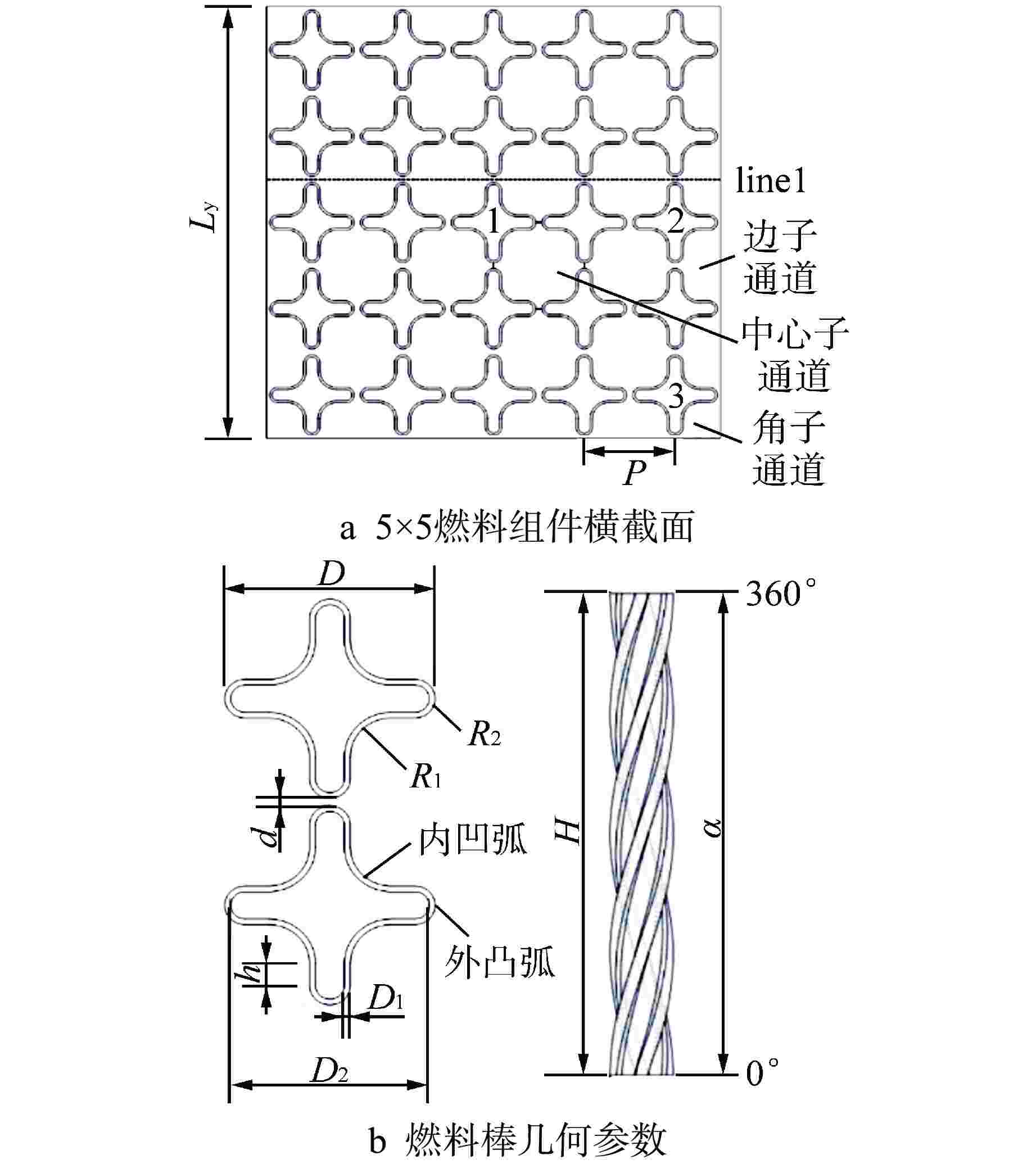

Numerical Study on Flow and Heat Transfer Characteristics of Subcooled Boiling in 5×5 Petal-shaped Fuel Rod Assembly

-

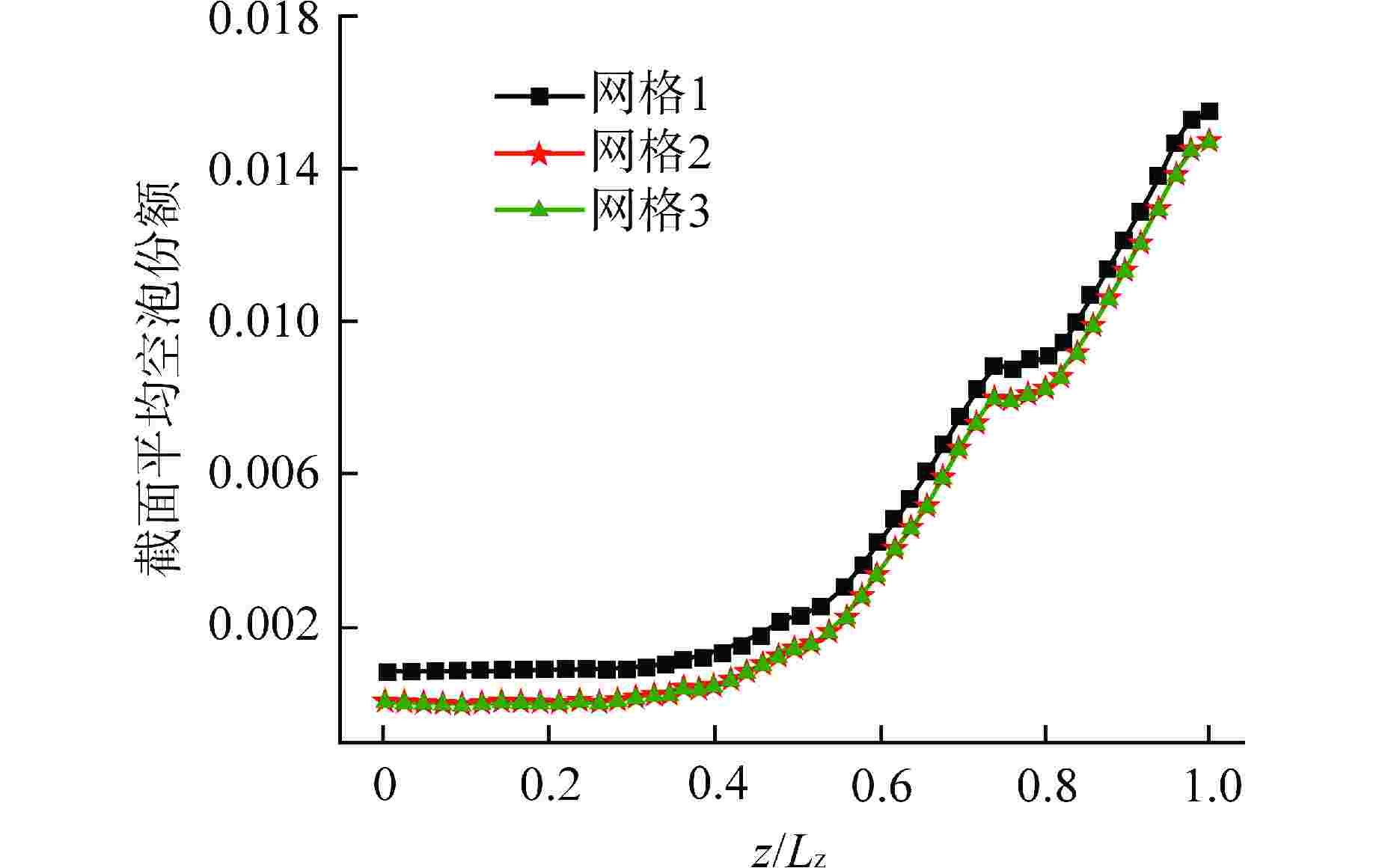

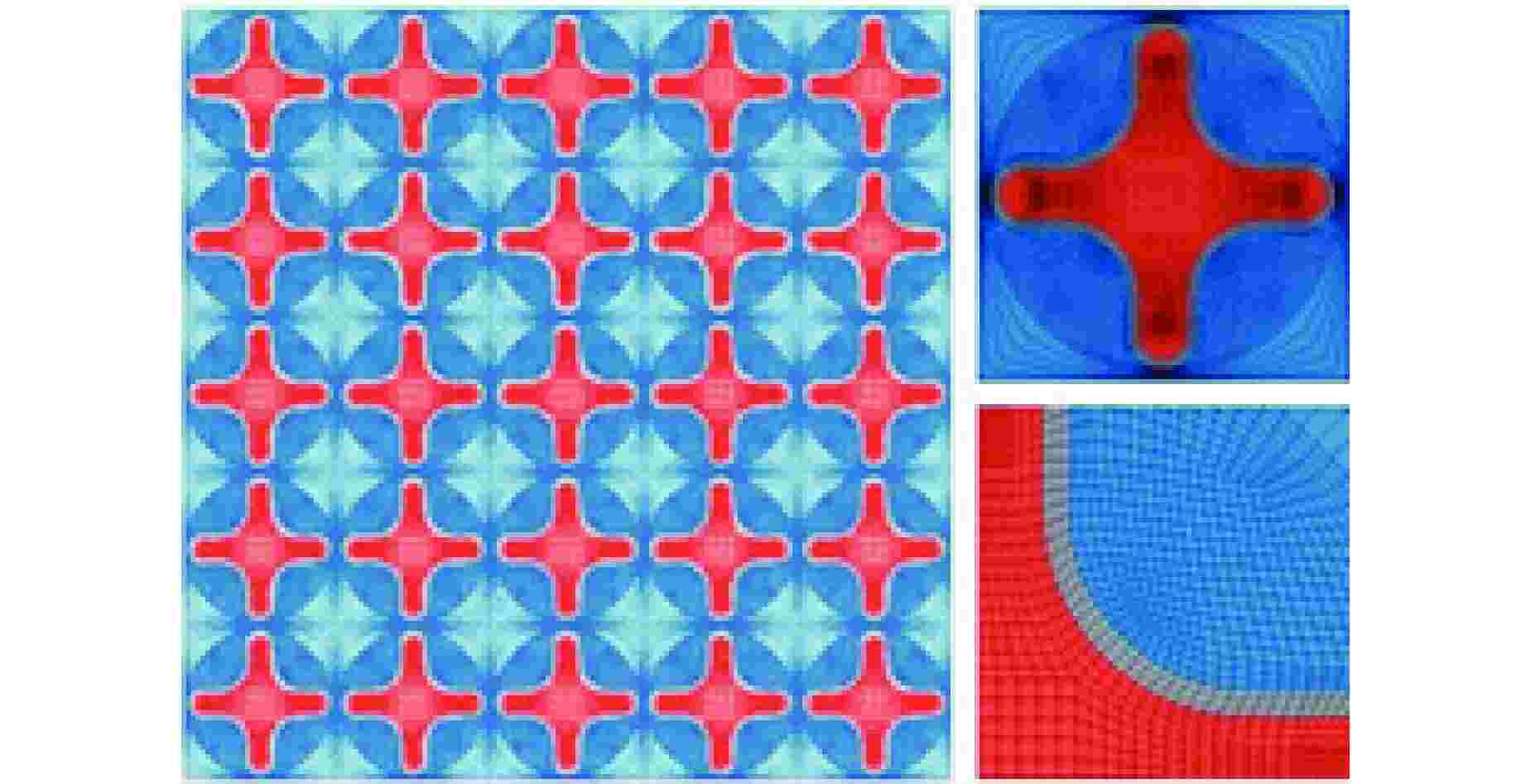

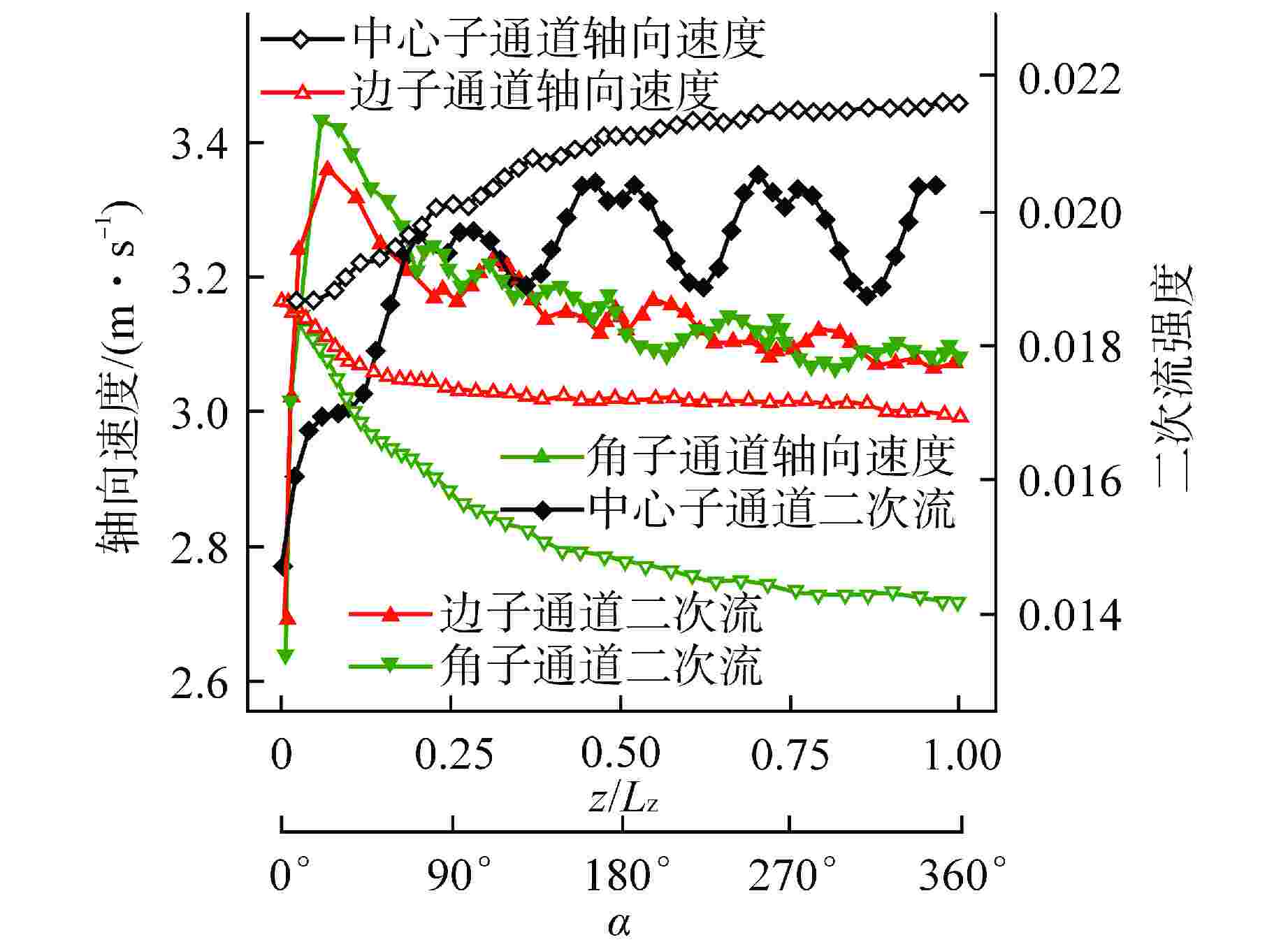

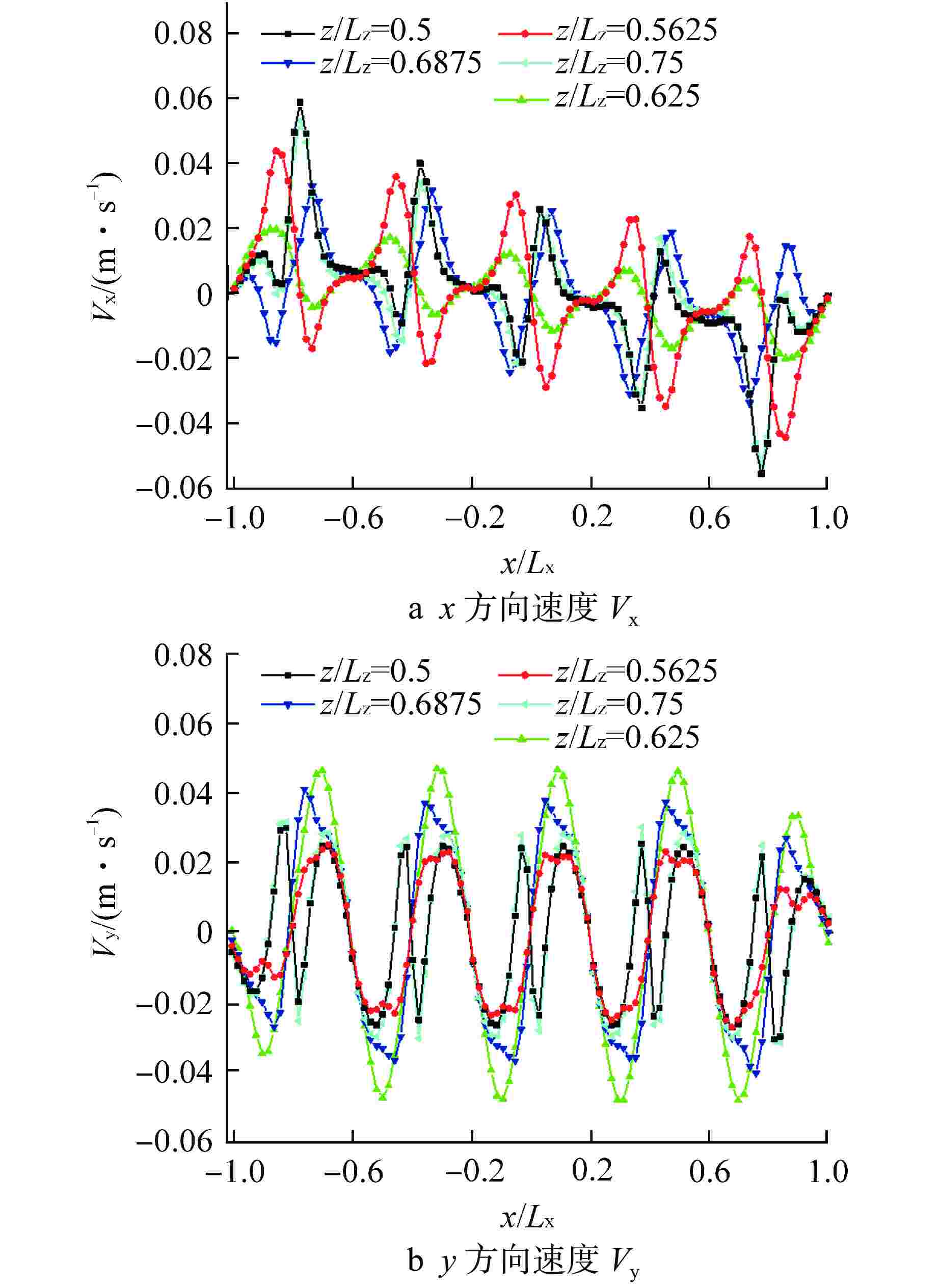

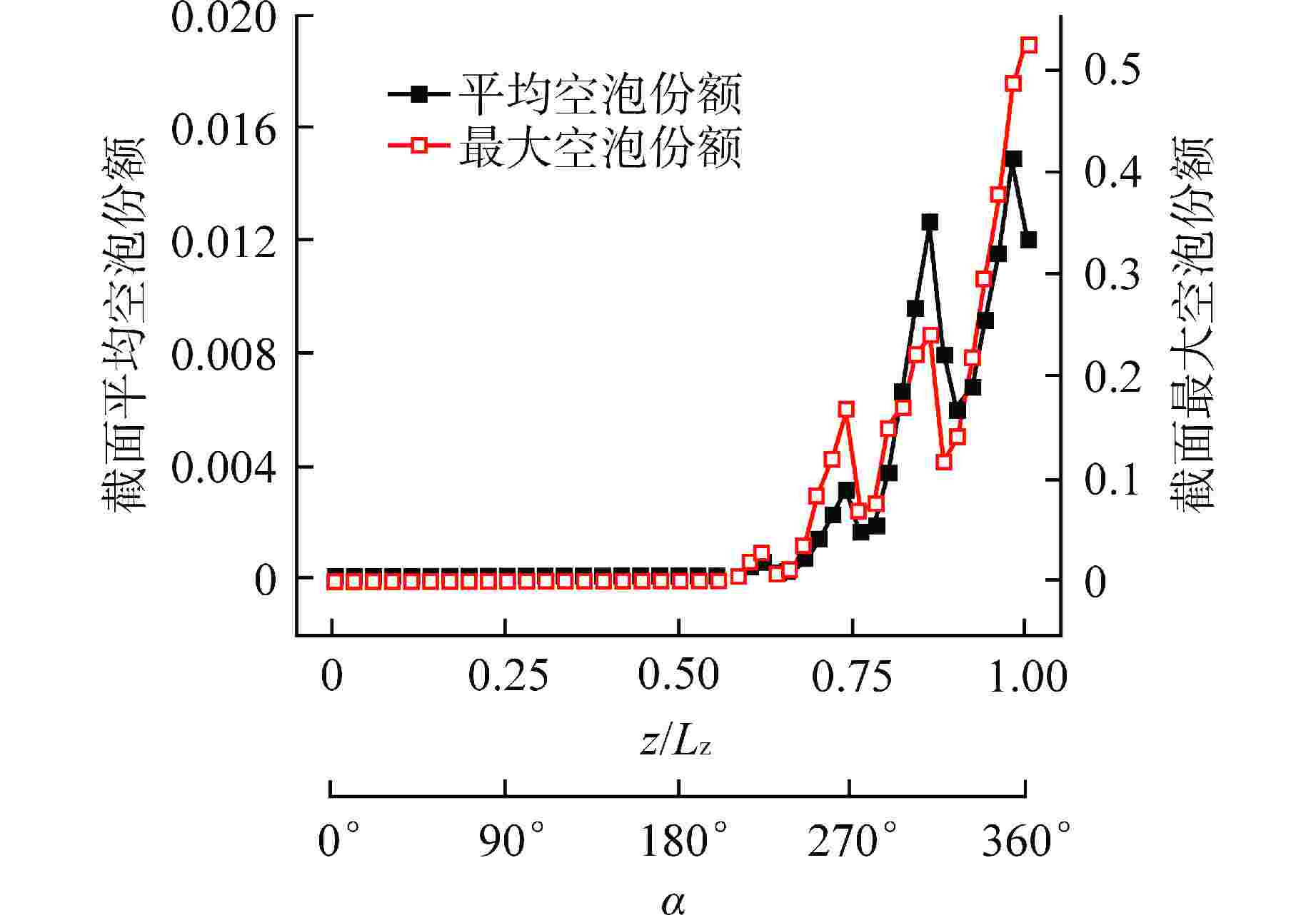

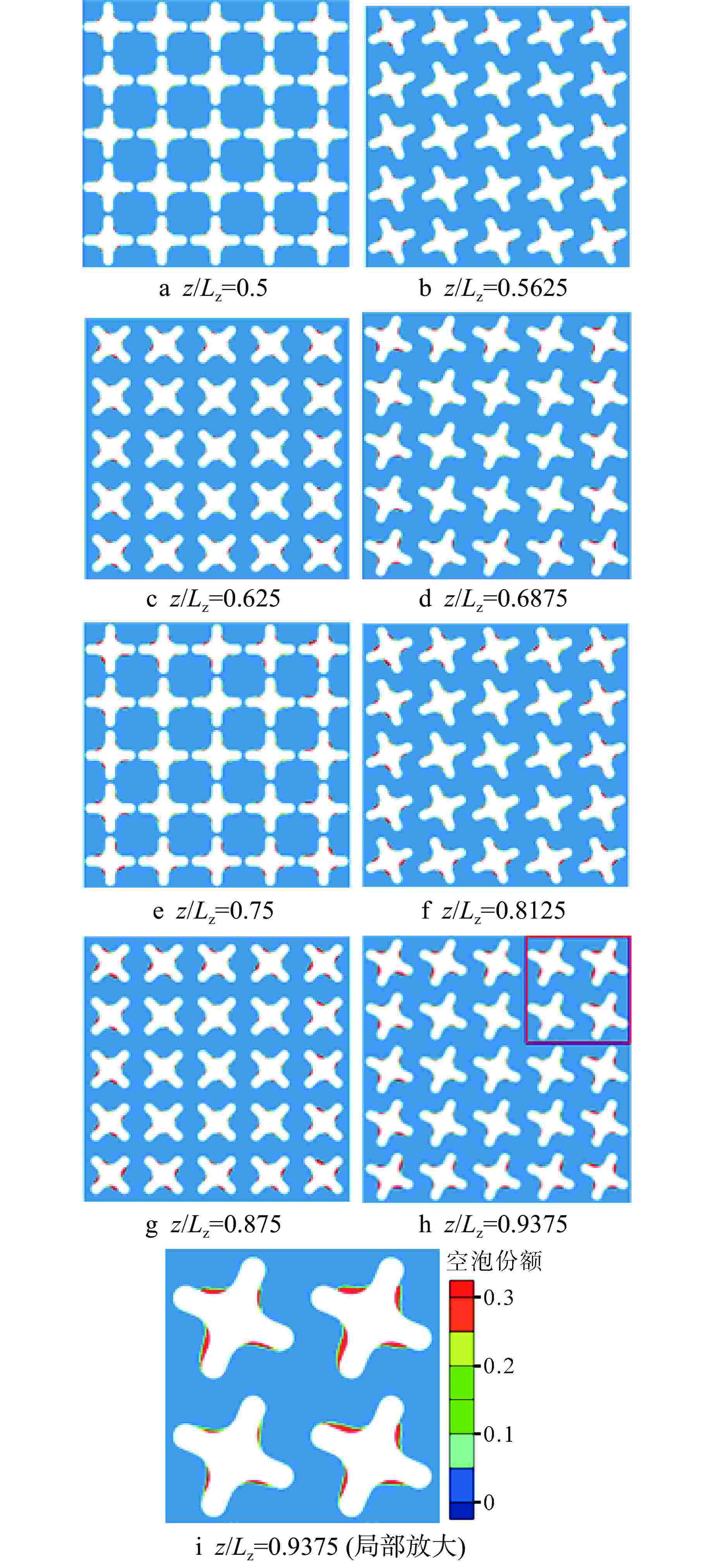

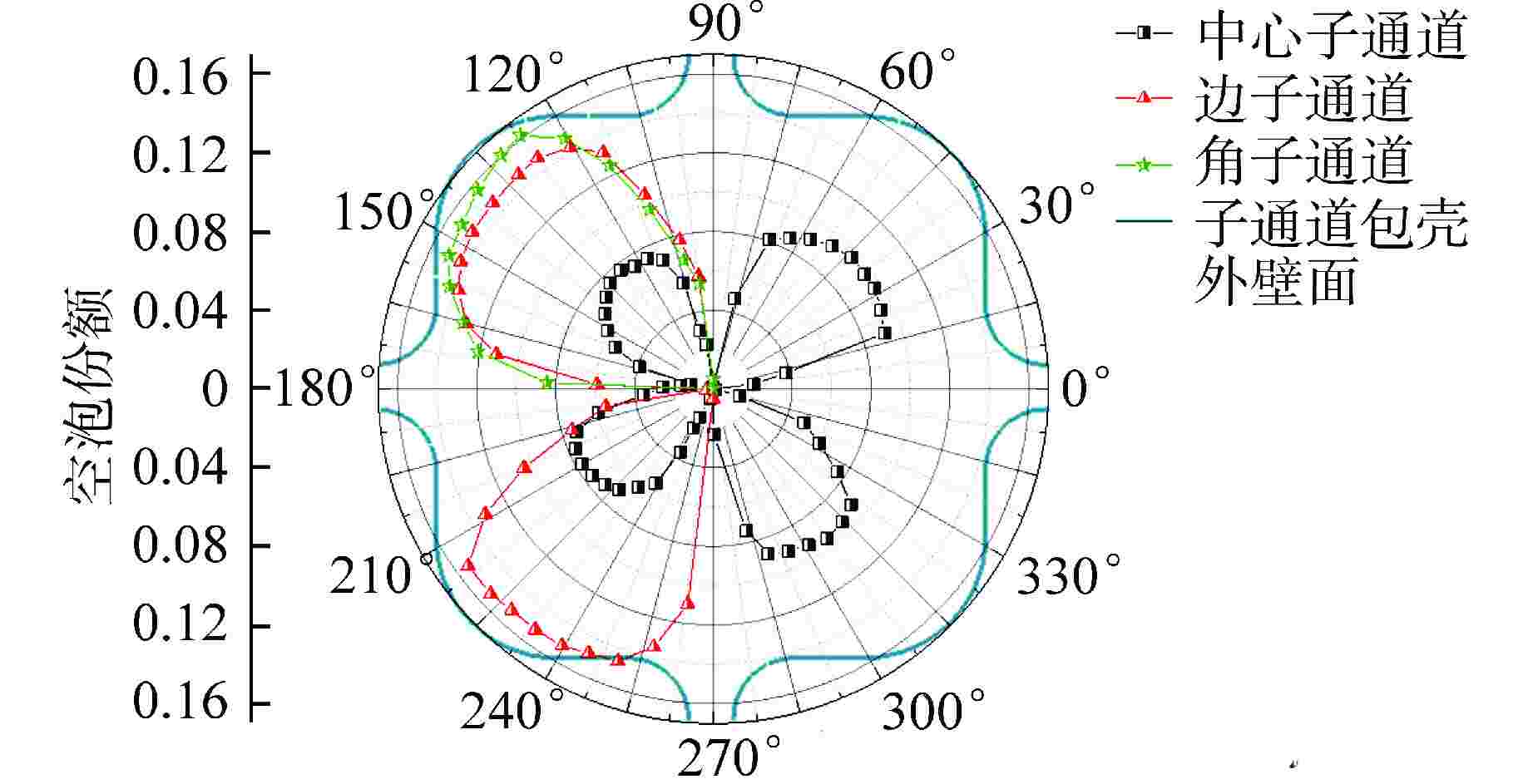

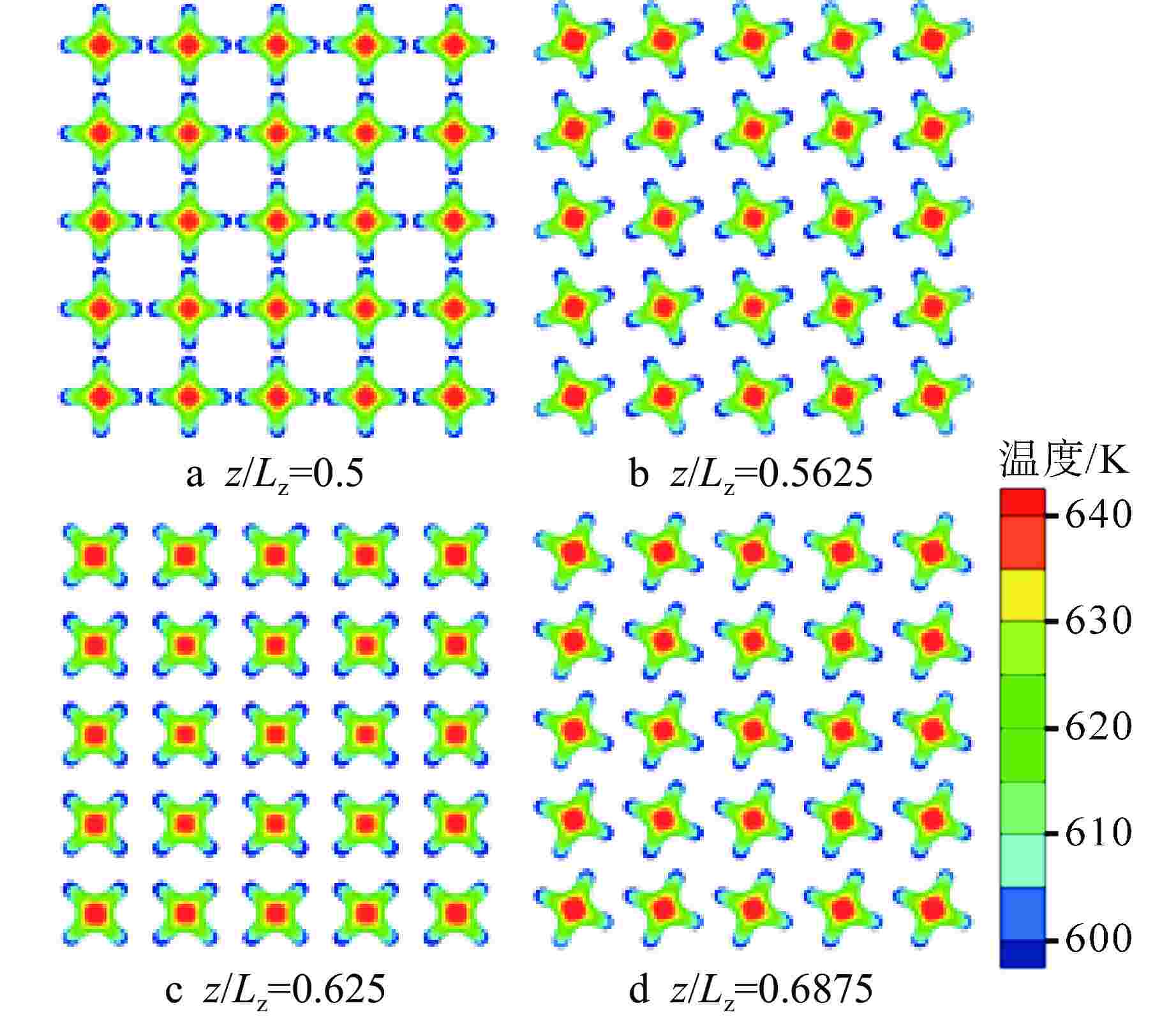

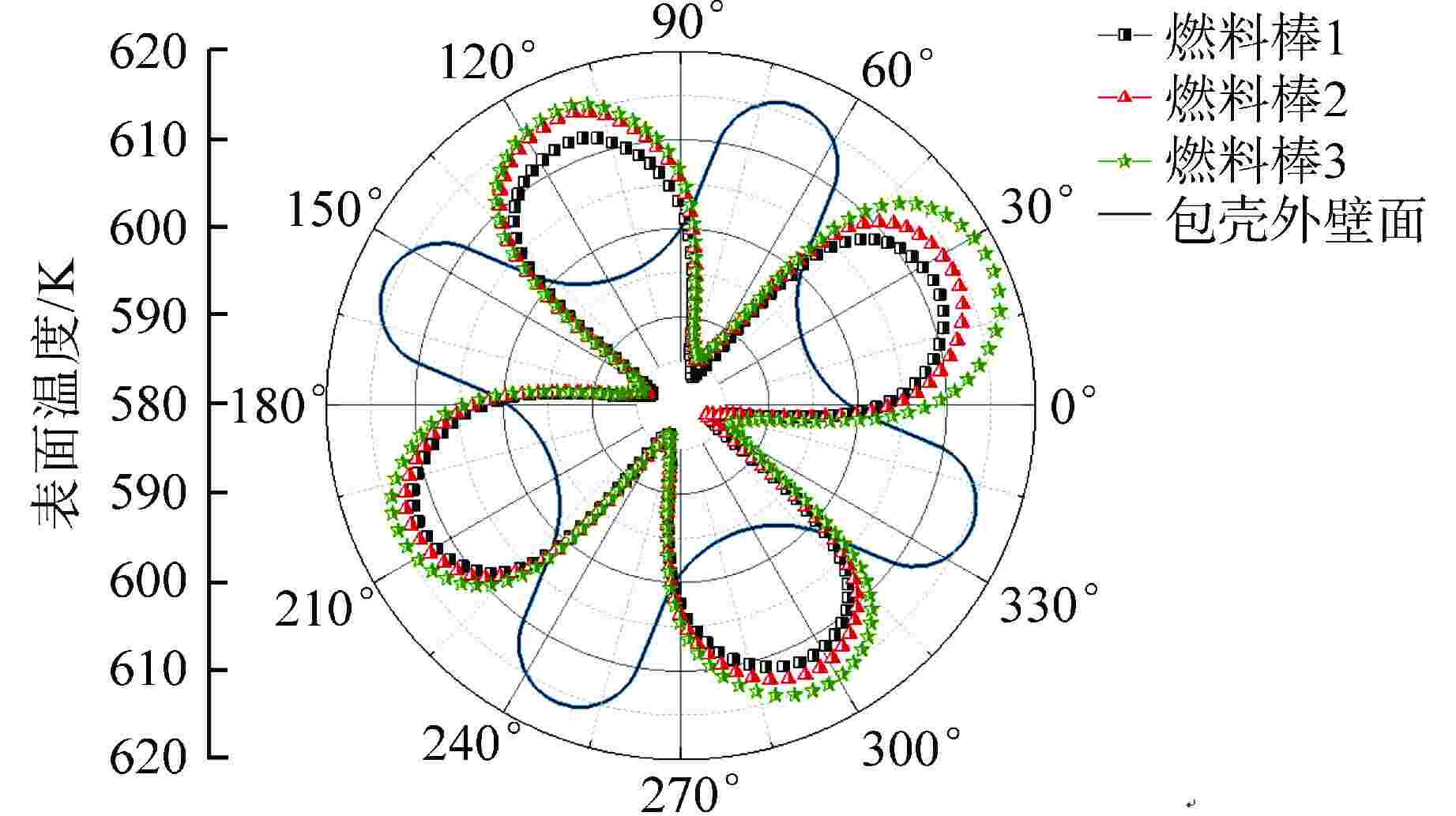

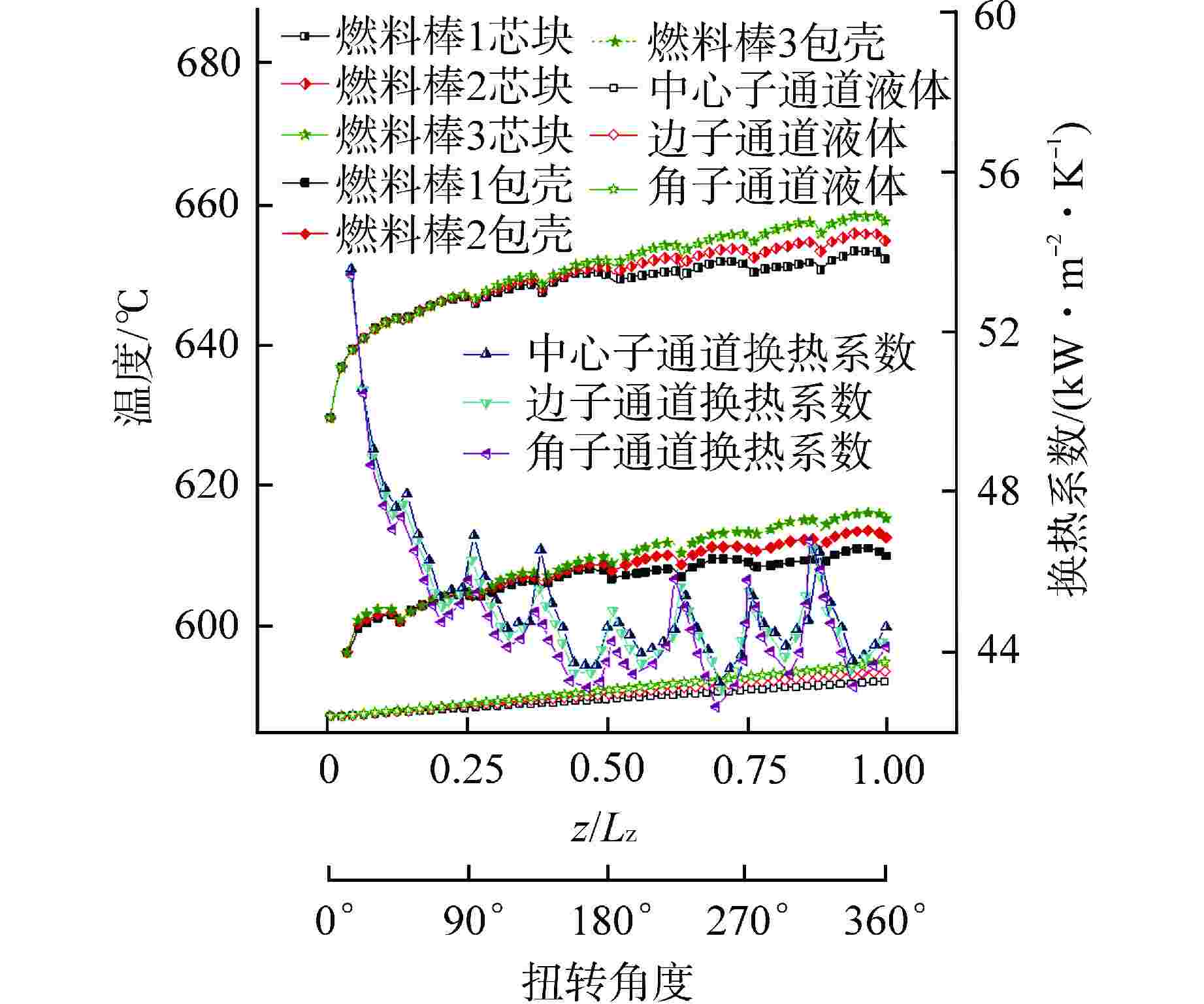

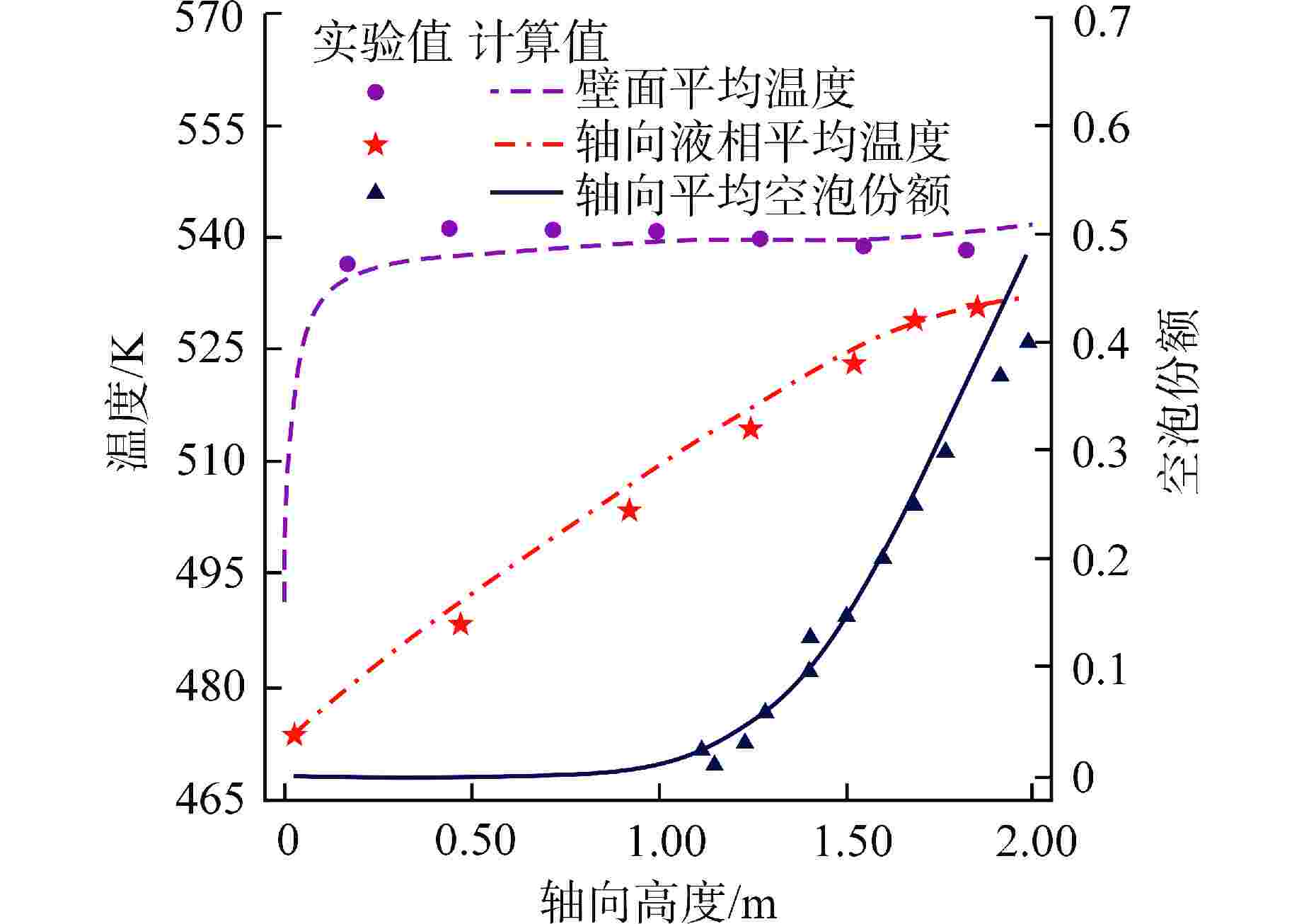

摘要: 使用欧拉两流体模型和伦斯勒理工学院(RPI)壁面沸腾模型并考虑燃料棒组件内流固耦合传热,探究了5×5花瓣形燃料棒组件在均匀体积热源条件下的过冷沸腾流动与换热特性,分析了不同子通道内的速度场、温度场、空泡份额分布以及换热系数分布规律等。研究发现,棒束通道内二次流强度沿轴向呈周期性波动变化;过冷沸腾工况下花瓣形燃料组件内空泡份额峰值出现在靠近出口处,汽泡主要在燃料棒内凹弧处产生,呈逆时针偏心分布,且角子通道的汽相体积份额明显大于中心子通道;在本文模拟工况下,芯块最高温度达到657.9 K,沿轴向燃料棒芯块高温区面积逐渐增大,且角子通道的冷却剂温度高于边子通道,中心子通道冷却剂平均温度最低,各子通道的换热系数沿轴向呈周期性波动。Abstract: Based on the Eulerian two-fluid model and the Rensselaer Polytechnic Institute (RPI) wall boiling model, and considering the fluid-solid coupling heat transfer in fuel rod assembly, the flow and heat transfer characteristics of subcooled boiling in the 5×5 petal-shaped fuel rod assembly under the condition of uniform volume heat source was studied, and the velocity field, temperature field, void fraction distribution and heat transfer coefficient distribution in different sub-channels were analyzed. The results show that the secondary flow intensity in the rod bundle channel changes periodically along the axial direction. Under subcooled boiling condition, the peak value of void fraction in petal-shape fuel assembly appears near the outlet. The bubbles are mainly generated at the elbow of the fuel rod and distribute eccentrically counterclockwise, and the volume fraction of vapor in the corner subchannel is obviously larger than that in the center subchannel. Under the simulated conditions in this paper, the maximum temperature of the pellet reaches 657.9 K. The area of high temperature zone of the fuel rod pellet increases gradually along the axial direction, and the coolant temperature in the corner subchannel is higher than that of the edge subchannel. The average coolant temperature of the central subchannel is the lowest, and the heat transfer coefficient of each subchannel fluctuates periodically along the axial direction.

-

表 1 网格参数

Table 1. Mesh Parameters

网格编号 轴向节点 Y+ 网格总数/万 1 250 120 1956.4 2 250 60 2856.7 3 250 12 3055.3 表 2 初始条件和边界条件

Table 2. Initial and Boundary Conditions

计算域 边界位置 边界类型 参数 流体域 进口 速度进口 速度:3.17 m/s 温度:570 K 空泡份额:0 出口 压力出口 压力:15.5 MPa 内壁面 耦合壁面 与包壳耦合 外壁面 壁面 绝热、无滑移 包壳 内壁面 耦合壁面 与燃料耦合 外壁面 耦合壁面 与流体域耦合 顶面、底面 壁面 绝热 燃料 外壁面 耦合壁面 与包壳耦合 顶面、底面 壁面 绝热 燃料固体域 体积热源 功率:2×108 W/m3 -

[1] DIAKOV A C, DMITRIEV A M, KANG J, et al. Feasibility of converting Russian icebreaker reactors from HEU to LEU fuel[J]. Science & Global Security, 2006, 14(1): 33-48. [2] PETROV Y V, ERYKALOV A N, ONEGIN M S. The fuel cycle of reactor PIK[C]//International Meeting on Reduced Enrichment for Research and Test Reactors. San Carlos de Bariloche: IAEA, 2002. [3] LO S, OSMAN J. CFD Modeling of boiling flow in PSBT 5×5 bundle[J]. Science and Technology of Nuclear Installations, 2012, 2012: 795935. [4] 李松蔚,张虹,姜胜耀,等. 棒束定位格架两相CFD模拟方法研究[J]. 核动力工程,2012, 33(2): 92-96. doi: 10.3969/j.issn.0258-0926.2012.02.020 [5] 王小军,陈炳德,黄彦平,等. 棒束定位格架空泡份额分布特性实验研究[J]. 核科学与工程,2003, 23(2): 110-113,131. [6] 李松蔚,李仲春,杜思佳,等. 带7道格架的5×5棒束两相性能CFD分析[J]. 核动力工程,2019, 40(3): 185-190. doi: 10.13832/j.jnpe.2019.03.0185 [7] ZHANG R, CONG T L, TIAN W X, et al. CFD analysis on subcooled boiling phenomena in PWR coolant channel[J]. Progress in Nuclear Energy, 2015, 81: 254-263. doi: 10.1016/j.pnucene.2015.02.005 [8] 董晓朦. 棒束通道沸腾传热与两相流动CFD分析及应用[D]. 哈尔滨: 哈尔滨工程大学, 2019. [9] BOL’SHAKOV V V, BASHKIRTSEV S M, KOBZAR’ L L, et al. Experimental study of burnout in channels with twisted fuel rods[J]. Thermal Engineering, 2007, 54(5): 386-389. doi: 10.1134/S0040601507050096 [10] SHIRVAN K. Numerical investigation of the boiling crisis for helical cruciform-shaped rods at high pressures[J]. International Journal of Multiphase Flow, 2016, 83: 51-61. doi: 10.1016/j.ijmultiphaseflow.2016.03.014 [11] 杜利鹏,蒋泽平,崔军,等. 花瓣形燃料元件棒束通道内过冷流动沸腾特性数值研究[J]. 原子能科学技术,2023, 57(2): 264-275. [12] CONG T L, XIAO Y, WANG B C, et al. Numerical study on the boiling heat transfer and critical heat flux in a simplified fuel assembly with 2×2 helical cruciform rods[J]. Progress in Nuclear Energy, 2022, 145: 104111. doi: 10.1016/j.pnucene.2021.104111 [13] Kurul N. On the modeling of multidimensional effects in boiling channels[J]. ANS. Proc. National Heat Transfer Con. Minneapolis, Minnesota, USA, 1991, 1991. 5. [14] KOCAMUSTAFAOGULLARI G. Pressure dependence of bubble departure diameter for water[J]. International Communications in Heat and Mass Transfer, 1983, 10(6): 501-509. doi: 10.1016/0735-1933(83)90057-X [15] LEMMERT M, CHAWLA J M. Influence of flow velocity on surface boiling heat transfer coefficient[M]//HAHNE E, GRIGULL U. Heat Transfer in Boiling. New York: Academic Press and Hemisphere, 1977: 237-247. [16] COLE R. A photographic study of pool boiling in the region of the critical heat flux[J]. AIChE Journal, 1960, 6(4): 533-538. doi: 10.1002/aic.690060405 [17] BARTOLEMEI G G, CHANTURIYA V M. Experimental study of true void fraction when boiling subcooled water in vertical tubes[J]. Thermal Engineering, 1967, 14(2): 123-128. [18] 蔡伟华,韦徵圣,李石磊,等. 5×5花瓣形燃料棒束组件内单相流动与换热特性数值模拟研究[J]. 原子能科学技术,2021, 55(11): 1939-1949. [19] SHIRVAN K, KAZIMI M S. Three dimensional considerations in thermal-hydraulics of helical cruciform fuel rods for LWR power uprates[J]. Nuclear Engineering and Design, 2014, 270: 259-272. doi: 10.1016/j.nucengdes.2014.01.015 [20] FANG Y L, QIN H, WANG C L, et al. Numerical investigation on thermohydraulic performance of high temperature hydrogen in twisted rod channels[J]. Annals of Nuclear Energy, 2021, 161: 108343. [21] 张琦,赵行斌,顾汉洋,等. 螺旋十字型燃料元件流动与换热特性的数值模拟分析//第十六届全国反应堆热工流体学术会议暨中核核反应堆热工水力技术重点实验室2019年学术年会论文集. 惠州:中国科学院近代物理研究所,2019:13. MIMOUNI S,BAUDRY C,GUINGO M,et al. Computational multi-fluid dynamics predictions of critical heat flux in boiling flow[J]. Nuclear Engineering and Design,2016, 299: 28-36. [22] ZHANG R, CONG T L, TIAN W X, et al. Effects of turbulence models on forced convection subcooled boiling in vertical pipe[J]. Annals of Nuclear Energy, 2015, 80: 293-302. doi: 10.1016/j.anucene.2015.01.039 [23] Mimouni S, Baudry C, Guingo M, et al. Computational multi-fluid dynamics predictions of critical heat flux in boiling flow[J]. Nuclear Engineering and Design, 2016, 299: 28-36. [24] MALONE J, TOTEMEIER A, SHAPIRO N, et al. Lightbridge corporation’s advanced metallic fuel for light water reactors[J]. Nuclear Technology, 2012, 180(3): 437-442. doi: 10.13182/NT12-A15354 [25] KAITY S, BANERJEE J, NAIR M R, et al. Microstructural and thermophysical properties of U-6Wt. %Zr alloy for fast reactor application[J]. Journal of Nuclear Materials, 2012, 427(1-3): 1-11. doi: 10.1016/j.jnucmat.2012.03.045 [26] TAKAHASHI Y, YAMAMOTO K, OHSATO T, et al. Heat capacities of uranium-zirconium alloys from 300 to 1100 K[J]. Journal of Nuclear Materials, 1989, 167: 147-151. doi: 10.1016/0022-3115(89)90436-4 [27] MURABAYASHI M, TANAKA S, TAKAHASHI Y. Thermal conductivity and heat capacity of zircaloy-2, -4 and unalloyed zirconium[J]. Journal of Nuclear Science and Technology, 1975, 12(10): 661-662. doi: 10.1080/18811248.1975.9733170 [28] TERAI T, TAKAHASHI Y, MASUMURA S, et al. Heat capacity and phase transition of zircaloy-4[J]. Journal of Nuclear Materials, 1997, 247: 222-226. doi: 10.1016/S0022-3115(97)00048-2 [29] HOFMAN G L, BILLONE M C, KOENIG J F, et al. Metallic fuels handbook[R]. Argonne: Argonne National Lab. , 2019. [30] SUZUKI M, SAITO H, UDAGAWA Y, et al. Light water reactor fuel analysis code FEMAXI-7: model and structure: JAEA-Data/Code 2013-014[R]. Mito-shi: Japan Atomic Energy Agency, 2014: 400. -

下载:

下载: