Study on Effect of Temperature on the Narrow Gap Ressistance Coefficient Test

-

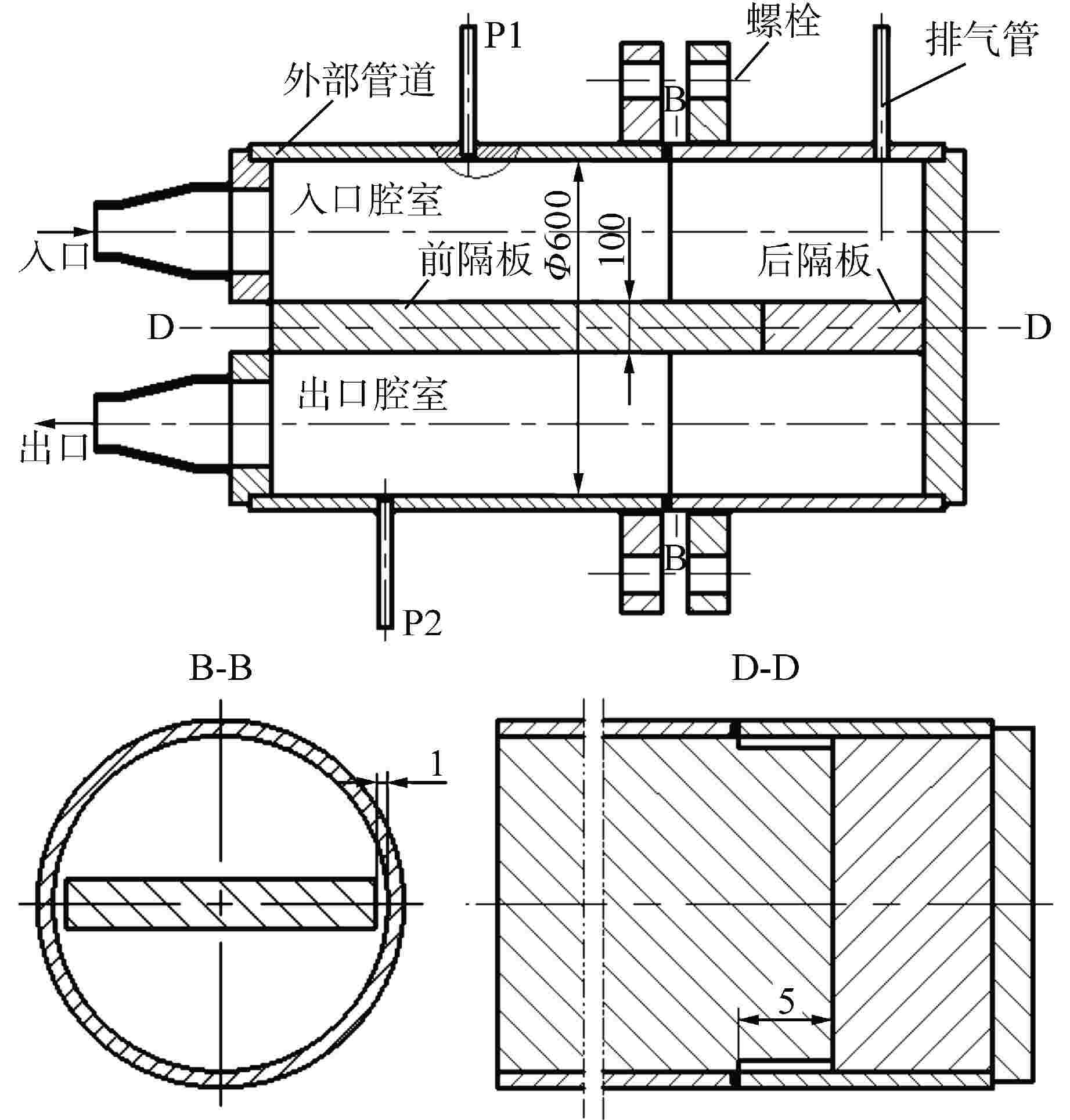

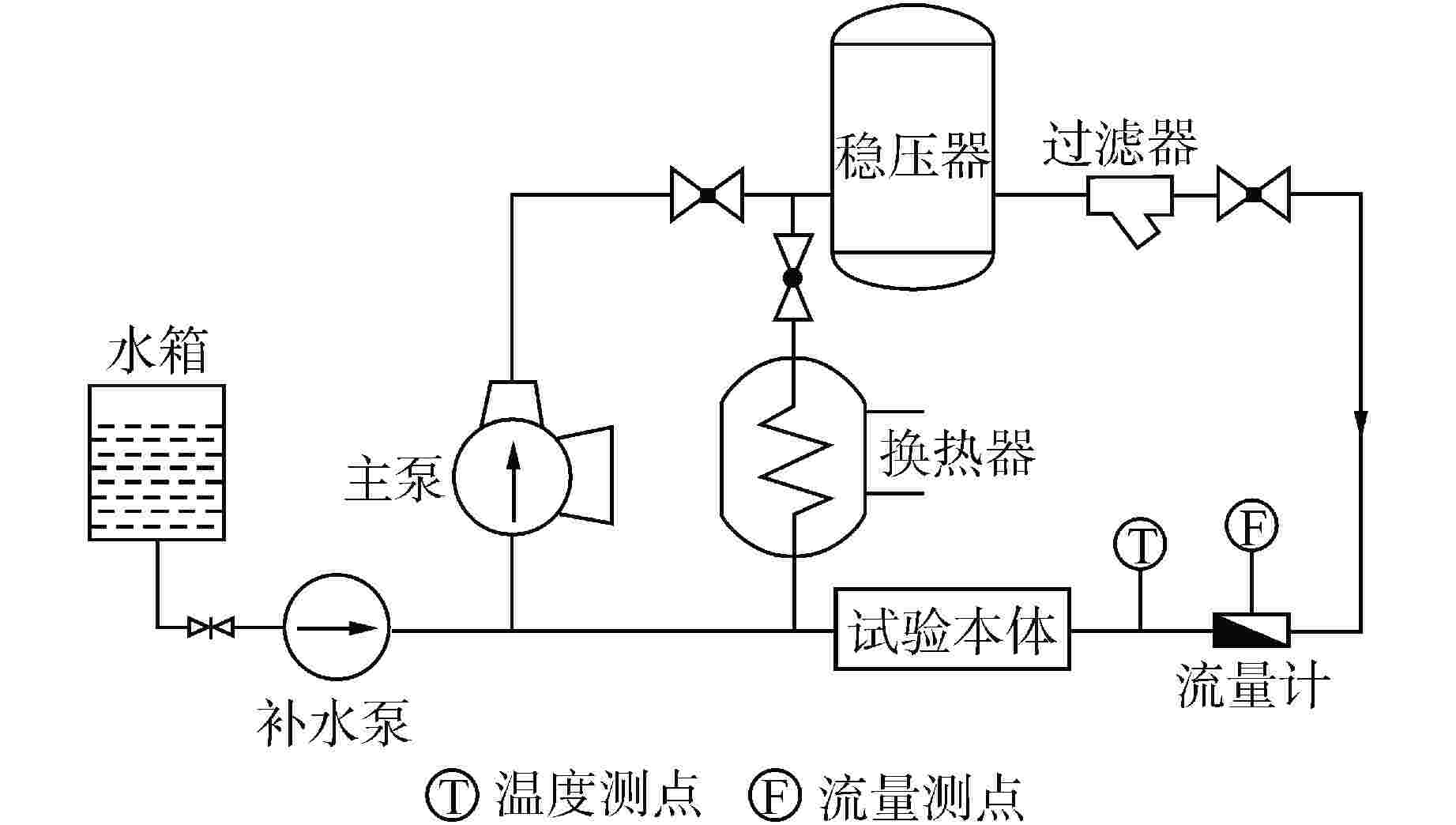

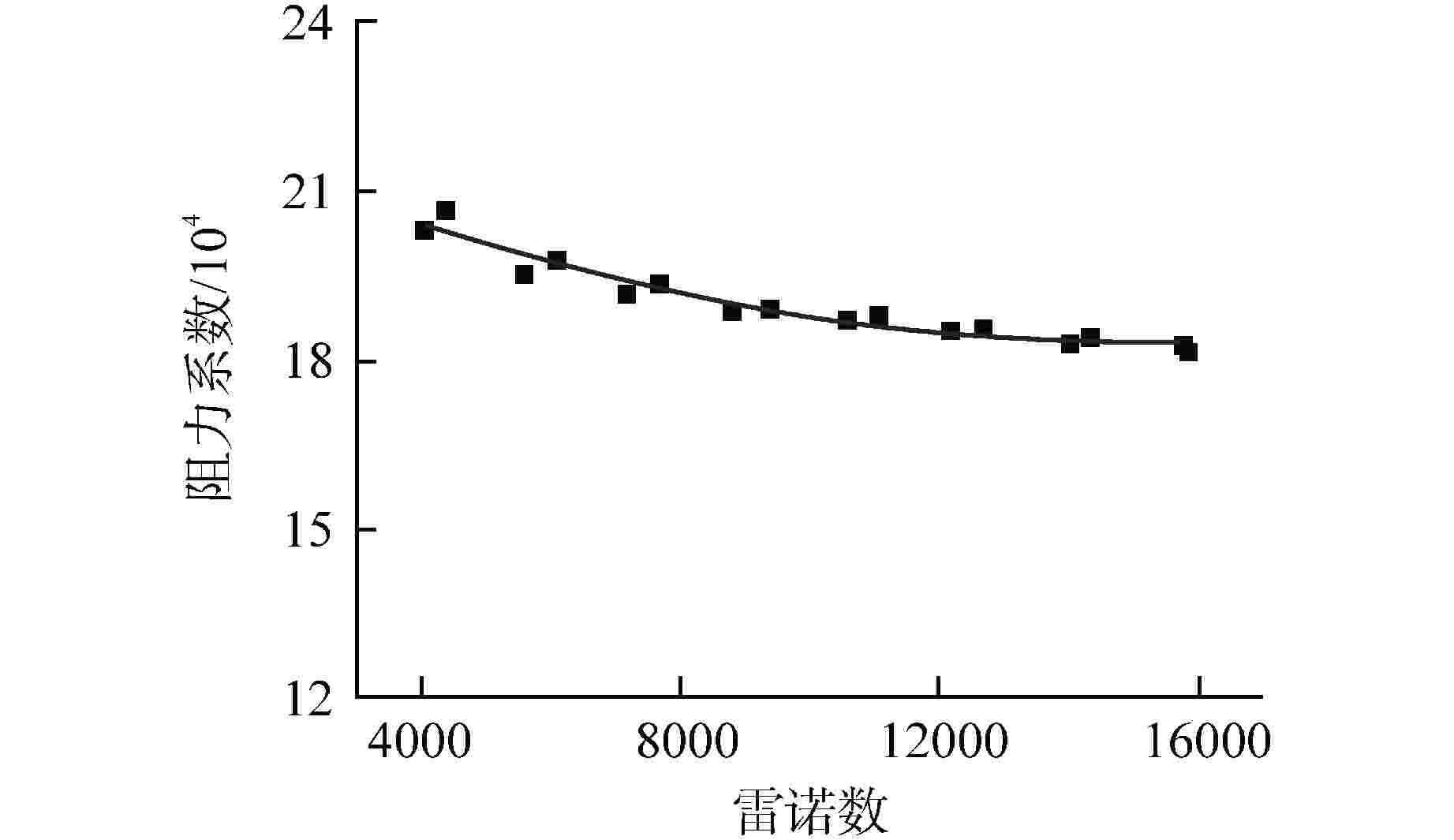

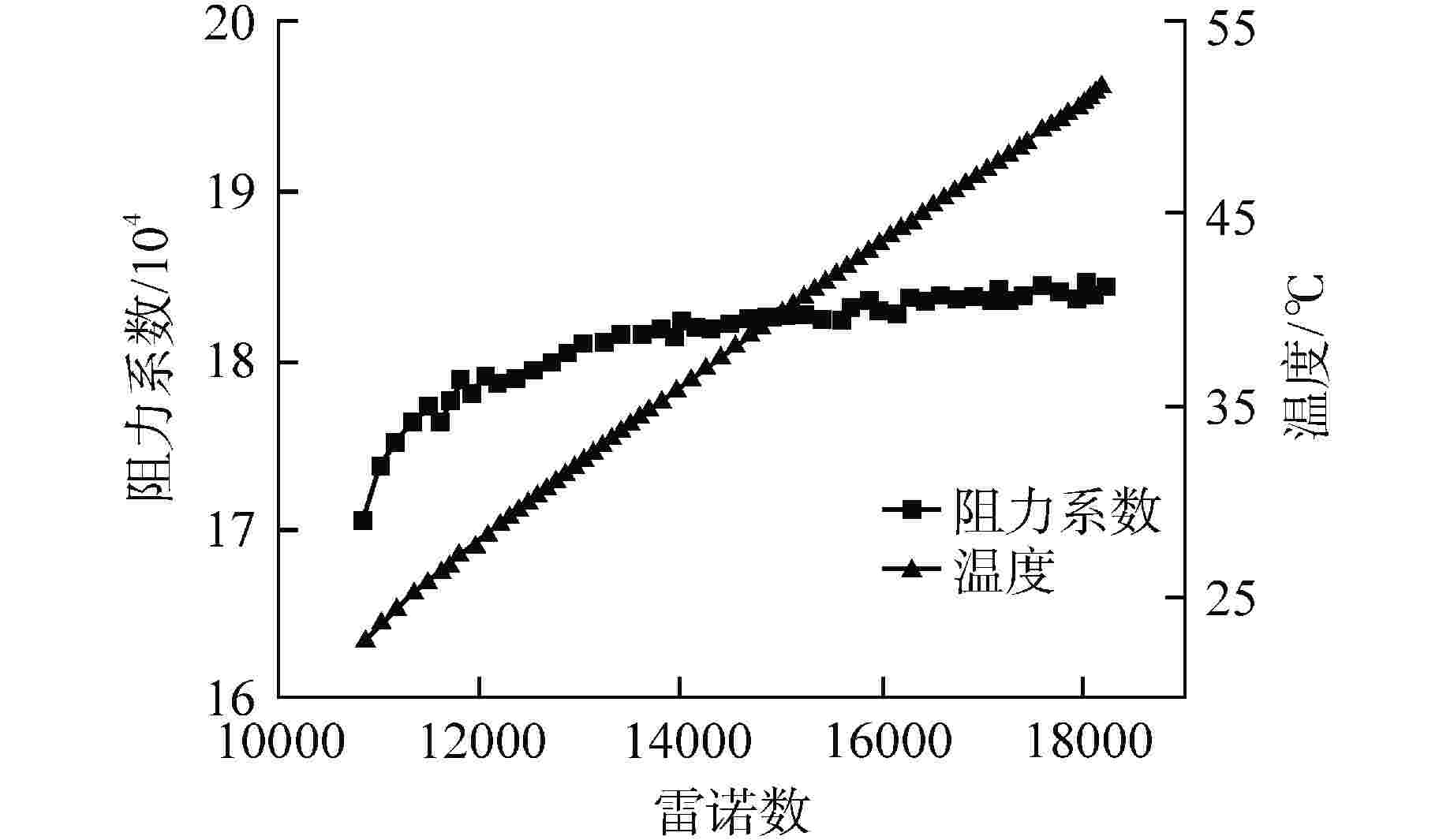

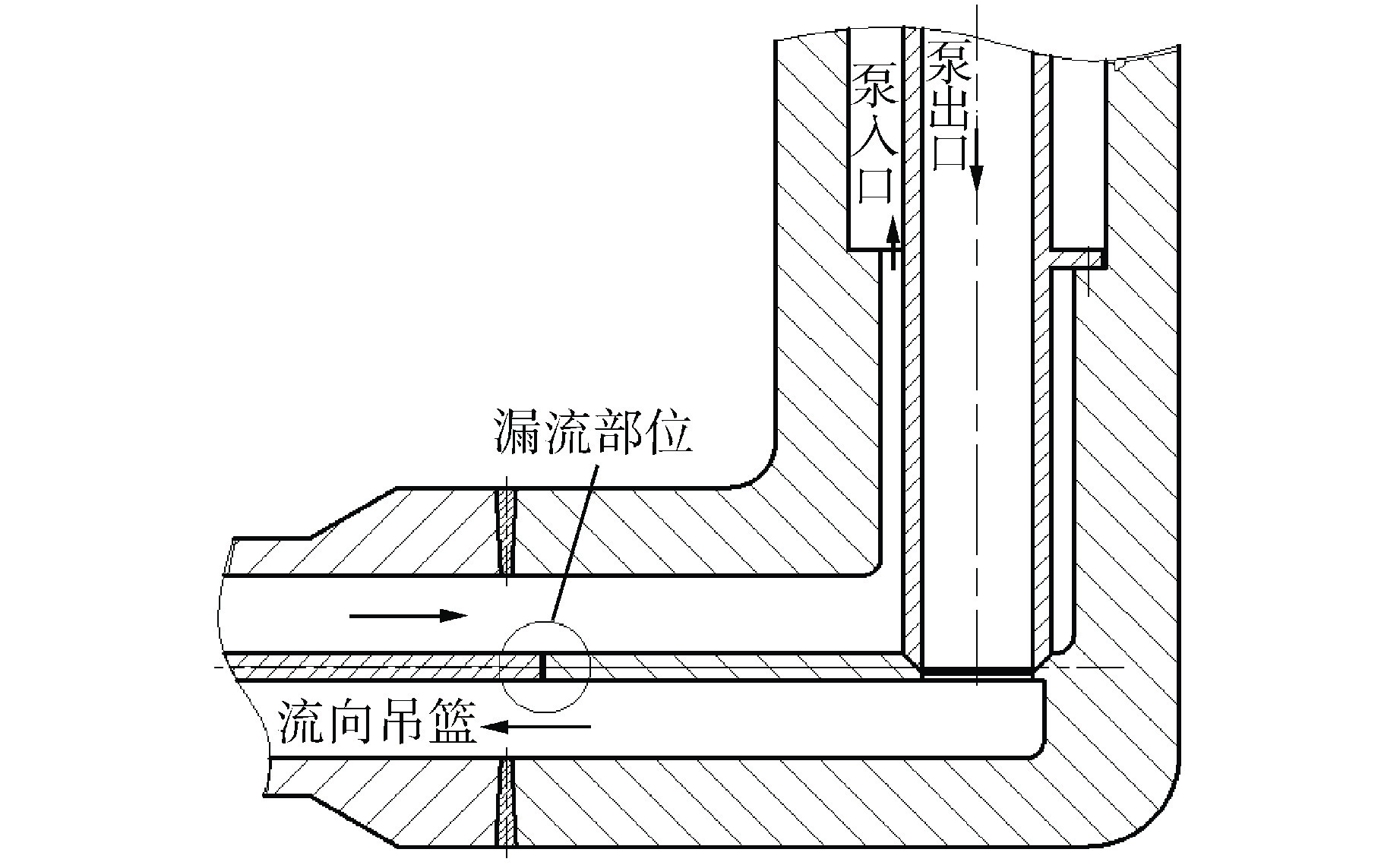

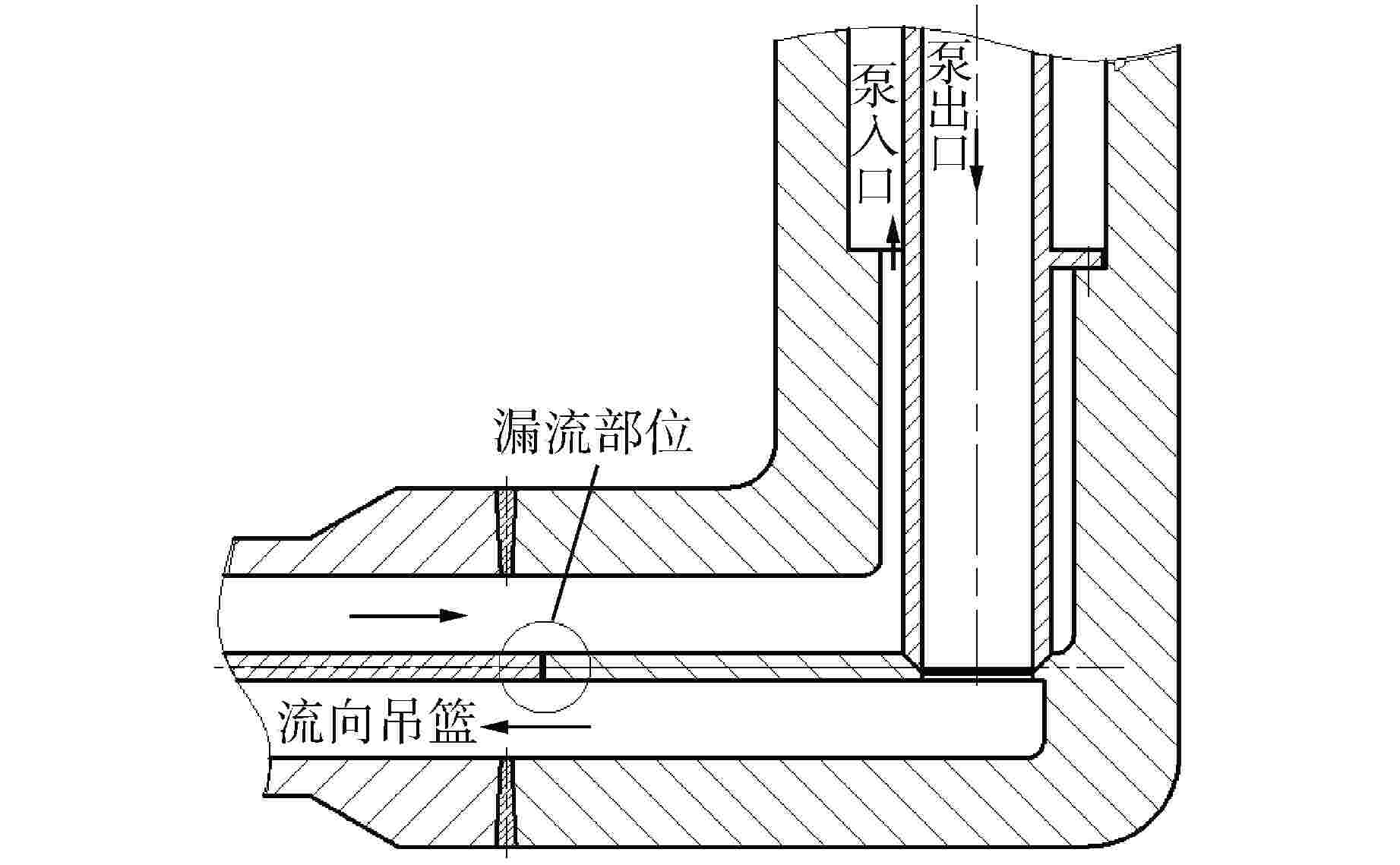

摘要: 压水反应堆内冷却剂旁漏流流道尺寸多是狭窄缝隙,狭窄缝隙尺寸很敏感,很容易受到系统压力、压差、温度、振动等因素的影响。微小的尺寸变化又会引起阻力系数明显改变,导致试验测得的雷诺数与阻力系数关系曲线与流体动力学基本原理相悖。本文通过开展恒温和升温条件下的狭窄缝隙流动阻力系数试验,研究温度变化对狭窄缝隙流动阻力系数的影响规律。升温试验中维持系统压力、试验本体压差、流量不变,逐渐升高试验流体温度,获得不同温度下的试验本体流动阻力系数。试验结果表明试验流体温度从23℃上升至52℃时,试验本体狭窄缝隙尺寸由于热胀冷缩导致接缝面更贴合,压紧力增大,流动阻力系数增幅达8%。Abstract: The coolant leakage and bypass flow channel in PWR is mostly a narrow gap. The size of narrow gap is sensitive to be easily affected by system pressure, differential pressure, temperature, vibration and other factors. Small size changes will cause significant changes in resistance coefficient, resulting in the measured Reynolds number and resistance coefficient curve contrary to the basic principles of fluid dynamics. In this paper, the study on effect of temperature change on the flow resistance coefficient in narrow gap is conducted under the conditions of constant temperature and temperature rise. During the temperature rise test, the system pressure, the differential pressure and flow of the test body stays unchanged, and gradually increase the temperature of the fluid, then obtain the resistance coefficient of the test body under different temperature. The test results show that when the temperature of the test fluid rises from 23°C to 52°C, the narrow gap of the test body is more closely fitted due to thermal expansion and cold contraction, and the flow resistance coefficient increases by 8%.

-

Key words:

- Leakage and bypass flow /

- Narrow gap /

- Resistance coefficient /

- Temperature rise test

-

表 1 试验用仪器仪表

Table 1. Test Measuring Instrument

仪表名称 测量参数 测量范围 精度 数量 温度变送器 回路水温度/℃ 0~100 0.5℃ 1 压力变送器 模型入口腔压力/MPa 0~2.5 0.1% 1 涡轮流量计 漏流流量/(m3·h−1) 1~10 0.5% 1 差压变送器 漏流差压/kPa 0~500 0.1% 1 0~2000 0.1% 1 -

[1] SATO H, JOHNSON R, SCHULTZ R. Computational fluid dynamic analysis of core bypass flow phenomena in a prismatic VHTR[J]. Annals of Nuclear Energy, 2010, 37(9): 1172-1185. doi: 10.1016/j.anucene.2010.04.021 [2] TRAVIS B W, EL-GENK M S. Thermal–hydraulics analyses for 1/6 prismatic VHTR core and fuel element with and without bypass flow[J]. Energy Conversion and Management, 2013, 67: 325-341. doi: 10.1016/j.enconman.2012.11.003 [3] TUNG Y H, JOHNSON R W, SATO H. Effects of graphite surface roughness on bypass flow computations for an HTGR[J]. Nuclear Engineering and Design, 2012, 252: 78-87. doi: 10.1016/j.nucengdes.2012.07.010 [4] WANG H H, HASSAN Y A, DOMINGUEZ-ONTIVEROS E. Experimental study of core bypass flow in a prismatic VHTR based on a two-layer block model[J]. Nuclear Engineering and Design, 2016, 306: 98-107. doi: 10.1016/j.nucengdes.2015.09.025 [5] TAK N I, KIM M H, LIM H S, et al. Validation of numerical methods to calculate bypass flow in a prismatic gas-cooled reactor core[J]. Nuclear Engineering and Technology, 2013, 45(6): 745-752. doi: 10.5516/NET.02.2013.521 [6] KIM M H, LIM H S. Evaluation of the influence of bypass flow gap distribution on the core hot spot in a prismatic VHTR core[J]. Nuclear Engineering and Design, 2011, 241(8): 3076-3085. doi: 10.1016/j.nucengdes.2011.05.009 [7] VAN RENSBURG J J J, KLEINGELD M. A CFD method to evaluate the integrated influence of leakage and bypass flows on the PBMR Reactor Unit[J]. Nuclear Engineering and Design, 2010, 240(11): 3841-3850. doi: 10.1016/j.nucengdes.2010.08.011 [8] VAN RENSBURG J J J, KLEINGELD M. Investigating leakage and bypass flows in an HTR using a CFD methodology[J]. Nuclear Engineering and Design, 2011, 241(12): 4960-4971. doi: 10.1016/j.nucengdes.2011.08.073 [9] YOON S J, LEE J H, KIM M H, et al. The effects of crossflow gap and axial bypass gap distribution on the flow characteristics in prismatic VHTR core[J]. Nuclear Engineering and Design, 2012, 250: 465-479. doi: 10.1016/j.nucengdes.2012.04.025 [10] 杨来生,宗桂芳. 秦山600MW反应堆旁漏流水力模拟实验研究[J]. 核动力工程,1999, 20(4): 317-322. [11] 王盛, 杨来生, 方颖, 等. CNP1000反应堆旁漏流、流量分配及交混特性研究[C]//罗琦. 中国核动力研究设计院科学技术年报(2009). 成都: 中国核动力研究设计院, 2011: 18-20. [12] 孟洋,李华奇,王盛. CNP1000反应堆控制棒导向管旁流试验研究[J]. 原子能科学技术,2007, 41(S1): 31-34. [13] 徐元利,李华奇,王盛. CNP1000反应堆出口管缝隙漏流试验研究[J]. 原子能科学技术,2007, 41(S1): 59-61. [14] 方颖,张伟,眭曦,等. CAP1400反应堆吊篮与围筒旁通流特性实验研究[J]. 原子能科学技术,2016, 50(2): 273-276. doi: 10.7538/yzk.2016.50.02.0273 [15] 眭曦,廖恒基,丁雷,等. 控制棒导向管外流道旁流特性实验研究[J]. 原子能科学技术,2018, 52(11): 1956-1961. doi: 10.7538/yzk.2018.youxian.0208 -

下载:

下载: