Numerical Study on Boiling Heat Transfer and Thermal-Mechanical Characteristics of Helical Cruciform Fuel Assembly

-

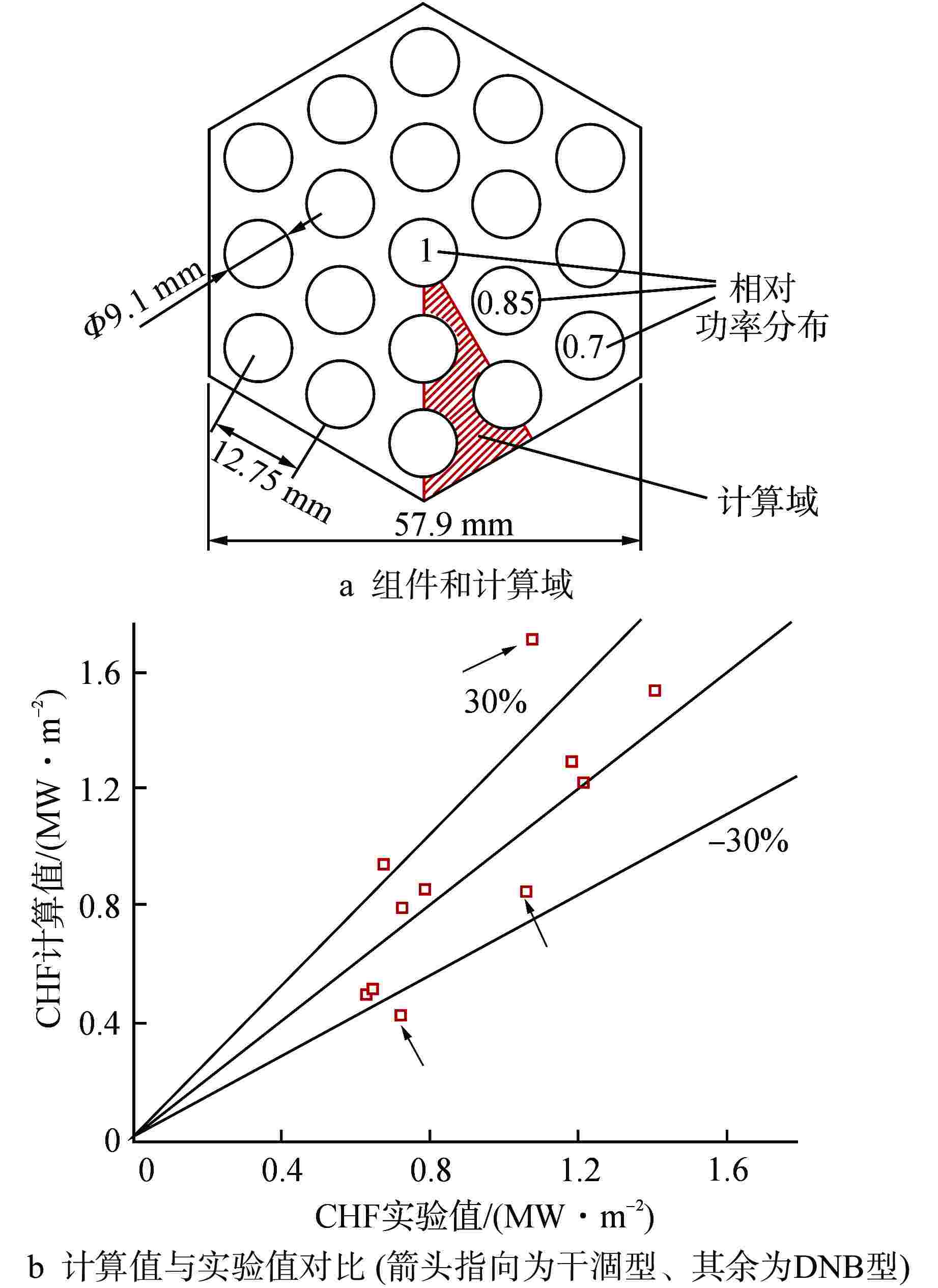

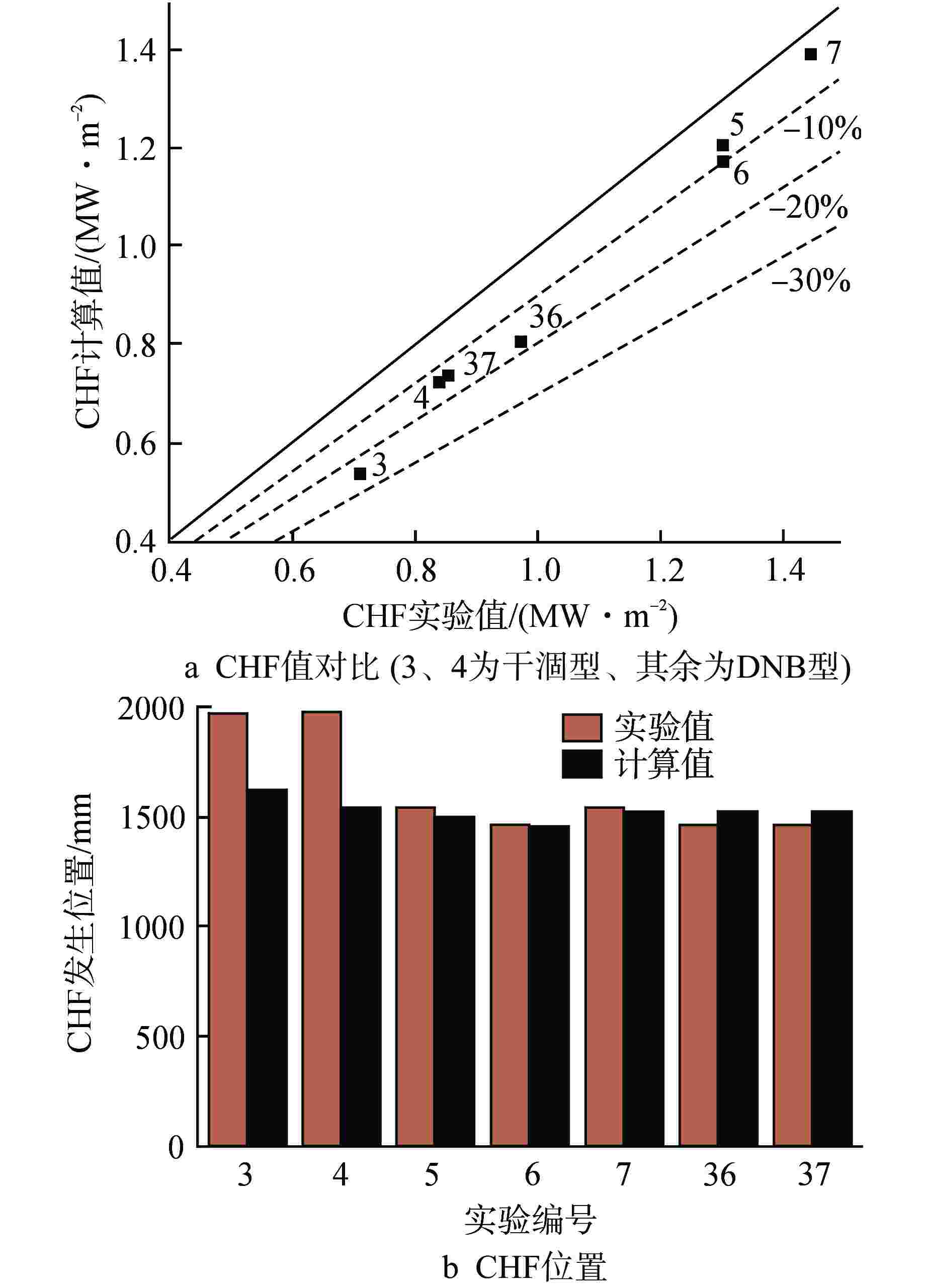

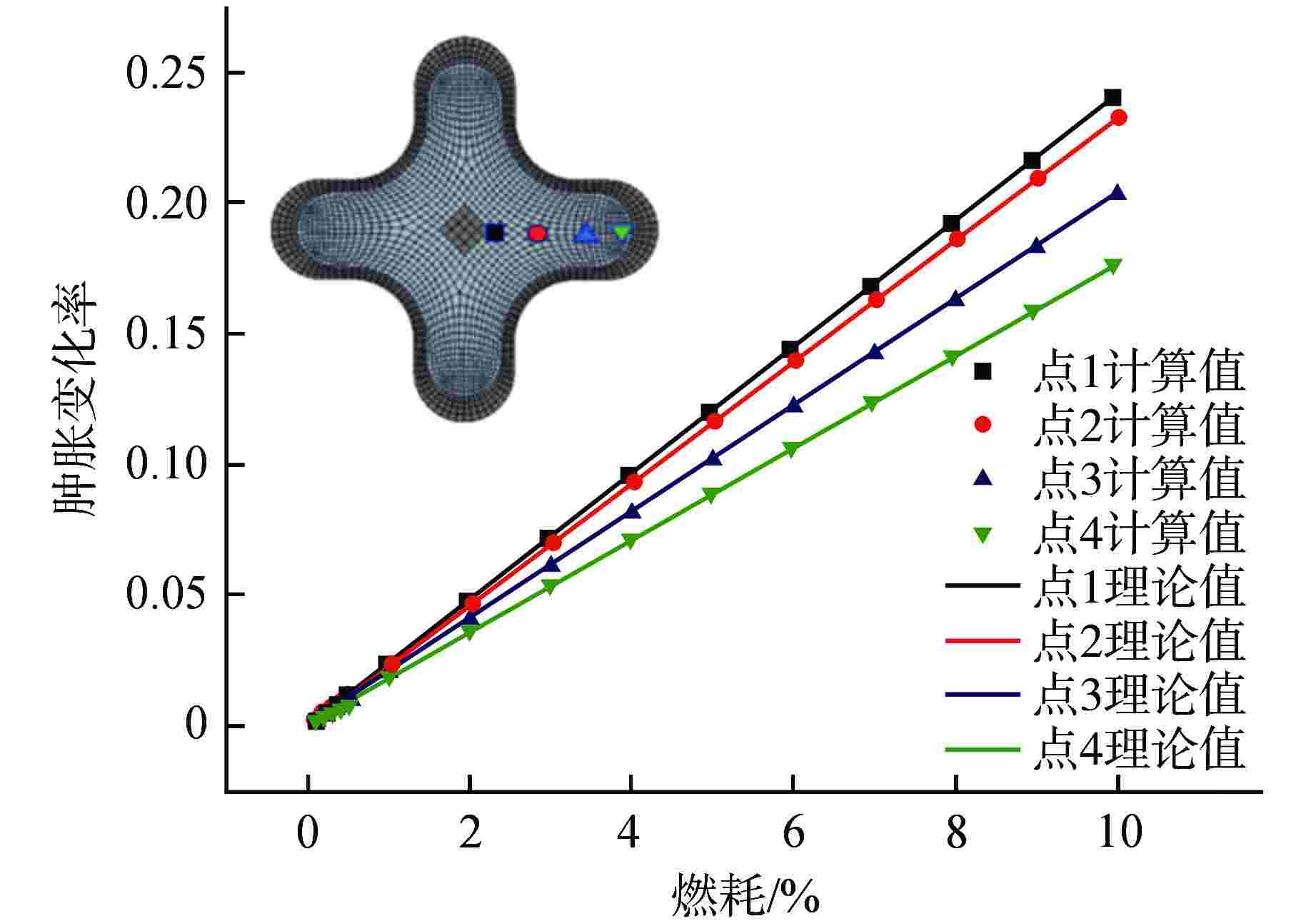

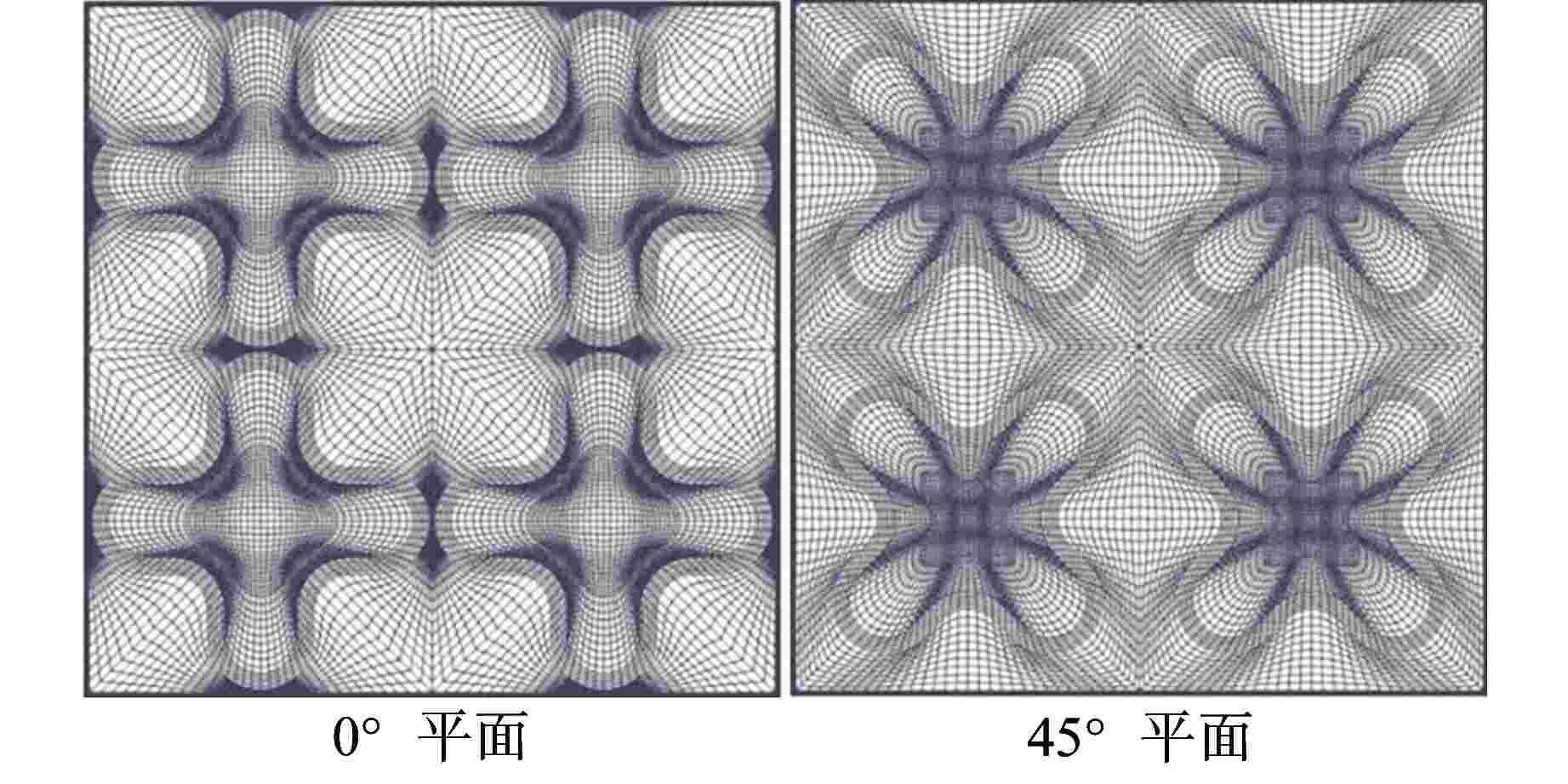

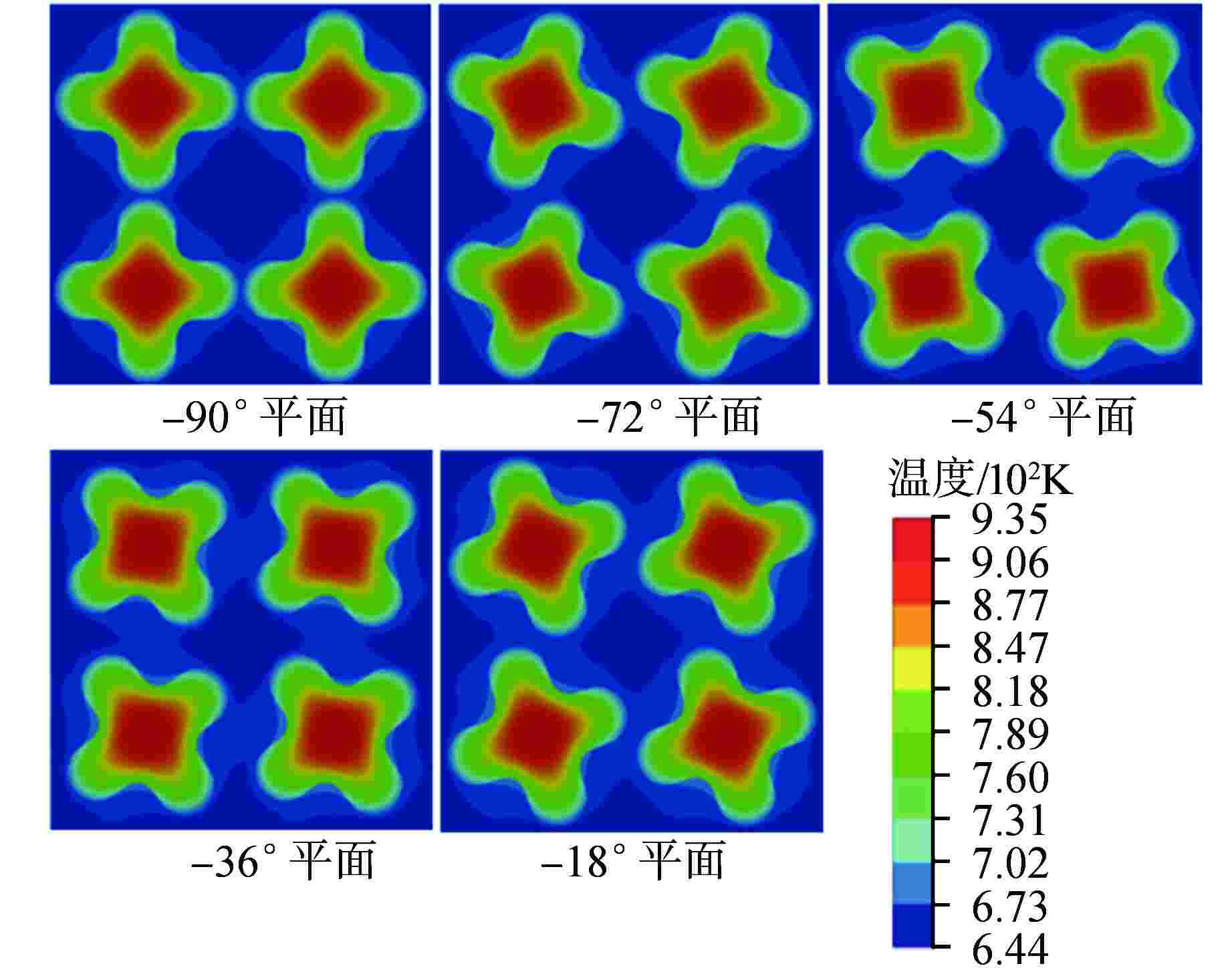

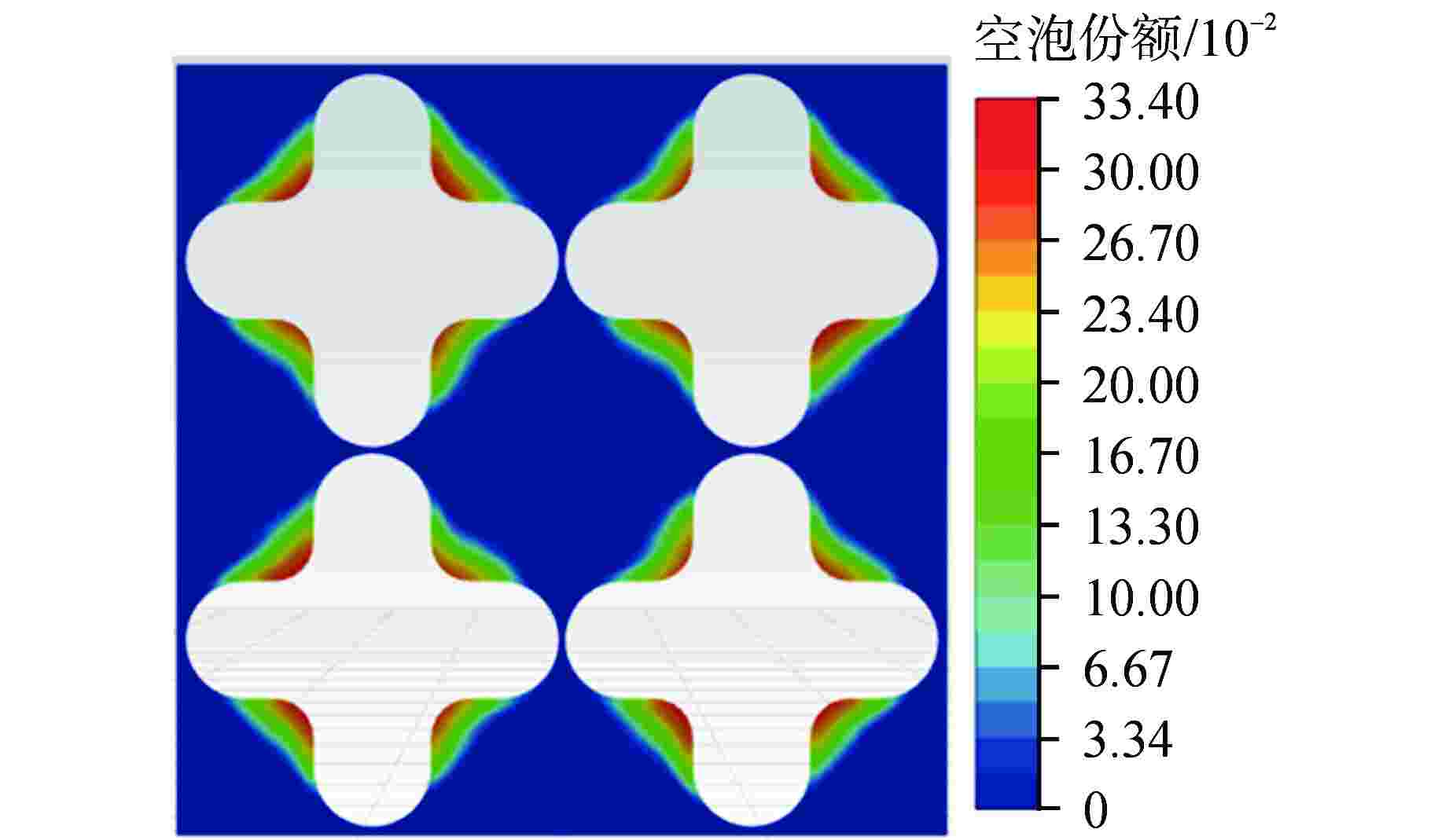

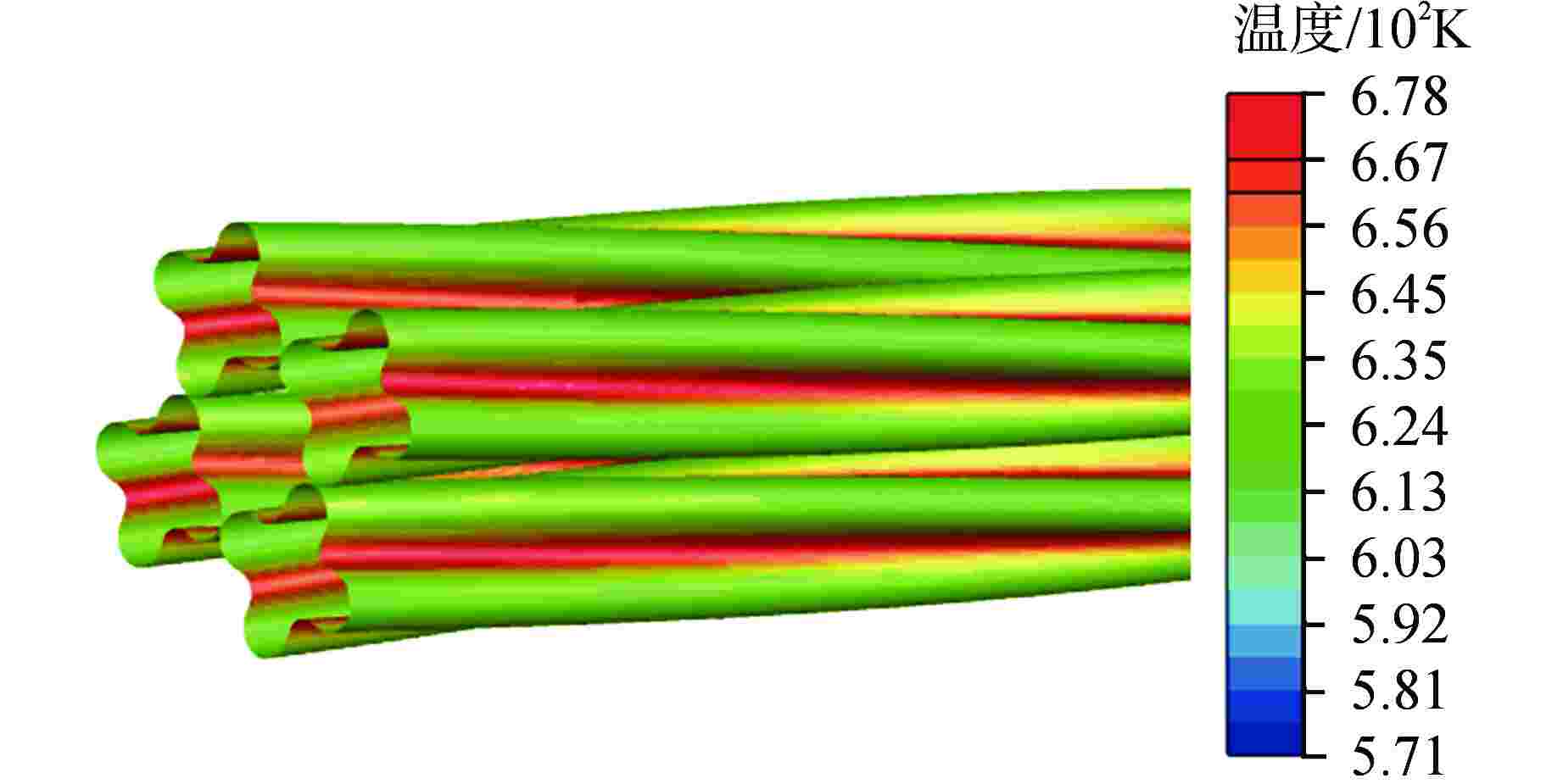

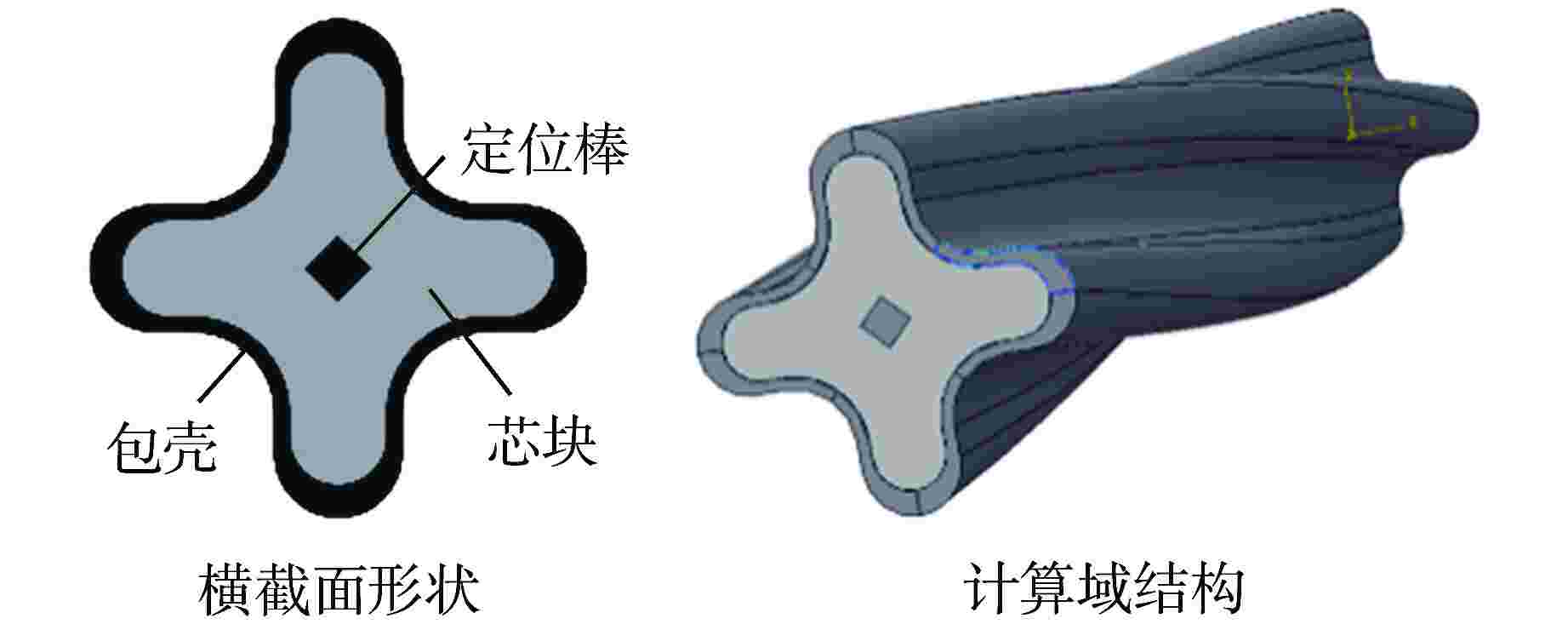

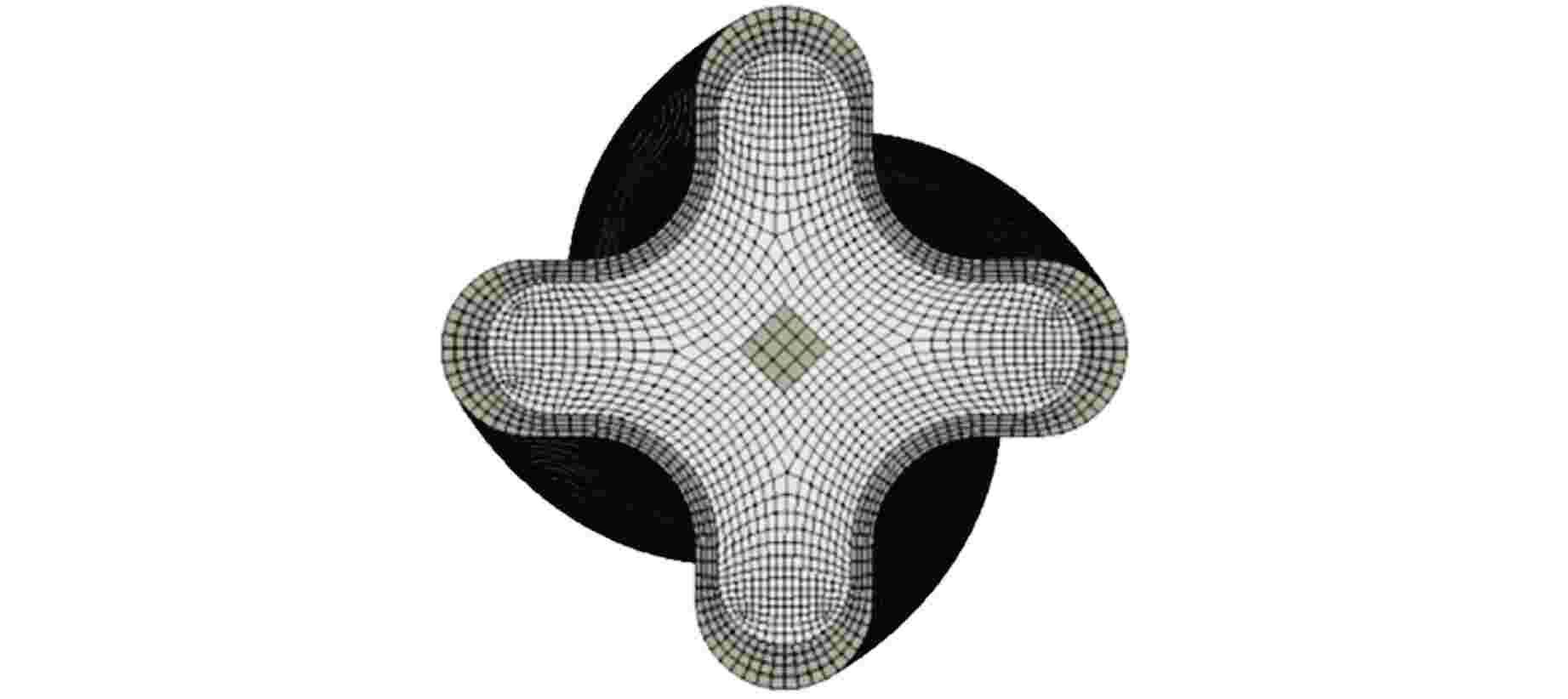

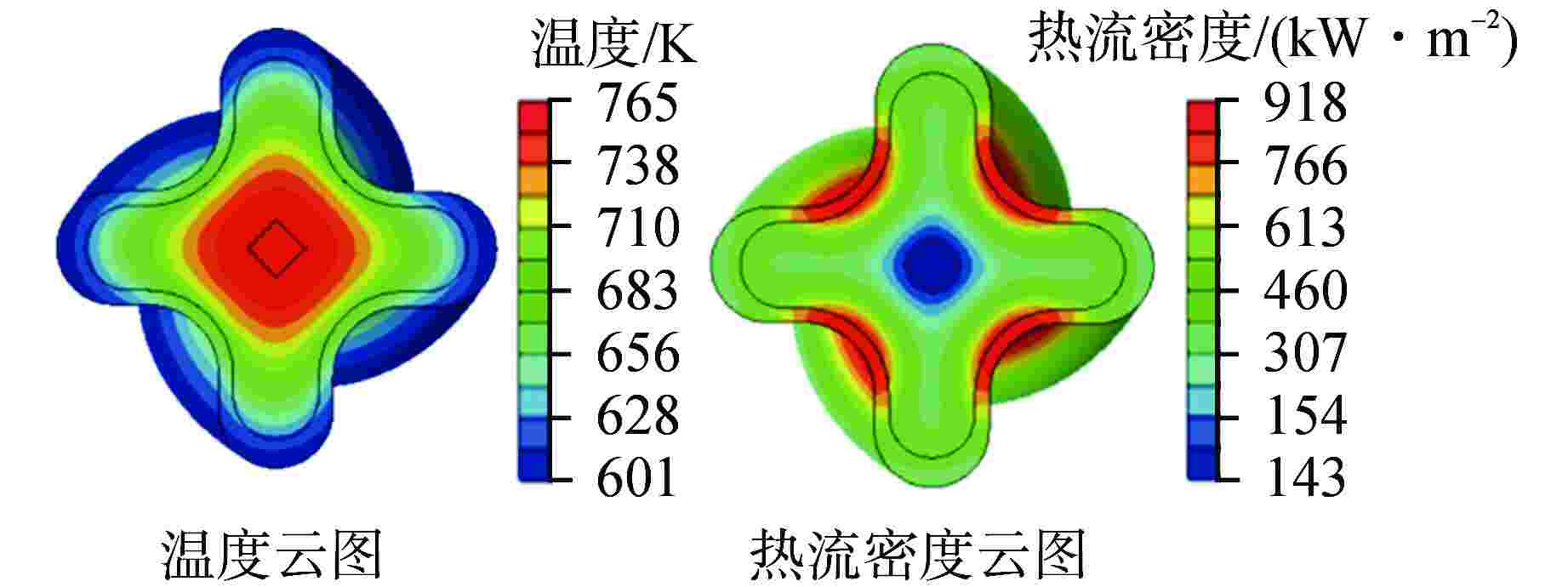

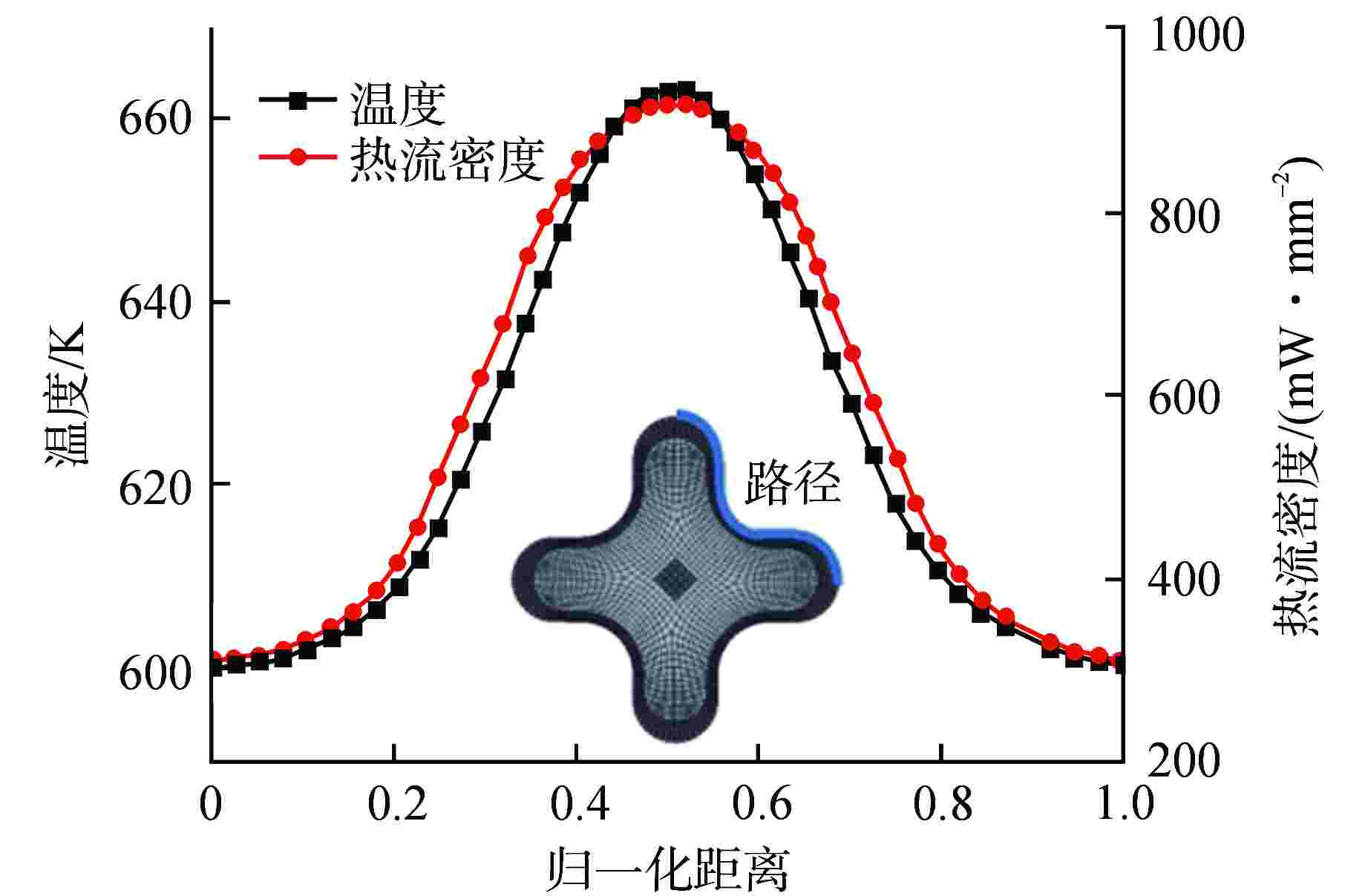

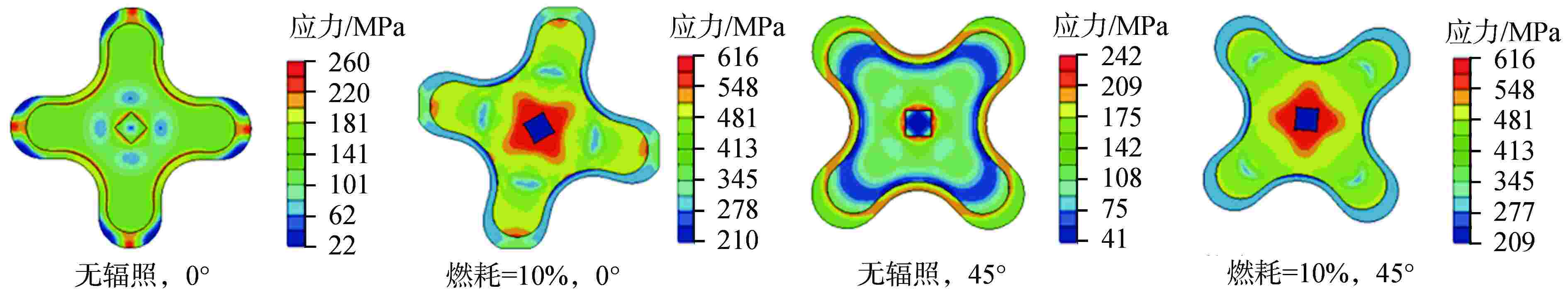

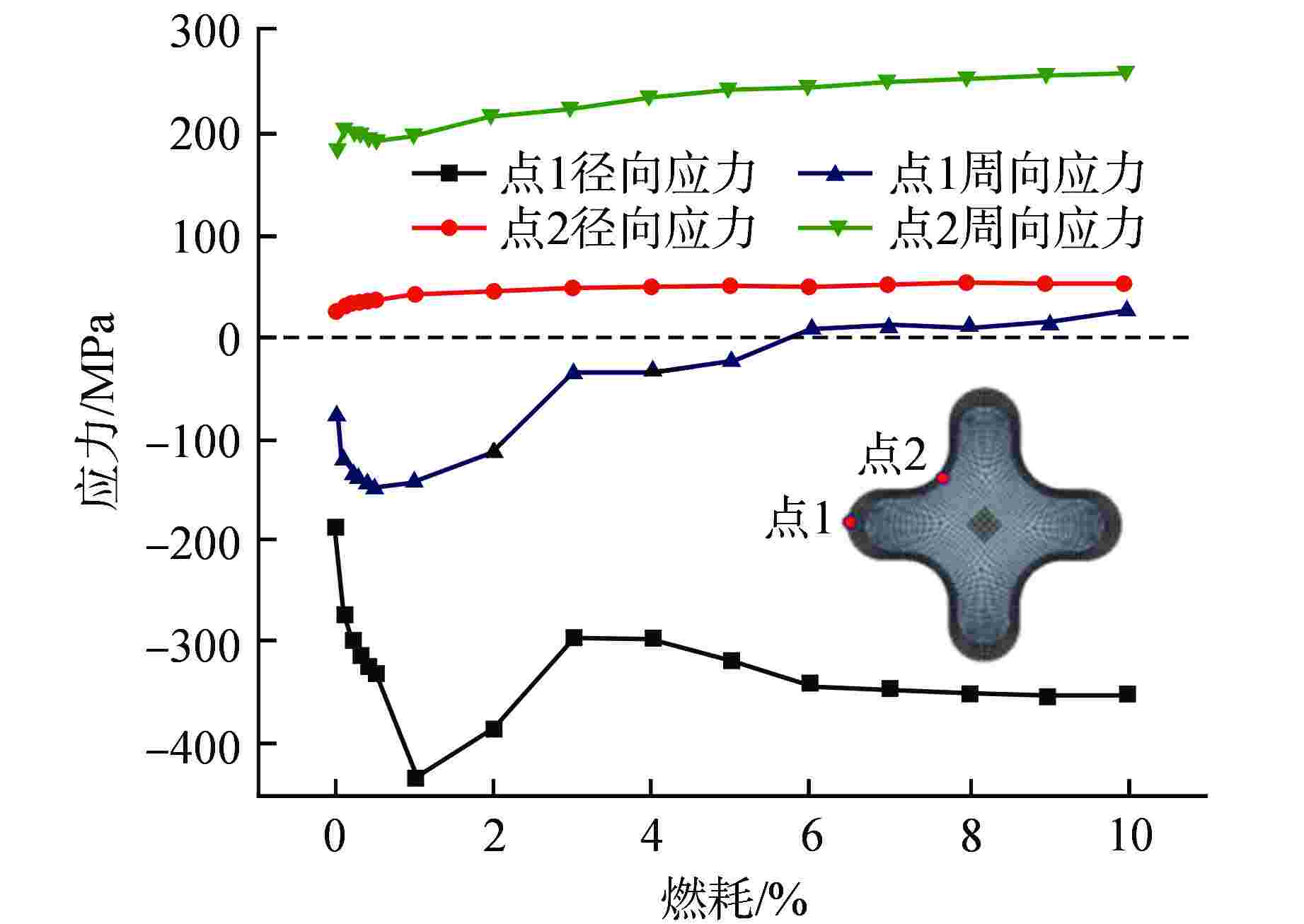

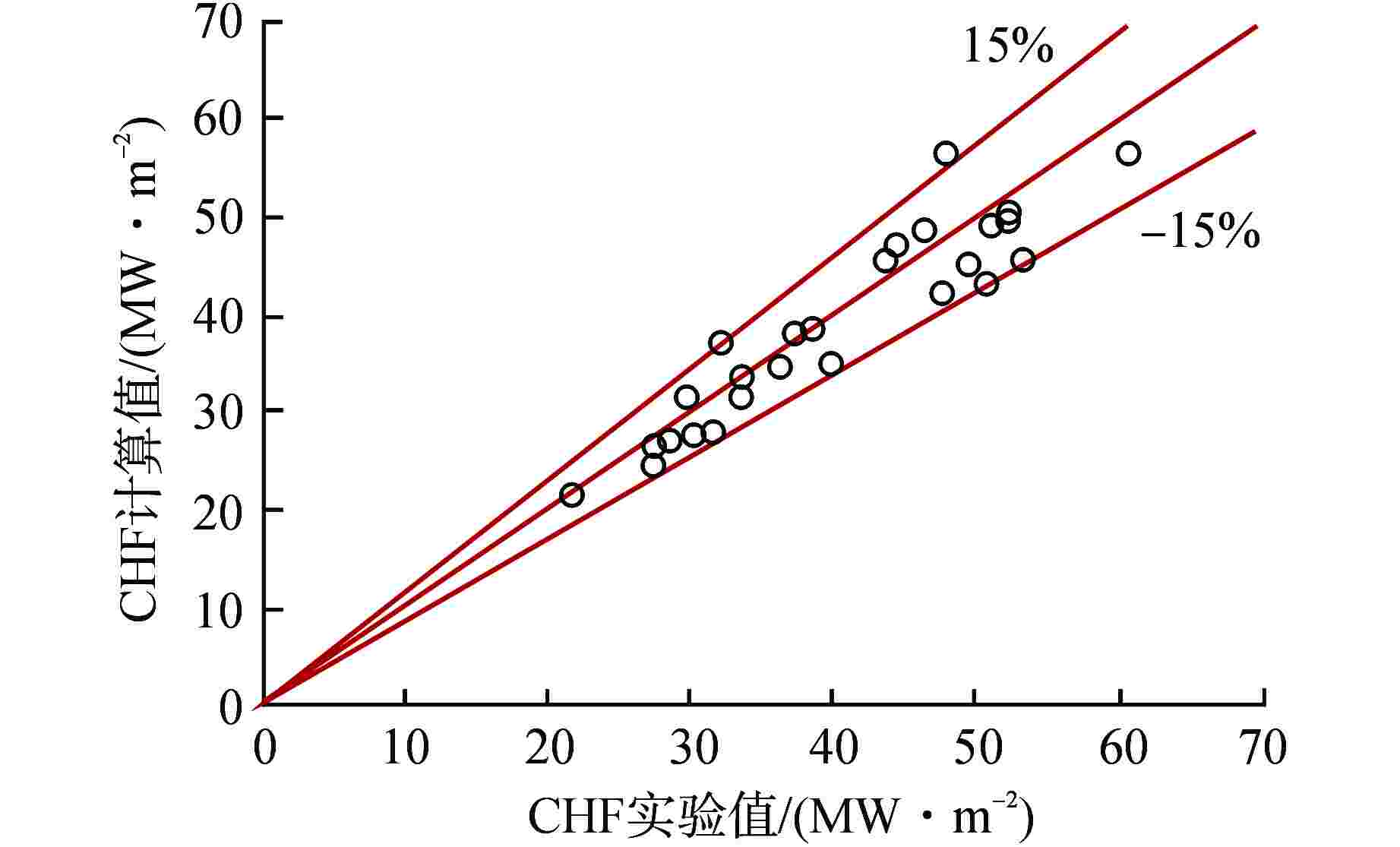

摘要: 螺旋十字燃料(HCF)组件是一种新型的燃料组件设计方案,相对于传统的圆棒或板状燃料,HCF组件具有强交混、自支撑、无格架的特点。为评价HCF组件在热工水力和力学方面的性能,本文基于流固共轭传热方法建立了HCF组件两相沸腾传热模型和燃料棒热力耦合分析模型,获得了两相条件下的燃料棒和冷却剂温度、冷却剂空泡份额等参数分布以及不同燃耗深度下的燃料棒应力分布。结果表明,相对于圆棒组件,HCF组件可降低燃料中心温度和表面平均热流密度;发生沸腾临界时,HCF组件的线功率密度高于传统圆棒组件。初步热力耦合分析发现,对于金属芯体无气隙的HCF元件,燃料棒在辐照条件下受到较大的应力。

-

关键词:

- 螺旋十字燃料(HCF) /

- 沸腾传热 /

- 临界热流密度(CHF) /

- 交混 /

- 热力耦合 /

- 燃料性能

Abstract: The helical cruciform fuel (HCF) assembly is an innovative design for nuclear reactor fuel. Compared to the traditional cylinder or plate type fuel, the HCF assembly has the features of intensive mixing, self-support and no requirement of spacer grid. The two-phase conjugate heat transfer model for HCF assembly and the thermal-mechanical analysis model for HCF rod were built to evaluate the performances of HCF from the aspects of thermohydraulics and mechanics, respectively. The distributions of fuel rod and coolant temperature and coolant void fraction under two-phase conditions, and the fuel rod stress distribution under different burnup were obtained. The results show that the HCF assembly can reduce the fuel center temperature and the average surface heat flux compared with traditional circular rod fuel assembly. When boiling crisis was triggered, the linear heat flux of HCF assembly was higher than that of traditional fuel assembly. The preliminary thermal-mechanical analysis shows that the fuel rod is subject to great stress under irradiation for HCF elements with metal core without air gap. -

-

[1] PETROV Y V, ERYKALOV A N, ONEGIN M S. The fuel cycle of reactor PIK[C]//2002 International Meeting on Reduced Enrichment for Research and Test Reactors. Bariloche, Argentina: RAS, 2002: 1-11. [2] CONBOY T M. Assessment of helical-cruciform fuel rods for high power density LWRs[D]. Cambridge, MA: Massachusetts Institute of Technology, 2010. [3] MALONE J, TOTEMEIER A, SHAPIRO N, et al. Lightbridge corporation’s advanced metallic fuel for light water reactors[J]. Nuclear Technology, 2012, 180(3): 437-442. doi: 10.13182/NT12-A15354 [4] ANSYS Inc.. ANSYS FLUENT theory guide[M]. Canonsburg, PA, USA: ANSYS Inc., 2011: 625-704. [5] IOILEV A, SAMIGULIN M, USTINENKO V, et al. Advances in the modeling of cladding heat transfer and critical heat flux in boiling water reactor fuel assemblies[C]. USA: The 12th International Topical Meeting on Nuclear Reactor Thermal Hydraulics (NURETH-12). Pittsburgh, Pennsylvania, 2007: 1-15. [6] KIM Y S, HOFMAN G L. AAA fuels handbook[M]. Argonne, Illinois, USA: Argonne National Laboratory, 2003: 26-30. [7] MIDDLEMAS S C, JANNEY D E. Current revision of the Metallic Fuels Handbook summarizing properties of fresh fuels[Z]. Idaho Falls, ID, United States: Idaho National Laboratory, 2020. [8] MACDONALD P E, THOMPSON L B. MATPRO: version 09. A handbook of materials properties for use in the analysis of light water reactor fuel rod behavior: TREE-NUREG-1005[R]. Idaho Falls, USA: Idaho National Laboratory, 1976. [9] DING S R, WANG Q M, HUO Y Z. Mechanical behaviors of the dispersion nuclear fuel plates induced by fuel particle swelling and thermal effect II: Effects of variations of the fuel particle diameters[J]. Journal of Nuclear Materials, 2010, 397(1-3): 80-91. doi: 10.1016/j.jnucmat.2009.12.012 [10] HAGRMAN D L, REYMANN G A. MATPRO-Version 11: A handbook of materials properties for use in the analysis of light water reactor fuel rod behavior: NUREG/CR-0497[R]. Idaho Falls, ID, United States: Idaho National Laboratory, 1979. -

下载:

下载: