Experimental Research on Characteristics of Reactor Coolant Pump Torque under Two-Phase Conditions

-

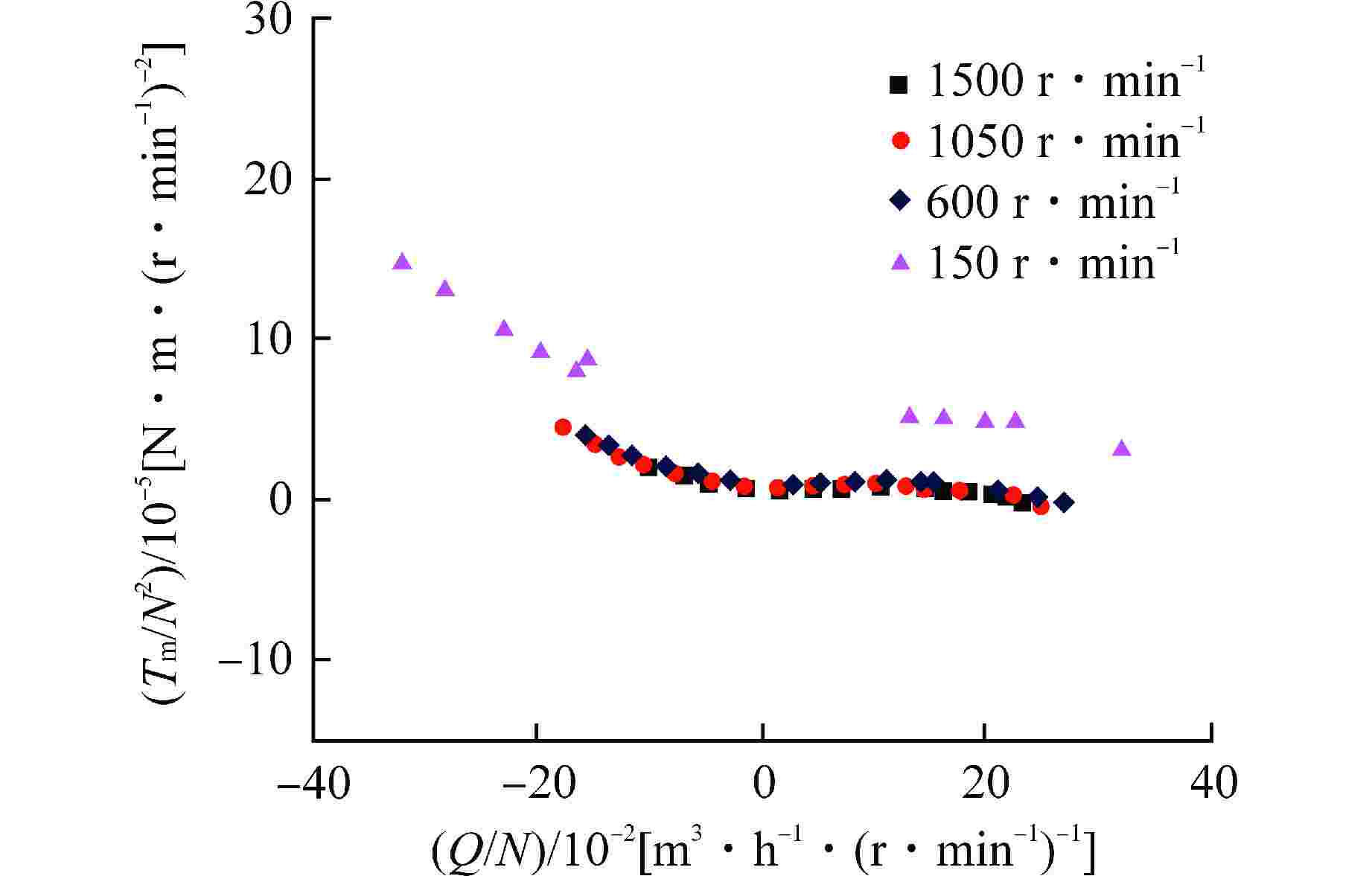

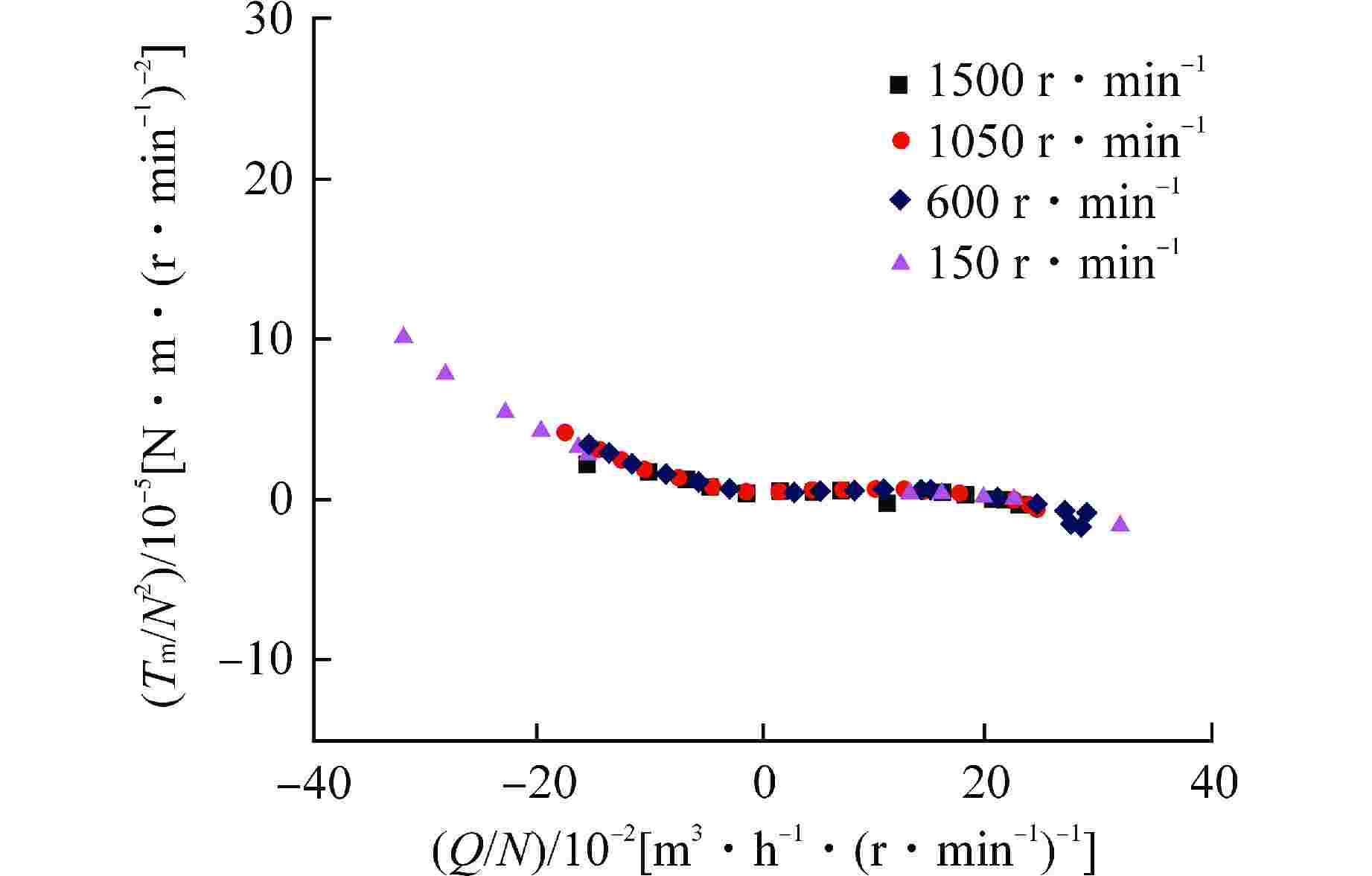

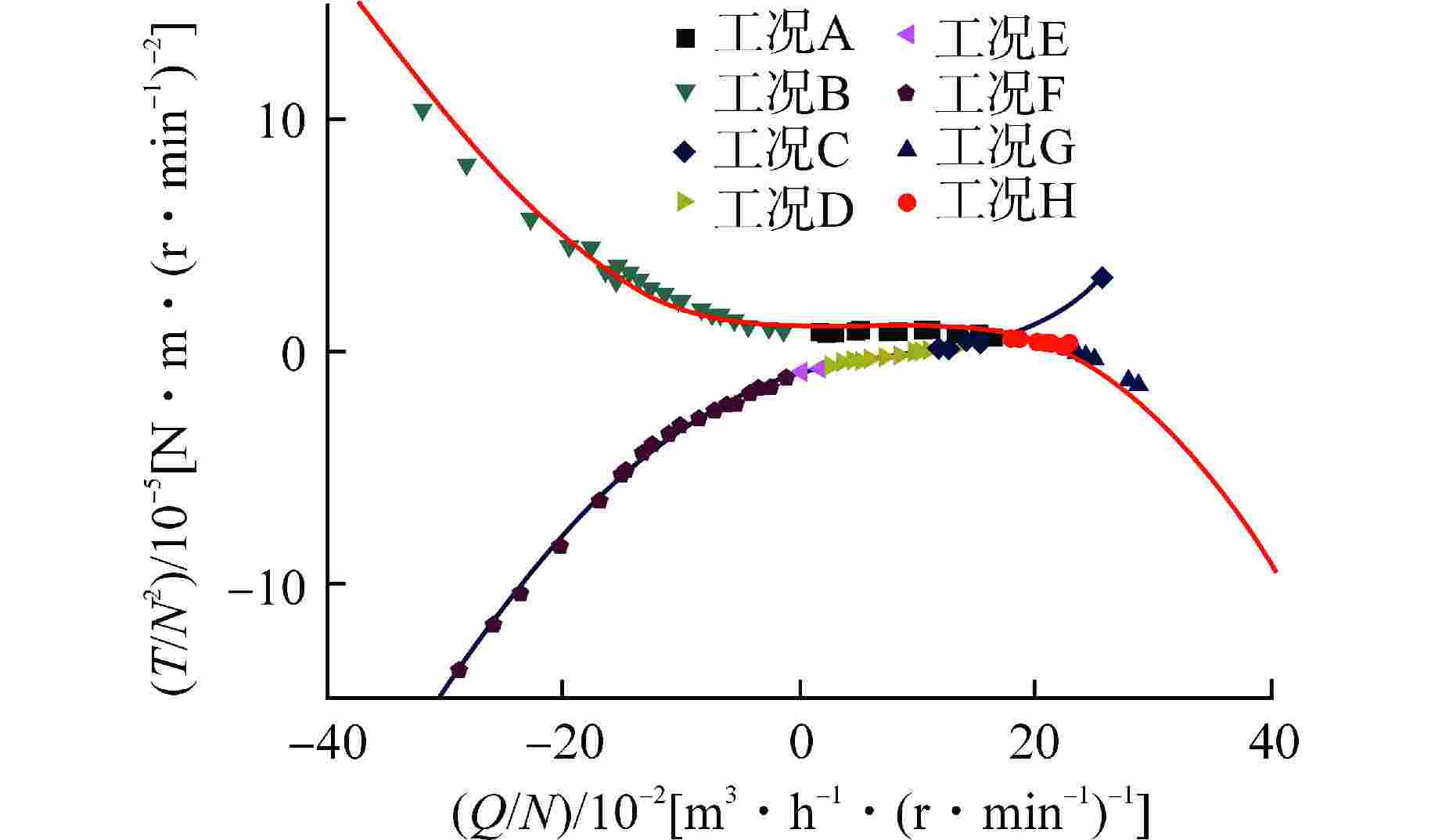

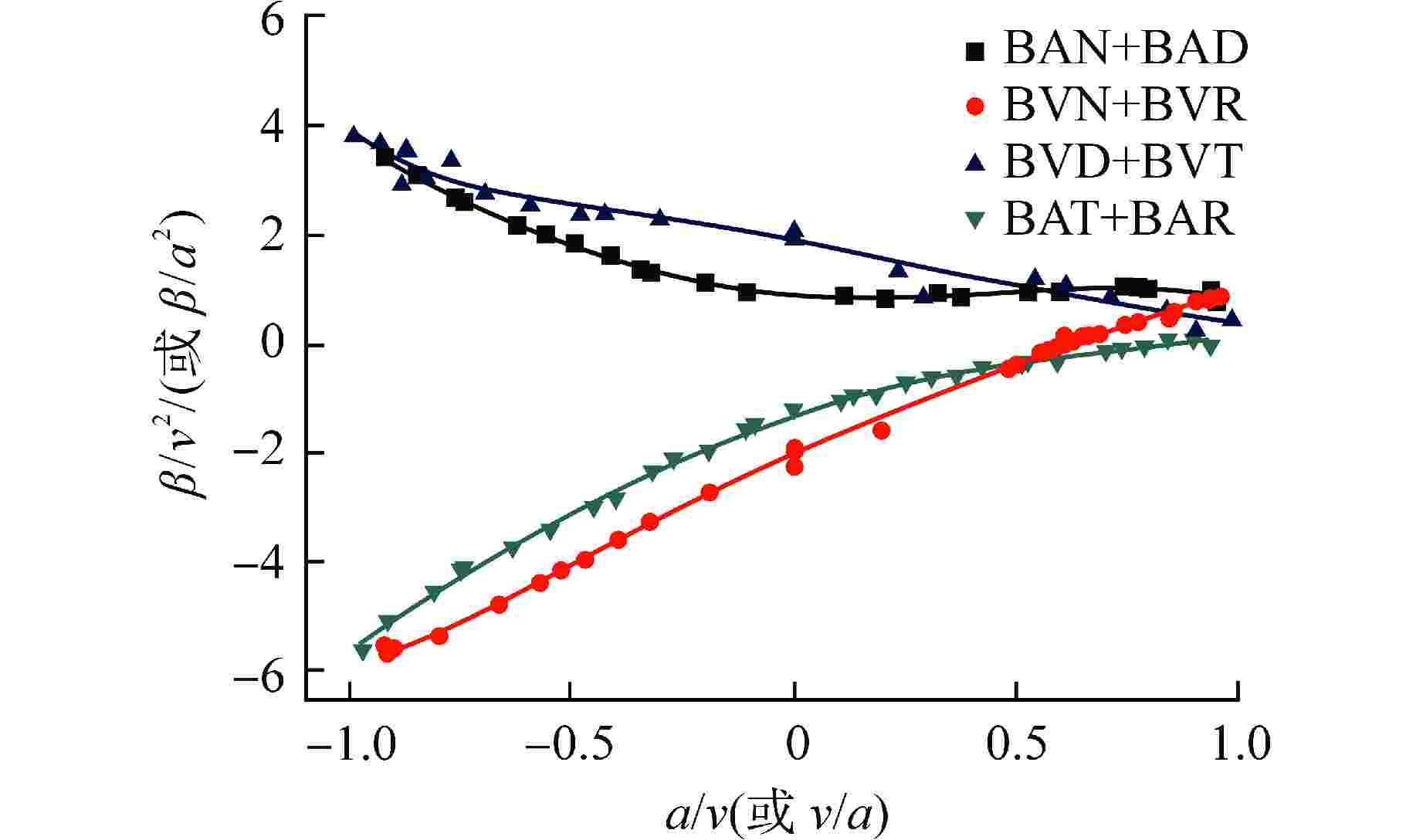

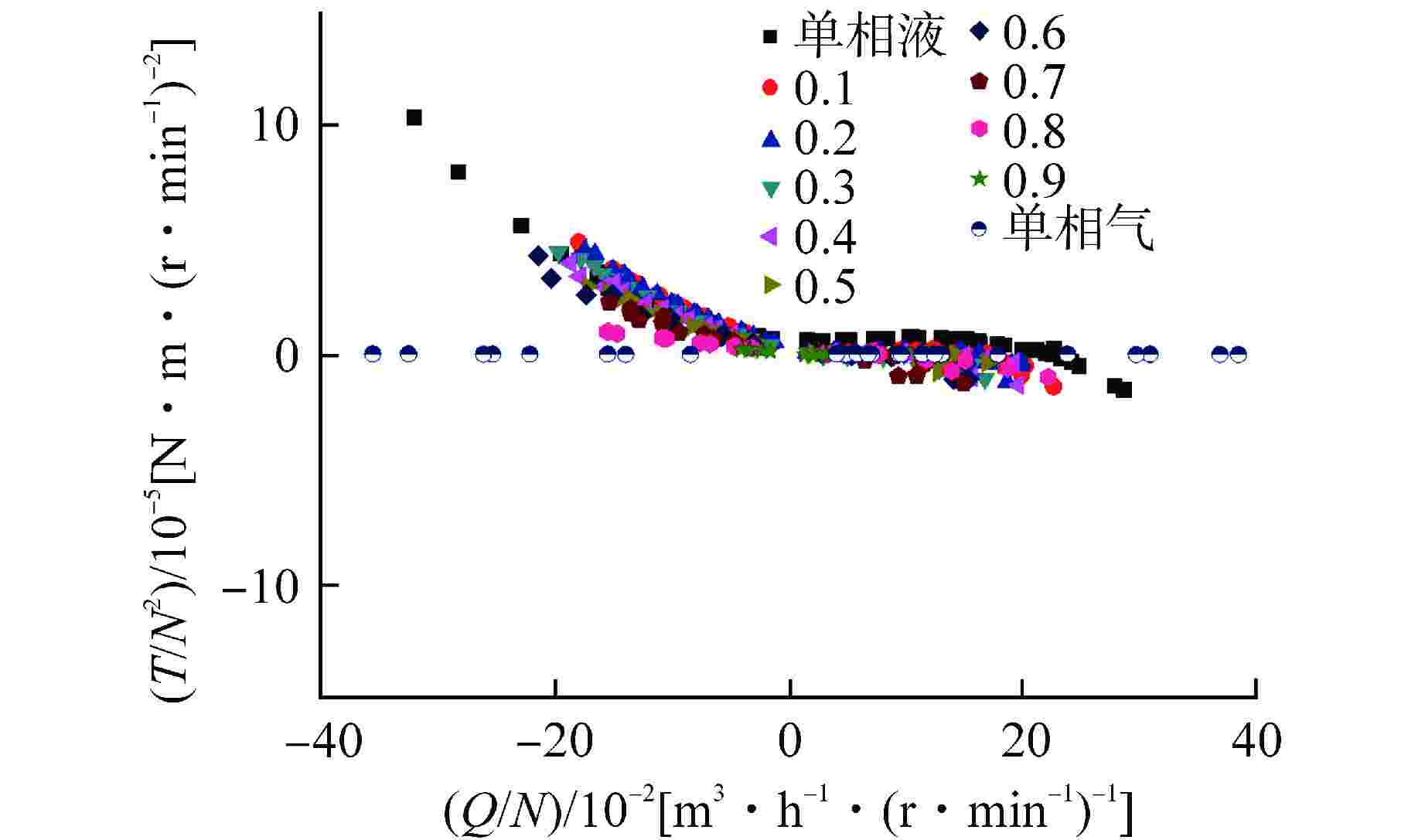

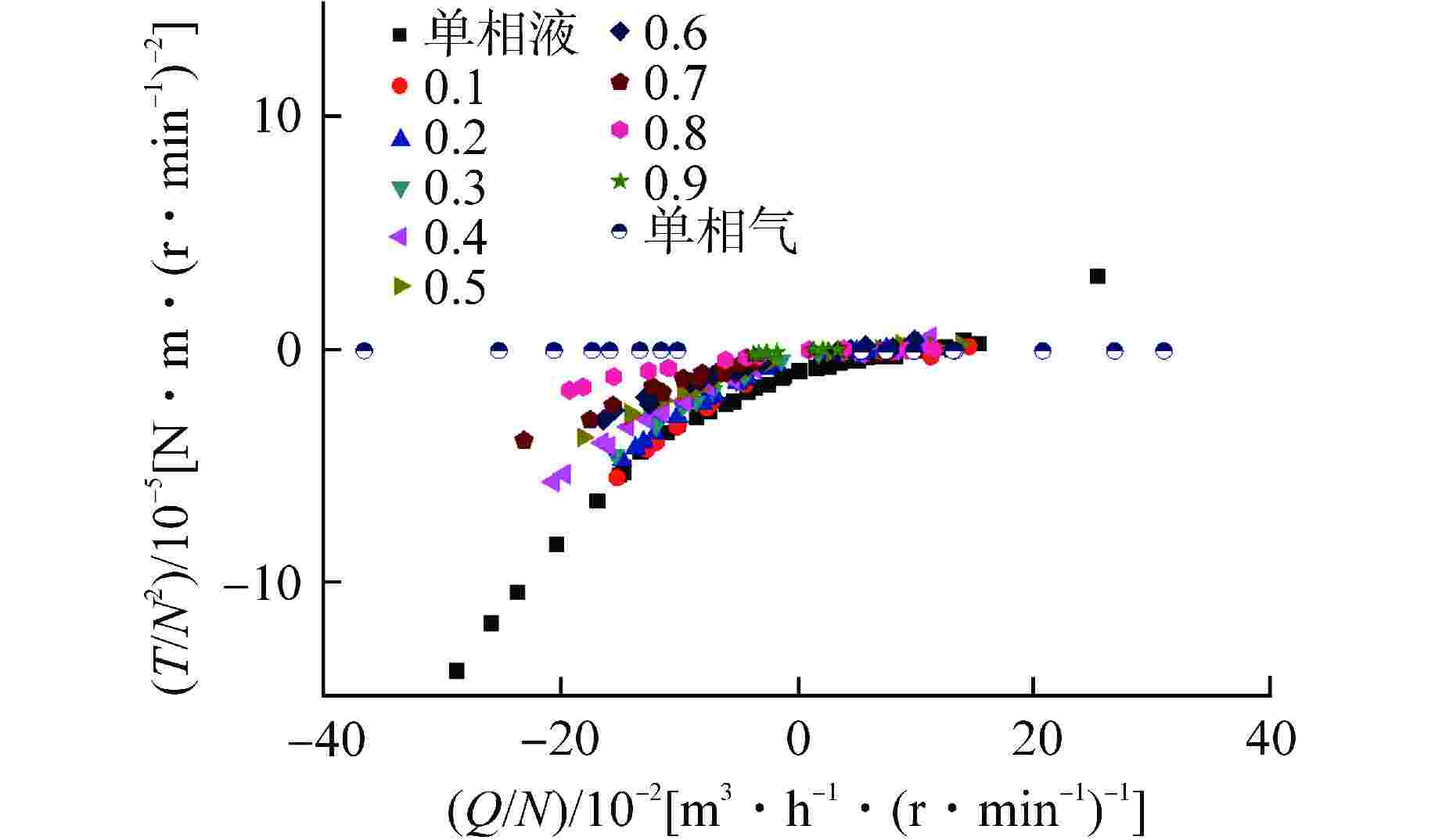

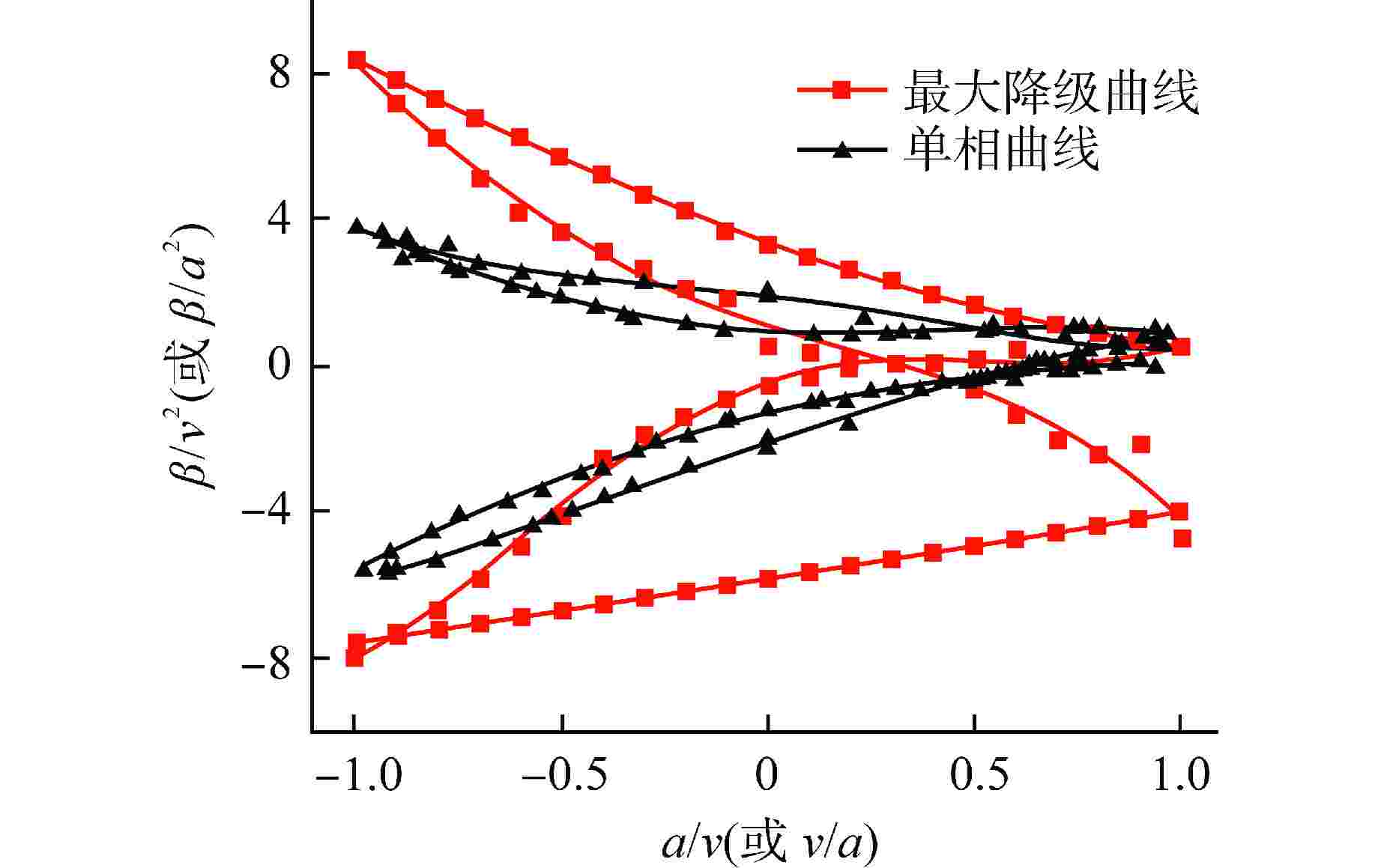

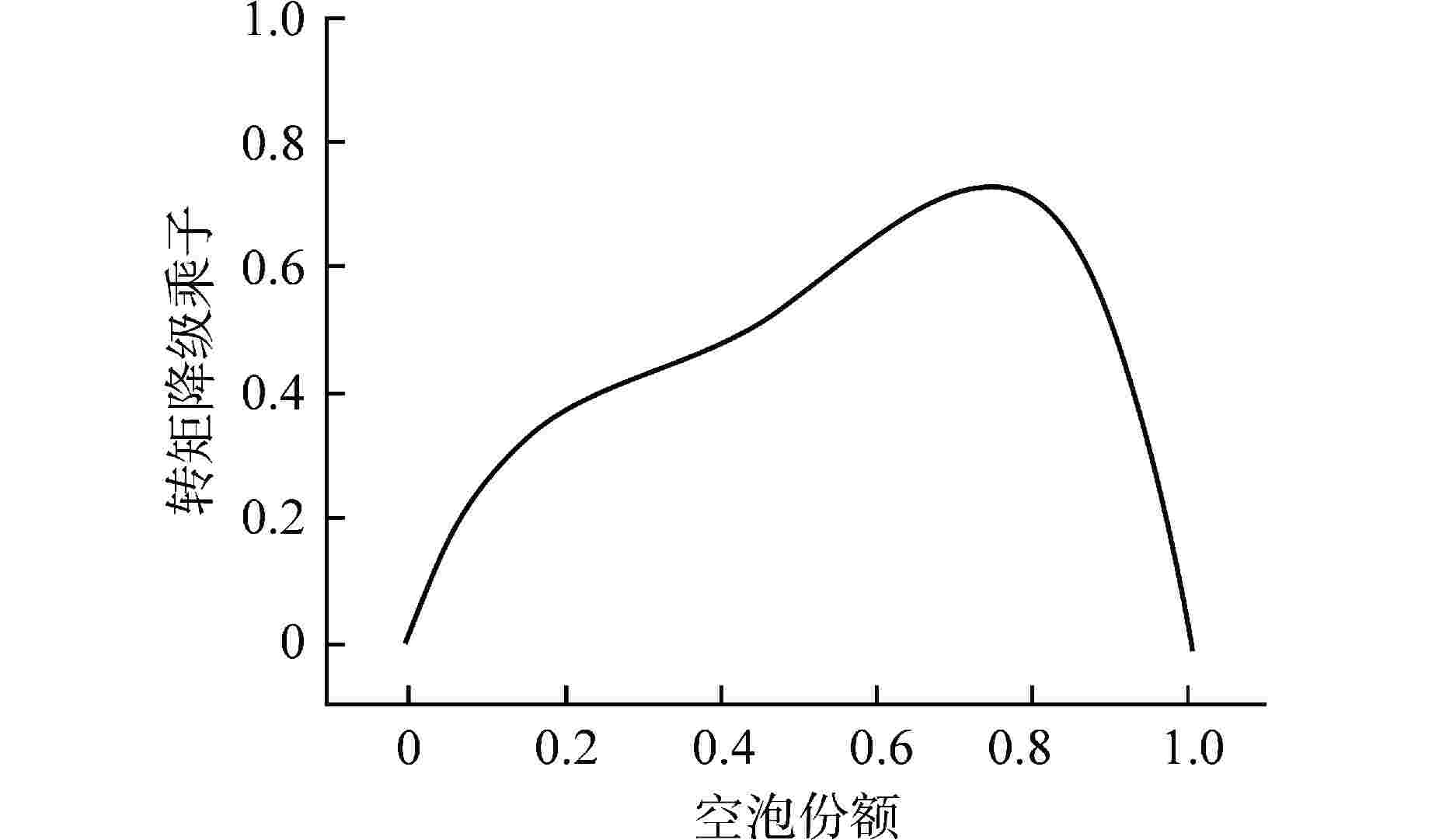

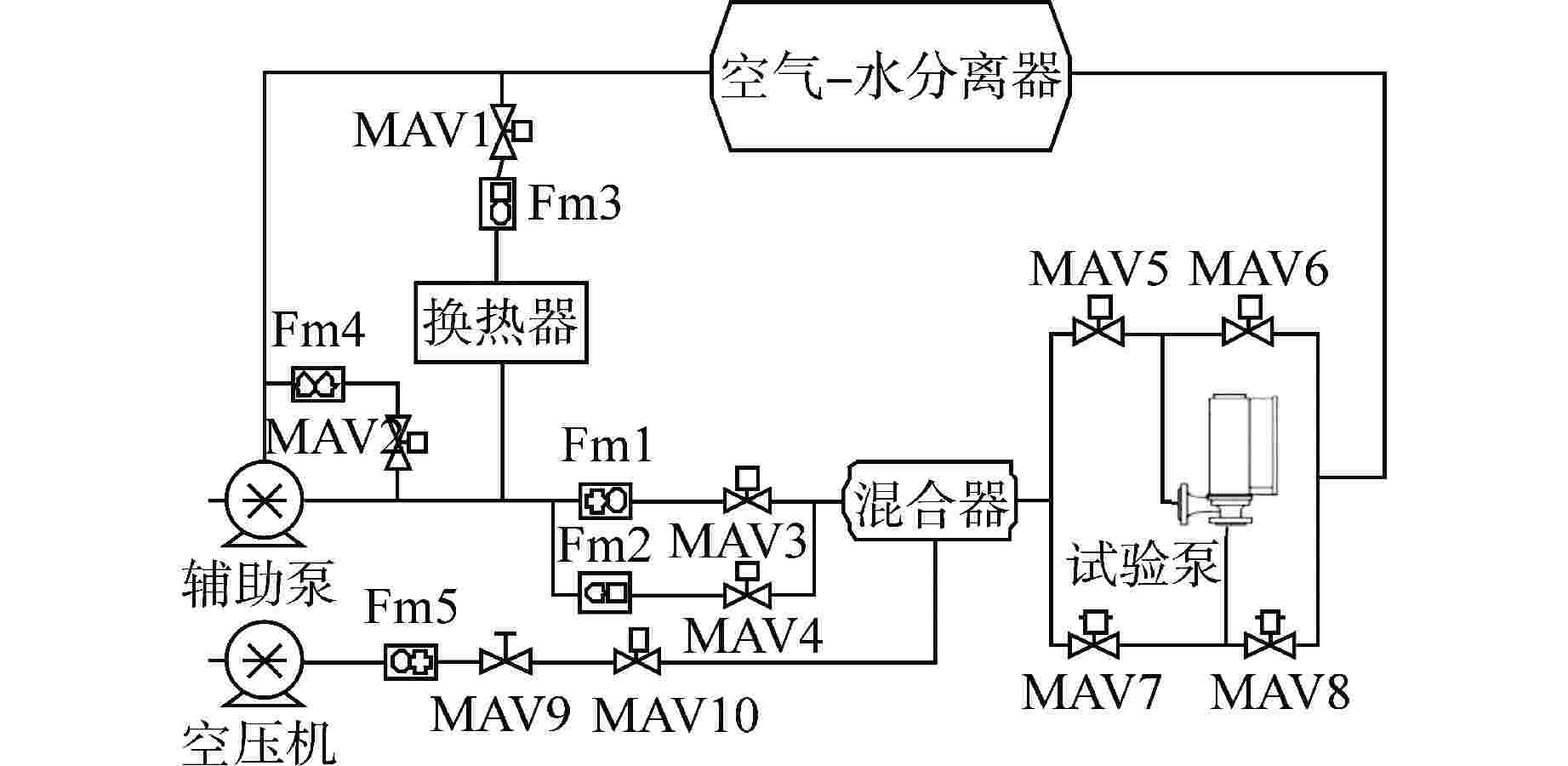

摘要: 为掌握主泵的两相转矩特性,本研究搭建专设台架,以经过模化缩比设计的试验泵为对象,开展试验研究。首先对泵多转速单相液条件下的正常工况、反水泵工况、正反耗能工况、正反水轮机工况等的流动特性开展试验,之后选取单相气和0.1~0.9空泡份额(空泡份额跨度为0.1)两相条件下的主泵针对上述工况逐一开展研究。利用比例定律对多转速下的实验数据进行整理,掌握了其转矩在不同空泡份额、不同流量、不同工况下的变化规律,在此数据基础上可同时处理得到适用于一回路安全分析软件的泵同源曲线。研究结果表明,随着空泡份额的增加,相同工况下的转矩不断减小,比例定律曲线逐渐向零点漂移,而同源曲线会存在先降级再回归的过程,当空泡份额达到0.7左右时,降级程度达到最大。Abstract: In order to grasp the torque characteristics of reactor coolant pump (RCP) under two-phase conditions, a special test platform was built in this study to carry out experimental research on a model pump based on the scale model of RCP. Firstly, the single-phase flow characteristics of the pump with multi-speed under normal condition, reverse pump condition, positive and negative energy consumption condition, obverse and reverse turbine condition, etc. were obtained. Then, the pump under single-phase air and two-phase 0.1-0.9 void fraction (the void fraction span is 0.1) was tested for the above conditions one by one. The proportionality law was used to sort out the experimental data at multiple speeds, and the variation rules of the torque under different void fractions, different flow rates and different conditions were obtained. Based on the data, homologous curve suitable for the primary circuit safety analysis software can be obtained simultaneously. The results show that with the increase of void fraction, the torque under the same condition decreases continuously, and the proportionality law curve drifts to zero gradually, while the homologous curve has the process of "degradation" first and then regression. When the void fraction reaches about 0.7, the degree of "degradation" reaches the maximum.

-

Key words:

- Nuclear coolant pump /

- Torque /

- Two-Phase flow /

- Void fraction /

- Proportionality law /

- Homologous curve

-

表 1 试验工况

Table 1. Test Conditions

α 泵转速/(r·min−1) 具体运行工况 0 ±1500、±1050、±600、±150 正常工况、反水泵工况、

正反耗能工况、正反水轮机

工况等0.1~0.9 ±1500、±1050、±600 1.0 ±1500、±1050 -

[1] 苏前华,王阔,邢军,等. 两相条件下主泵特性试验研究[J]. 核动力工程,2021, 42(1): 129-132. [2] 郭义航. 离心泵扭矩和转速的非定常特性研究[D]. 镇江: 江苏大学, 2017. [3] 钱卫东. AP1400核主泵的四象限特性试验研究[J]. 水泵技术,2015(5): 7-12. [4] 杨绪剑,张策,王丽平. 离心泵四象限运行特性曲线试验系统[J]. 机床与液压,2008, 36(4): 71-72,76. [5] 郑梦海. 泵测试实用技术[M]. 第二版. 北京: 机械工业出版社, 2011: 40-44. [6] CHOI K Y, KIM Y S, YI S J, et al. Development of a pump performance model for an integral effect test facility[J]. Nuclear Engineering and Design, 2008, 238(10): 2614-2623. doi: 10.1016/j.nucengdes.2008.04.005 [7] OLSON D J. Single- and two-phase performance characteristics of the MOD-1 semiscale pump under steady state and transient fluid conditions: ANCR-1165[R]. U.S.: Aerojet Nuclear Company, 1974. [8] OLSON D J. Experimental data report for single and two-phase steady state tests of the 1-1/2 loop MOD-1 semiscale system pump:ANCR-1165[R]. U.S.: Aerojet Nuclear Company, 1974. [9] Relap5/MOD3.3 code manual volume II: user’s guide and input requirement[M]. Rockville, Maryland: U. S. Nuclear Regulatory Commissionn, 2001: 44-54. [10] 高璞珍. 核动力装置用泵[M]. 哈尔滨: 哈尔滨工程大学出版社, 2009: 36-37. [11] MITRA D R. Fluid-elastic instability in tube arrays subjected to air-water and steam-water cross-flow[D]. Los Angeles: University of California, 2005. -

下载:

下载: