Study on General Corrosion Behavior of Two Alumina-forming Austenitic Stainless Steels in Supercritical Carbon Dioxide

-

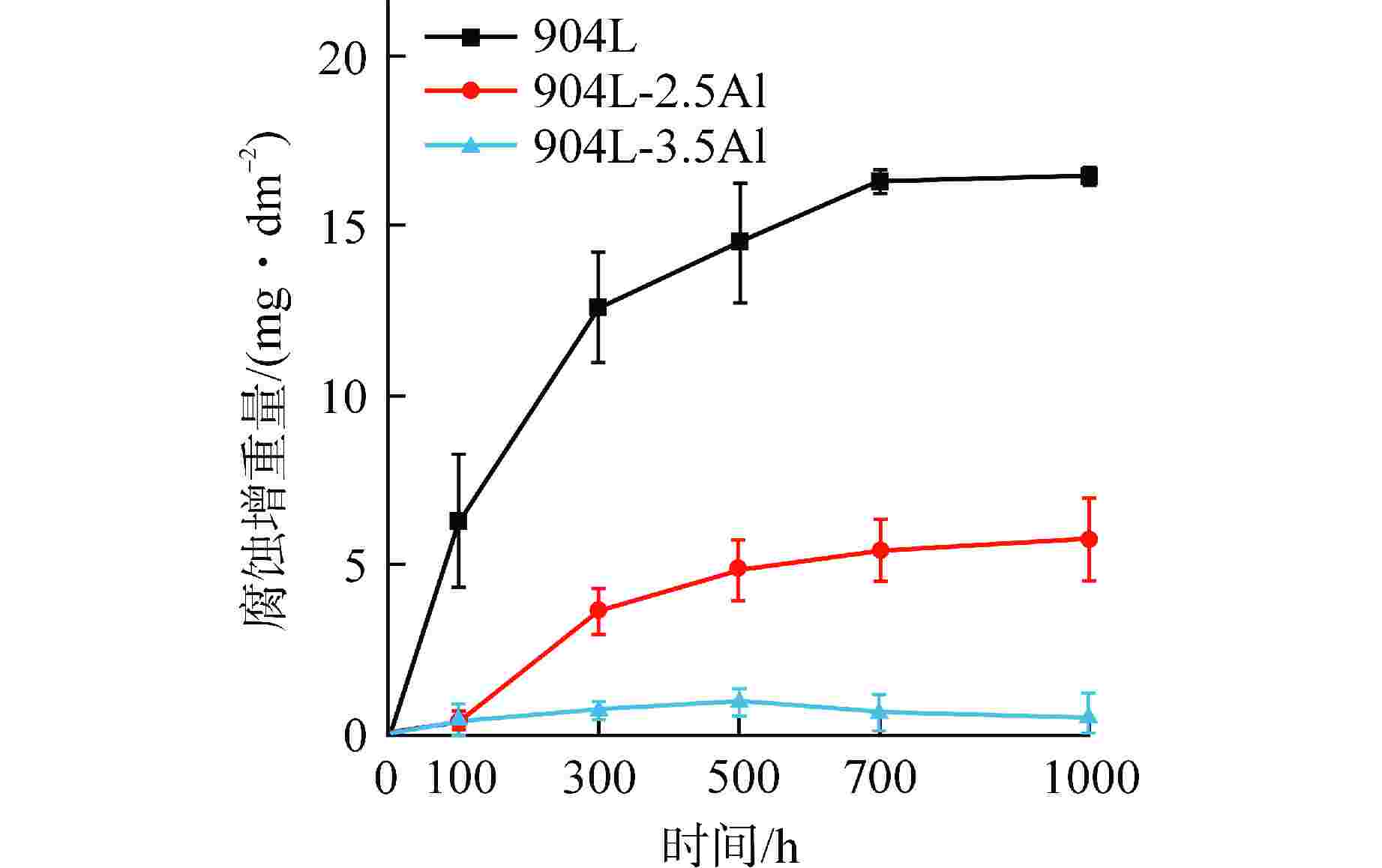

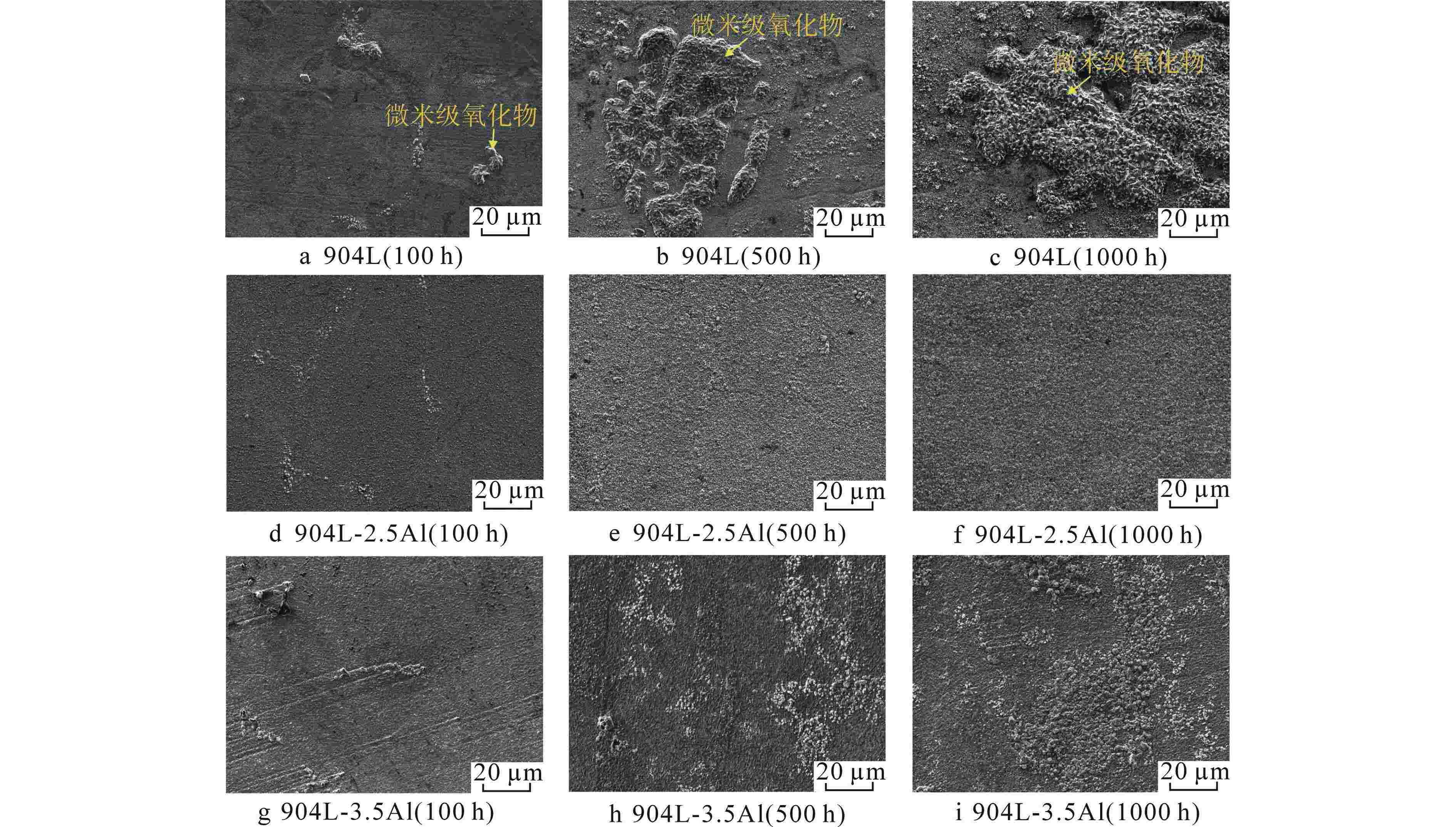

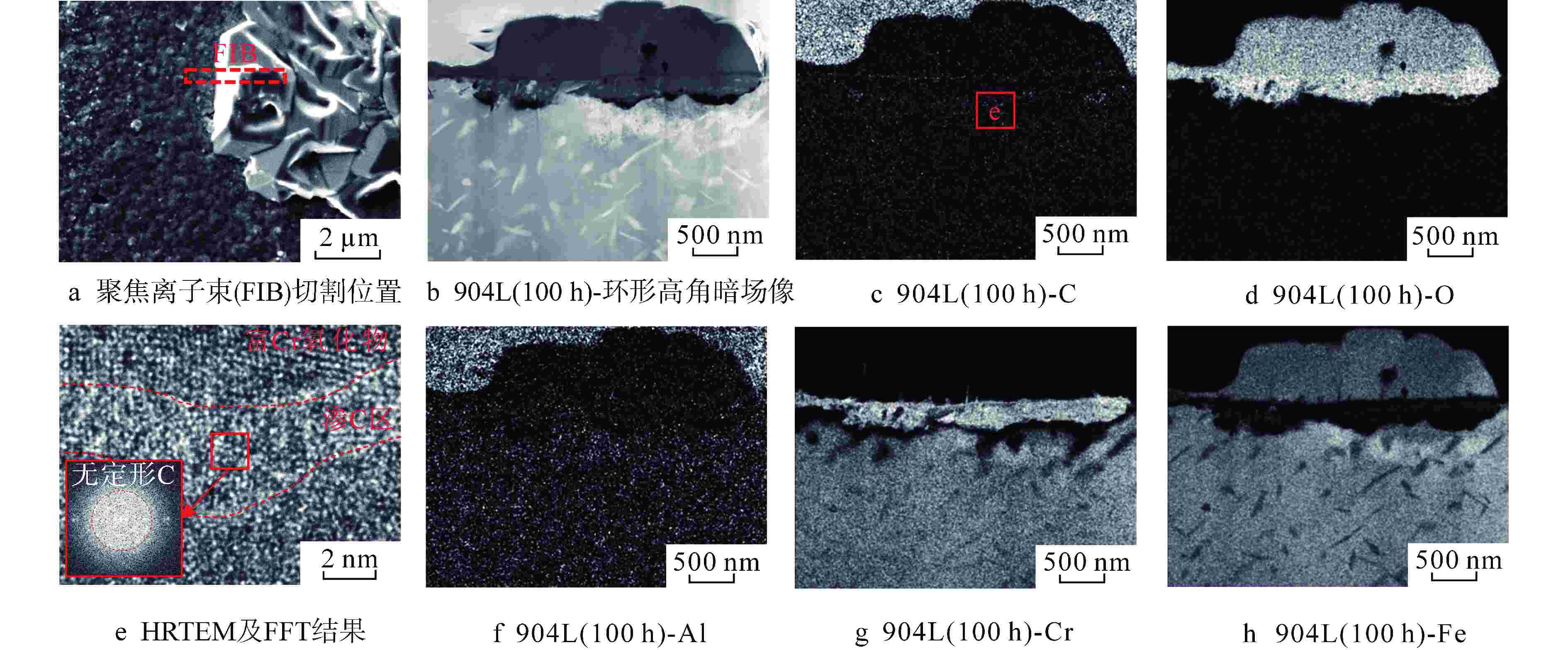

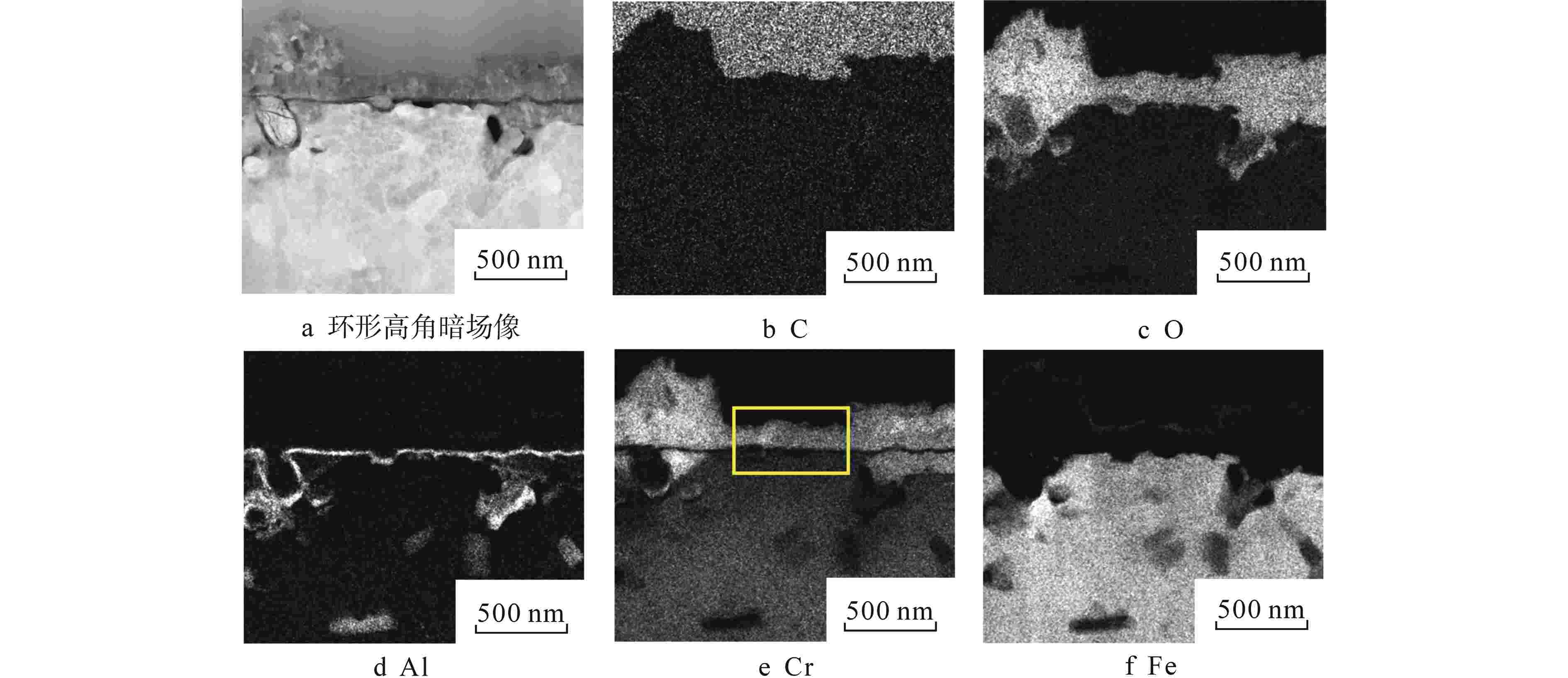

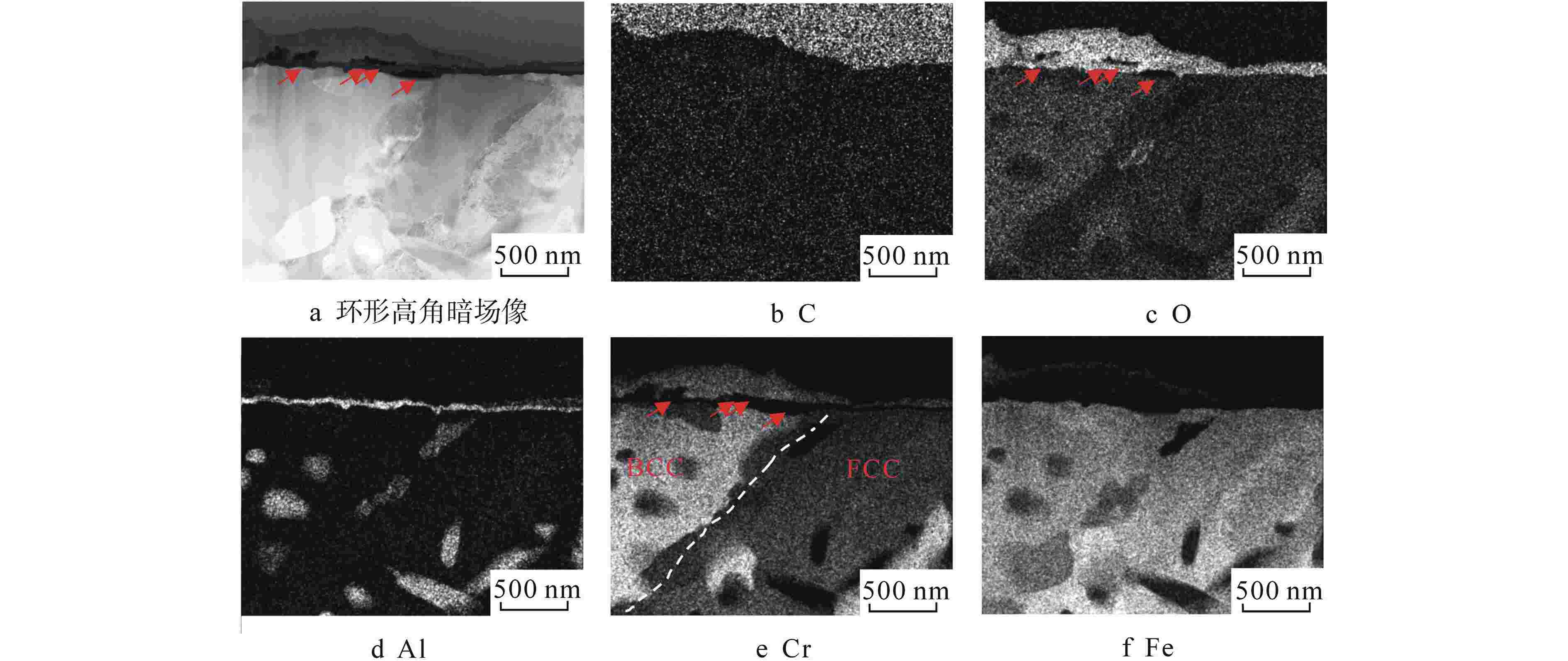

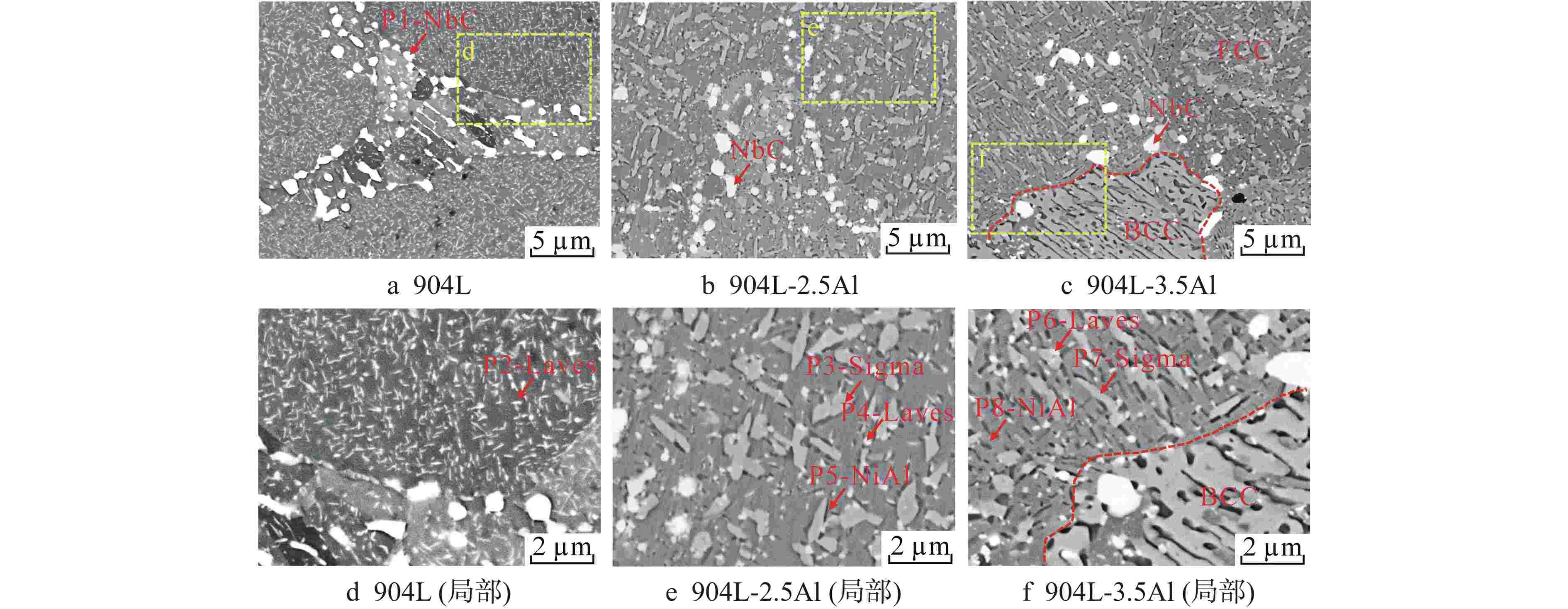

摘要: 为评估新型含铝奥氏体不锈钢在超临界二氧化碳(sCO2)核反应堆中的应用前景,通过实验研究了两种新型含铝奥氏体不锈钢(904L-2.5Al和904L-3.5Al不锈钢)及其基材(904L不锈钢)在600℃/20 MPa的sCO2中的均匀腐蚀行为。运用增重法评价了材料的腐蚀动力学规律,采用扫描电镜、透射电镜和能谱仪分析了腐蚀前后材料的形貌、结构和化学成分。结果表明,所有材料的腐蚀增重近似服从抛物线生长规律。随着Al含量的增加,材料的腐蚀增重量明显降低,904L-3.5Al不锈钢具有最低的腐蚀增重量。腐蚀后,904L不锈钢表面生成富Fe氧化物,发生渗碳;904L-2.5Al和904L-3.5Al不锈钢表面生成了连续的富Cr/Al氧化膜,未发生渗碳行为。Al含量的增加促进了材料表面保护性富Cr/Al氧化膜的形成,增强了材料在sCO2中的耐氧化及渗碳性能。

-

关键词:

- 超临界二氧化碳(sCO2) /

- 新型含铝奥氏体不锈钢 /

- 均匀腐蚀 /

- 渗碳

Abstract: To evaluate the application prospect of alumina-forming austenitic stainless steels in supercritical carbon dioxide nuclear reactors, the general corrosion behavior of two alumina-forming austenitic stainless steels (904L-2.5Al and 904L-3.5Al stainless steels) and its base steel (904L stainless steel) in supercritical carbon dioxide (sCO2) at 600℃ and 20 MPa was investigated through experiments. The corrosion kinetics of materials are evaluated by weight gain method, and the morphology, structure and chemical composition of materials before and after corrosion are analyzed by scanning electron microscope, transmission electron microscope and energy dispersive spectrometer. The results show that the weight gain of all materials approximates the parabolic growth law. The weight gain is lowered by increasing the content of Al, and 904L-3.5Al stainless steel has the lowest weight gain. After exposure, Fe-rich oxide is formed on the surface of 904L stainless steel, and carburization occurs. Continuous Cr/Al-rich oxide scales are formed on the surface of 904L-2.5Al and 904L-3.5Al stainless steels, while no carburization is occurred. Higher Al content facilitates the formation of protective Cr/Al-rich oxides on the material surface, which improves the oxidation and carburization resistance of materials after exposure to sCO2. -

表 1 实验用材料的化学成分 %

Table 1. Chemical Composition of Experimental Materials

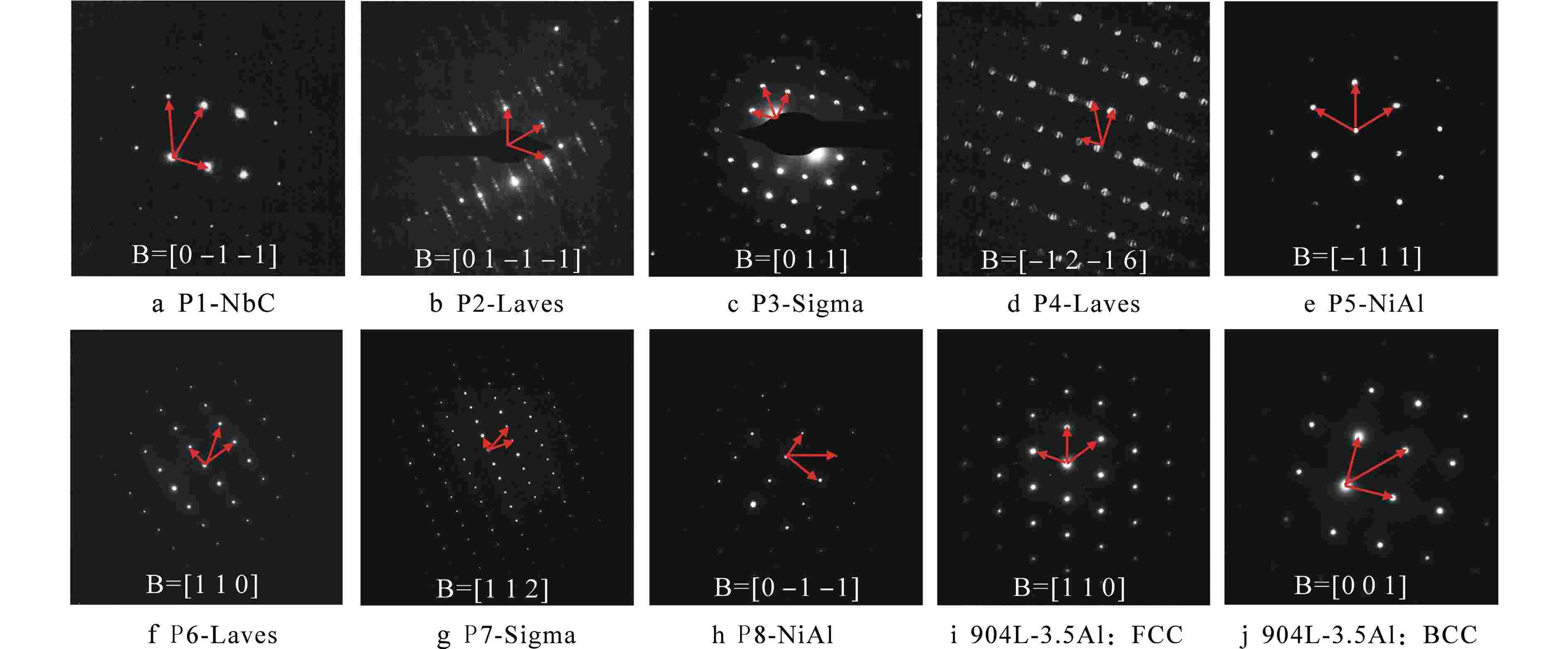

材料 wC wAl wSi wS wCr wMn wFe wNi wCu wNb wMo 904L 0.076 0.036 1.373 0.001 19.082 1.874 余量 25.376 1.481 0.870 3.691 904L-2.5Al 0.079 2.212 1.263 — 19.509 2.006 余量 25.634 1.591 0.821 3.406 904L-3.5Al 0.079 3.236 1.181 0.001 19.705 1.872 余量 25.090 1.602 0.900 3.891 w—质量分数 表 2 图1中析出相化学成分 %

Table 2. Chemical Compositions of the Precipitates Marked in Figure 1

析出相 wC wAl wSi wCr wFe wNi wNb wMo P1-NbC 19.9 — — — 0.1 — 77.3 2.7 P2-Laves — — 3.8 16.6 34.9 18.2 4.0 22.5 P3-Sigma — — 2.8 39.2 39.9 6.8 — 11.9 P4-Laves — — 6.9 11.1 30.0 11.8 6.3 33.9 P5-NiAl — 23.0 — — 9.5 67.5 — — P6-Laves — — 5.5 17.2 31.1 15.2 — 30.9 P7-Sigma — — 1.7 44.0 39.6 8.4 — 6.3 P8-NiAl — 15.0 — — 14.5 70.6 — — -

[1] 黄彦平,王俊峰. 超临界二氧化碳在核反应堆系统中的应用[J]. 核动力工程,2012, 33(3): 21-27. [2] 梁志远,桂雍,赵钦新. 超临界CO2动力循环高温材料腐蚀研究进展[J]. 动力工程学报,2021, 41(11): 910-917. [3] 肖博,朱忠亮,李瑞涛,等. 超临界二氧化碳工质发电系统候选材料高温腐蚀研究现状与进展[J]. 热力发电,2020, 49(10): 30-37. doi: 10.19666/j.rlfd.202006155 [4] 刘蔚伟,杨鸿,姜峨,等. 超临界二氧化碳核能动力转换系统关键材料腐蚀行为研究[J]. 原子能科学技术,2021, 55(S2): 242-248. [5] GUO T S, XU Y M, LIU S J, et al. Characteristics of the corrosion products on three scratched heat-resisting alloys in closed-loop supercritical and high-temperature CO2[J]. Corrosion Science, 2022, 198: 110148. doi: 10.1016/j.corsci.2022.110148 [6] CAO G, FIROUZDOR V, SRIDHARAN K, et al. Corrosion of austenitic alloys in high temperature supercritical carbon dioxide[J]. Corrosion Science, 2012, 60: 246-255. doi: 10.1016/j.corsci.2012.03.029 [7] LEE H J, KIM H, KIM S H, et al. Corrosion and carburization behavior of chromia-forming heat resistant alloys in a high-temperature supercritical-carbon dioxide environment[J]. Corrosion Science, 2015, 99: 227-239. doi: 10.1016/j.corsci.2015.07.007 [8] XU X Q, ZHANG X F, CHEN G L, et al. Improvement of high-temperature oxidation resistance and strength in alumina-forming austenitic stainless steels[J]. Materials Letters, 2011, 65(21-22): 3285-328. doi: 10.1016/j.matlet.2011.07.021 [9] YAMAMOTO Y, BRADY M P, LU Z P, et al. Creep-resistant, Al2O3-forming austenitic stainless steels[J]. Science, 2007, 316(5823): 433-436. doi: 10.1126/science.1137711 [10] ZHANG J Q, SPECK P, YOUNG D J. Metal dusting of alumina-forming creep-resistant austenitic stainless steels[J]. Oxidation of Metals, 2012, 77(3-4): 167-187. doi: 10.1007/s11085-011-9279-x [11] WEN D H, LI Z, JIANG B B, et al. Effects of Nb/Ti/V/Ta on phase precipitation and oxidation resistance at 1073 K in alumina-forming austenitic stainless steels[J]. Materials Characterization, 2018, 144: 86-98. doi: 10.1016/j.matchar.2018.07.007 [12] YAMAMOTO Y, BRADY M P, SANTELLA M L, et al. Overview of strategies for high-temperature creep and oxidation resistance of alumina-forming austenitic stainless steels[J]. Metallurgical and Materials Transactions A, 2011, 42(4): 922-931. doi: 10.1007/s11661-010-0295-2 [13] 刘珠,郭相龙,王鹏,等. 310S不锈钢在超临界二氧化碳中的腐蚀行为研究[J]. 核动力工程,2020, 41(S1): 183-187. doi: 10.13832/j.jnpe.2020.S1.0183 [14] 倪一帆,杨昌顺,赵双群. T91和HR3C钢在600℃/25 MPa超临界二氧化碳中的腐蚀行为[J]. 腐蚀与防护,2022, 43(1): 18-23. [15] HE L F, ROMAN P, LENG B, et al. Corrosion behavior of an alumina forming austenitic steel exposed to supercritical carbon dioxide[J]. Corrosion Science, 2014, 82: 67-76. doi: 10.1016/j.corsci.2013.12.023 [16] BERGNER D, KHADDOUR Y. Impurity and chemical diffusion of Al in BCC and Fcc iron[J]. Defect and Diffusion Forum, 1993, 95-98: 709-714. doi: 10.4028/www.scientific.net/DDF.95-98.709 [17] WILLIAMS P I, FAULKNER R G. Chemical volume diffusion coefficients for stainless steel corrosion studies[J]. Journal of Materials Science, 1987, 22(10): 3537-3542. doi: 10.1007/BF01161455 [18] KIM C, KIM H, HEO W, et al. High-temperature steam oxidation behavior of alumina-forming duplex FeNiCrAl and ferritic FeCrAl alloys at 800℃ to 1050℃[J]. Corrosion Science, 2021, 190: 109658. doi: 10.1016/j.corsci.2021.109658 [19] MAHAFFEY J T. Effect of partial pressure of oxygen and activity of carbon on the corrosion of high temperature alloys in s-CO2 environments[D]. Madison: The University of Wisconsin-Madison, 2017. [20] CHEN H S, KIM S H, KIM C, et al. Corrosion behaviors of four stainless steels with similar chromium content in supercritical carbon dioxide environment at 650℃[J]. Corrosion Science, 2019, 156: 16-31. doi: 10.1016/j.corsci.2019.04.043 [21] OLEKSAK R P, HOLCOMB G R, CARNEY C S, et al. Effect of surface finish on high-temperature oxidation of steels in CO2, supercritical CO2, and air[J]. Oxidation of Metals, 2019, 92(5-6): 525-540. doi: 10.1007/s11085-019-09938-6 [22] HOLCOMB G, HAWK J, ROZMAN K, et al. Materials performance in supercritical CO2 in comparison with atmospheric pressure CO2 and supercritical steam: NETL-PUB-1178[R]. Pittsburgh: National Energy Technology Lab, 2016. [23] LEE H J, SUBRAMANIAN G O, KIM S H, et al. Effect of pressure on the corrosion and carburization behavior of chromia-forming heat-resistant alloys in high-temperature carbon dioxide environments[J]. Corrosion Science, 2016, 111: 649-658. doi: 10.1016/j.corsci.2016.06.004 [24] LIM J Y, MCKRELL T J, EASTWICK G, et al. Corrosion of materials in supercritical carbon dioxide environments[C]//Proceedings of CORROSION 2008. New Orleans: OnePetro, 2008. -

下载:

下载: