Study on Hydrogen Induced Delayed Cracking Behavior of Zirconium Alloys Caused by Surface Defects

-

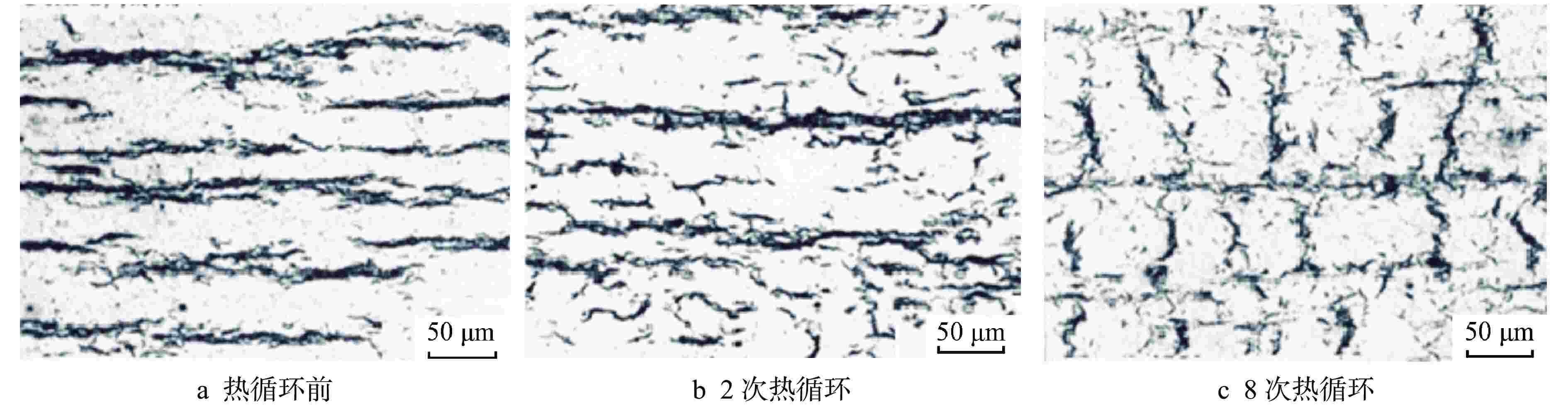

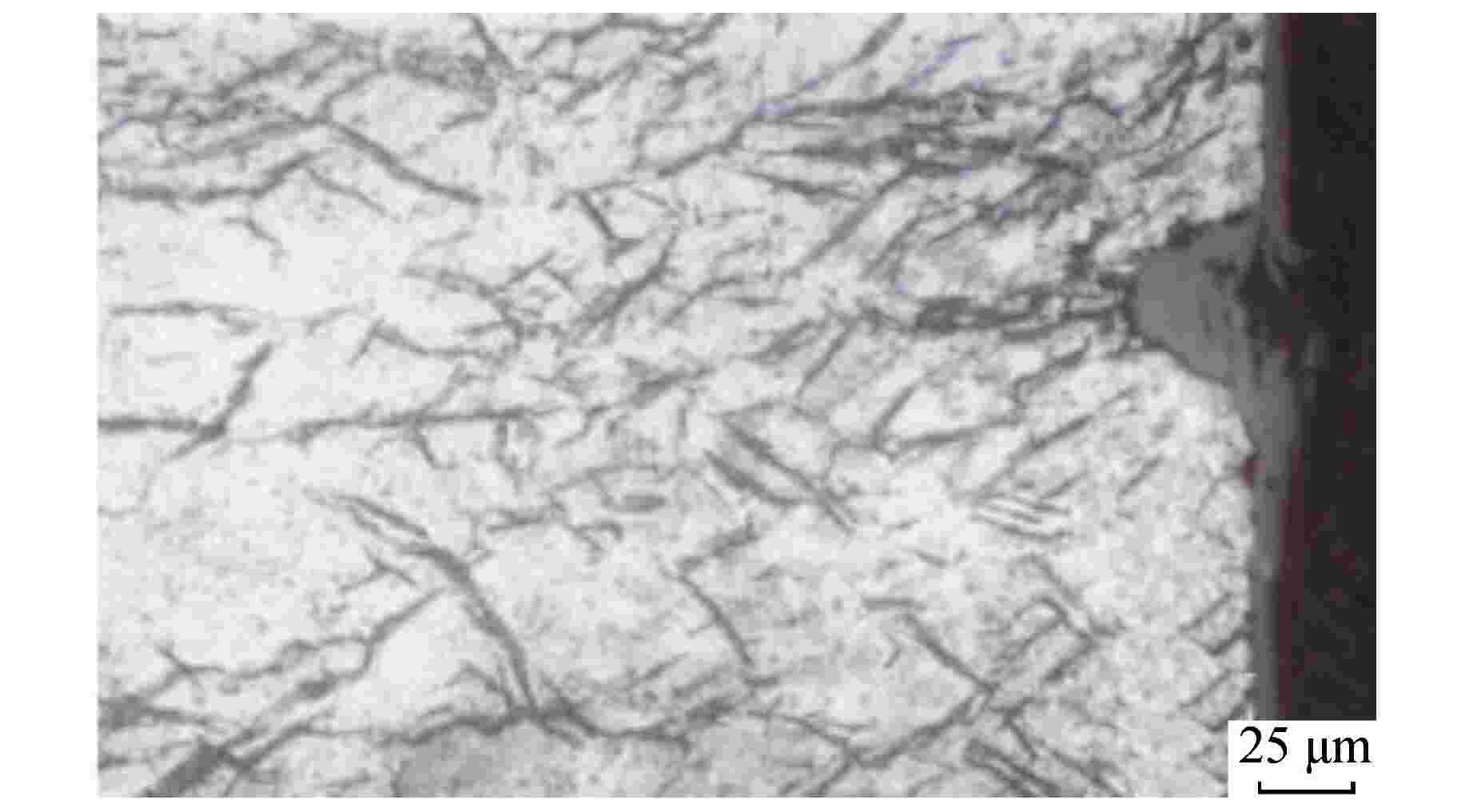

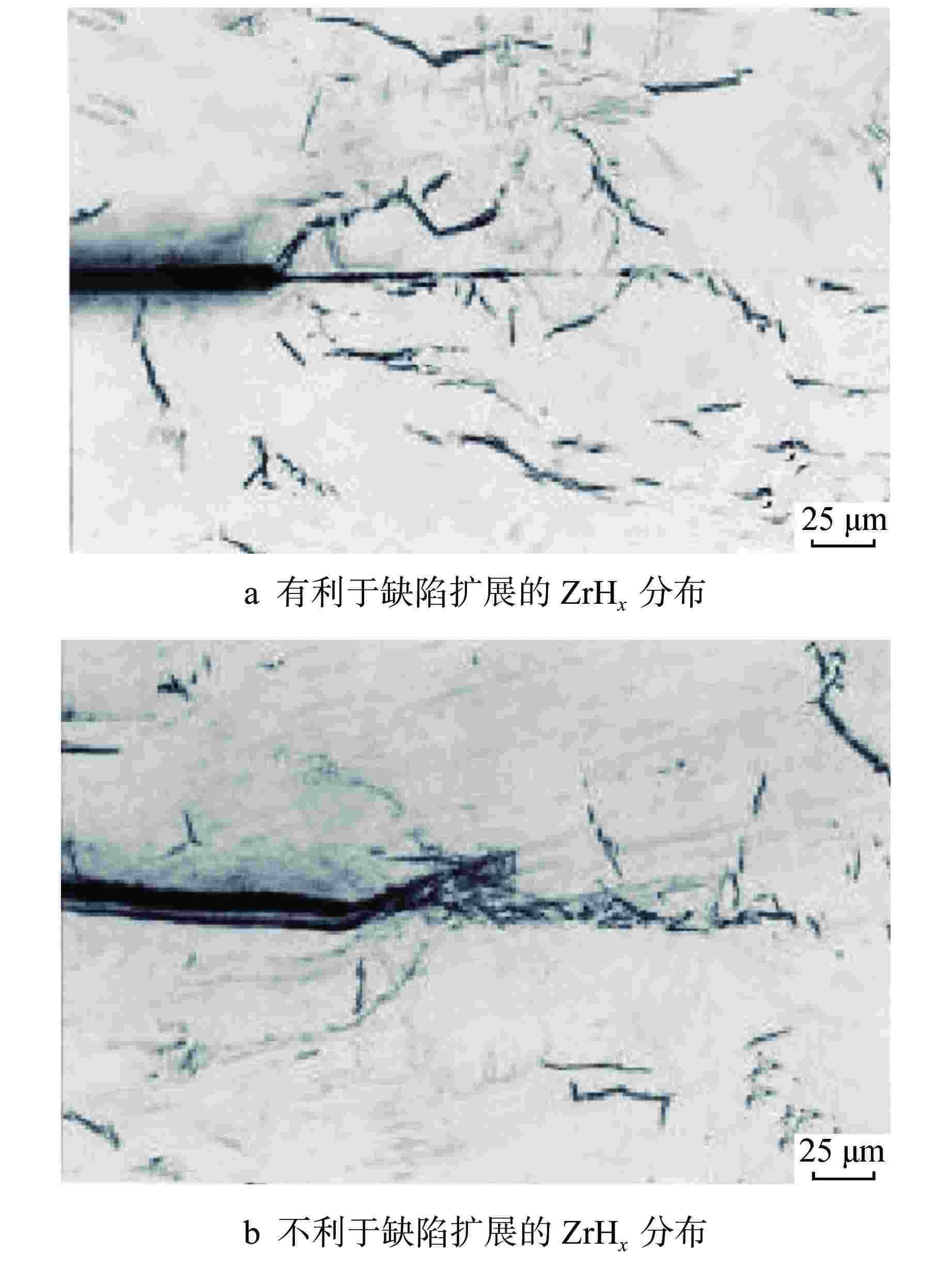

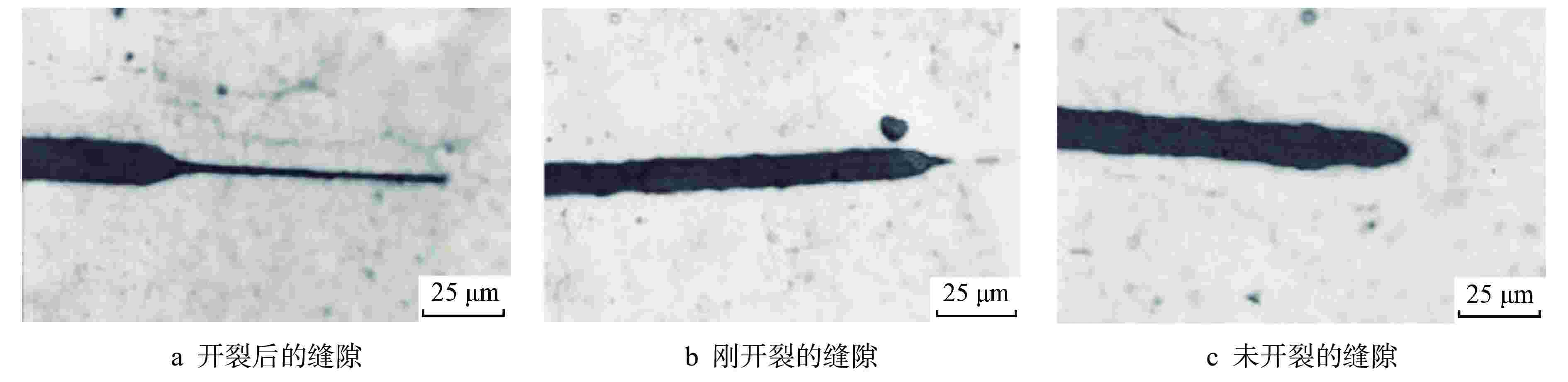

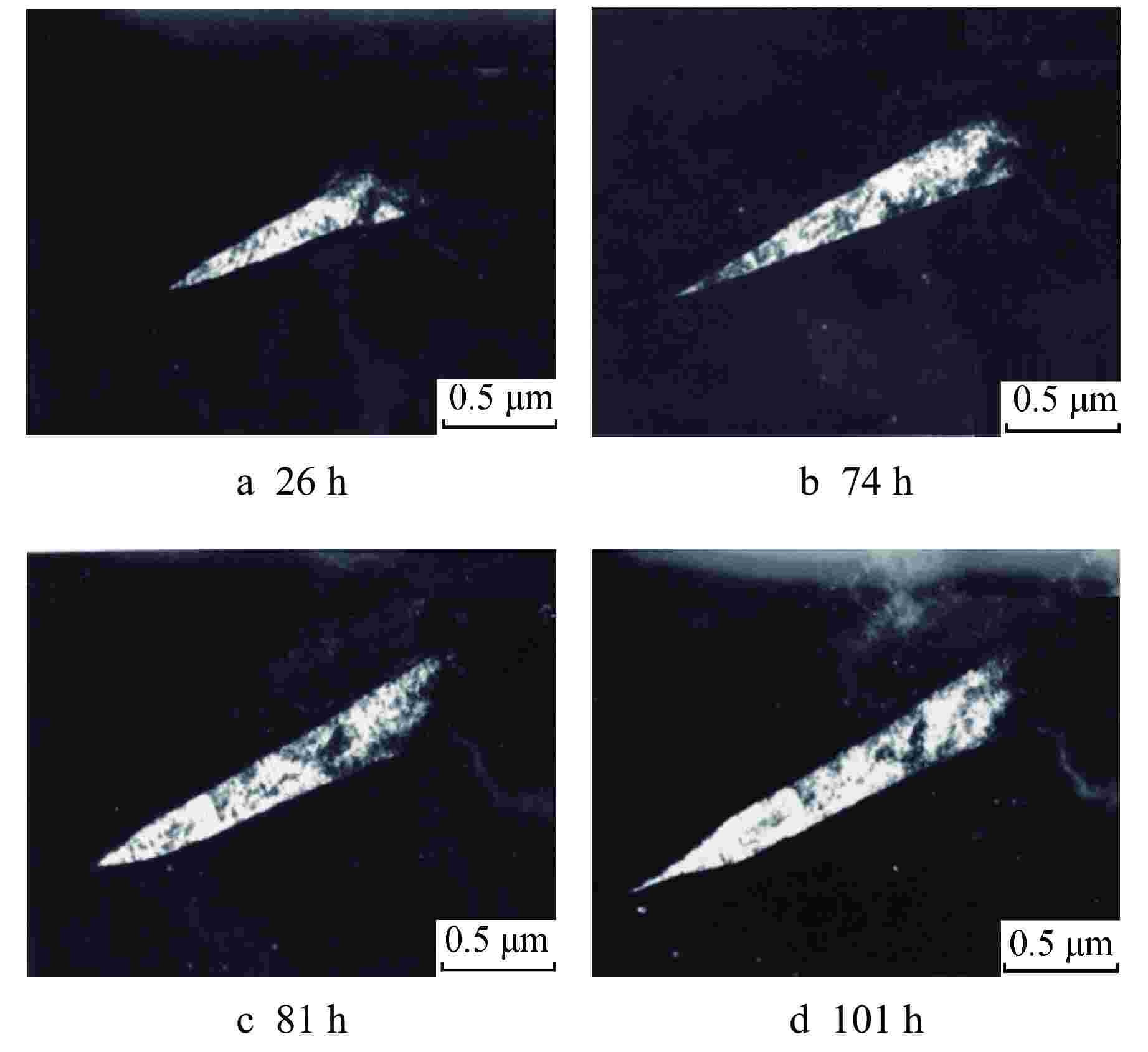

摘要: 核反应堆用锆合金构件在服役过程中会发生氢致延迟开裂(HIDC)而失效,构件表面的微缺陷是否会引起HIDC是值得研究的问题。本文采用真空电子束焊接方法制备表面有微缝隙缺陷的样品,以研究这类微缝隙缺陷在400℃过热蒸汽中腐蚀以及在350℃高压水中热循环处理过程中的行为。由于这类缺陷处会形成尖劈状的氧化膜并镶嵌在金属中,在氧化膜前端将形成应力集中和应力梯度区,引起氢的扩散、富集和氢化物析出,即使样品中原先没有残余应力,也没有受到外加应力的作用,也会发生HIDC导致裂纹扩展而开裂。因此,在设计和加工制造核反应堆堆芯中锆合金的各种结构件时,需要重视如何避免锆合金构件表面可能生成这种缺陷的问题。

-

关键词:

- 锆合金 /

- 氢化锆 /

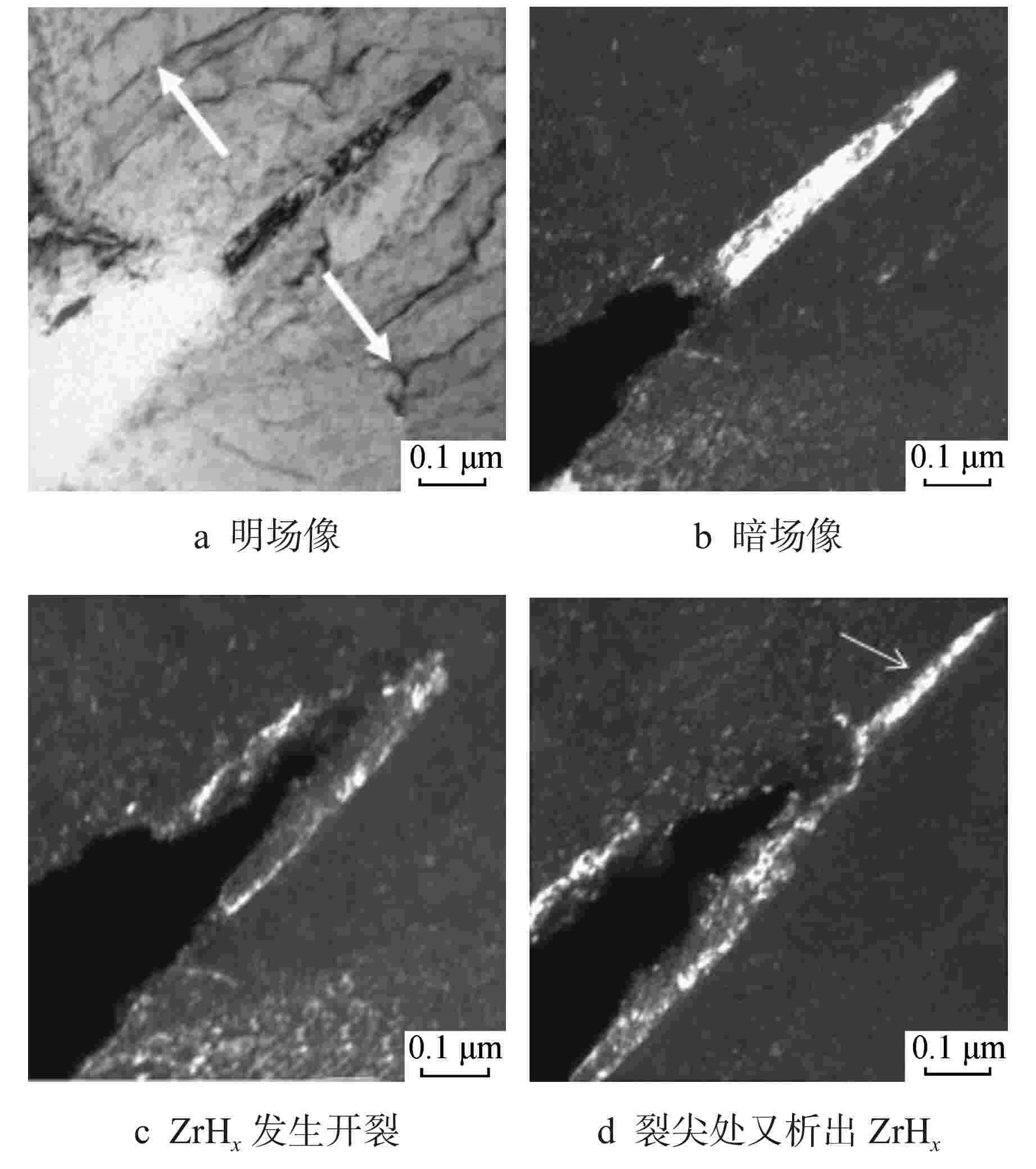

- 氢致延迟开裂(HIDC) /

- 表面缺陷 /

- 氧化膜

Abstract: Zirconium alloy components used in nuclear reactors maybe occur to fail due to hydrogen induced delayed cracking (HIDC) during service. Whether the microdefects on the surface of the components will cause HIDC is worth studying. In this paper, samples with microcrack defects on the surface of zirconium alloy were prepared by vacuum electron beam welding method, and the corrosion behavior of these microcrack defects during thermal cycling treatment in high-pressure water at 350℃ after corrosion in superheated steam at 400℃ was studied. As the formation of a wedge-like oxide film embedded in the metal at such defects, a tensile stress concentration and stress gradient zone will be formed at the front end of the wedge-like oxide film, resulting in the diffusion and enrichment of hydrogen, and the precipitation of hydrides. In this case, even if the samples are not subjected to external stress and have no residual stresses, these defects will also cause HIDC, leading to defect extension and cracking. Therefore, when designing and manufacturing various zirconium alloy components used in the nuclear reactor core, attention should be paid to how to avoid such defects formed on the surface of such components. -

表 1 样品经20次和60次热循环后8处微缺陷缝隙深度的变化(20次/60次)

Table 1. The Changes of Crack Depth of 8 Micro-Defects after 20 and 60 Thermal Cycles of the Samples (20 Times/60 Times)

缝隙编号 1 2 3 4 5 6 7 8 深度变化/mm 0.45/0.58 0.41/0.50 0.49/0.88 0.80/0.95 0.95/1.23 0.48/0.48 0.75/0.81 0.63/0.70 -

[1] KEARNS J J. Terminal solubility and partitioning of hydrogen in the alpha phase of zirconium, Zircaloy-2 and Zircaloy-4[J]. Journal of Nuclear Materials, 1967, 22(3): 292-303. doi: 10.1016/0022-3115(67)90047-5 [2] 卡恩R W, 哈森 P, 克雷默 E J. 材料科学与技术丛书(第10B卷, 核材料-第Ⅱ部分)[M]. 周邦新, 赵文金等, 译. 北京: 科学出版社, 1999: 1-48. [3] SIMPSON C J, ELLS C E. Delayed hydrogen embrittlement in Zr-2.5 wt% Nb[J]. Journal of Nuclear Materials, 1974, 52(2): 289-295. doi: 10.1016/0022-3115(74)90174-3 [4] JHA A, SARKAR S, SINGH I V, et al. A study on the effect of residual stresses on hydride assisted crack in Zr-2.5Nb pressure tube material using XFEM[J]. Theoretical and Applied Fracture Mechanics, 2022, 121: 103536. doi: 10.1016/j.tafmec.2022.103536 [5] 刘建章. 核结构材料[M]. 北京: 化学工业出版社, 2007: 142-173. [6] 姚美意, 栾佰峰. 水冷核反应堆用锆合金[M]. 周邦新. 核反应堆材料(中册). 上海: 上海交通大学出版社, 2021: 459-675. [7] 周邦新,郑斯奎,汪顺新. Zr-2合金中应力及应变诱发氢化锆析出过程的电子显微镜原位研究[J]. 金属学报,1989, 25(3): A190-A195. [8] 彭剑超,李强,刘仁多,等. Zr-4合金中氢化物析出长大的透射电镜原位研究[J]. 稀有金属材料与工程,2011, 40(8): 1377-1381. [9] 周邦新,蒋有荣. Zr-4管中氢化物分布的应力再取向研究[J]. 核动力工程,1992, 13(5): 66-69. [10] 蒋有荣,周邦新,杨敏华. Zr-4板中氢化物应力再取向的研究[J]. 核动力工程,1993, 14(4): 368-373,380. [11] ZHOU B X, YAO M Y, MIAO Z, et al. The cracking induced by oxidation-hydriding in welding joints of Zircaloy-4 plates[J]. Journal of Shanghai University (English Edition), 2003, 7(1): 18-20. doi: 10.1007/s11741-003-0045-4 -

下载:

下载: