Abstract:

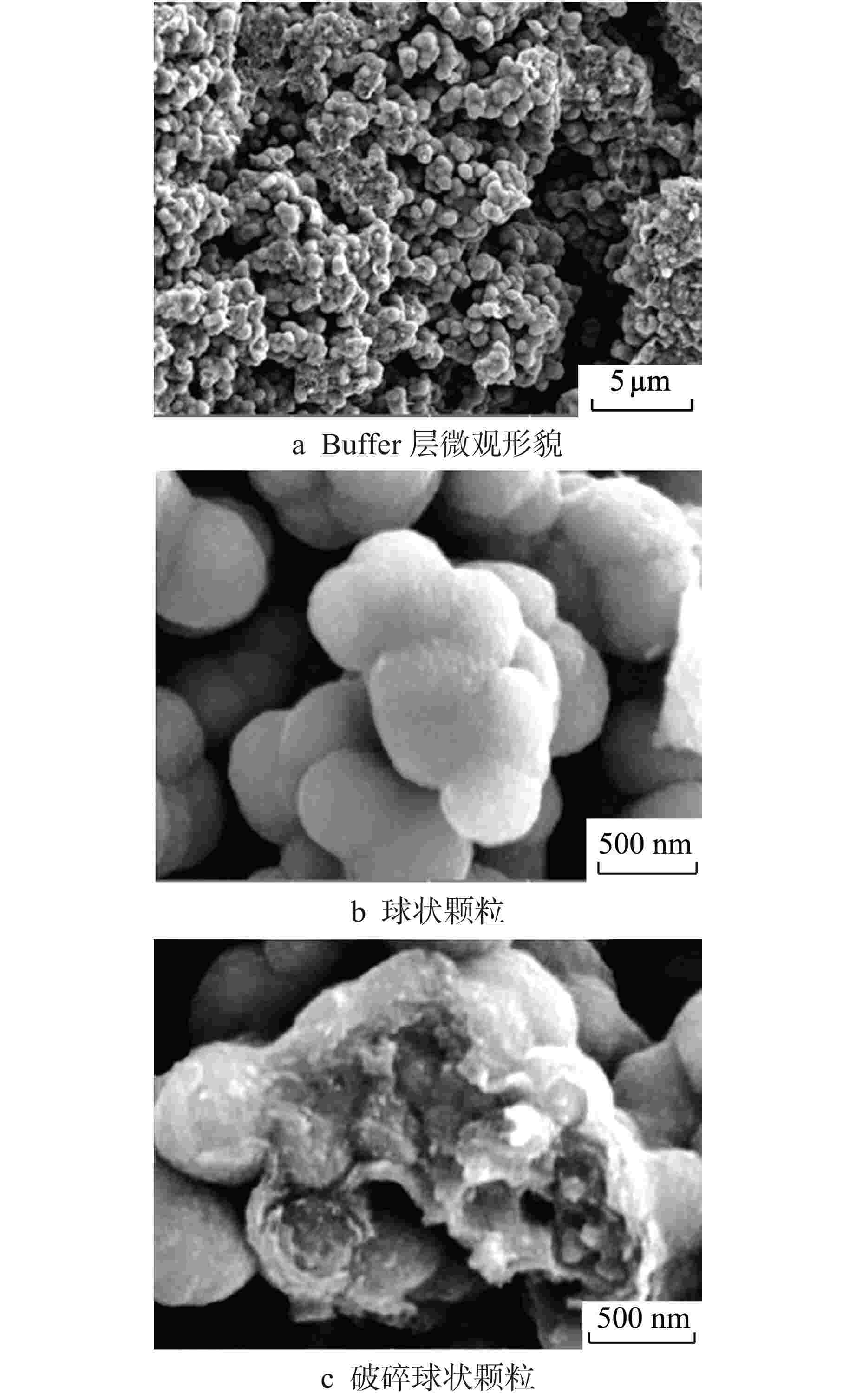

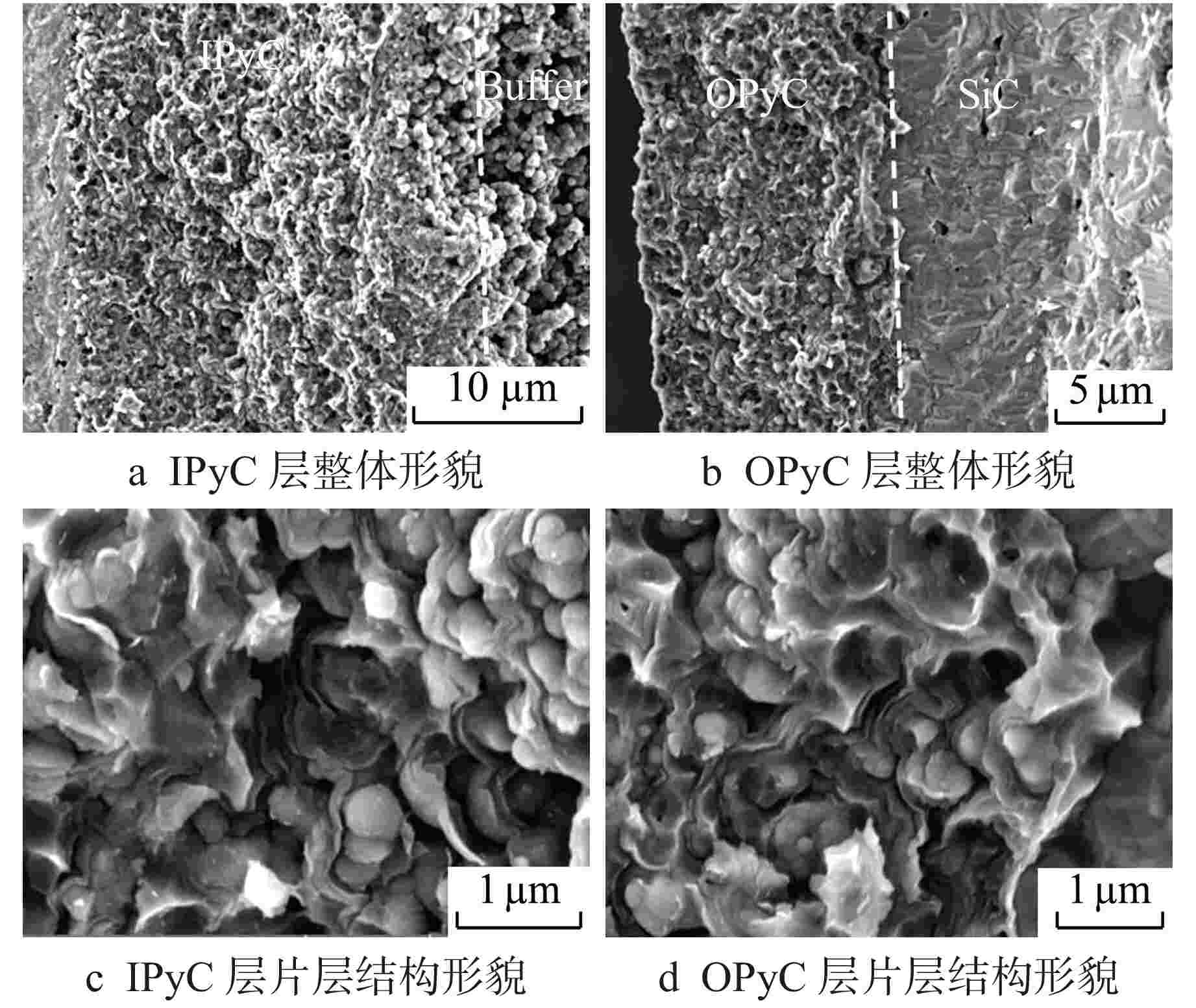

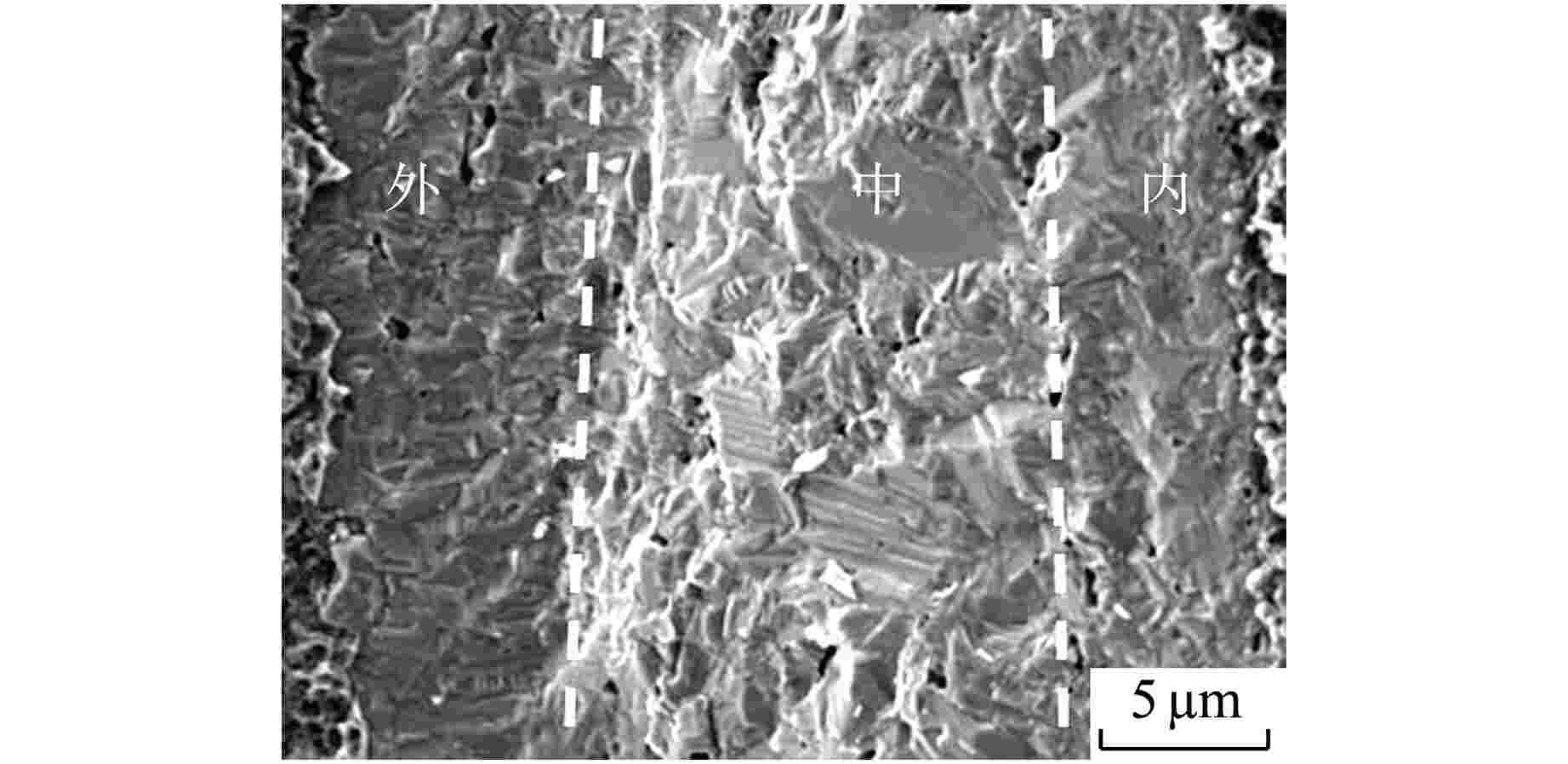

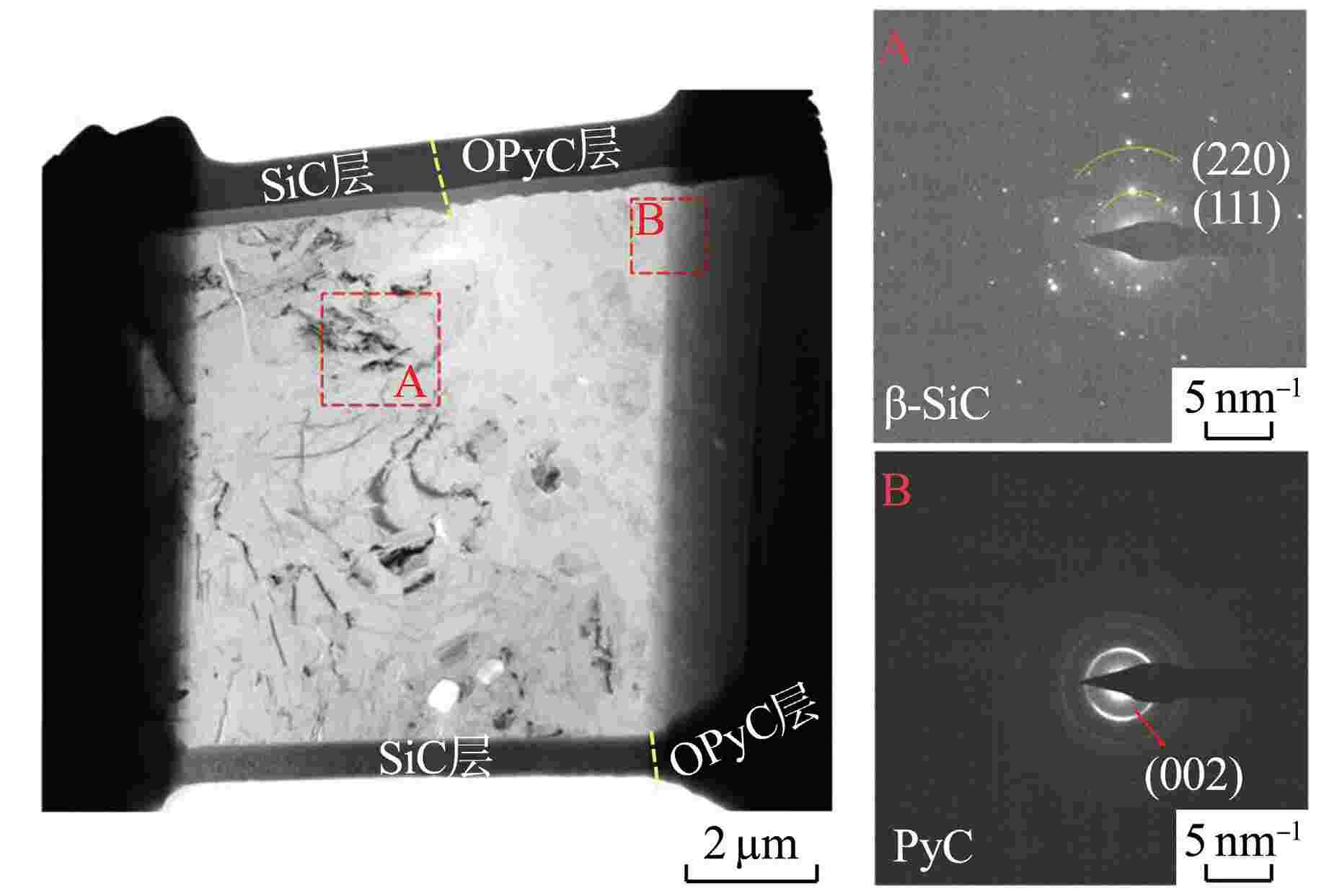

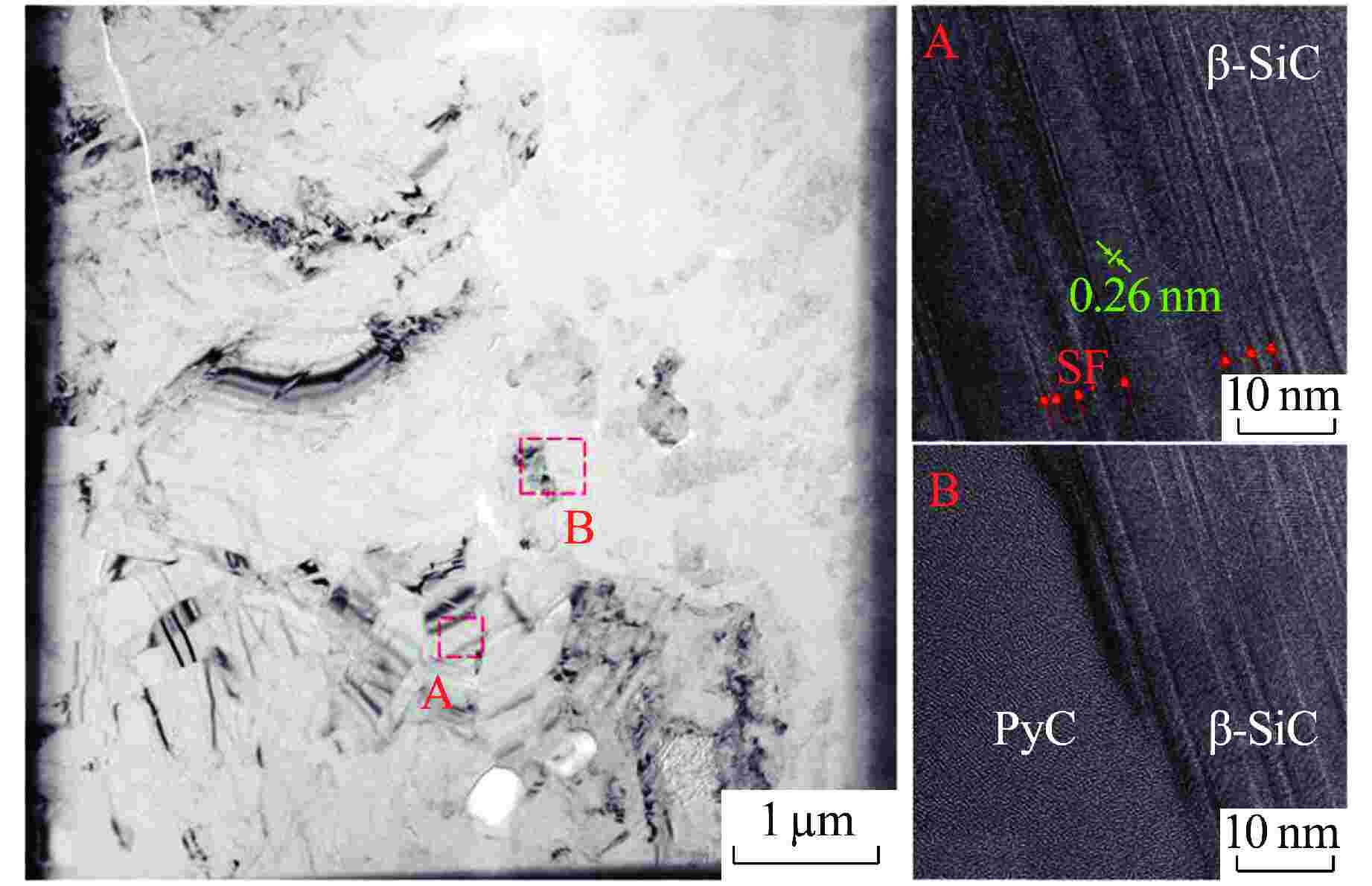

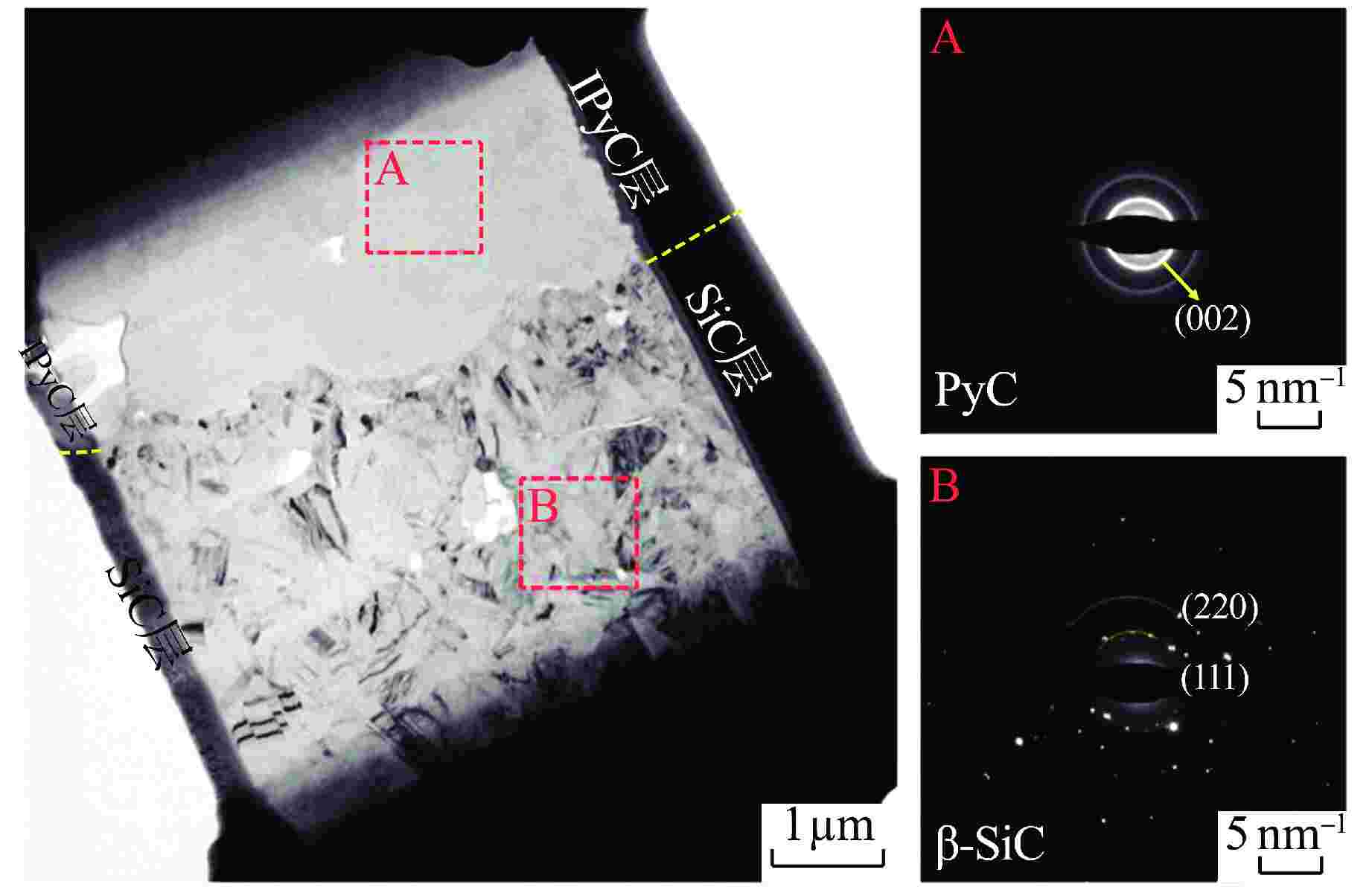

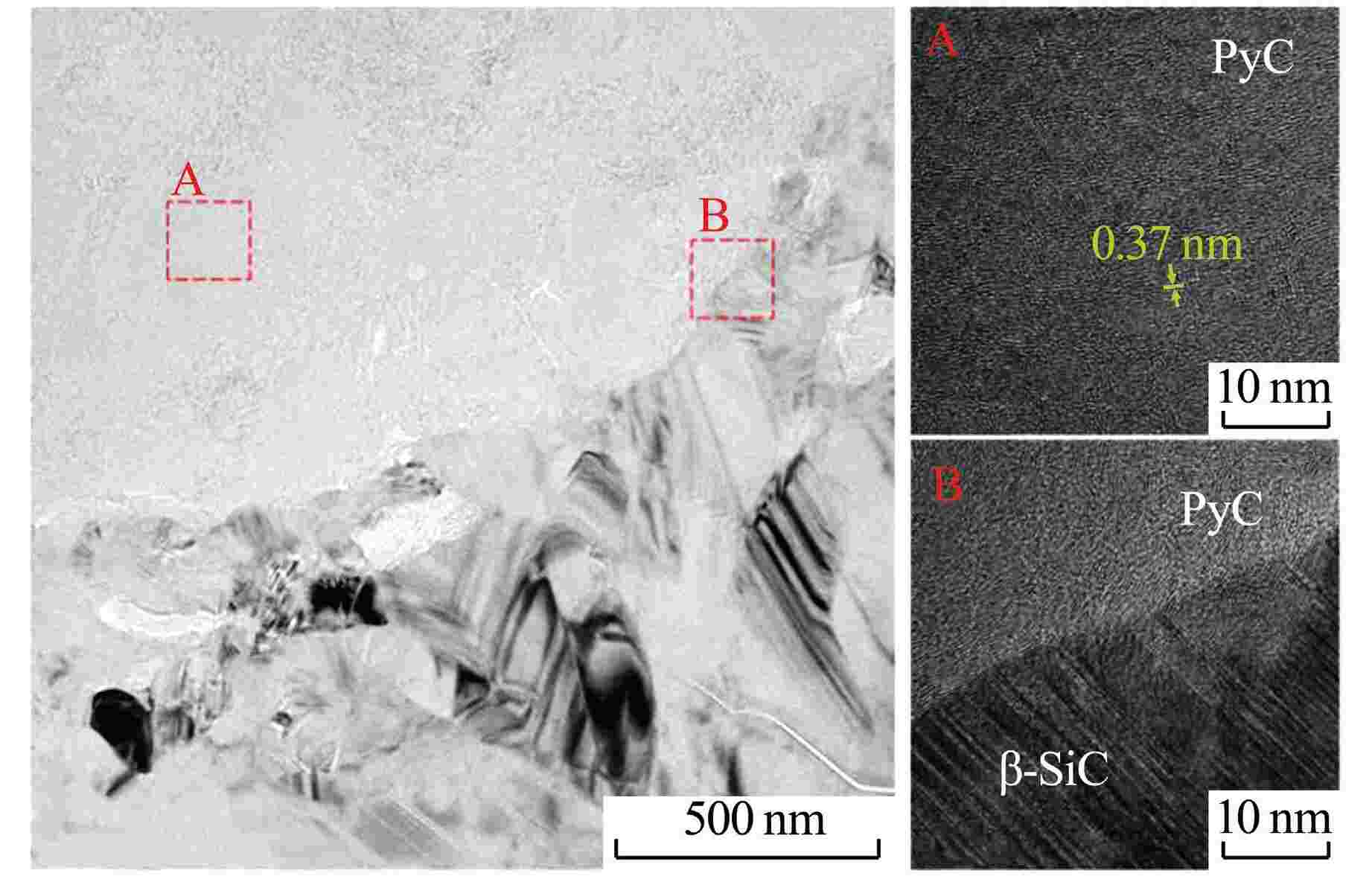

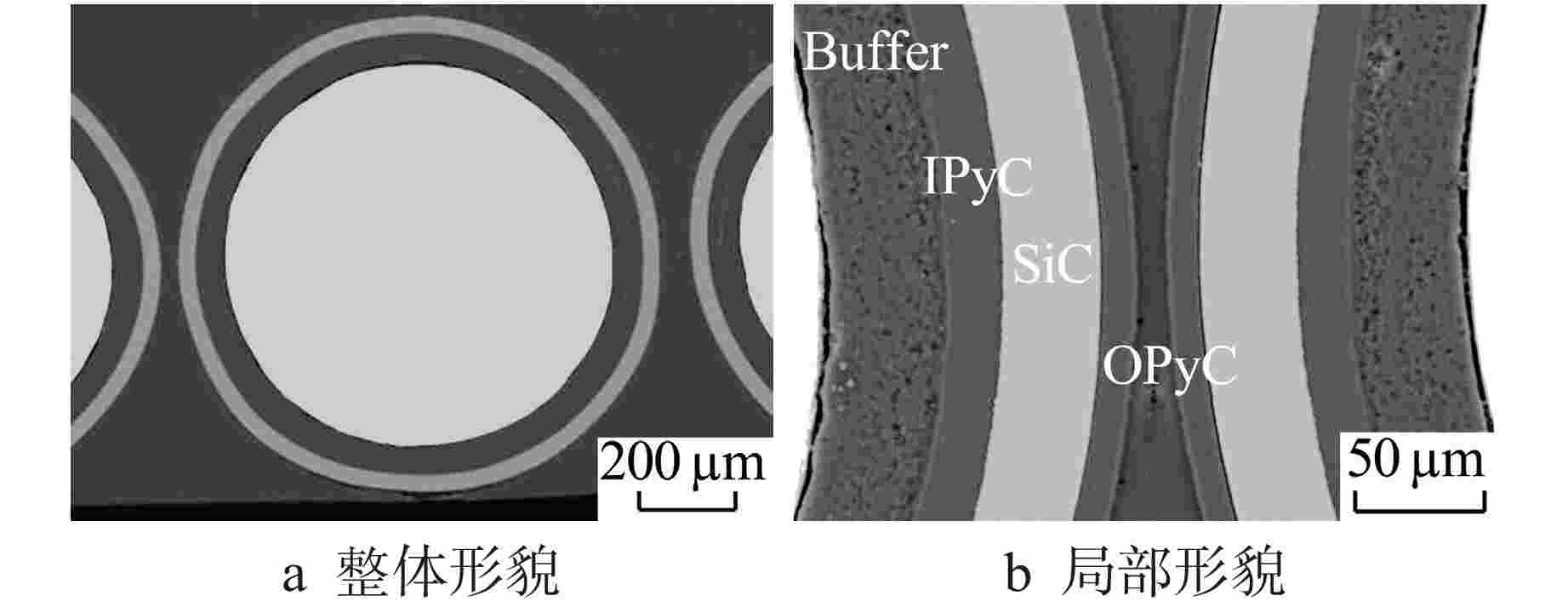

The TRISO microspheres were prepared by fluidized-bed chemical vapor deposition (FBCVD) process with ZrO

2 microspheres as simulated cores. The microstructures of the coating layers of the microspheres were inspected by SEM and TEM, and the elastic modulus as well as Vickers hardness of the coating layers were tested by micro indentation. Furthermore, the fracture strength of the SiC layer was tested by the crushing test. The results indicate that: ①the Buffer layer of the TRISO microspheres is composed of a large number of spherical particles, and there are many large pores in the coating layer; ②the microstructures of the IPyC and OPyC layers are similar, which are composed of a large number of spherical carbon particles coated with lamellar structure, with relatively high density; ③ the SiC layer exists in a typical β-SiC crystal state, and the atomic layer spacing is 0.26 nm; ④among all the coating layers, the Buffer layer has the lowest elastic modulus and hardness, which are about 13.29 GPa and 1.78 GPa respectively; however, the elastic modulus and hardness of inner PyC layer are about 25.80 GPa and 3.18 GPa respectively, and the elastic modulus and hardness of outer layer PyC are about 28.15 GPa and 3.66 GPa respectively; ⑤ for SiC layer, it has the highest elastic modulus and hardness, which are about 141.4 GPa and 21.3 GPa respectively, and its average fracture strength is 2581 GPa. The different structures of TRISO microspheres coatings come from different deposition process, and the thermal decomposition reaction of precursor gas is the key to controlling the coating structure. This paper studies the structure and mechanical characteristics of the TRISO microspheres, and obtains corresponding performance data, which has important guiding significance for the design and application of TRISO microspheres and the prediction of in-reactor radiation.

下载:

下载: