Performance Prediction and Structural Parameter Optimization of Control Rod Hydraulic Buffer Based on GA-BP Neural Network

-

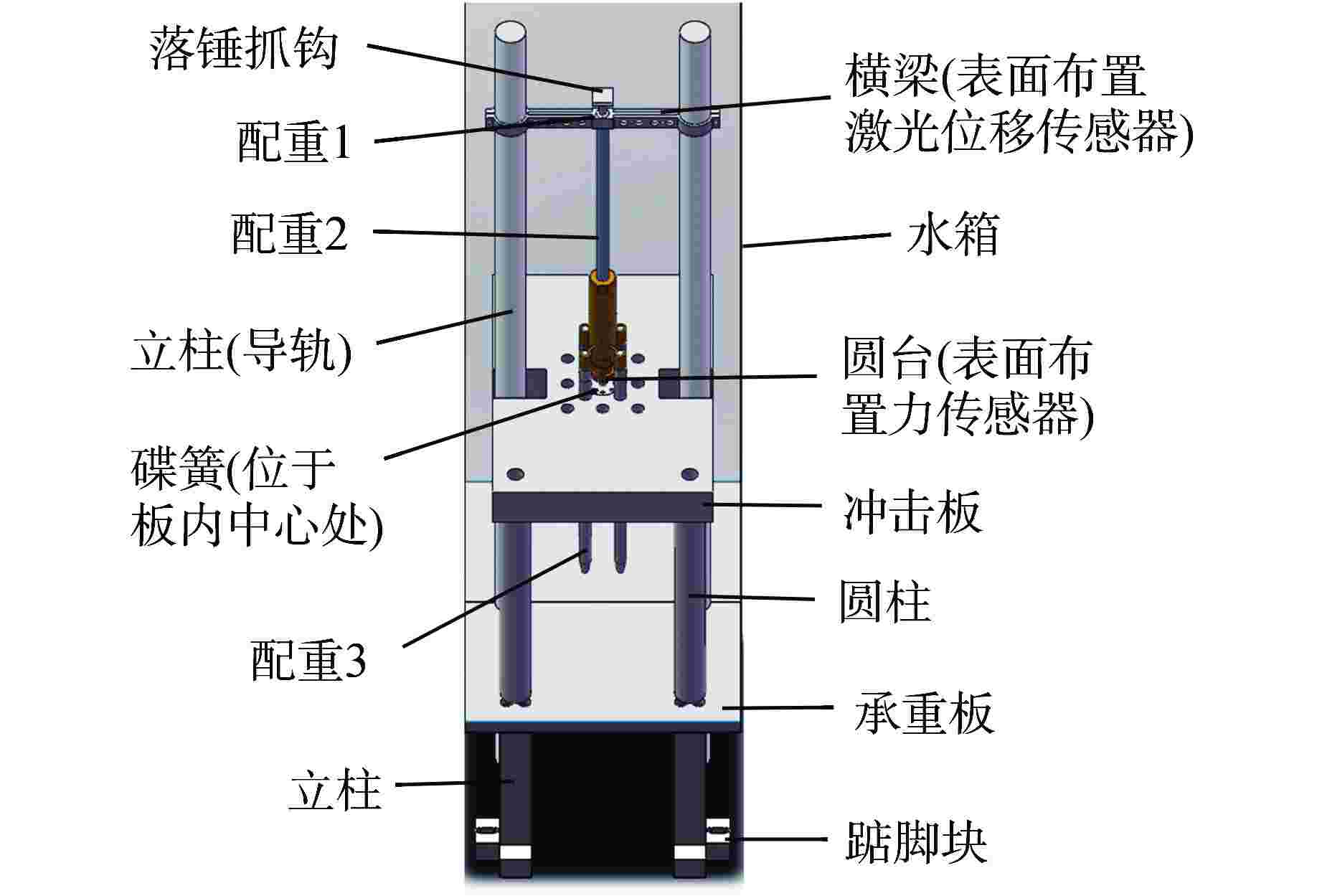

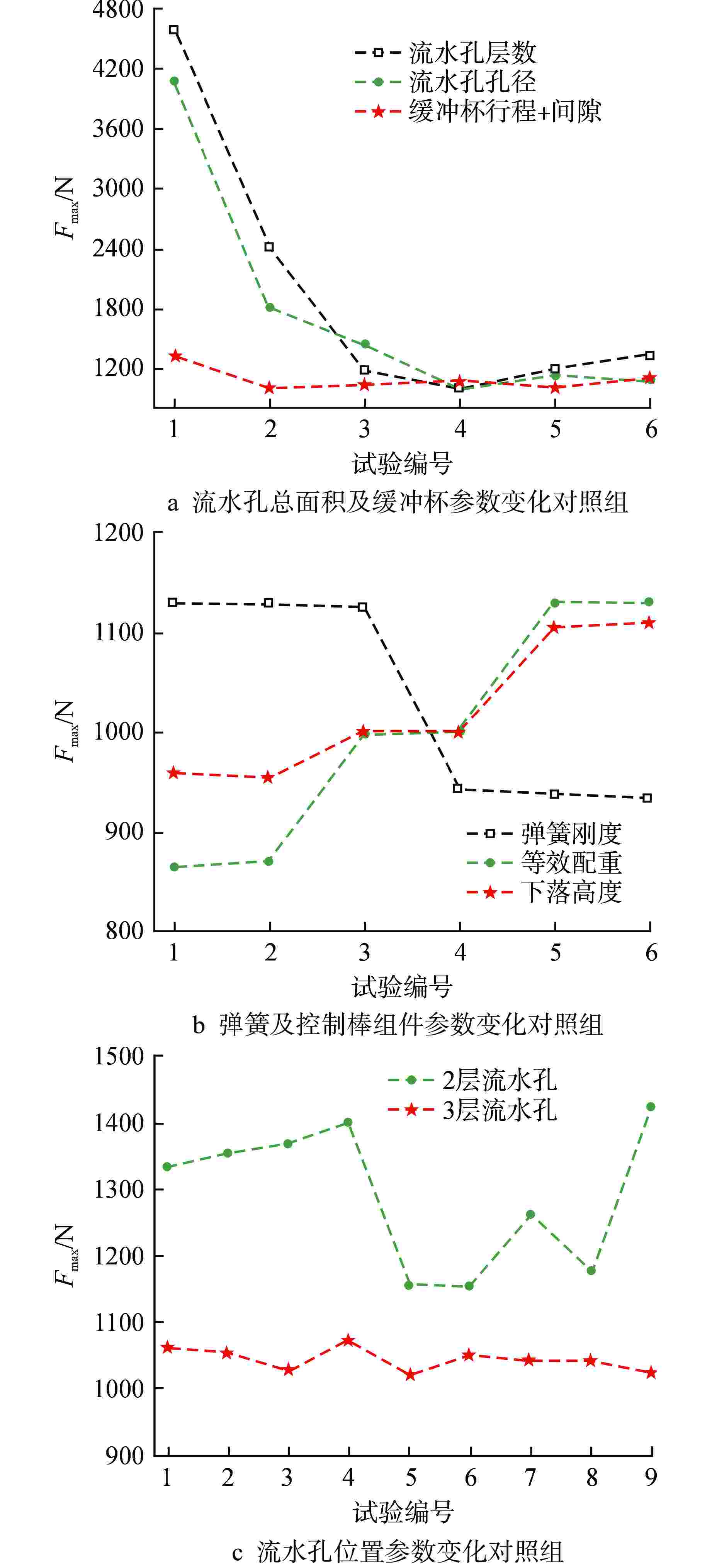

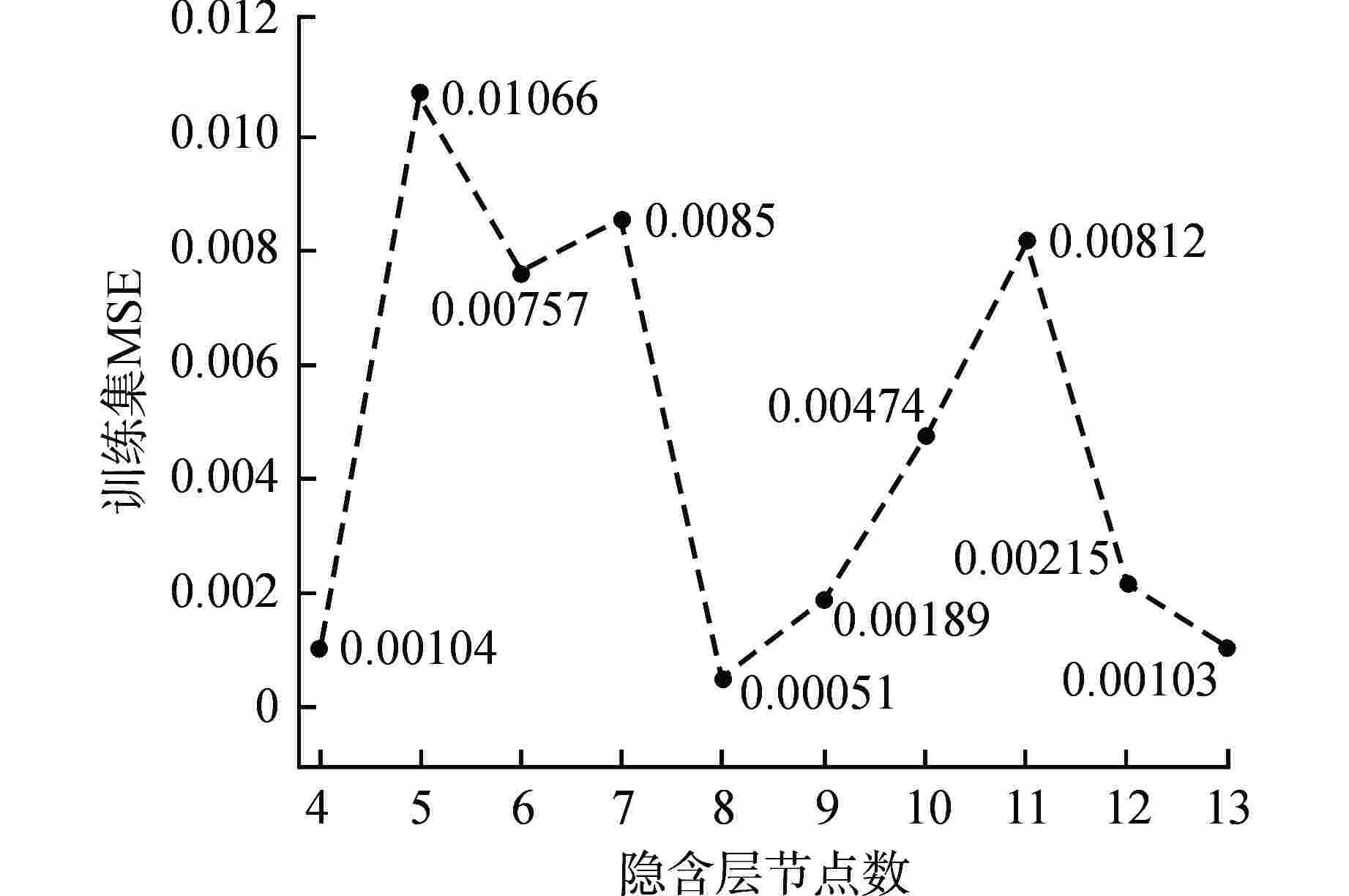

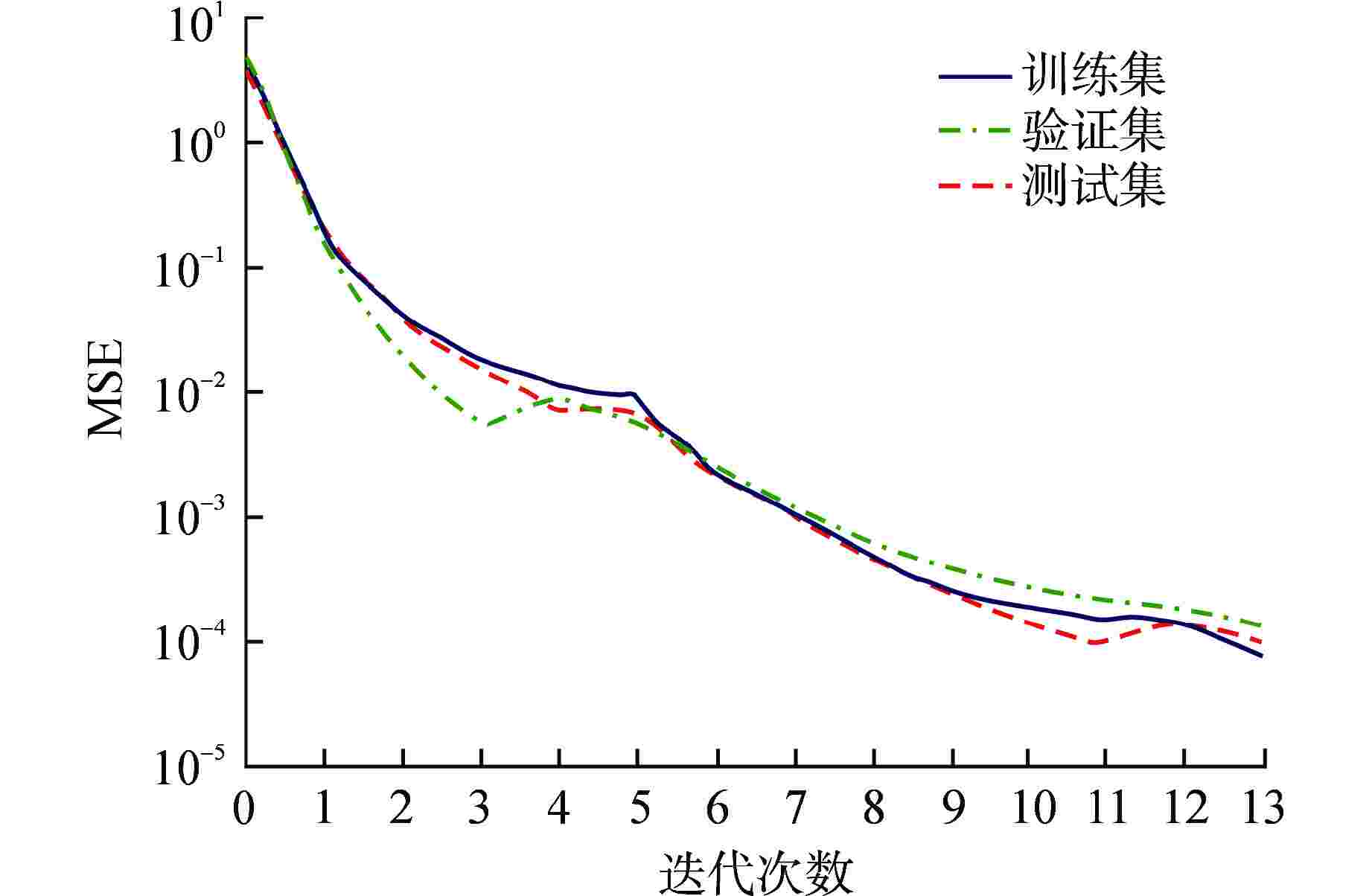

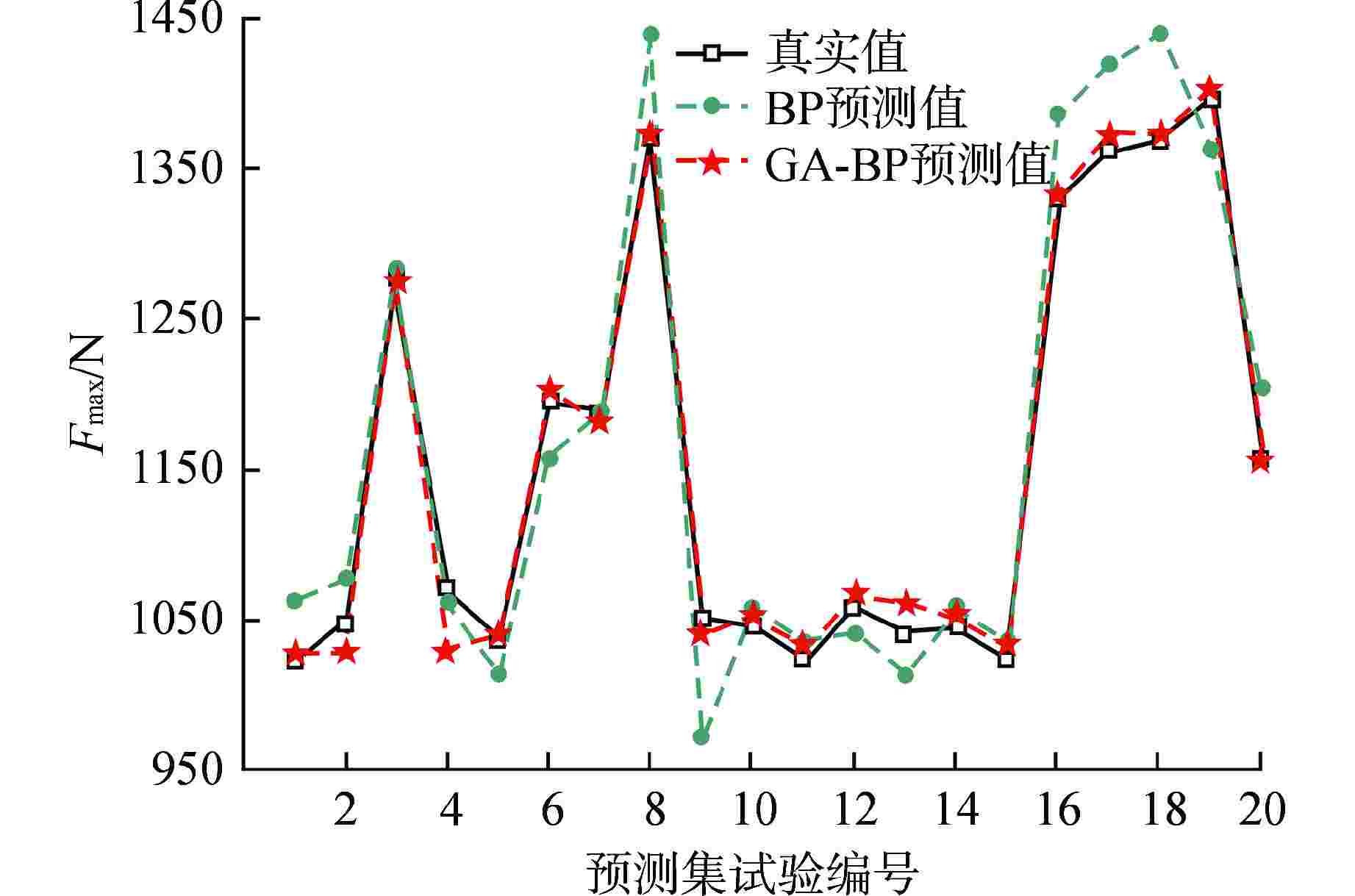

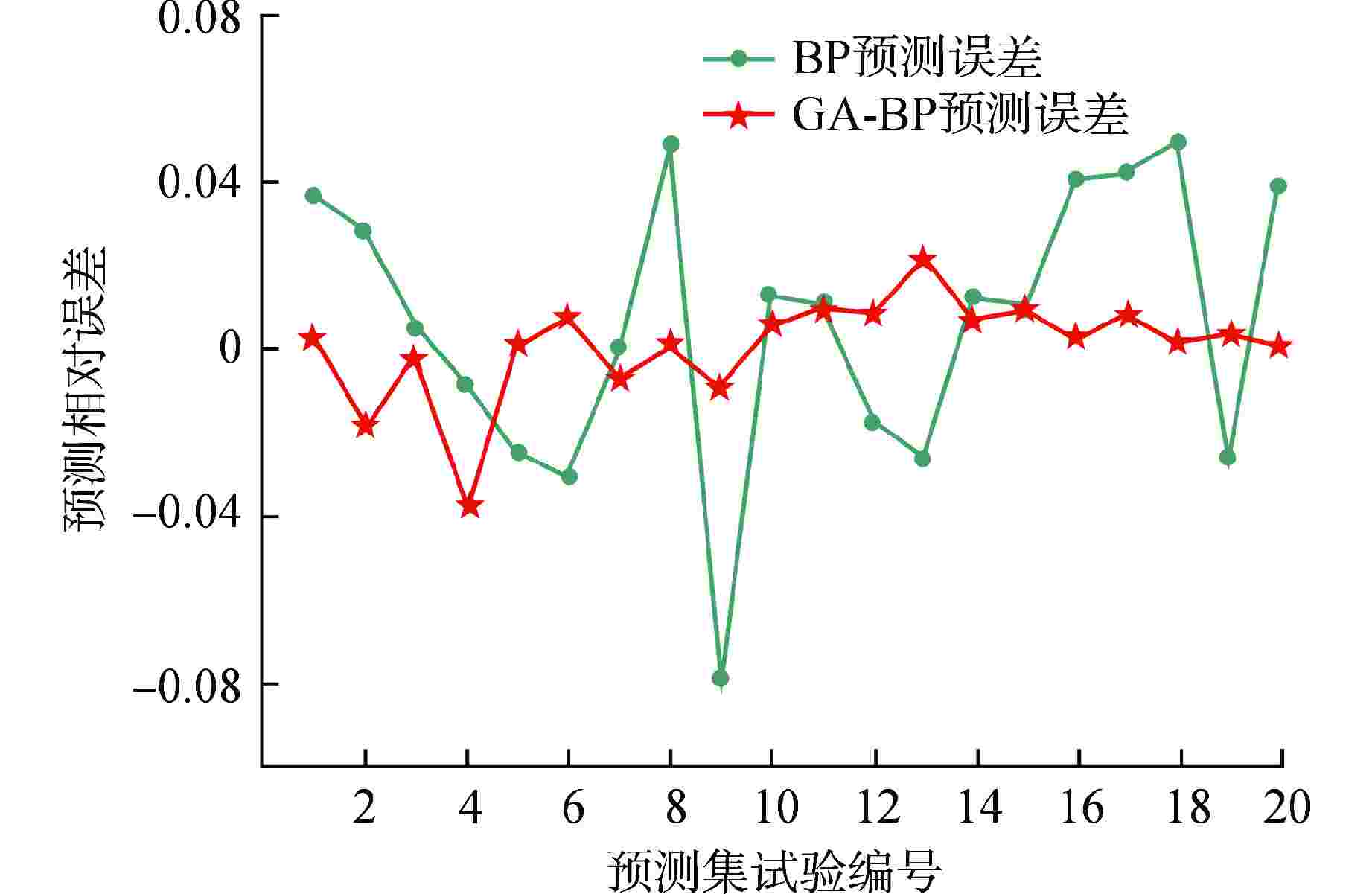

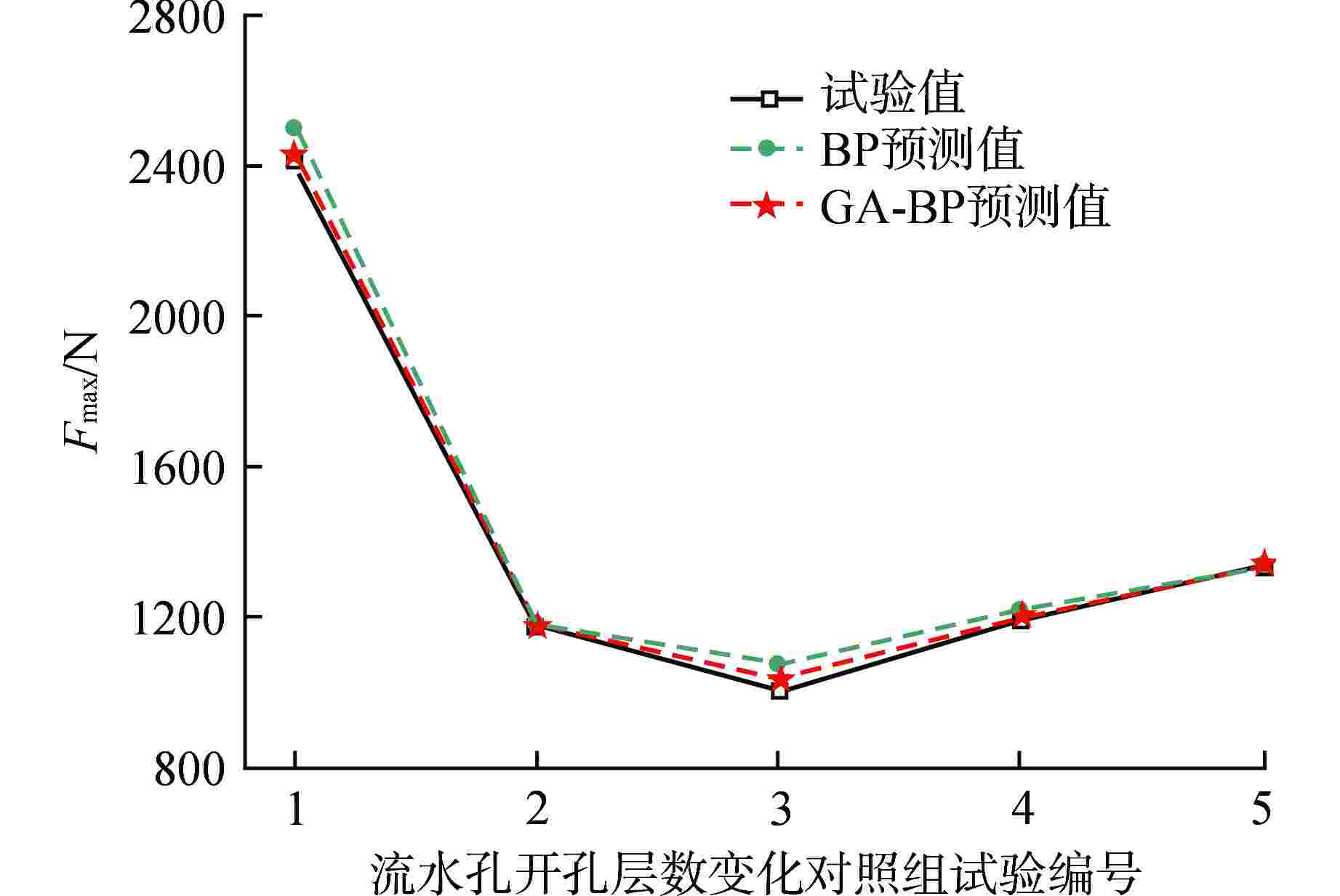

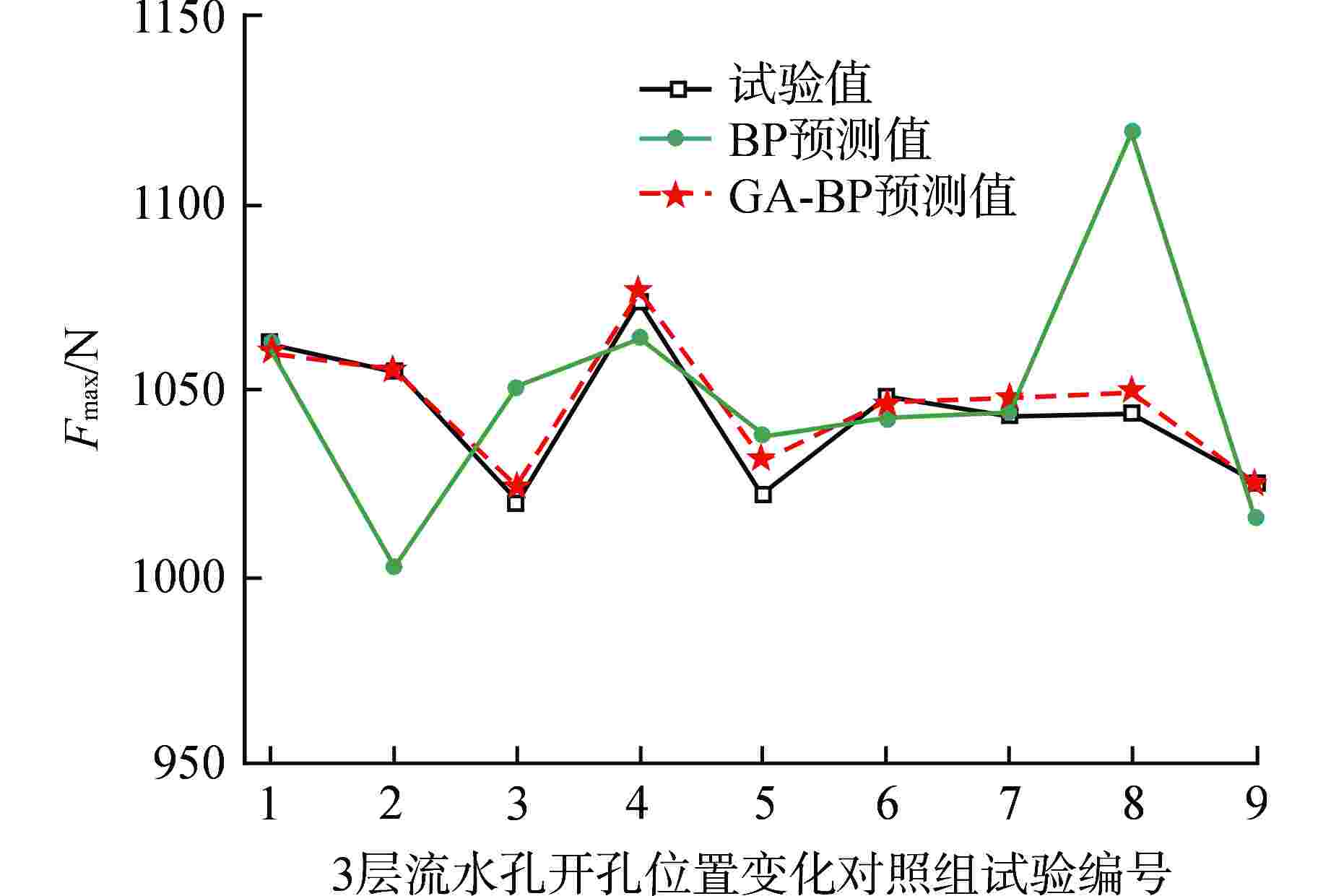

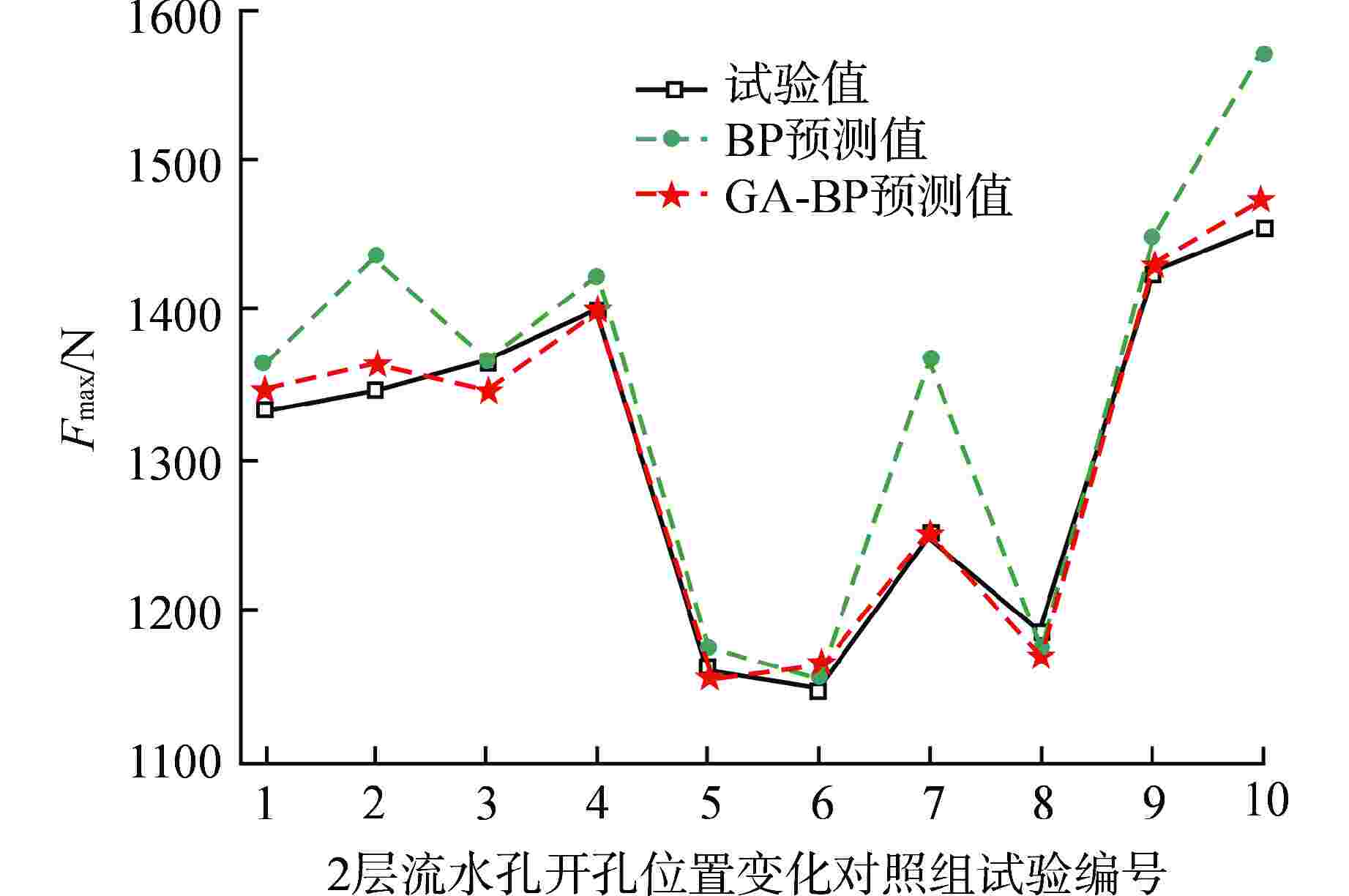

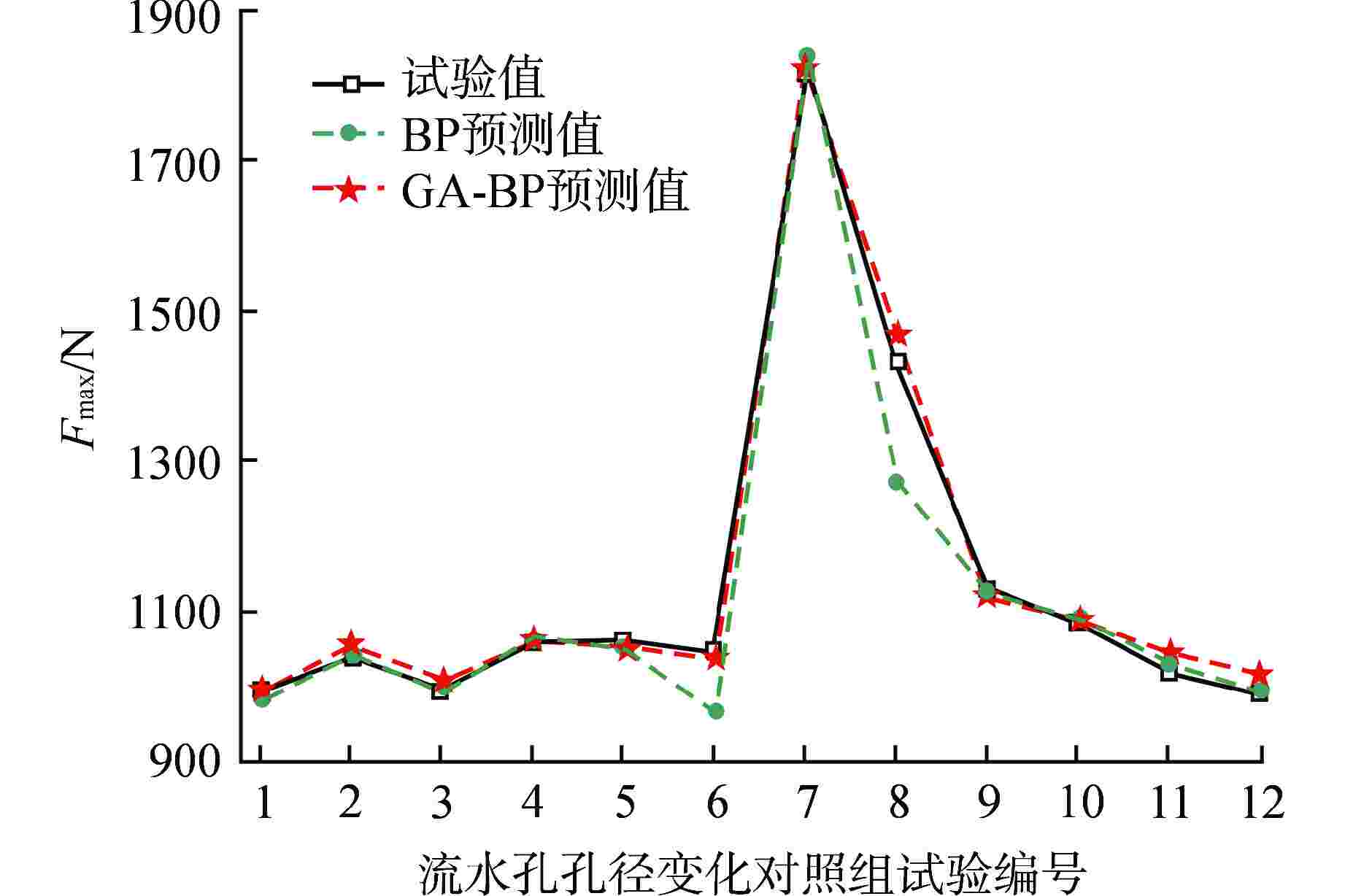

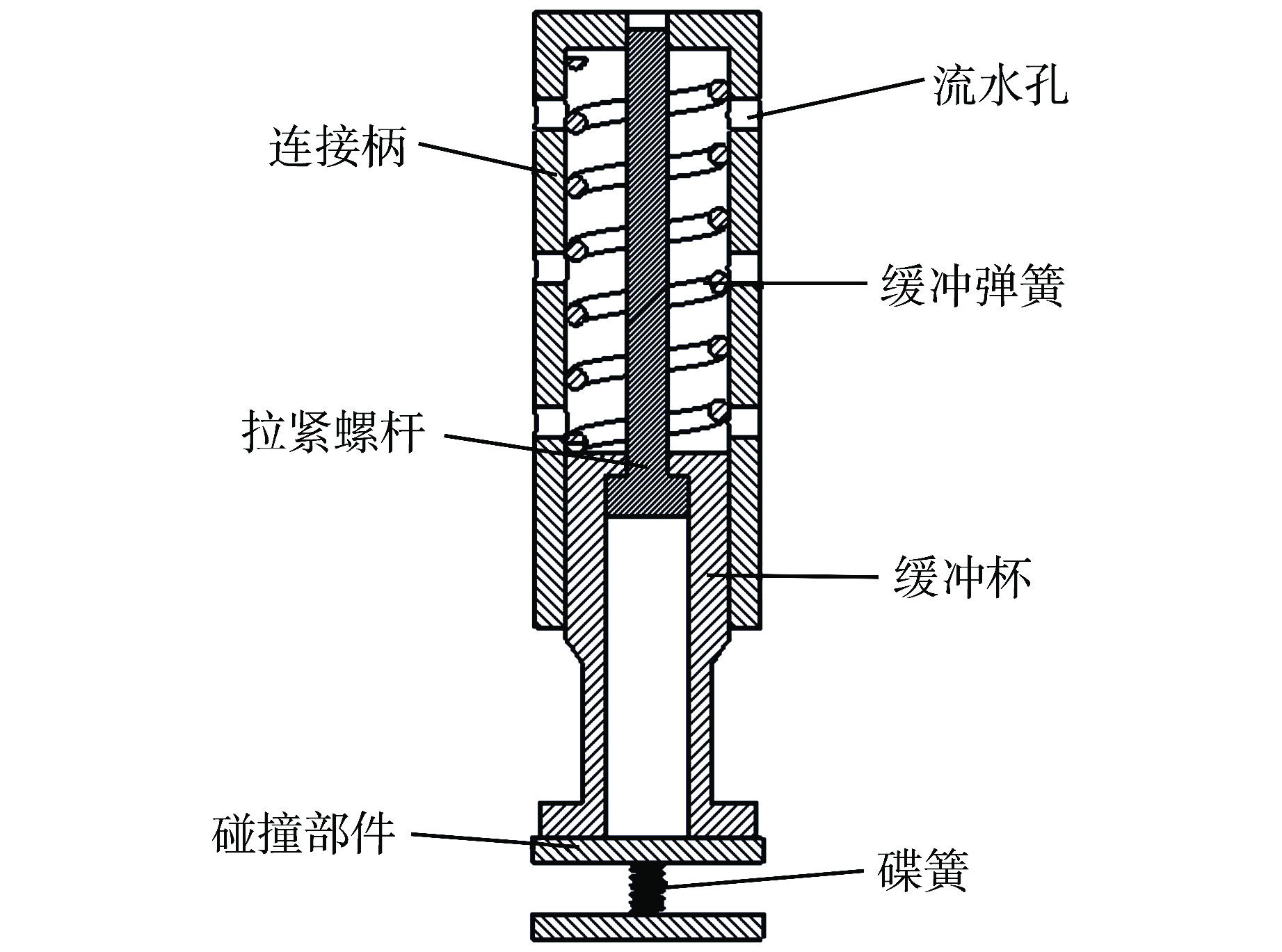

摘要: 为通过遗传算法(GA)改进的反向传播(BP)神经网络模型预测控制棒组件水力缓冲器的缓冲性能,并实现结构参数优化,本研究对一种特定的控制棒组件水力缓冲器静水中的落棒进行模拟试验,变换试验可调参数,设置不同的试验工况,获取了大量的试验数据,通过GA-BP神经网络对控制棒组件落棒过程的最大冲击力进行预测,并构建优化数学模型,使用非线性规划函数(fmincon)进行求解,获得更优的结构参数组合。结果表明:GA-BP神经网络模型相较于BP神经网络模型具有更高的预测精度,通过fmincon函数可以实现对控制棒组件最大冲击力优化数学模型的快速求解。因此,本文的优化方法可为水力缓冲器的结构优化设计提供一定的参考。Abstract: In order to predict the buffer performance of hydraulic buffers of control rod assemblies by back-propagation (BP) neural network model improved by genetic algorithm (GA) and to realize the optimization of structural parameters. In this study, we simulated the falling rod in hydrostatic water for a specific control rod assembly hydrodynamic buffer. By changing the adjustable parameters of the test and setting up different test conditions, a large number of test data were obtained. The maximum impact force of control rod assembly in the process of rod falling was predicted by GA-BP neural network, and an optimized mathematical model was constructed. The nonlinear programming function (fmincon) is used to solve the problem, and a more optimal combination of structural parameters is obtained. The results show that the GA-BP neural network model has higher prediction accuracy compared with the BP neural network mdoel, and the fmincon function can realize fast solution of the optimal mathematical model of the maximum impact force of the control rod assembly. Therefore, the optimization method in this paper can provide some reference for the structural optimization design of hydraulic buffers.

-

表 1 控制棒组件可调参数

Table 1. Adjustable Parameters for Control Rod Assembly

参数 可调整的范围 第1层流水孔孔径/mm 0~4 第2层流水孔孔径/mm 0~4 第3层流水孔孔径/mm 0~4 第4层流水孔孔径/mm 0~4 第5层流水孔孔径/mm 0~4 连接柄与缓冲杯间隙/mm 0.15~0.30 缓冲杯行程/mm 30~70 弹簧刚度/(N ∙ mm−1) 1.5~3.8 等效配重/kg 6.4~8.8 下落高度/mm 340~400 表 2 BP与GA-BP神经网络模型的预测结果误差

Table 2. Errors in Prediction Results of BP and GA-BP Models

神经网络模型 MAE/N MAPE/% RMSE/N BP 39.51 3.35 55.10 GA-BP 9.29 0.82 11.58 -

[1] 颜达鹏,杜华,刘佳,等. 控制棒驱动线缓冲结构碰撞缓冲过程分析方法[J]. 核动力工程,2017, 38(S2): 64-69. doi: 10.13832/j.jnpe.2017.S2.0064 [2] 段春辉,王留兵,杜华,等. 控制棒驱动线水力缓冲特性仿真研究[J]. 机床与液压,2015, 43(22): 73-76,90. doi: 10.3969/j.issn.1001-3881.2015.22.025 [3] 张吉斌,李垣明,黄春兰,等. 控制棒组件缓冲结构缓冲设计方法研究[J]. 中国核电,2021, 14(1): 35-39. [4] LEE Y K, LEE J H, KIM H W, et al. Drop performance test of conceptually designed control rod assembly for prototype generation IV sodium-cooled fast reactor[J]. Nuclear Engineering and Technology, 2017, 49(4): 855-864. doi: 10.1016/j.net.2016.12.004 [5] SON J G, LEE J H, KIM H W, et al. Influence of design modification of control rod assembly for prototype generation IV sodium-cooled Fast Reactor on drop performance[J]. Nuclear Engineering and Technology, 2019, 51(3): 922-929. doi: 10.1016/j.net.2018.11.014 [6] 李恬,魏炳乾,黎闫,等. 控制棒下行运动特性影响因素分析[J]. 核动力工程,2022, 43(1): 127-132. doi: 10.13832/j.jnpe.2022.01.0127 [7] 肖忠,马超,郭晓明. 燃料组件结构参数对于控制棒组件落棒缓冲效果的敏感性分析[J]. 核动力工程,2016, 37(5): 111-114. doi: 10.13832/j.jnpe.2016.05.0111 [8] SIMPSON T W, POPLINSKI J D, KOCH P N, et al. Metamodels for computer-based engineering design: survey and recommendations[J]. Engineering With Computers, 2001, 17(2): 129-150. doi: 10.1007/PL00007198 [9] SIMPSON T W, BOOKER A J, GHOSH D, et al. Approximation methods in multidisciplinary analysis and optimization: a panel discussion[J]. Structural and Multidisciplinary Optimization, 2004, 27(5): 302-313. [10] 余本国. BP神经网络局限性及其改进的研究[J]. 山西农业大学学报:自然科学版,2009, 29(1): 89-93. [11] 吴天山,于鸿彬,李小青,等. 基于遗传算法的BP神经网络熔融沉积成型翘曲变形预测研究[J]. 热加工工艺,2019, 48(22): 48-52. doi: 10.14158/j.cnki.1001-3814.2019.22.012 [12] XING Y H, LI F F. Research on the influence of hidden layers on the prediction accuracy of GA-BP neural network[J]. Journal of Physics:Conference Series, 2020, 1486(2): 022010. doi: 10.1088/1742-6596/1486/2/022010 [13] 魏雨晨,李旭东,刘治国,等. 基于GA-BP神经网络的航空铝合金预腐蚀疲劳寿命预测[J]. 环境技术,2022, 40(5): 178-182,205. doi: 10.3969/j.issn.1004-7204.2022.05.037 [14] 熊伟. 基于改进BP神经网络的车床主轴优化设计的研究[D]. 镇江: 江苏大学, 2016. [15] 郭春艳. 基于改进BP神经网络的板弹簧优化设计[D]. 成都: 西南交通大学, 2021. [16] 曹保金,秦小屿. MATLAB优化工具箱在机械优化设计中的应用[J]. 现代机械,2009(6): 11-13. doi: 10.3969/j.issn.1002-6886.2009.06.006 -

下载:

下载: