Research on Hoop Mechanical Property of Zr-Sn-Nb Alloy Cladding Tubes in Vacuum

-

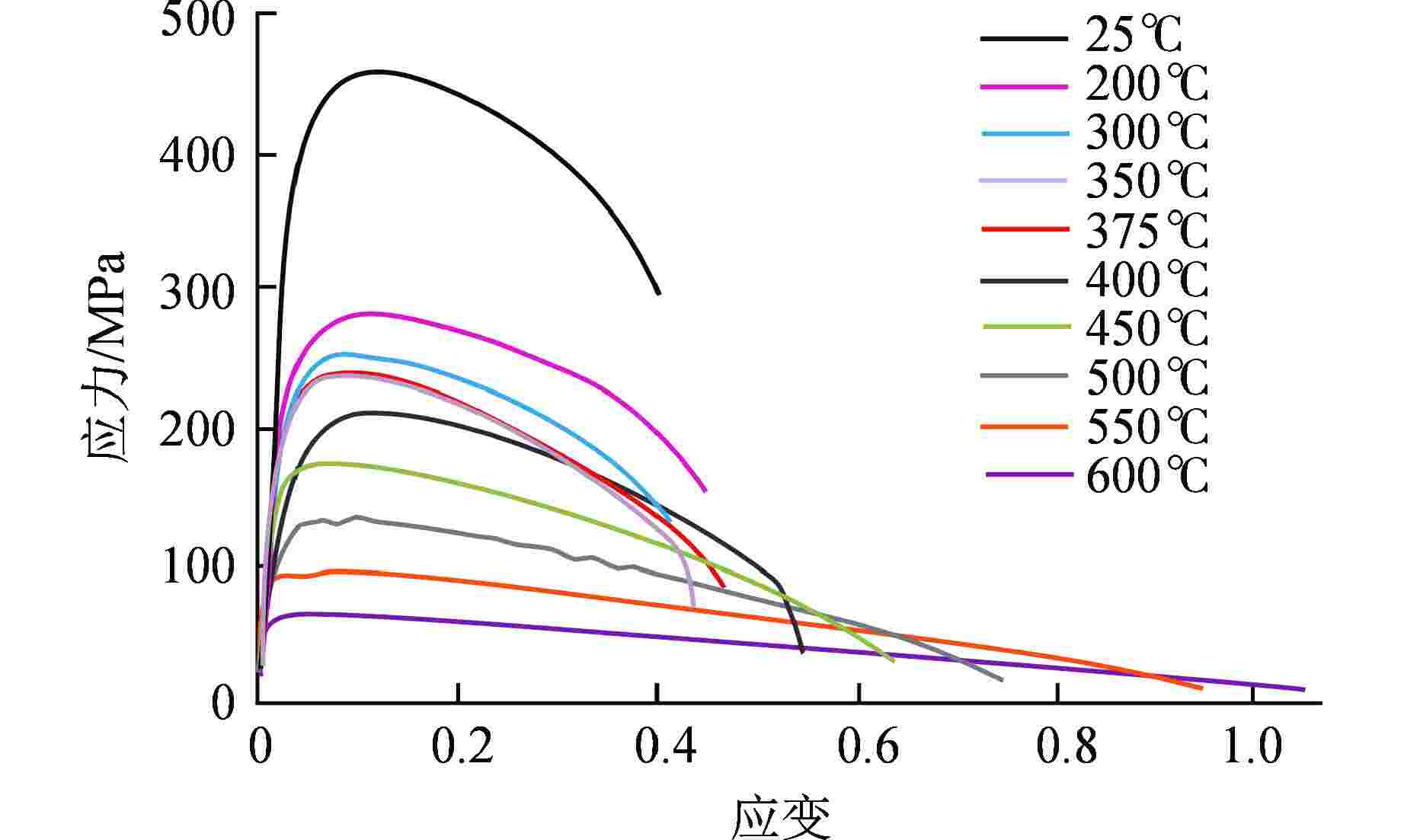

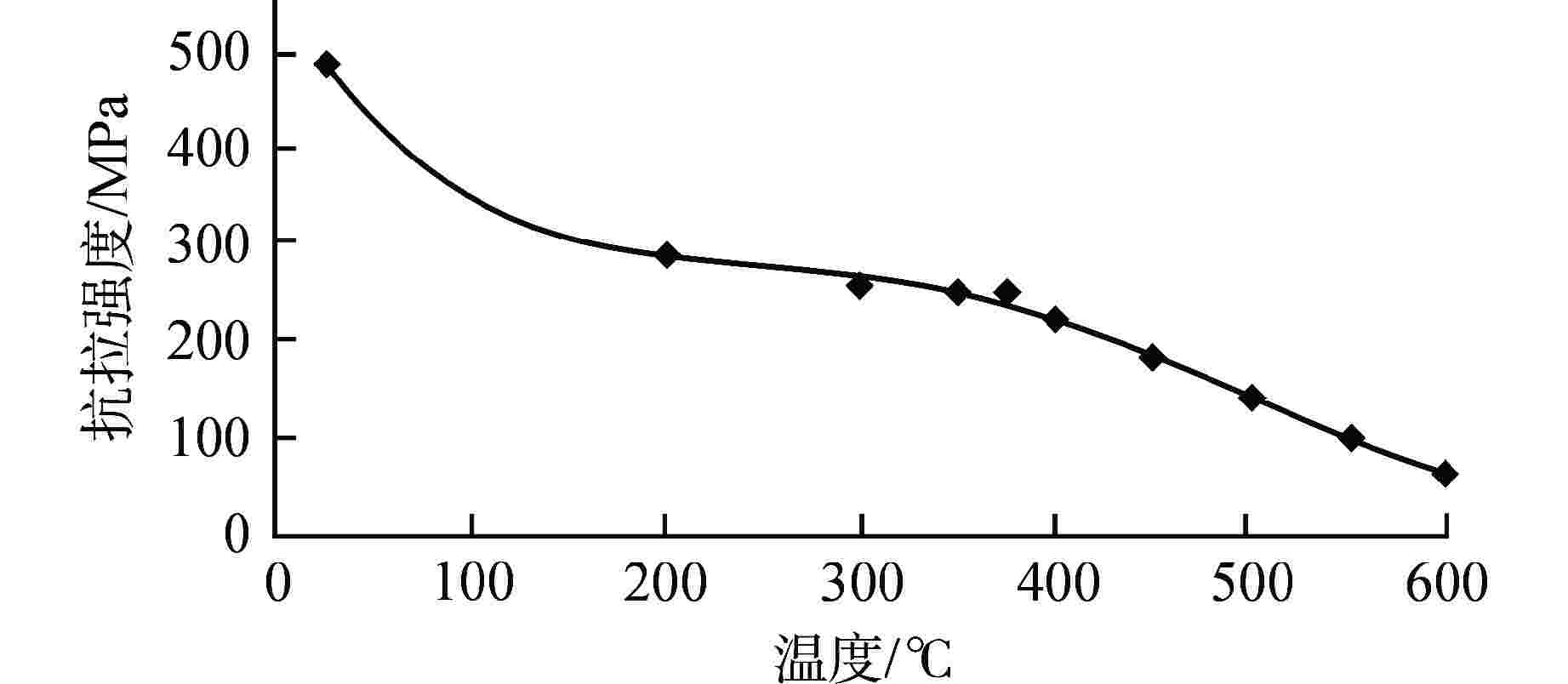

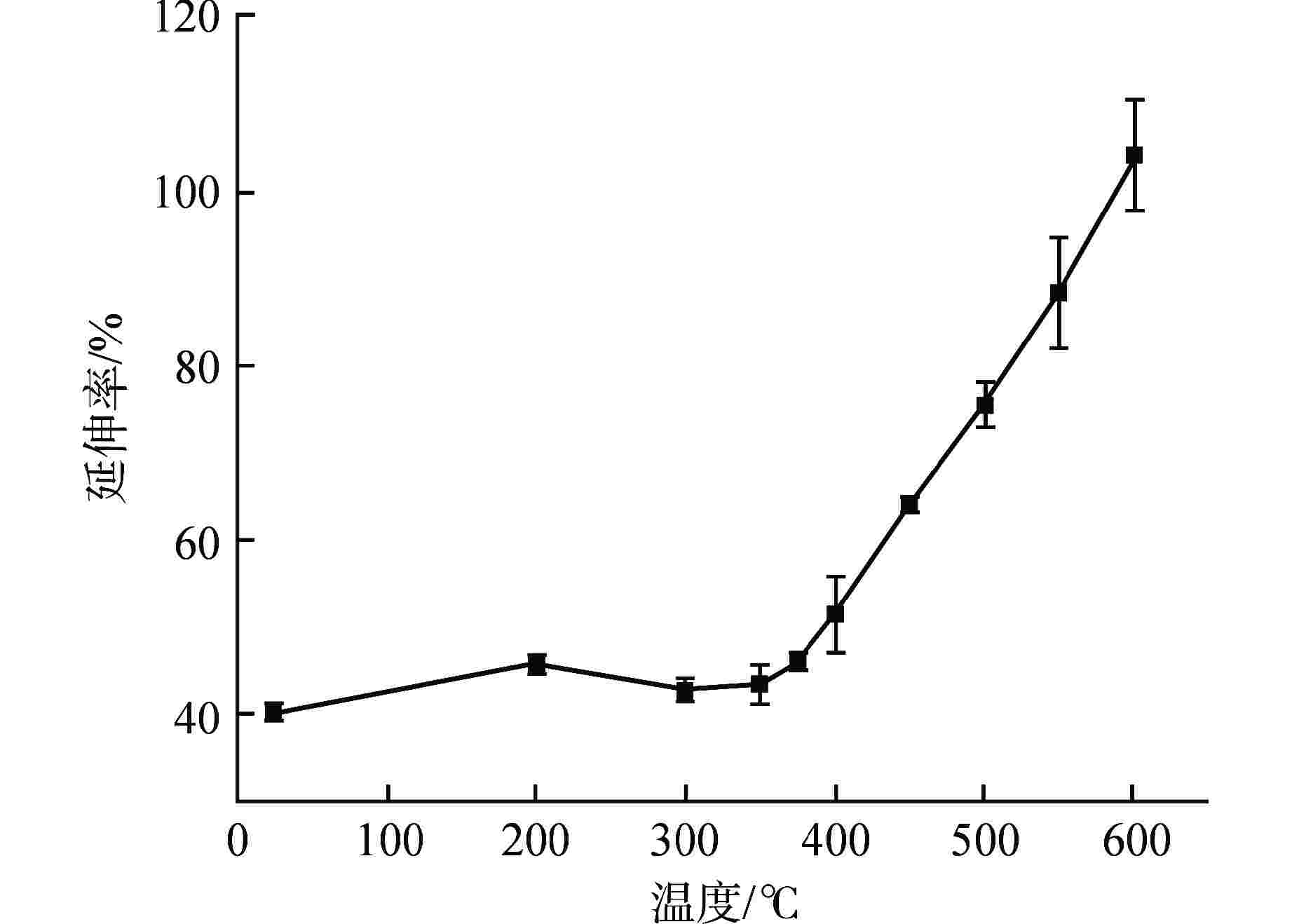

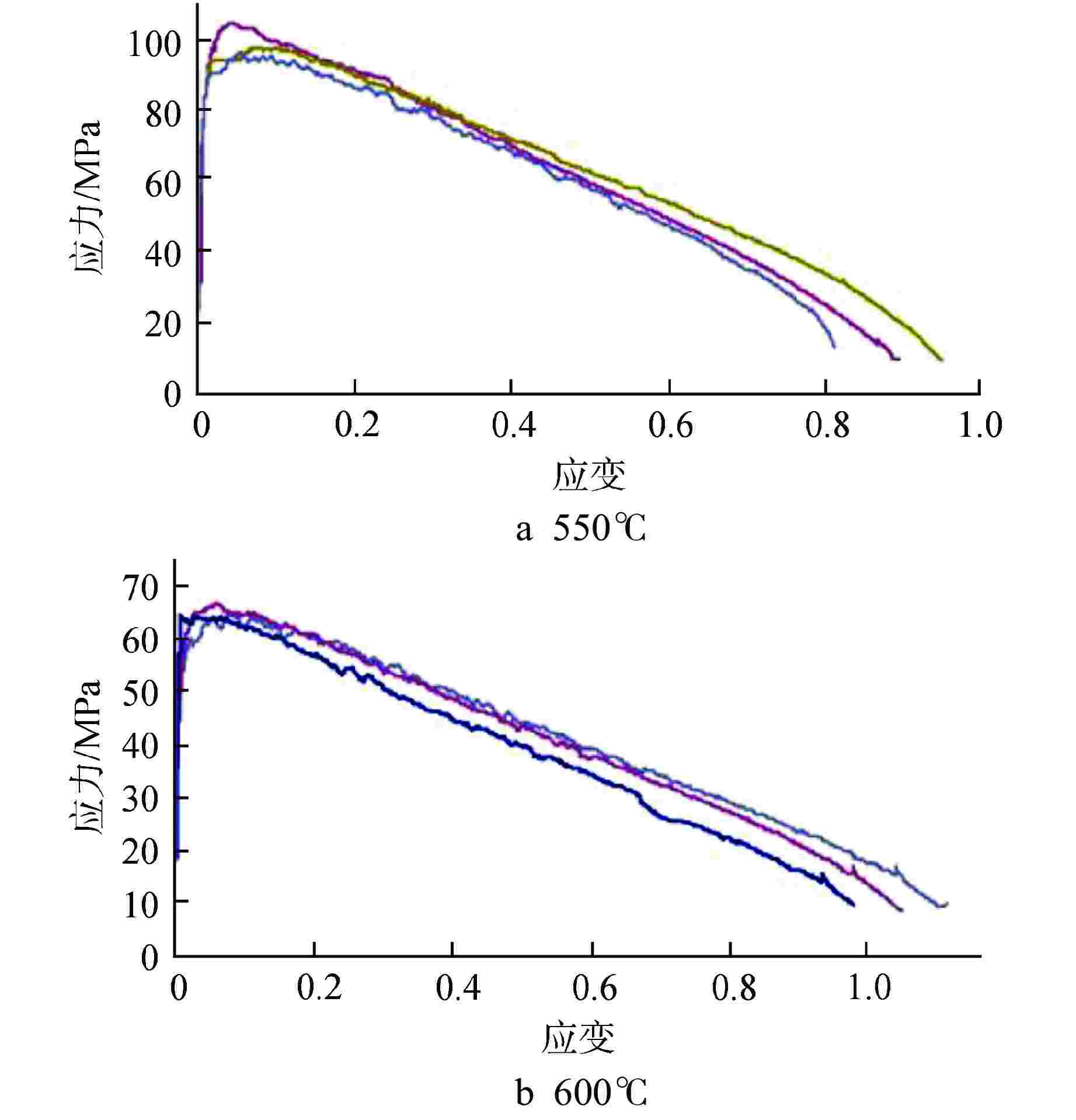

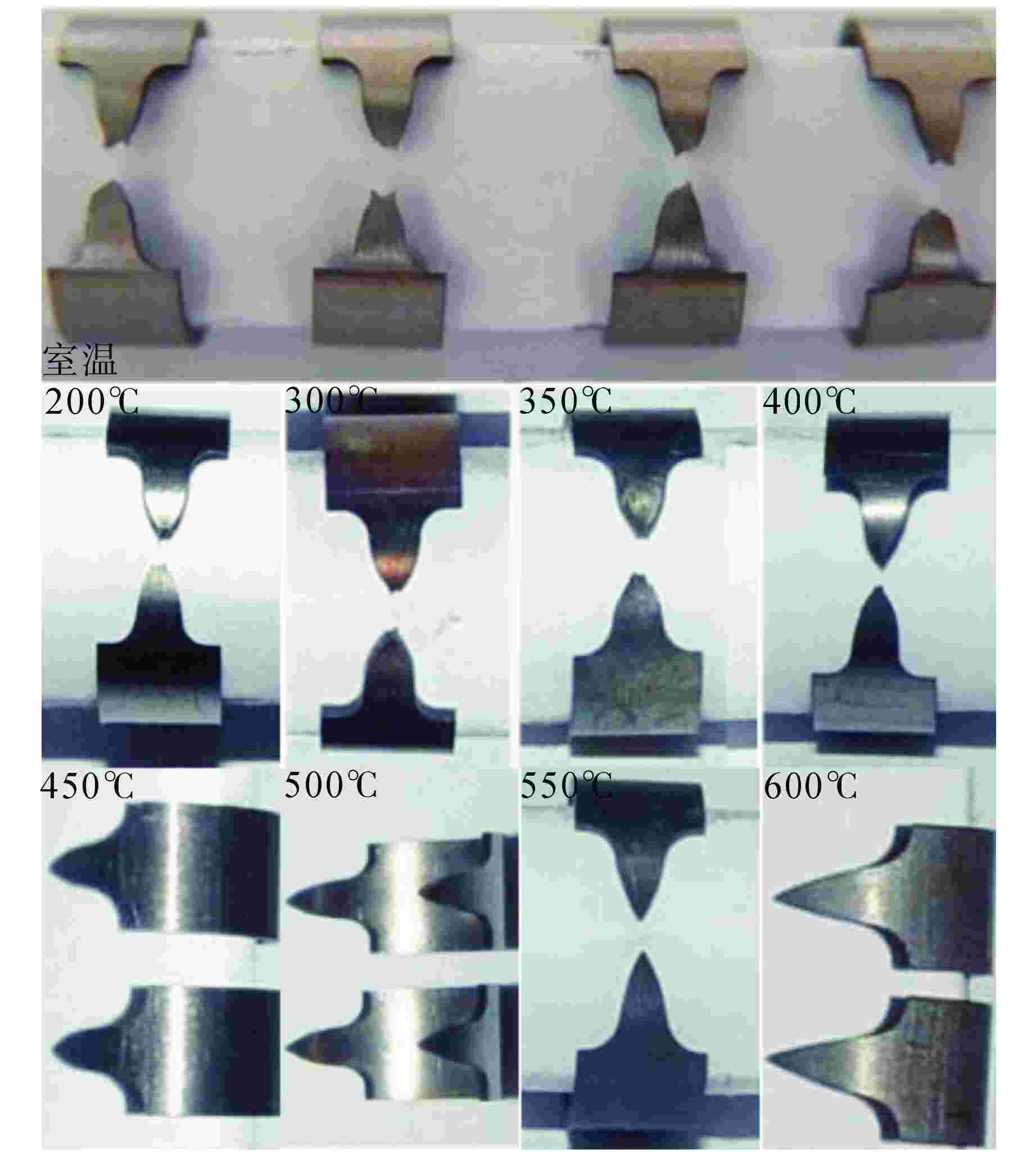

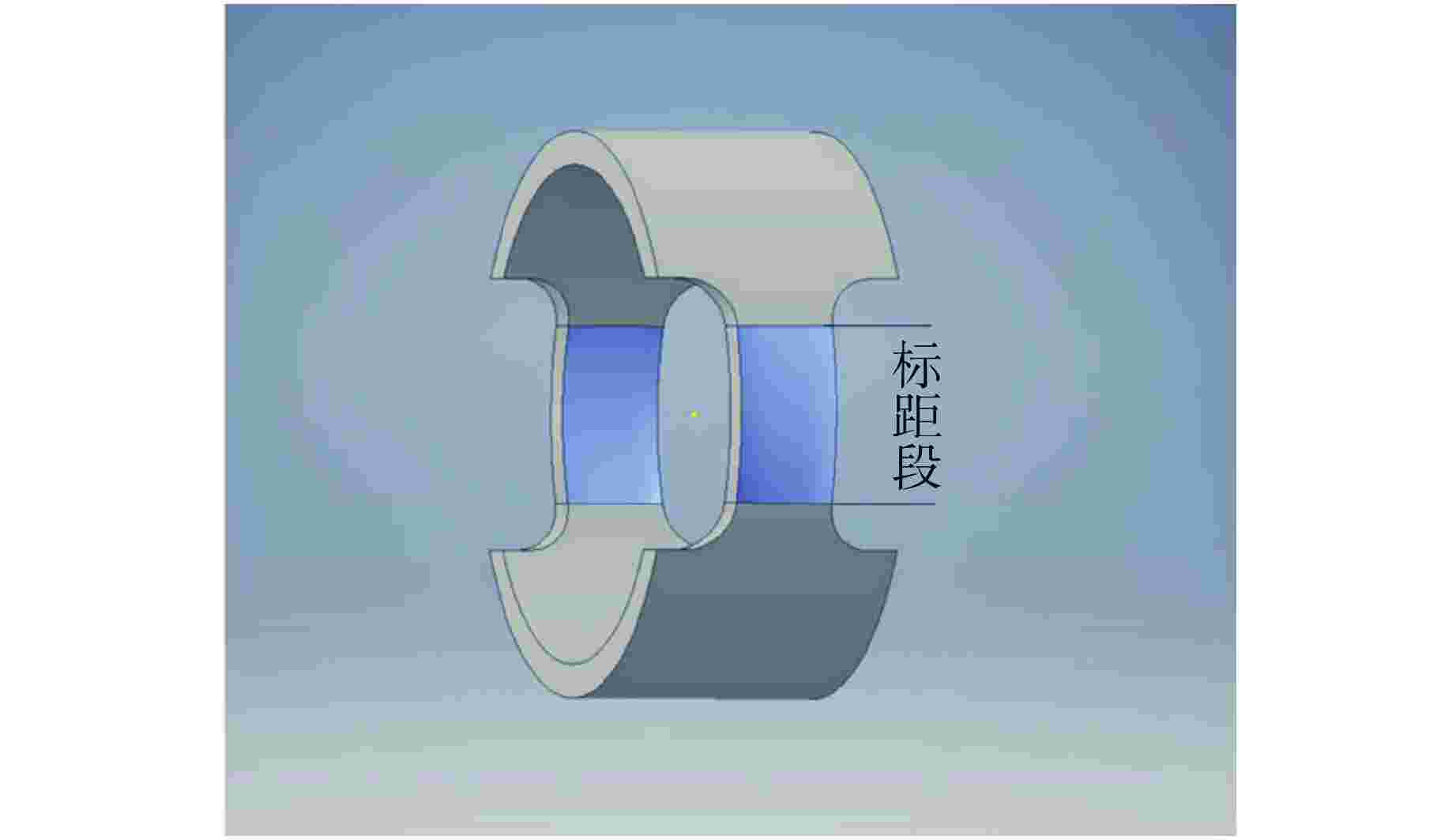

摘要: 目前关于小尺寸管材环向拉伸的方法没有标准可参考,国内外锆合金包壳管环向拉伸研究方法也不统一,对于国产Zr-Sn-Nb合金包壳管,环向力学性能尚处于空白。本文采用带标距的环形试样,获得了Zr-Sn-Nb合金包壳管真空环向拉伸力学性能数据。结果表明:室温至600℃ 时,环向拉伸强度和延伸率均随温度上升而下降,但在300~400℃ 之间受动态应变时效的影响环向拉伸强度出现不随温度变化的平台段,相同温度条件下,真空环向拉伸强度低于轴向拉伸,差距随着温度升高而扩大;550℃和600℃时,受动态再结晶的影响环向拉伸曲线发生波浪式抖动;不同温度断口特征差异明显,说明环向拉伸断裂形式严重依赖试样变形温度。

-

关键词:

- Zr-Sn-Nb合金 /

- 真空环向拉伸 /

- 动态应变时效

Abstract: At present, there is no reference standard for hoop tensile testing of small-diameter tubes and there is also no uniform research method for hoop tensile testing of zirconium alloy cladding tubes in the worldwide research field. As to home-made Zr-Sn-Nb alloy cladding tubes, there is no data in hoop mechanical property. In this paper, the hoop tensile mechanical properties of Zr-Sn-Nb alloy cladding tubes in vacuum were obtained by using the hoop specimen with a gauge section. The results show that hoop tensile strengths and elongations dropped with temperature rise from room temperature to 600℃, but there is an abnormal phenomenon with flat stage in strength at 300-400℃ due to the influence of the dynamic strain aging, the hoop tensile strengths are lower than the axial tensile strengths at the same temperature in vacuum, and the gap widened as the temperature increased; the hoop tensile curve at 550℃ and 600℃ jitters wavelike due to the influence of dynamic recrystallization; the fracture characteristics vary significantly at different temperatures, indicating that the hoop tensile fracture mode depended on the temperature heavily.-

Key words:

- Zr-Sn-Nb alloy /

- Hoop tensile in vacuum /

- Dynamic stain aging

-

表 1 Zr-Sn-Nb合金包壳管轴向与环向抗拉强度比较

Table 1. Hoop Tensile Strength Comparison on Axial and Hoop Direction of Zr-Sn-Nb Alloy Cladding Tubes

温度/℃ 轴向抗拉强度/MPa 环向抗拉强度/MPa 25 507 485 200 323 290 300 282 260 350 260 250 375 250 400 245 220 450 215 183 500 175 141 550 133 100 600 99 65 -

[1] KIM S K, BANG J G, KIM D H, et al. Mechanical property evaluation of high burn-up nuclear fuel cladding using the ring tensile test[J]. Metals and Materials International, 2009, 15(4): 547-553. doi: 10.1007/s12540-009-0547-0 [2] LE SAUX M, BESSON J, CARASSOU S, et al. A model to describe the anisotropic viscoplastic mechanical behavior of fresh and irradiated Zircaloy-4 fuel claddings under RIA loading conditions[J]. Journal of Nuclear Materials, 2008, 378(1): 60-69. doi: 10.1016/j.jnucmat.2008.04.017 [3] DESQUINES J, KOSS D A, MOTTA A T, et al. The issue of stress state during mechanical tests to assess cladding performance during a reactivity-initiated accident (RIA)[J]. Journal of Nuclear Materials, 2011, 412(2): 250-267. doi: 10.1016/j.jnucmat.2011.03.015 [4] BATES D W, KOSS D A, MOTTA A T, et al. Influence of specimen design on the deformation and failure of Zircaloy cladding[C]//Proceedings of the 2000 International Topical Meeting on LWR Fuel Performance. Park City: Argonne National Lab., 2000. [5] MAHMOOD S T, MURTY K L. Localized plastic flow, anisotropic mechanical properties and crystallographic texture in Zircaloy sheet[J]. Journal of Materials Engineering, 1989, 11(4): 315-329. doi: 10.1007/BF02834141 [6] PIERRON O N, KOSS D A, MOTTA A T. Tensile specimen geometry and the constitutive behavior of Zircaloy-4[J]. Journal of Nuclear Materials, 2003, 312(2-3): 257-261. doi: 10.1016/S0022-3115(02)01554-4 [7] NAGASE F, SUGIYAMA T, FUKETA T. Optimized ring tensile test method and hydrogen effect on mechanical properties of Zircaloy cladding in hoop direction[J]. Journal of Nuclear Science and Technology, 2009, 46(6): 545-552. doi: 10.1080/18811248.2007.9711560 [8] 谭军. 锆合金的热激活变形与动态应变时效研究[D]. 成都: 中国核动力研究设计院, 2009 [9] 谭军,李聪,孙超,等. Zr-4合金应力松弛过程中的热激活变形与动态应变时效[J]. 金属学报,2009, 45(2): 173-177. doi: 10.3321/j.issn:0412-1961.2009.02.008 [10] 弗罗斯特B R T. 核材料(第II部分)[M]. 周邦新, 译. 北京: 科学出版社, 1999: 18. [11] 刘建章. 核结构材料[M]. 北京: 化学工业出版社, 2007: 79-82. -

下载:

下载: