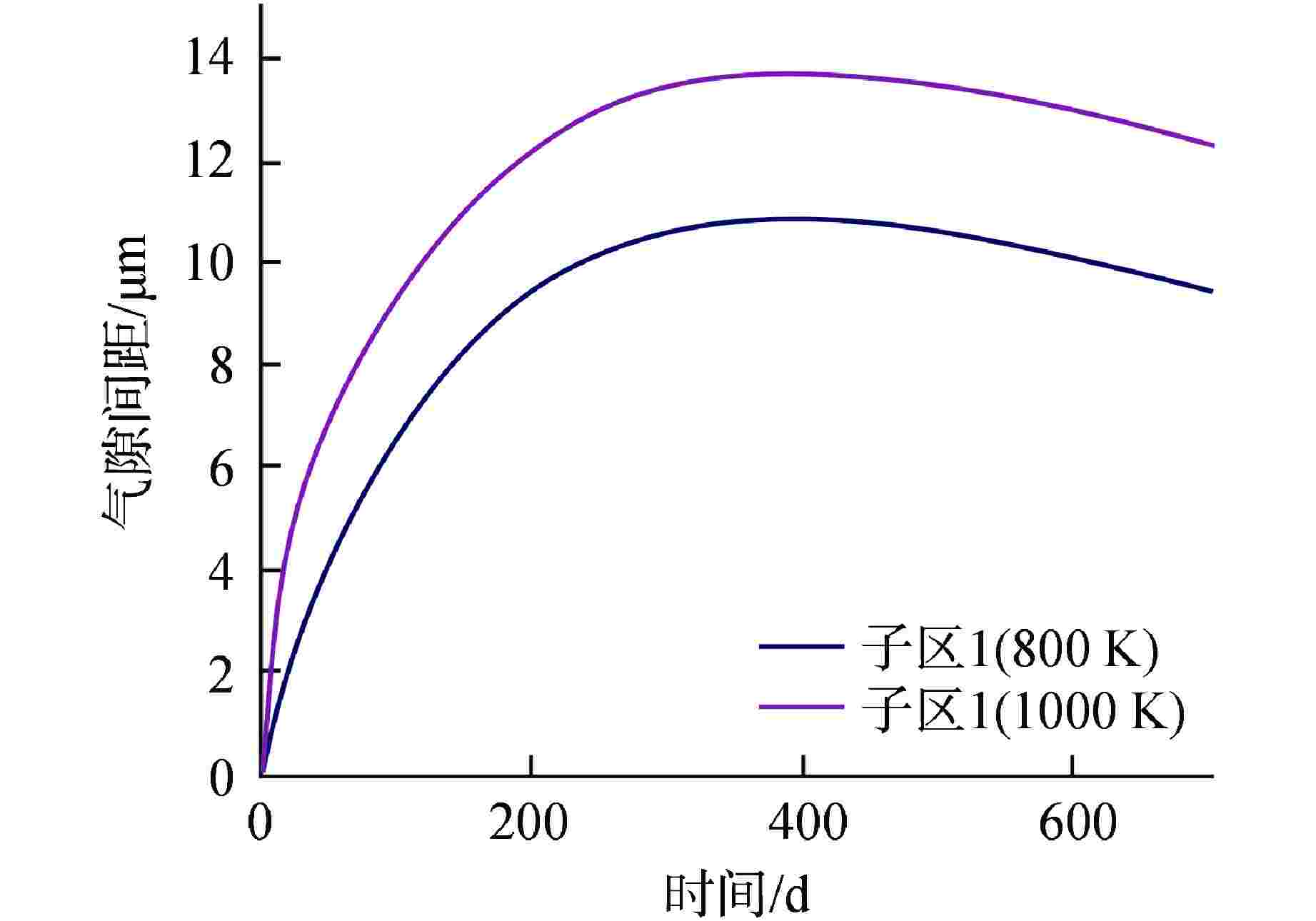

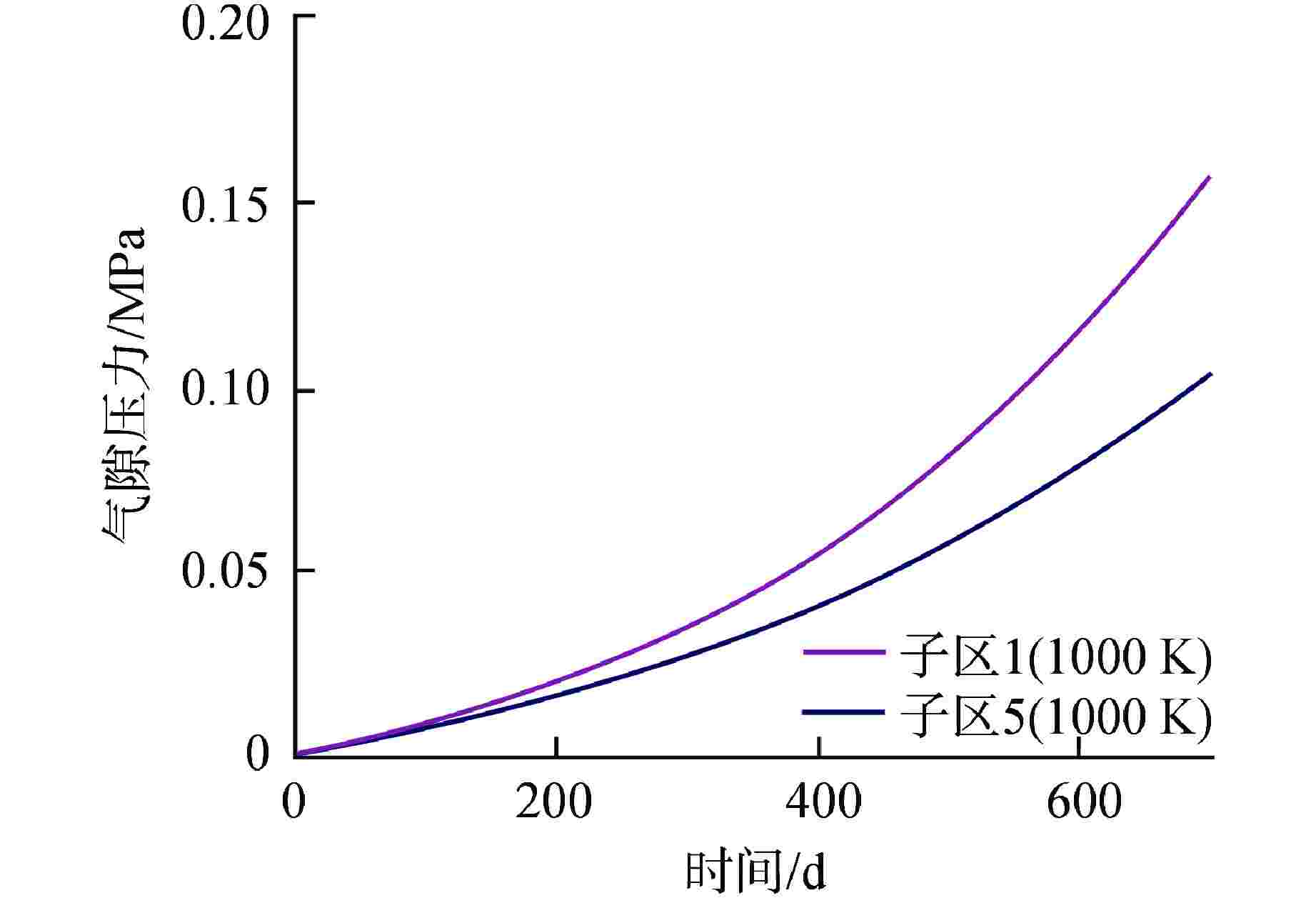

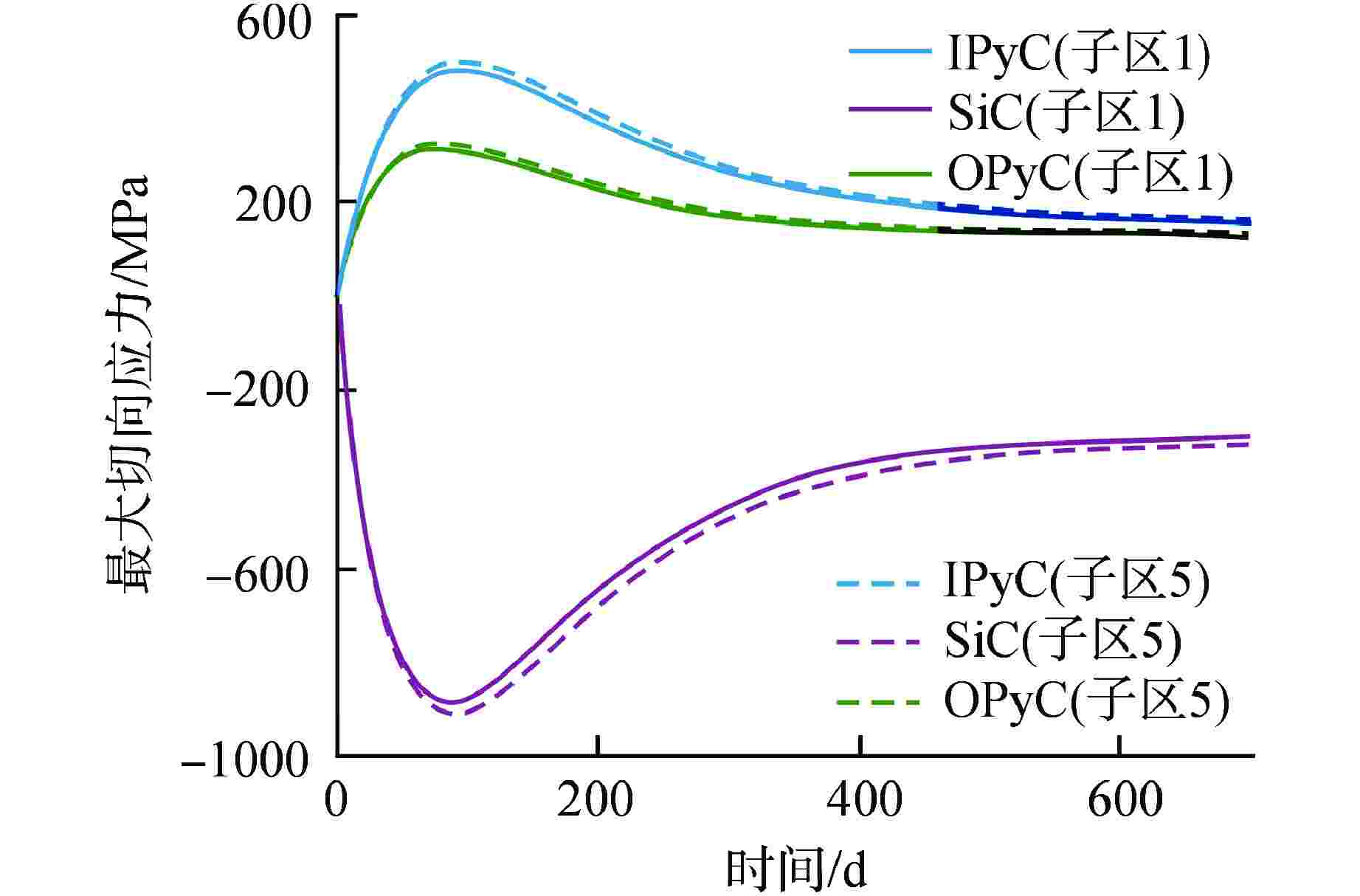

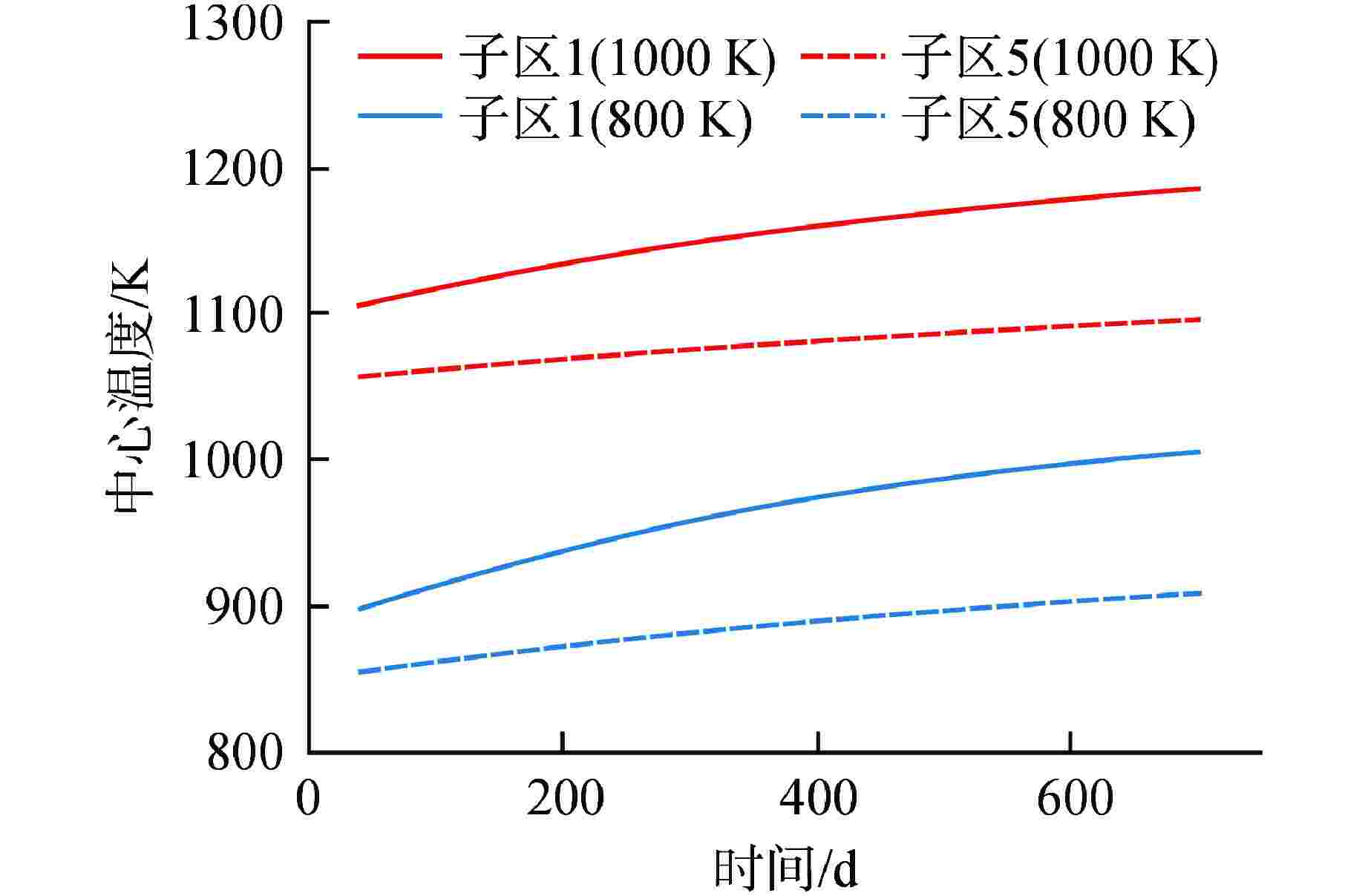

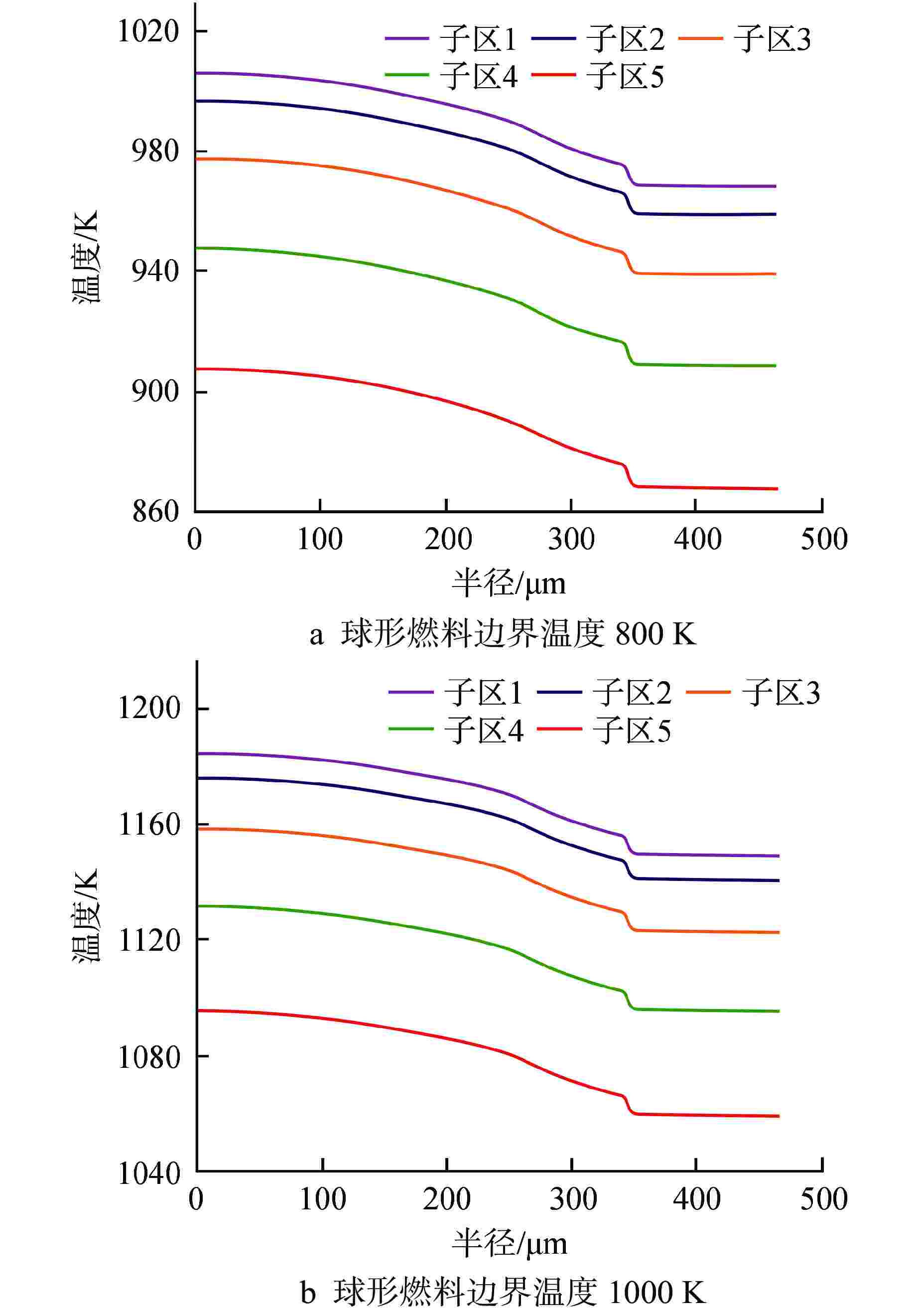

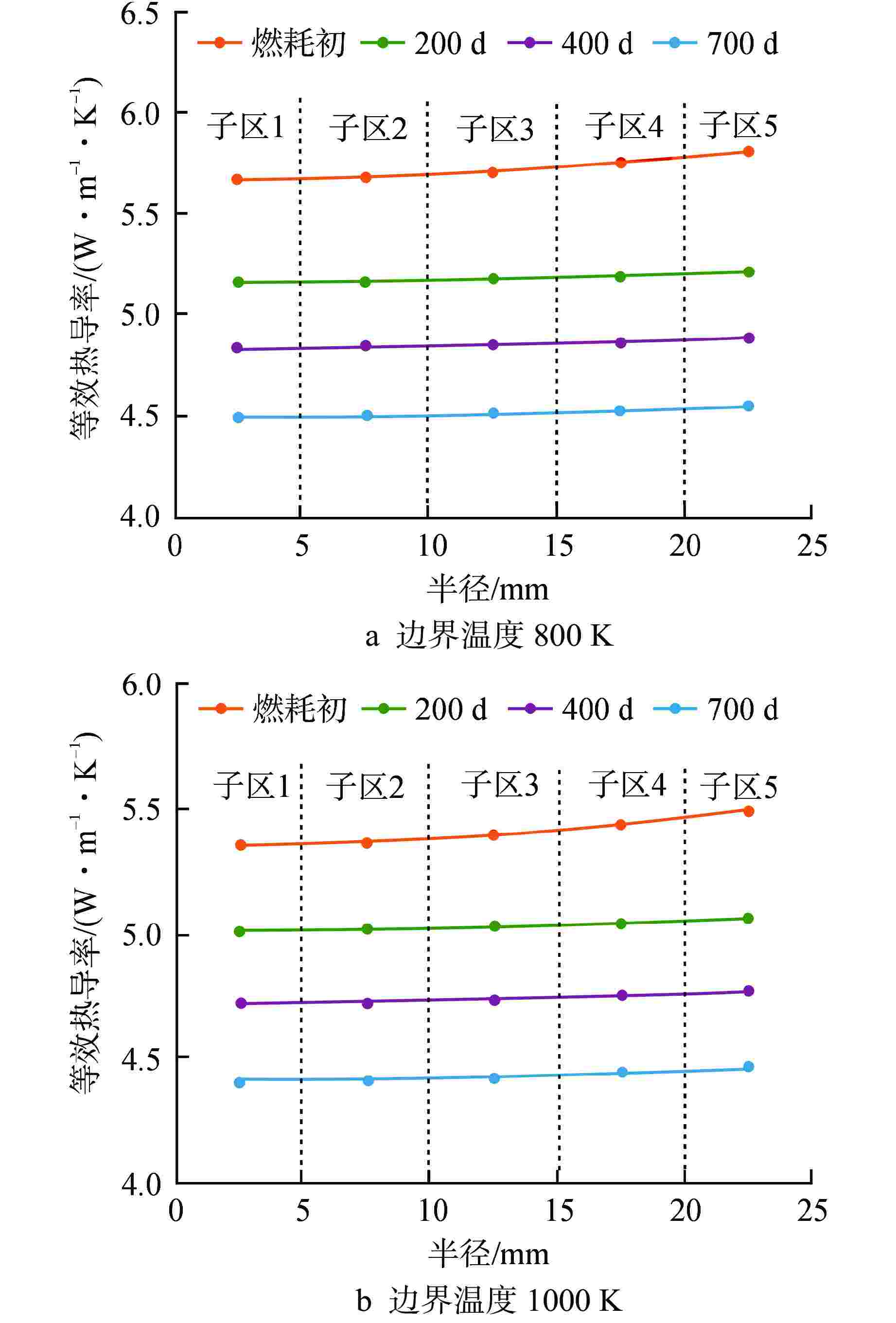

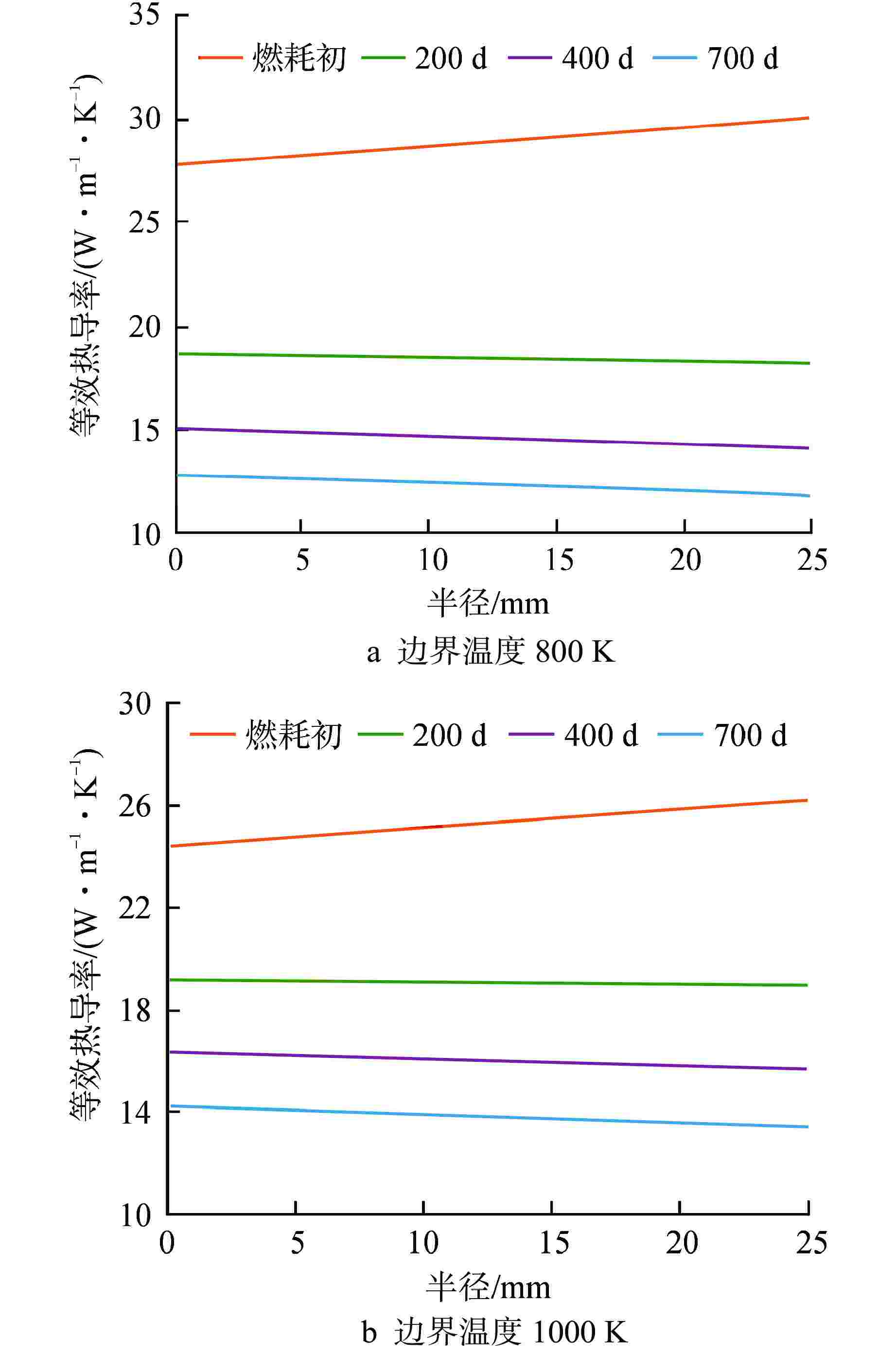

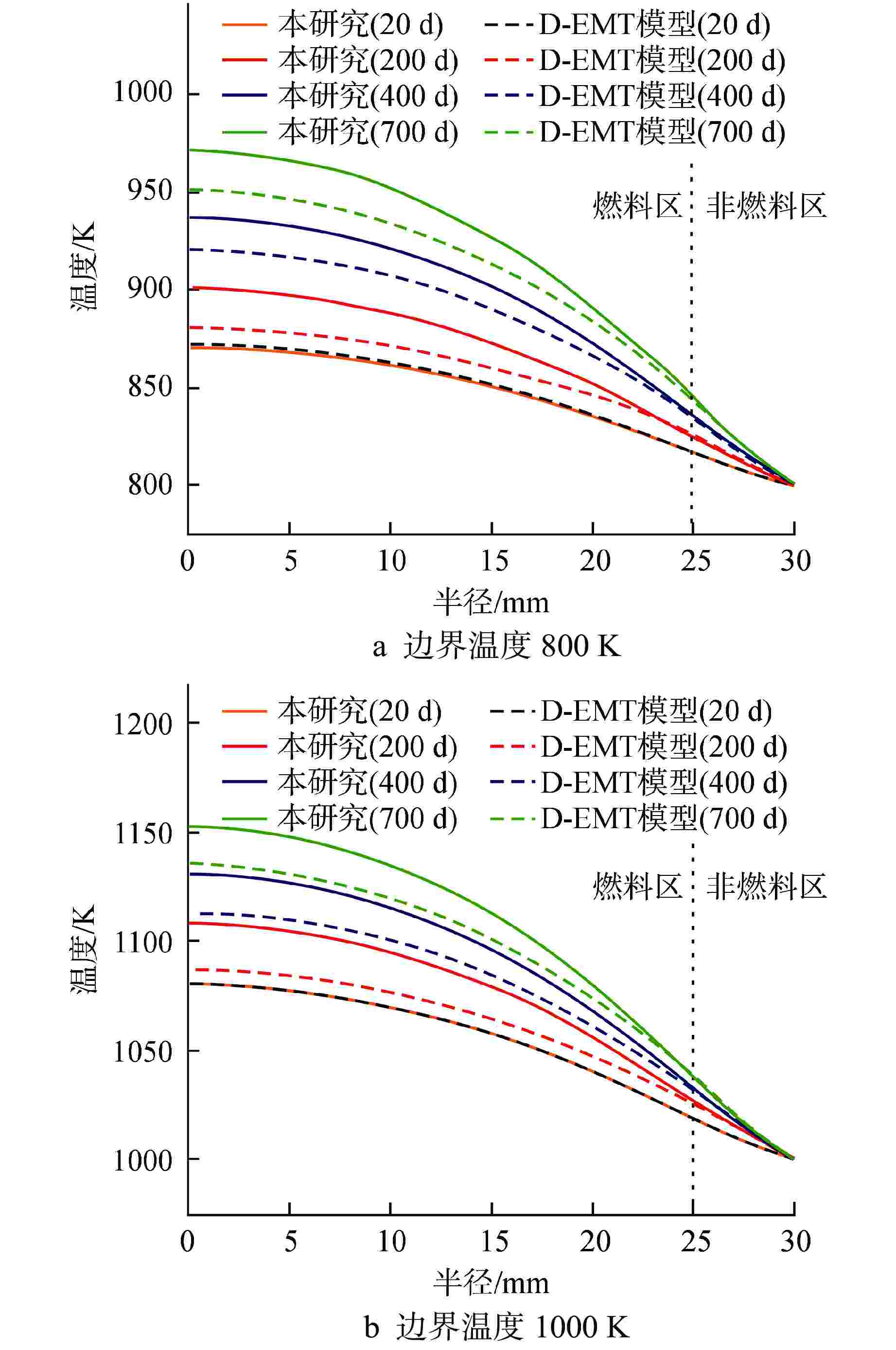

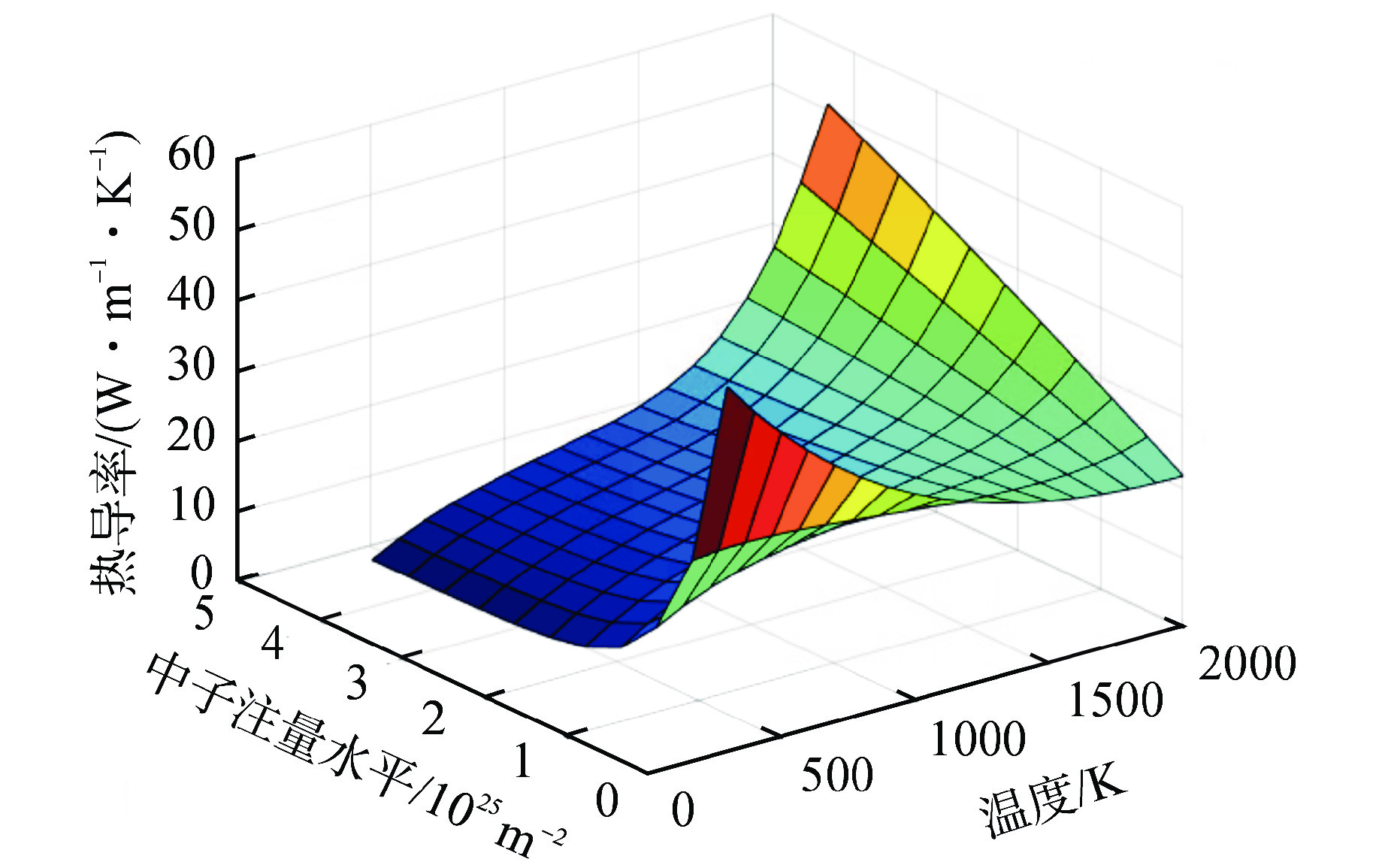

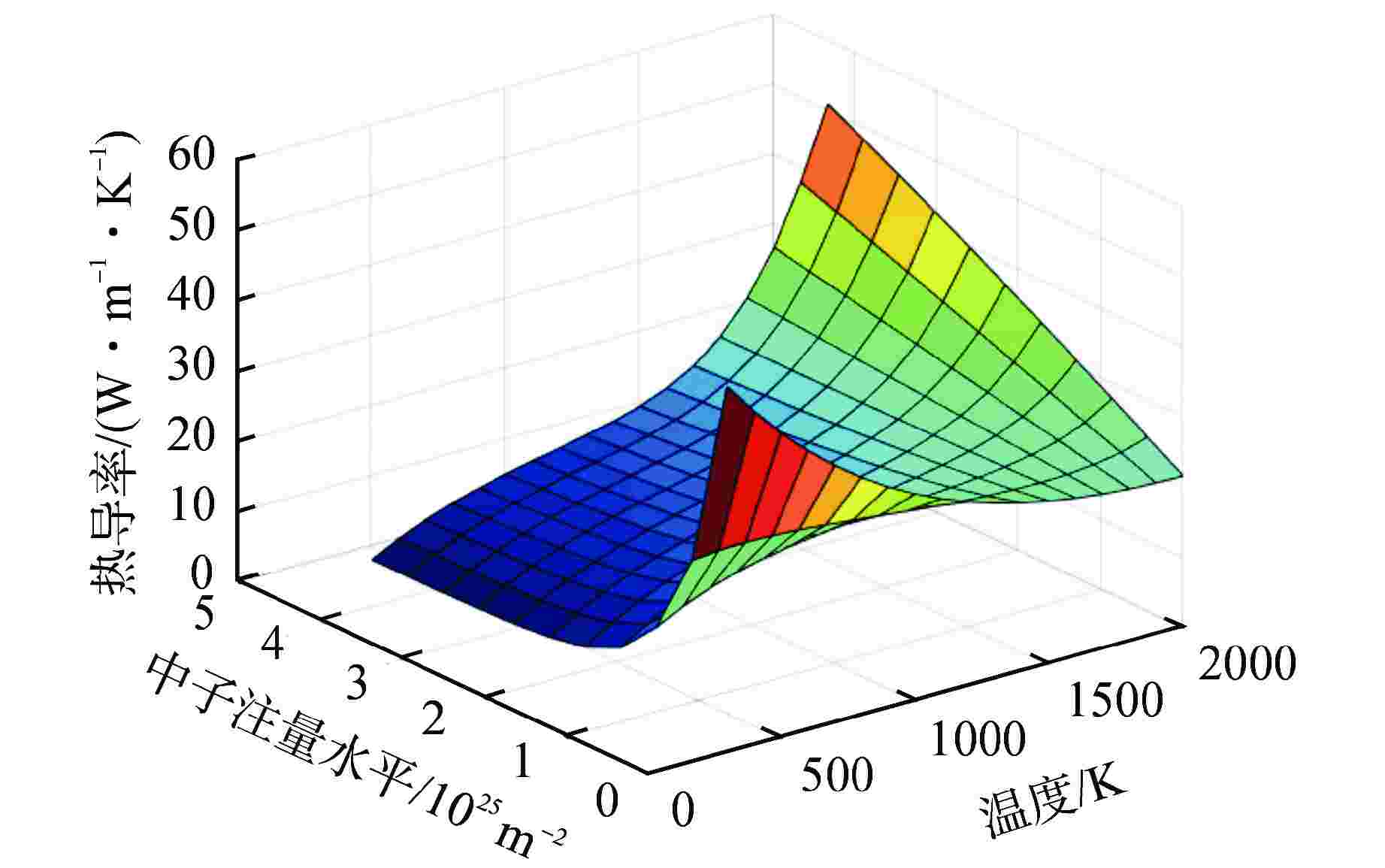

摘要: 由于三层各向同性(TRISO)颗粒弥散型燃料元件结构复杂且其材料性能随着辐照水平不断变化,不同燃耗下燃料元件的等效热导率不易确定。本研究基于COMSOL软件完成了TRISO颗粒性能分析程序开发,并与BISON程序预测值进行了对比分析。随后,基于COMSOL软件与MATLAB联合仿真建立了球形燃料元件等效热导率的计算方法,实现了球形燃料元件和TRISO颗粒模型间的在线耦合计算。在此基础上,获得了不同边界温度、燃耗条件下燃料元件径向等效热导率分布及温度场分布。计算结果表明,快中子注量达到3×1025 m–2时,TRISO等效导热率下降约20%,燃料等效热导率下降约15 W/(m·K)。为了验证本研究方法的有效性,用微分-有效介质理论模型(D-EMT)计算燃料的等效导热率,得到的球形燃料中心温度预测值相比本研究方法的预测值低约25 K。本文研究方法更能真实反映球形燃料元件在反应堆内的温度场变化。Abstract: Due to the complex structure of TRI-Structural Isotropic (TRISO) dispersion fuel elements and its material properties that change under irradiation, it is difficult to determine the equivalent thermal conductivity (ETC) of fuel element under different burnup. In this study, the TRISO particle performance analysis program is developed based on COMSOL software, and compared with the predicted value of BISON program. Then, based on the joint simulation of COMSOL and MATLAB, the calculation method of equivalent thermal conductivity of spherical fuel element is established, and the online coupling calculation between spherical fuel element and TRISO particle model is realized. On this basis, the radial equivalent thermal conductivity distribution and temperature field distribution of fuel element under different boundary temperature and burnup conditions are obtained. The calculation results show that when the fast neutron flux reaches 3×1025 m–2, the equivalent thermal conductivity of TRISO decreases by about 20%, and the equivalent thermal conductivity of fuel decreases by about 15 W/(m·K). In order to demonstrate the effectiveness of this method, the equivalent thermal conductivity of fuel is calculated by differential-effective medium theory model (D-EMT). The predicted value of spherical fuel center temperature is about 25 K lower than that of this method. The research method in this paper can more truly reflect the temperature field change of spherical fuel element in the reactor.

-

Key words:

- Equivalent thermal conductivity /

- Spherical fuel element /

- TRISO particles /

- Coupling /

- COMSOL

-

表 1 材料物性参数

Table 1. Thermal and Mechanical Properties of TRISO

材料 密度/(kg·m-3) 杨氏模量/GPa 泊松比 热膨胀系数/10−6 K−1 UO2 11000 220 0.34 10 Buffer 1000 20 0.23 5.7 PyC 1900 47 0.23 5.7 SiC 3180 340 0.13 4.9 -

[1] 张作义,吴宗鑫,王大中,等. 我国高温气冷堆发展战略研究[J]. 中国工程科学,2019, 21(1): 12-19. [2] 钱立波,余红星,孙玉发,等. TRISO燃料颗粒等效导热系数理论模型研究[J]. 核动力工程,2020, 41(6): 69-74. doi: 10.13832/j.jnpe.2020.06.0069 [3] 李文杰,余红星,肖忠,等. 高体积份额下包覆颗粒弥散燃料等效热学模型[J]. 核动力工程,2021, 42(4): 96-100. doi: 10.13832/j.jnpe.2021.04.0096 [4] PROGELHOF R C, THRONE J L, RUETSCH R R. Methods for predicting the thermal conductivity of composite systems: a review[J]. Polymer Engineering and Science, 1976, 16(9): 615-625. doi: 10.1002/pen.760160905 [5] 钱立波,余红星,孙玉发,等. 固-固二元复合材料等效导热系数模型研究综述及评价[J]. 原子能科学技术,2020, 54(3): 409-420. doi: 10.7538/yzk.2019.youxian.0310 [6] FOLSOM C, XING C H, JENSEN C, et al. Experimental measurement and numerical modeling of the effective thermal conductivity of TRISO fuel compacts[J]. Journal of Nuclear Materials, 2015, 458: 198-205. doi: 10.1016/j.jnucmat.2014.12.042 [7] 李垣明,唐昌兵,余红星,等. 锆基弥散微封装燃料等效传热系数数值模拟研究[J]. 核动力工程,2018, 39(2): 76-79. doi: 10.13832/j.jnpe.2018.02.0076 [8] ZHANG C, WU Y W, LIU S C, et al. Multidimensional multiphysics modeling of TRISO particle fuel with SiC/ZrC coating using modified fission gas release model[J]. Annals of Nuclear Energy, 2020, 145: 107599. doi: 10.1016/j.anucene.2020.107599 [9] TOPTAN A, JIANG W, NOVASCONE S R, et al. Matrix graphite material models in pebbles and compacts for BISON: INL/EXT-21-64643[R]. Idaho Falls: Idaho National Laboratory, 2021. [10] LUCUTA P G, MATZKE H, HASTINGS I J. A pragmatic approach to modelling thermal conductivity of irradiated UO2 fuel: Review and recommendations[J]. Journal of Nuclear Materials, 1996, 232(2-3): 166-180. doi: 10.1016/S0022-3115(96)00404-7 [11] PETTI D, MARTIN P, PHÉLIP M, et al. Development of improved models and designs for coated-particle gas reactor fuels: INEEL/EXT-05-02615[R]. Bechtel BWXT, Idaho: Idaho National Engineering and Environmental Laboratory, 2004. [12] HALES J D, WILLIAMSON R L, NOVASCONE S R, et al. Multidimensional multiphysics simulation of TRISO particle fuel[J]. Journal of Nuclear Materials, 2013, 443(1-3): 531-543. doi: 10.1016/j.jnucmat.2013.07.070 [13] 崔羿,丁淑蓉,赵云妹,等. 考虑晶界扩散和气泡联合的UO2燃料裂变气体模型[J]. 核动力工程,2012, 33(S2): 9-12. [14] PROKSCH E, STRIGL A, NABIELEK H. Production of carbon monoxide during burn-up of UO2 kerneled HTR fuel particles[J]. Journal of Nuclear Materials, 1982, 107(2-3): 280-285. doi: 10.1016/0022-3115(82)90426-3 [15] ZHANG C, WANG Y Y, WU Y W, et al. Preliminary numerical investigation of TRISO-Matrix interface debonding characteristics in fully ceramic microencapsulated fuel[J]. Annals of Nuclear Energy, 2021, 159: 108338. doi: 10.1016/j.anucene.2021.108338 [16] 陈平,李伟,李垣明,等. TRISO燃料颗粒三维多物理场耦合计算模型开发[J]. 核动力工程,2017, 38(5): 169-174. doi: 10.13832/j.jnpe.2017.05.0169 [17] 张培源,严波. 多相固体的等效导热系数[J]. 重庆大学学报,1989, 12(6): 15-20. [18] MCLAUGHLIN R. A study of the differential scheme for composite materials[J]. International Journal of Engineering Science, 1977, 15(4): 237-244. doi: 10.1016/0020-7225(77)90058-1 [19] ZHANG Z Y, DONG Y J, LI F, et al. The Shandong Shidao Bay 200 MWe High-temperature gas-cooled reactor pebble-bed module (HTR-PM) demonstration power plant: an engineering and technological innovation[J]. Engineering, 2016, 2(1): 112-118 -

下载:

下载: