Development and Application of Cooling Characteristic Analysis Code for Molten Debris Bed

-

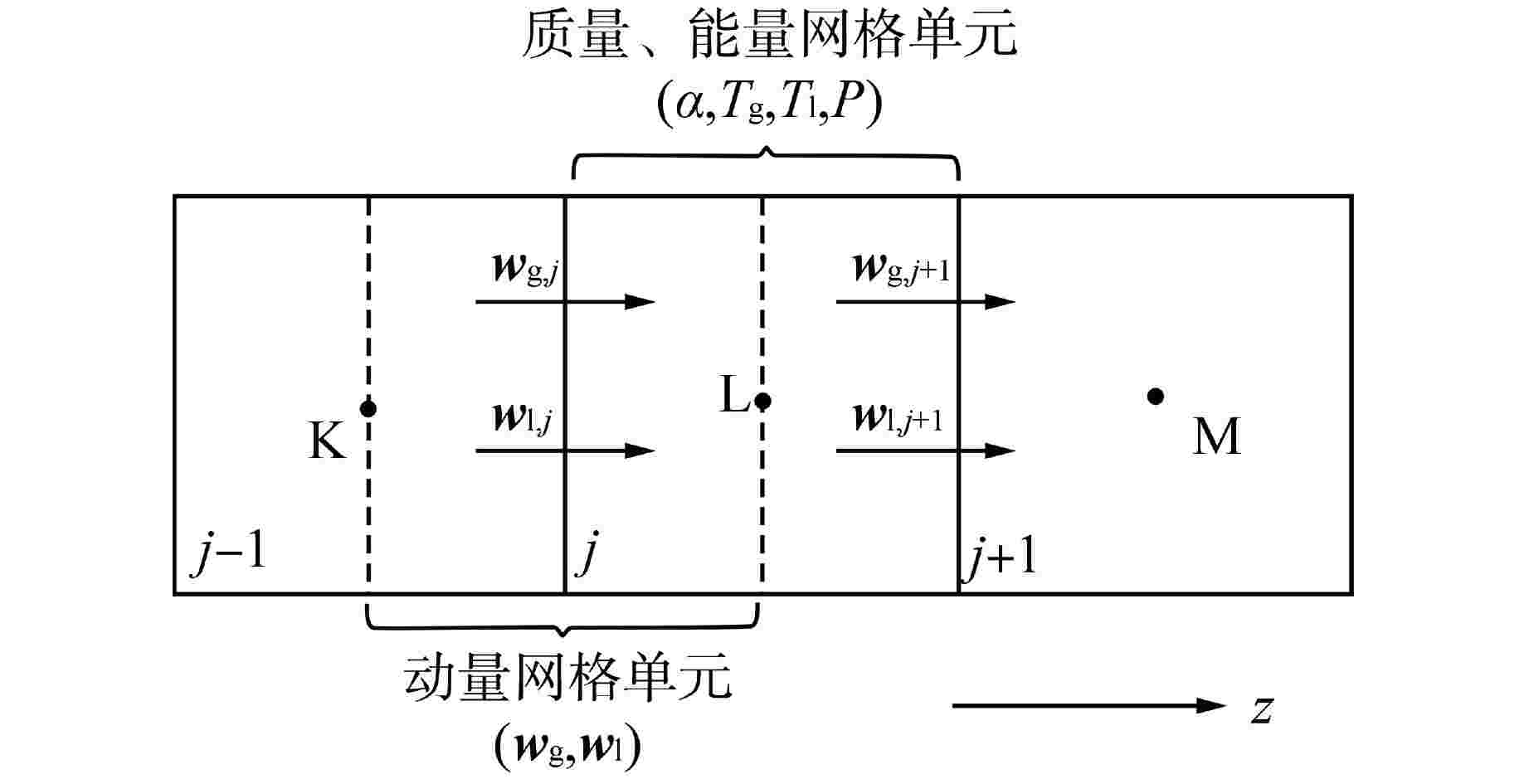

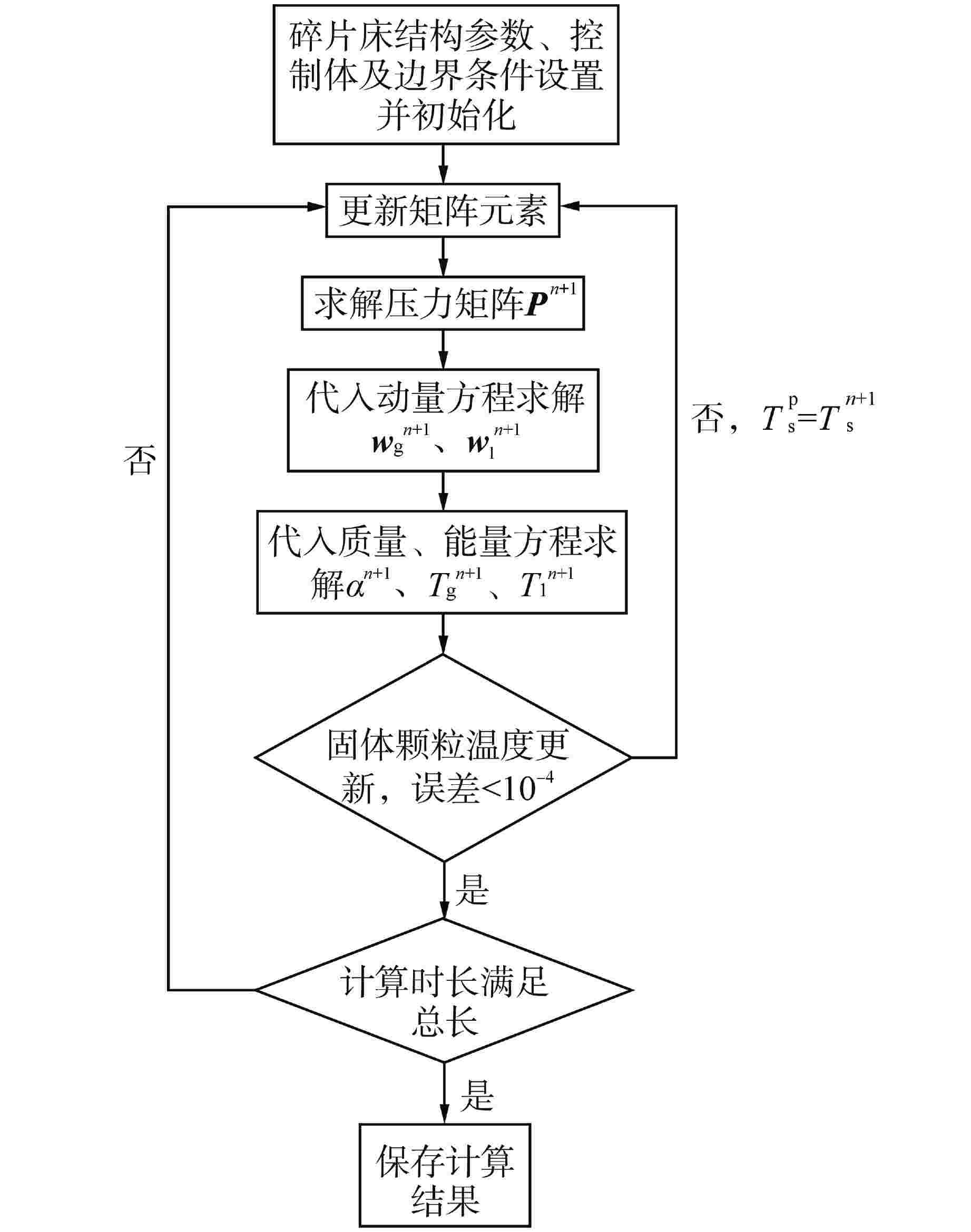

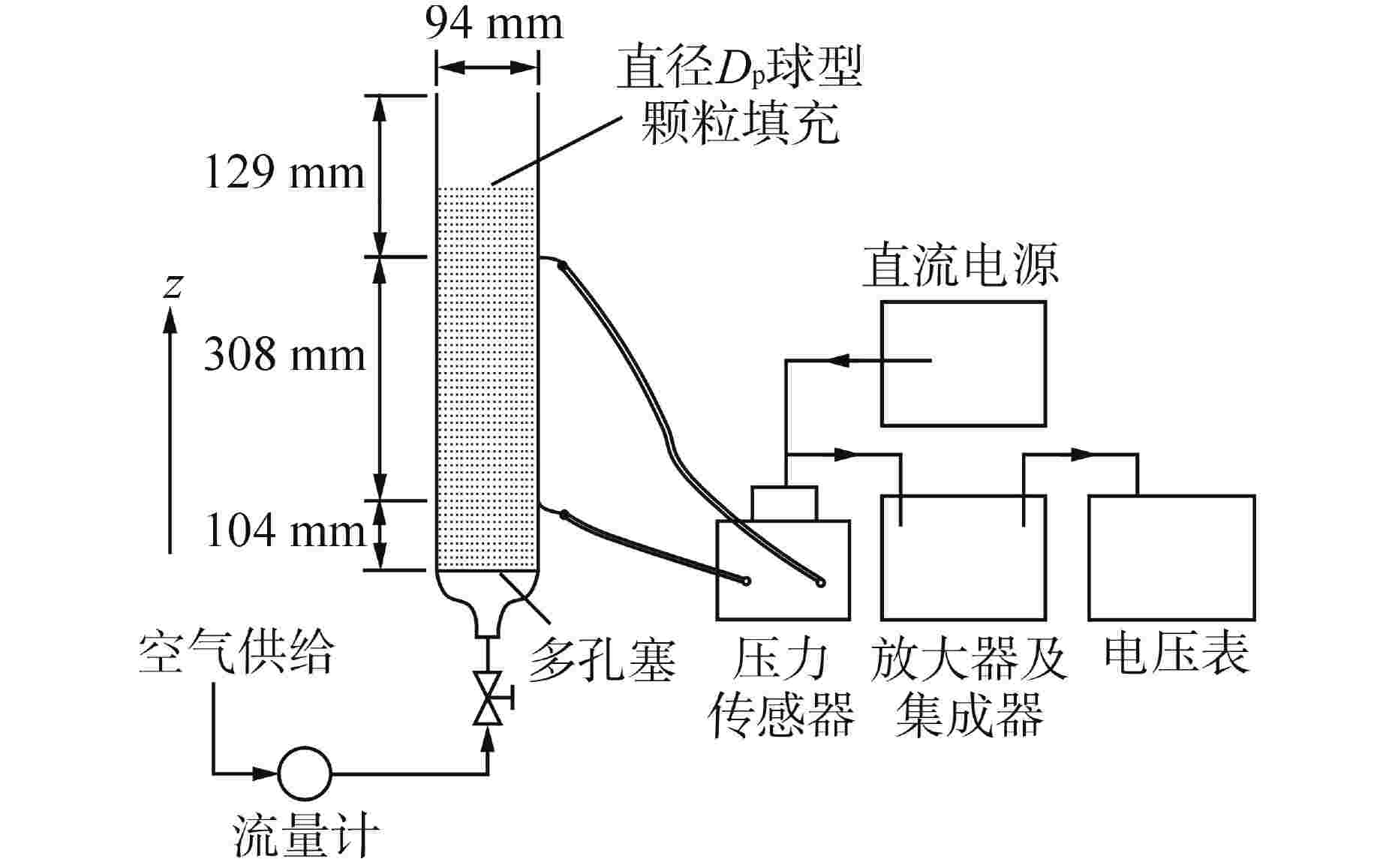

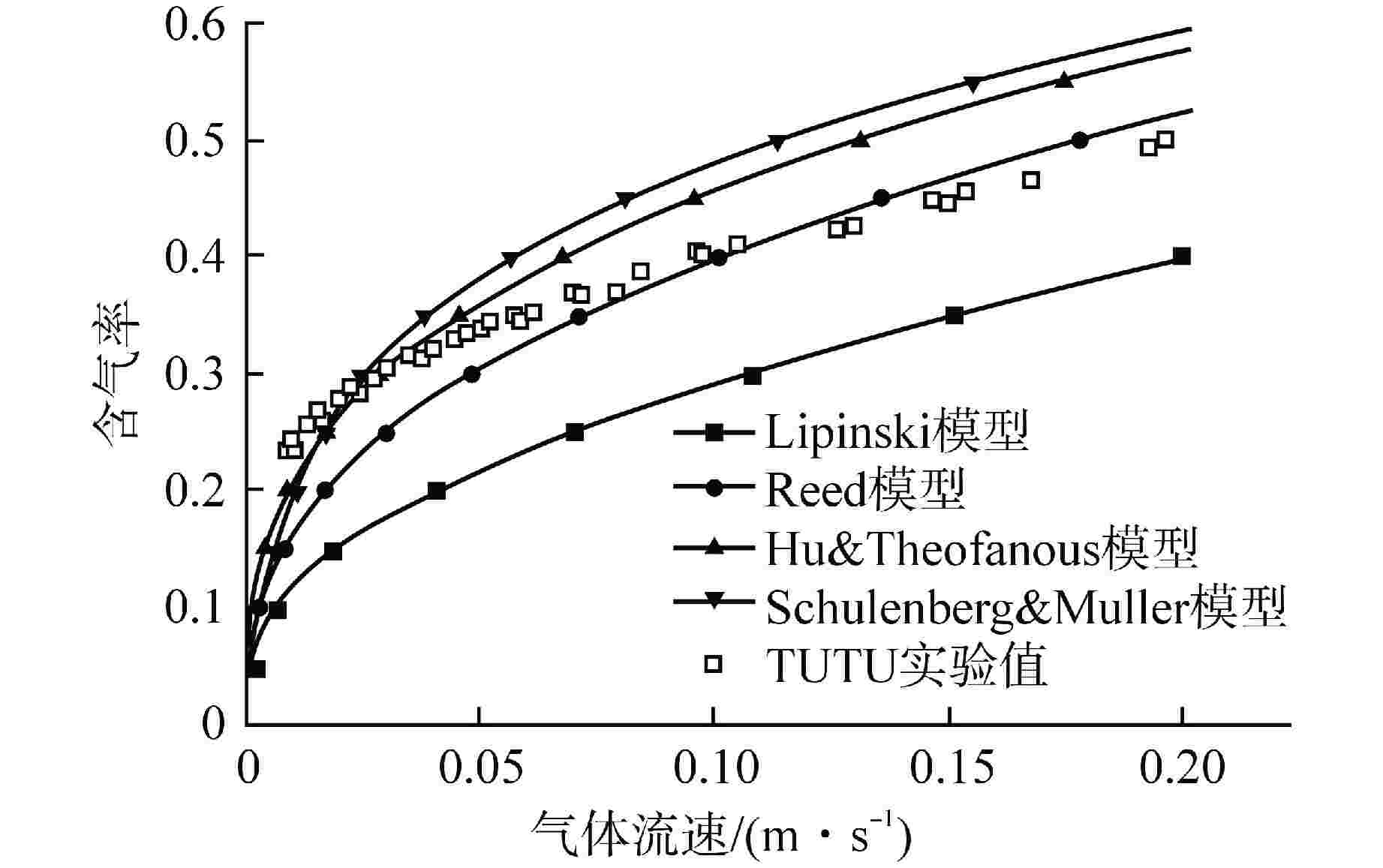

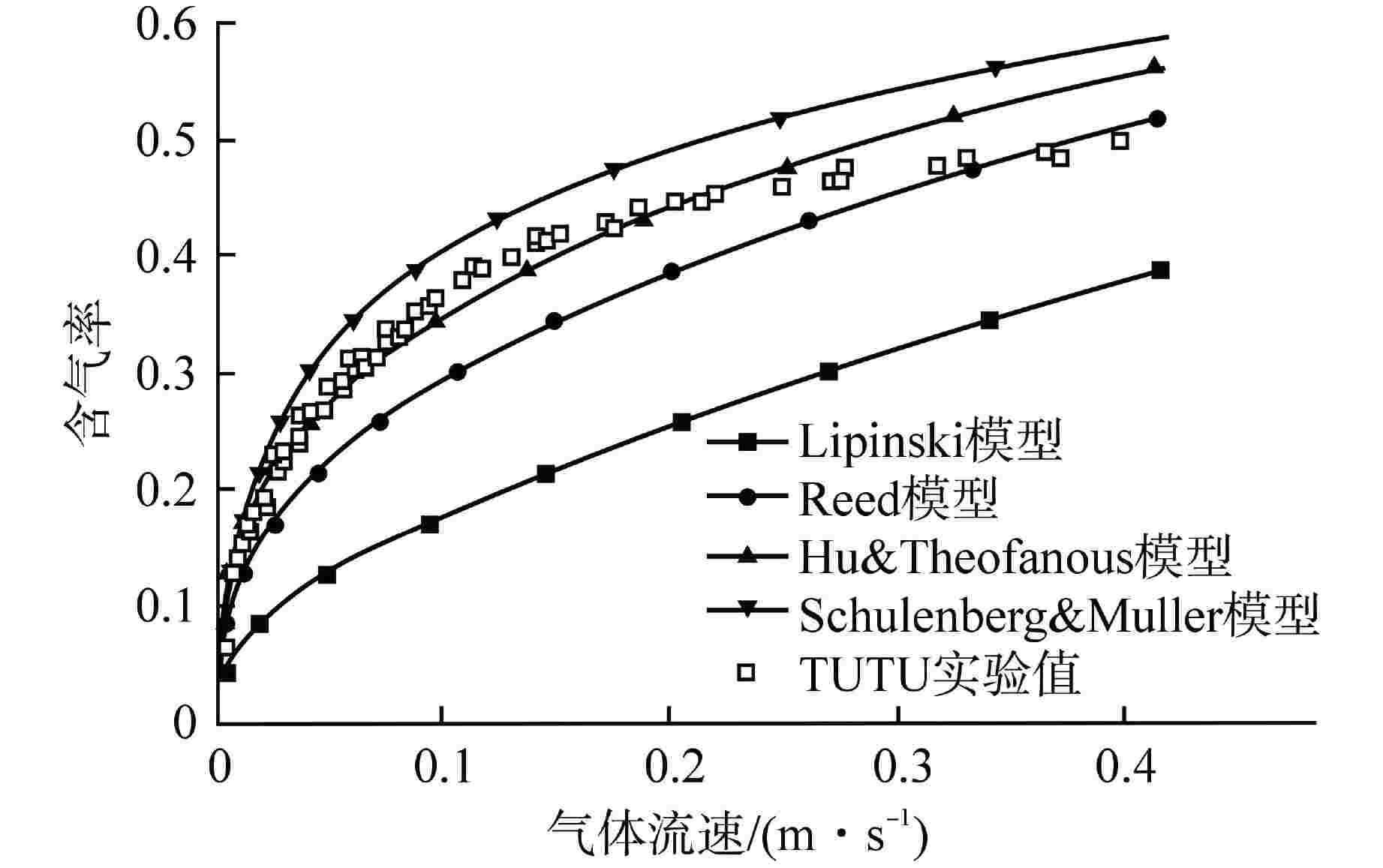

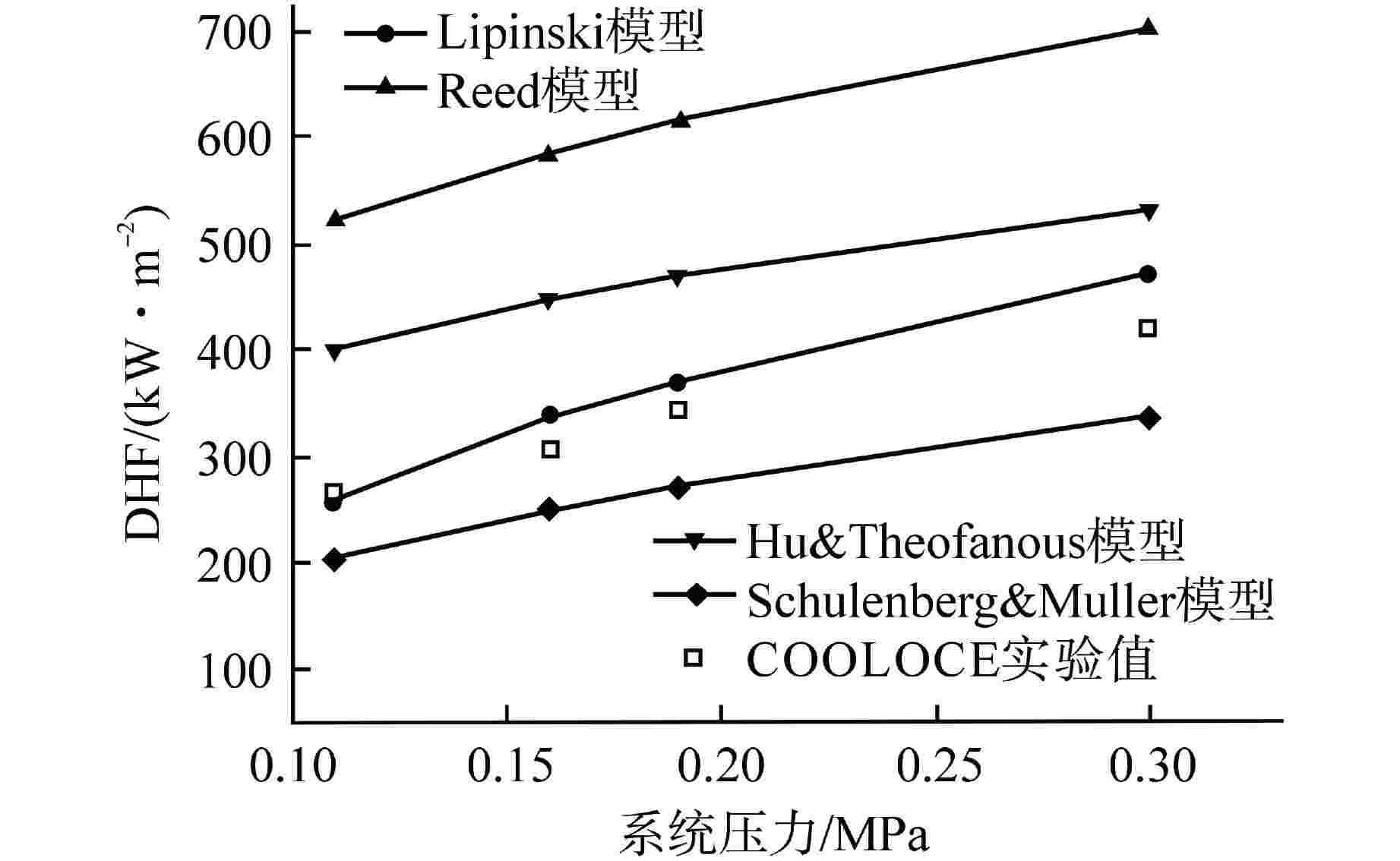

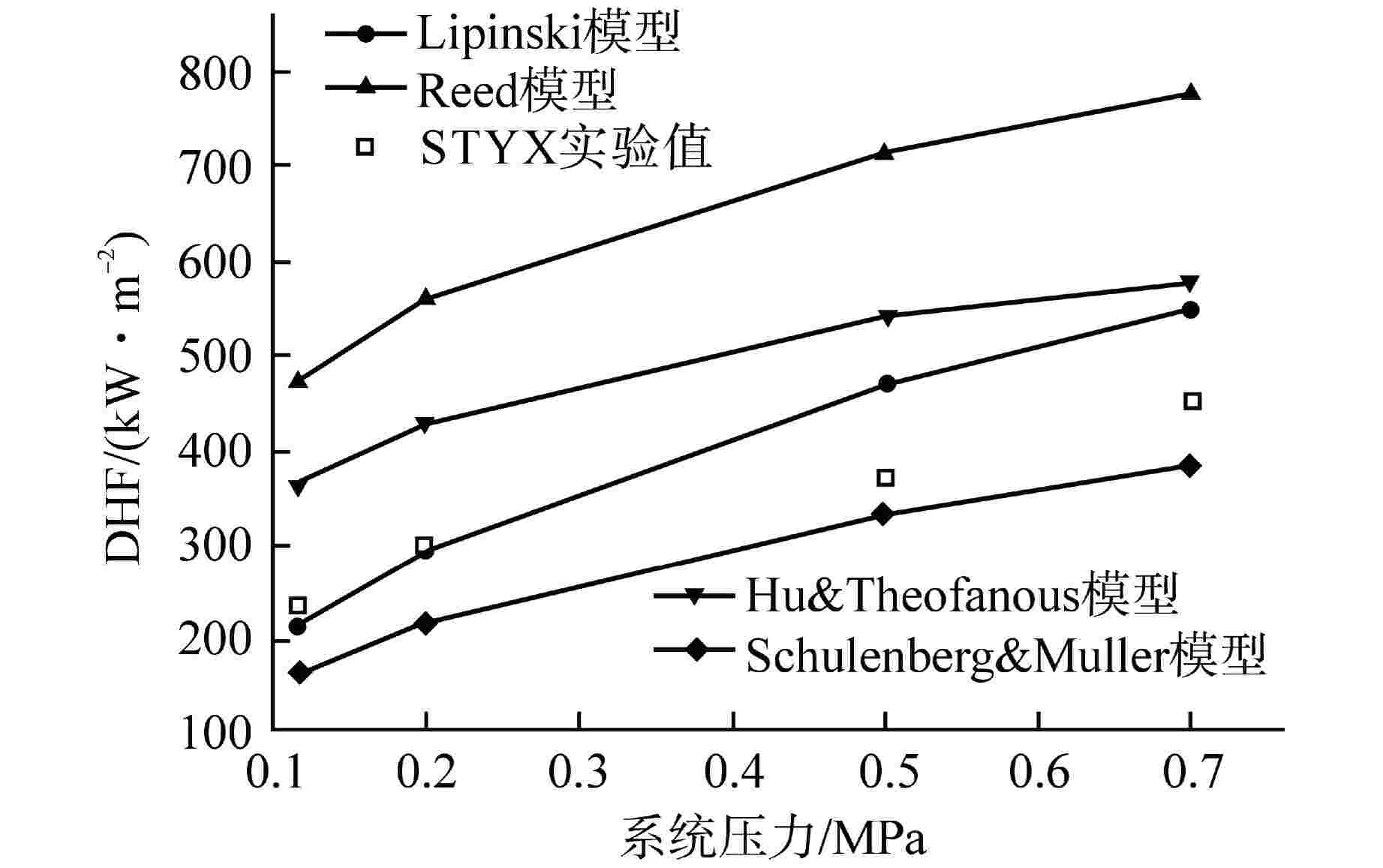

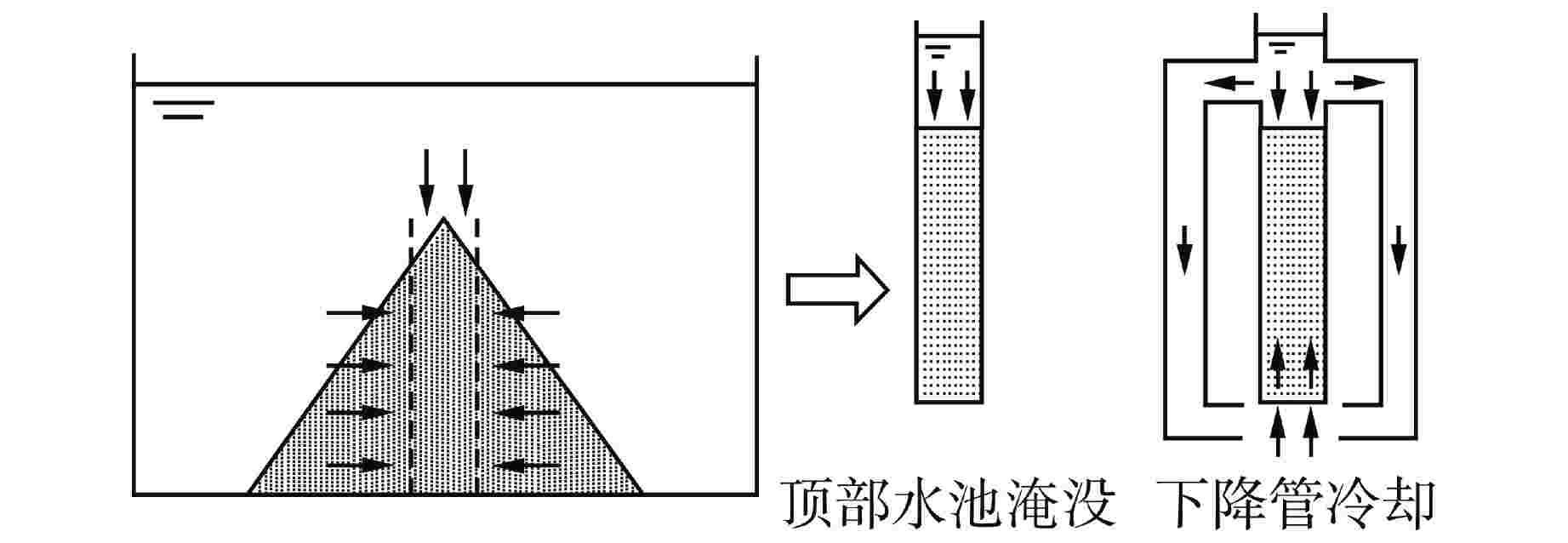

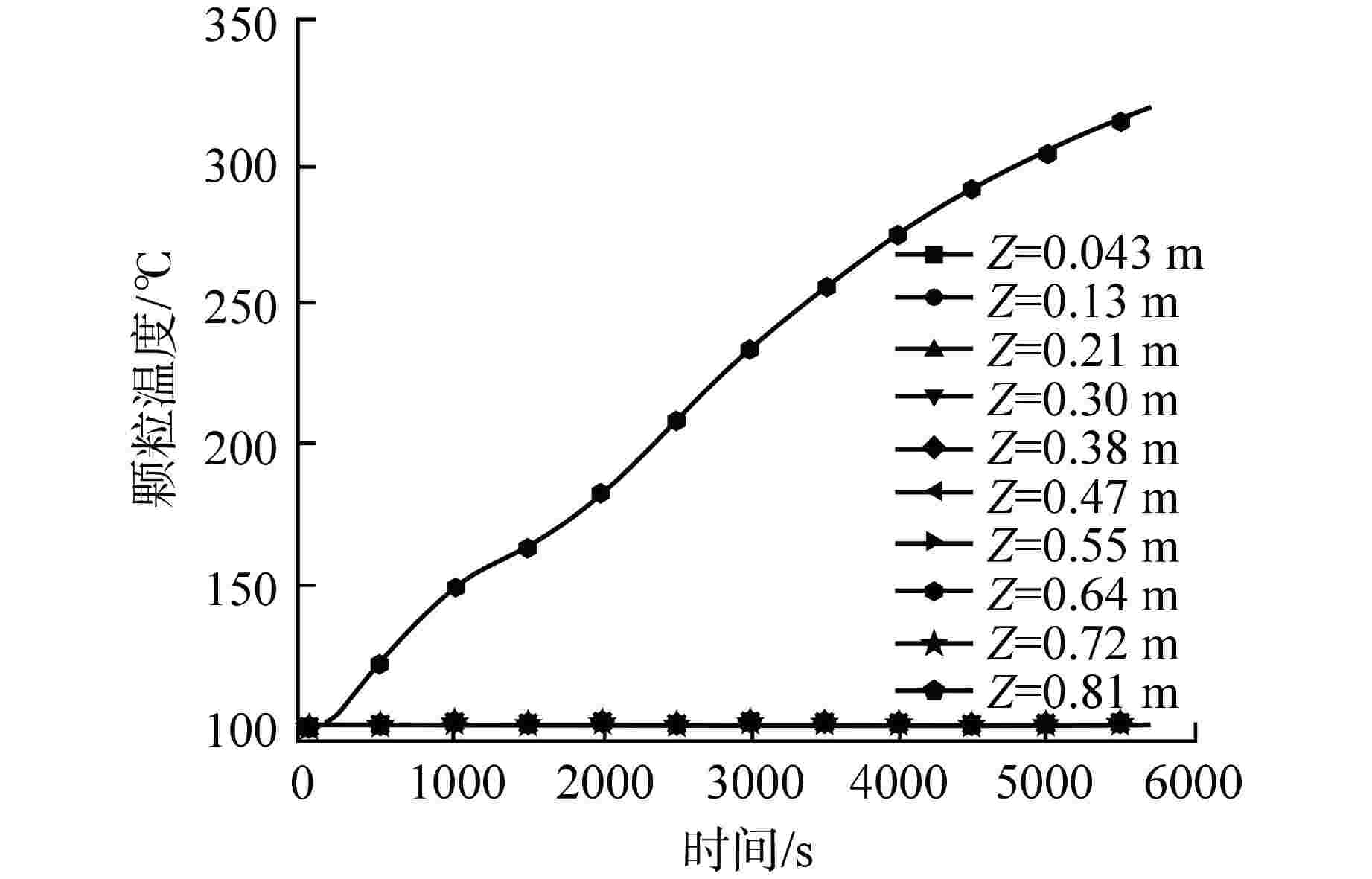

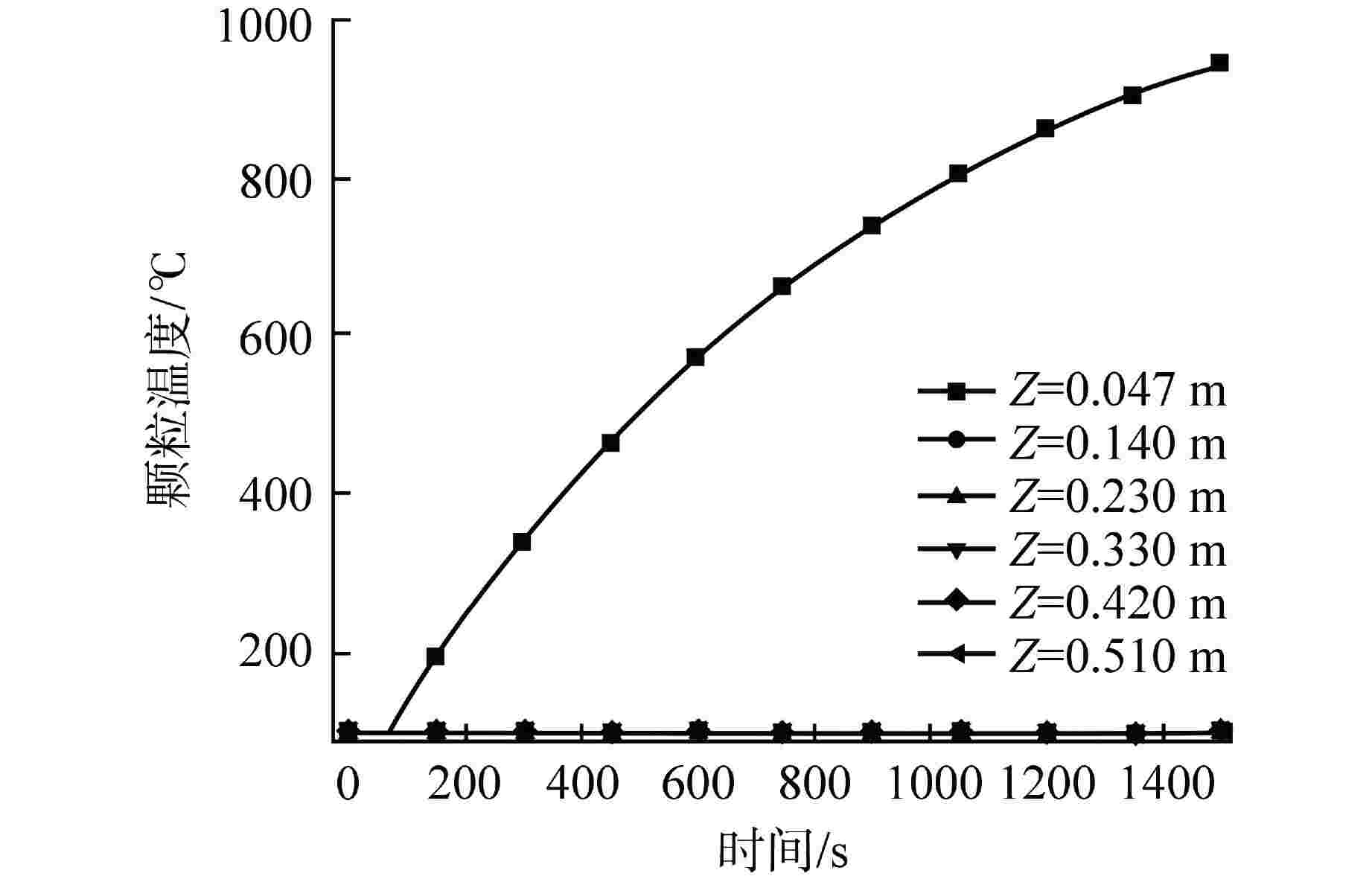

摘要: 为分析压水堆严重事故后期形成碎片床的冷却特性,开发了熔融物碎片床冷却特性分析程序。以一维六方程的两相流模型为基础,应用多孔介质流动沸腾传热模型描述碎片床内两相流动传热物理过程,采用控制容积积分法、半隐式、一阶迎风格式对方程进行离散、求解。应用TUTU、COOLOCE、STYX实验结果,从两相流动及干涸热流密度(DHF)2个方面对模型进行验证,发现Hu&Theofanous模型和Reed模型对于粒径相对较大的碎片床的两相流动预测结果较好,而Lipinski模型对小颗粒碎片床的低压DHF的预测精度较高。利用程序对压水堆严重事故条件下熔融物碎片床的冷却能力进行预测,在1 MW/m3颗粒释热率、顶部水池淹没条件下,碎片床可被冷却高度为0.56 m;采用自然循环驱动底部注水冷却方式,碎片床可被冷却高度升至0.85 m。

-

关键词:

- 严重事故 /

- 碎片床 /

- 多孔介质 /

- 沸腾传热 /

- 干涸热流密度(DHF)

Abstract: To analyze the cooling characteristics of debris bed formed in the late stage of severe accident in pressurized water reactor, an analysis code for molten debris bed cooling was developed. Based on the one-dimensional six-equation two-phase flow model, the physical process of two-phase flow and heat transfer in the debris bed was described by using the porous medium flow boiling heat transfer model, and the equations were discretized and solved by using the controlled volume integral method, semi-implicit method and first-order upwind scheme. The results of TUTU, COOLOCE and STYX experiments were used to validate the model from aspects: two-phase flow and dry-out heat flux (DHF). It was found that Hu&Theofanous model and Reed model had better prediction results for the two-phase flow of debris bed with relatively large particle size, while Lipinski model had higher prediction accuracy for the low-pressure DHF of small particle debris bed. The cooling capacity of molten debris bed in severe accident of PWR was predicted by the code. At a particle heat release rate of 1 MW/m3, the cooling height of debris bed was 0.56 m under top-flooding condition; and the height increased to 0.85 m by using bottom-flooding driven by natural circulation.-

Key words:

- Severe accident /

- Debris bed /

- Porous media /

- Boiling heat transfer /

- Dry-out heat flux (DHF)

-

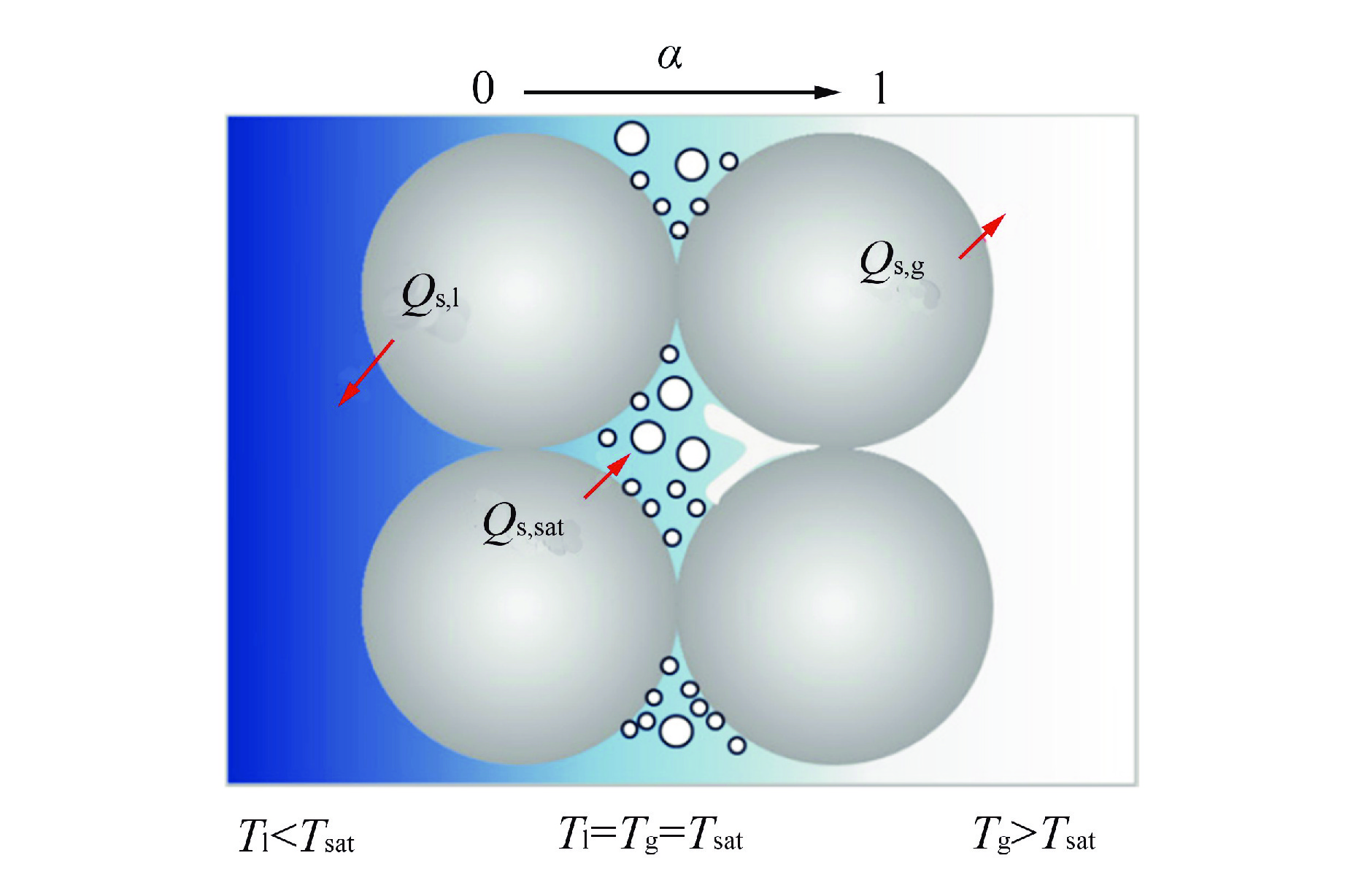

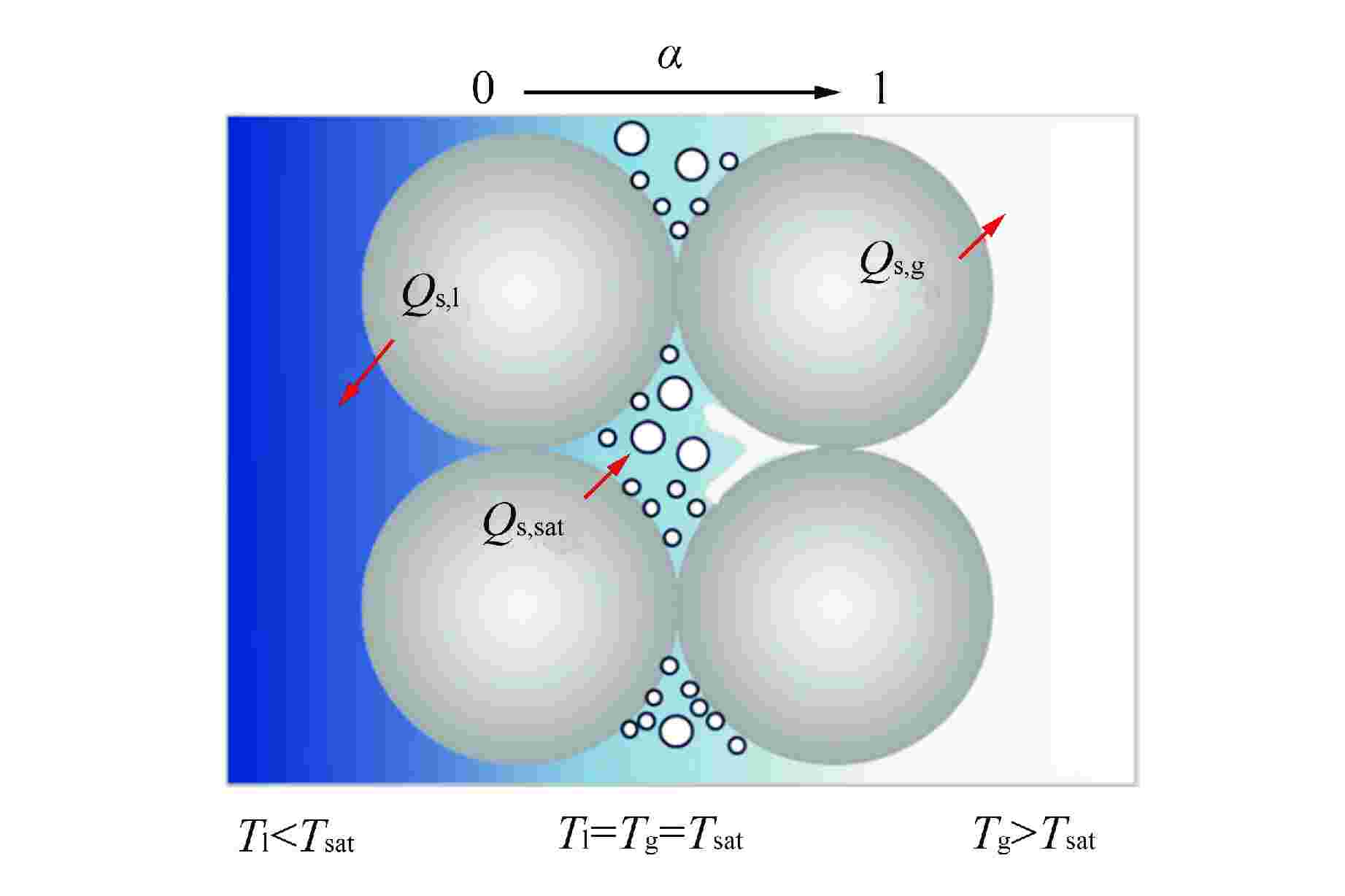

图 1 传热过程简图[8]

Figure 1. Diagram of Heat Transfer Process

-

[1] ERGUN S. Fluid flow through packed columns[J]. Chemical Engineering Progress, 1952, 48(2): 89-94. [2] LIPINSKI R J. A one-dimensional particle bed dryout model[J]. Transactions of the American Nuclear Society, 1981, 38: 386-387. [3] REED A W. The effect of channeling on the dryout of heated particulate beds immersed in a liquid pool[D]. Cambridge, USA: Massachusetts Institute of Technology, 1982. [4] TUNG V X, DHIR V K. A hydrodynamic model for two-phase flow through porous media[J]. International Journal of Multiphase Flow, 1988, 14(1): 47-65. doi: 10.1016/0301-9322(88)90033-X [5] LI L X, ZOU X M, LOU J J, et al. Pressure drops of single/two-phase flows through porous beds with multi-sizes spheres and sands particles[J]. Annals of Nuclear Energy, 2015, 85: 290-295. doi: 10.1016/j.anucene.2015.05.025 [6] SCHMIDT W. Interfacial drag of two-phase flow in porous media[J]. International Journal of Multiphase Flow, 2007, 33(6): 638-657. doi: 10.1016/j.ijmultiphaseflow.2006.09.006 [7] LINDHOLM I, HOLMSTRÖM S, MIETTINEN J, et al. Dryout heat flux experiments with deep heterogeneous particle bed[J]. Nuclear Engineering and Design, 2006, 236(19-21): 2060-2074. doi: 10.1016/j.nucengdes.2006.03.036 [8] RAHMAN S. Coolability of corium debris under severe accident conditions in light water reactors[D]. Stuttgart: Universität Stuttgart, 2013. [9] RAVERDY B, MEIGNEN R, PIAR L, et al. Capabilities of MC3D to investigate the coolability of corium debris beds[J]. Nuclear Engineering and Design, 2017, 319: 48-60. doi: 10.1016/j.nucengdes.2017.04.005 [10] HU K, THEOFANOUS T G. On the measurement and mechanism of dryout in volumetrically heated coarse particle beds[J]. International Journal of Multiphase Flows, 1991, 17(4): 519-532. doi: 10.1016/0301-9322(91)90047-7 [11] SCHULENBERG T, MULLER U. An improved model for two-phase flow through beds of coarse particles[J]. International Journal of Multiphase Flow, 1987, 13(1): 87-97. doi: 10.1016/0301-9322(87)90009-7 [12] ROHSENOW W M. A method of correlating heat transfer data for surface boiling of liquids[J]. Heat Transfer, 1952, 74(4): 969-973. [13] LIENHARD J H. A heat transfer textbook[M]. Englewood Cliffs: Prentice-Hall, 1987: 457. [14] TUTU N K, GINSBERG T, CHEN J C. Interfacial drag for two-phase flow through high permeability porous beds[J]. Journal of Heat Transfer, 1984, 106(4): 865-870. doi: 10.1115/1.3246765 [15] TAKASUO E, HOLMSTRÖM S, KINNUNEN T, et al. The COOLOCE experiments investigating the dryout power in debris beds of heap-like and cylindrical geometries[J]. Nuclear Engineering and Design, 2012, 250: 687-700. doi: 10.1016/j.nucengdes.2012.06.015 -

下载:

下载: