Neutronic and Thermal-Hydraulic Performance Analysis of Helical Cruciform Fuel Rods

-

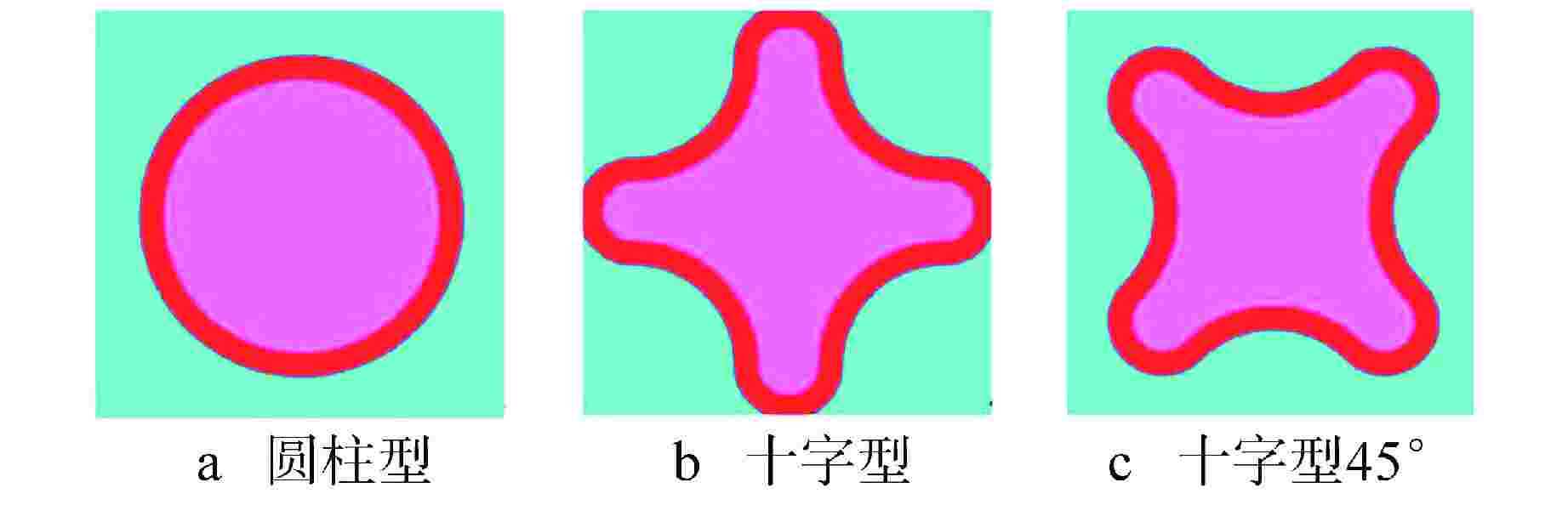

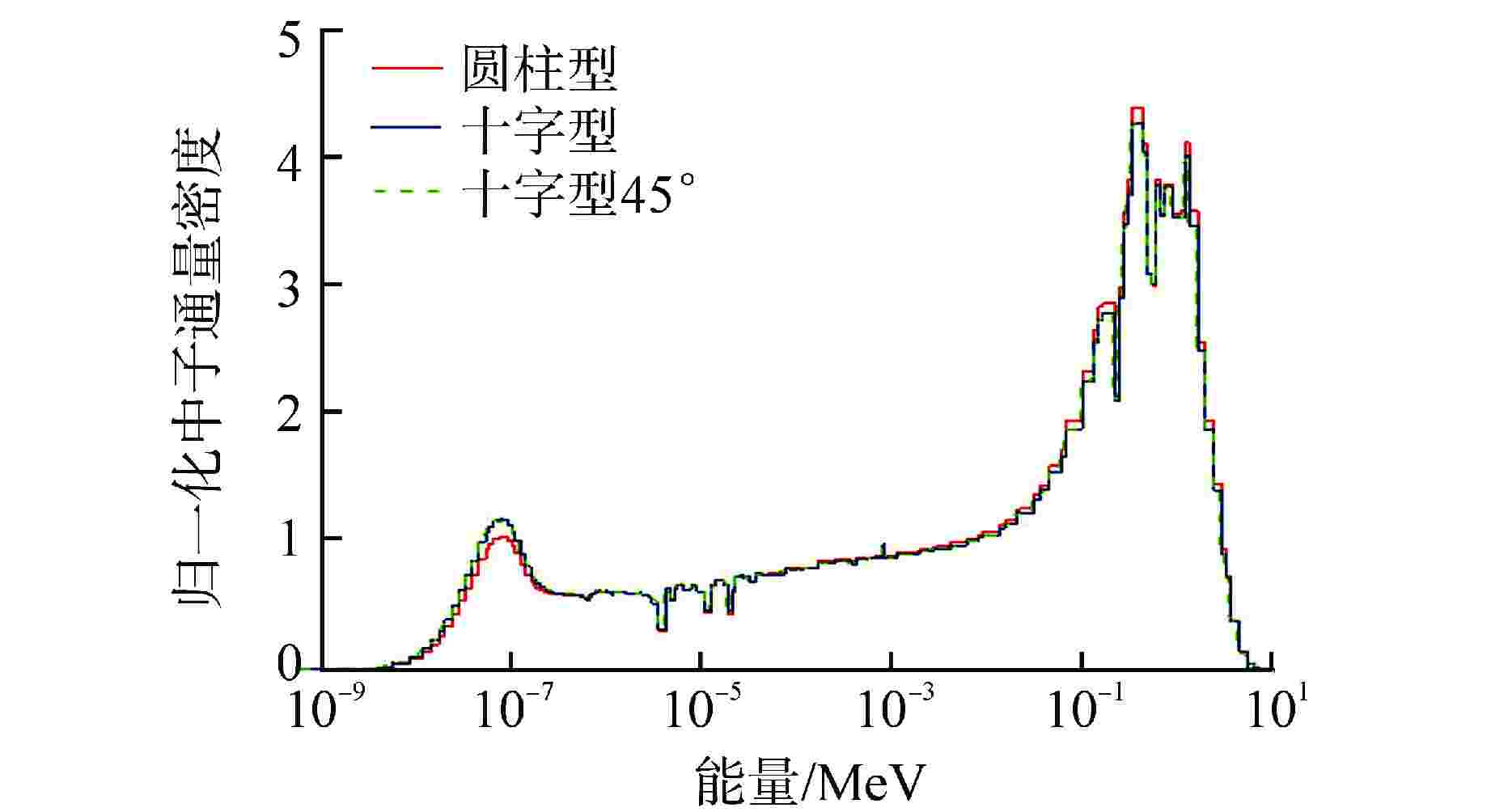

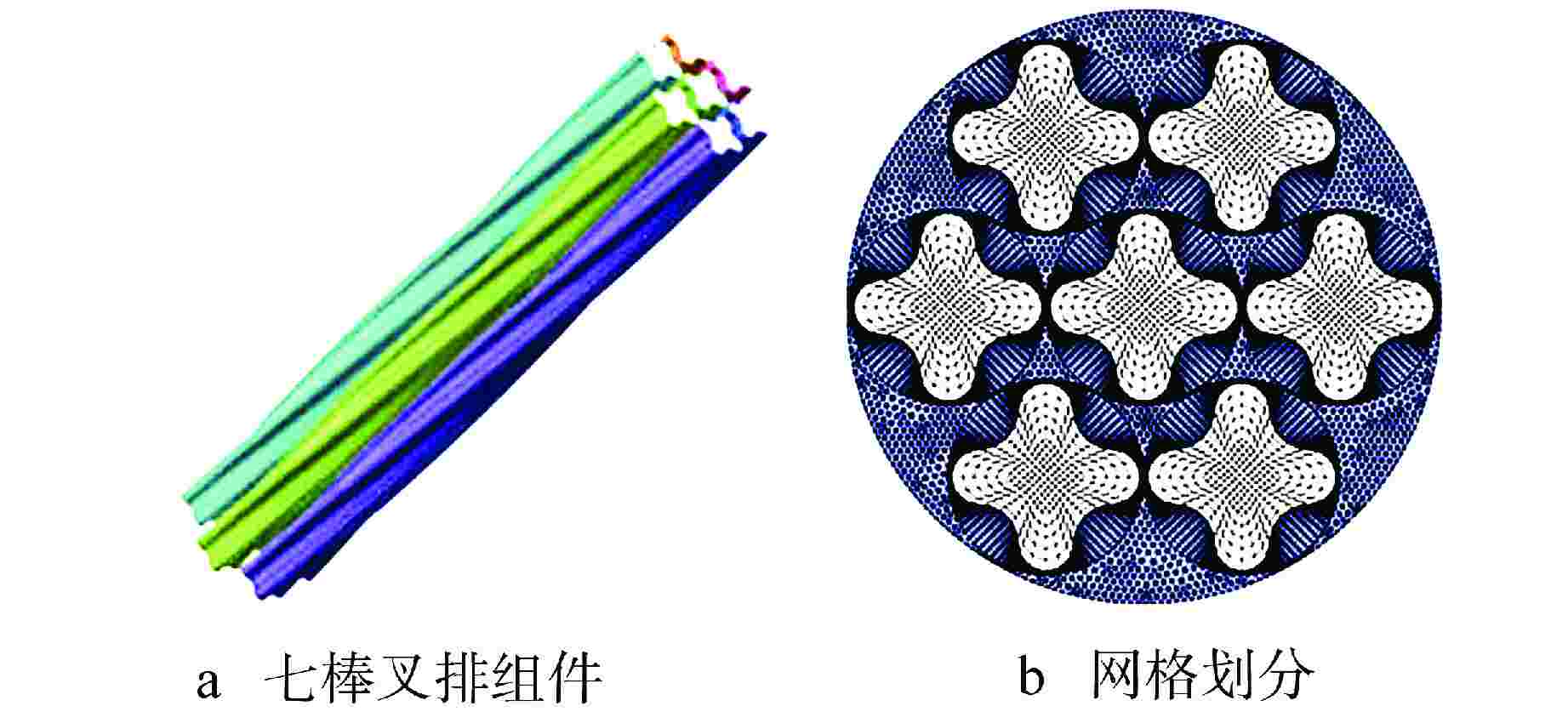

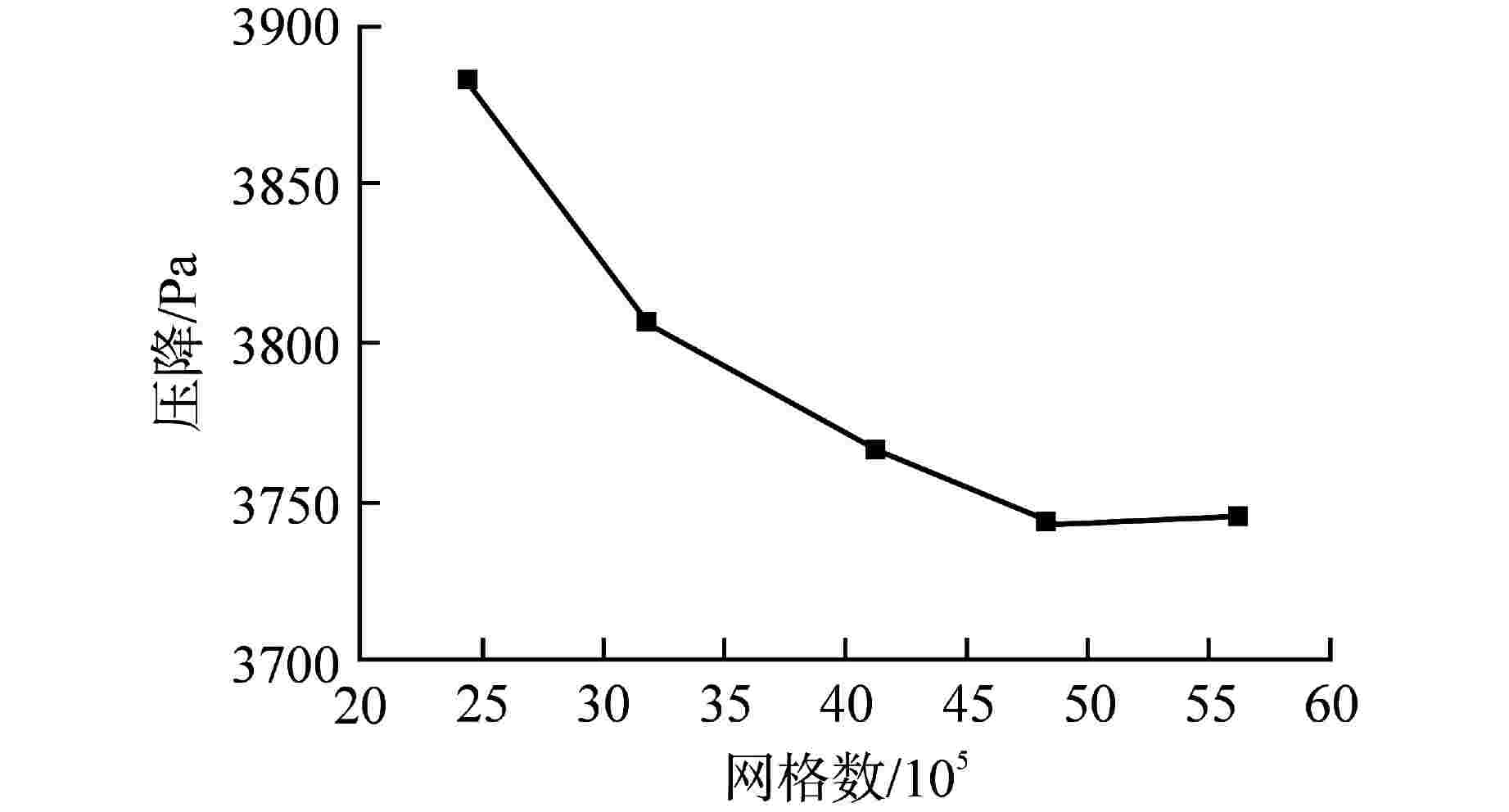

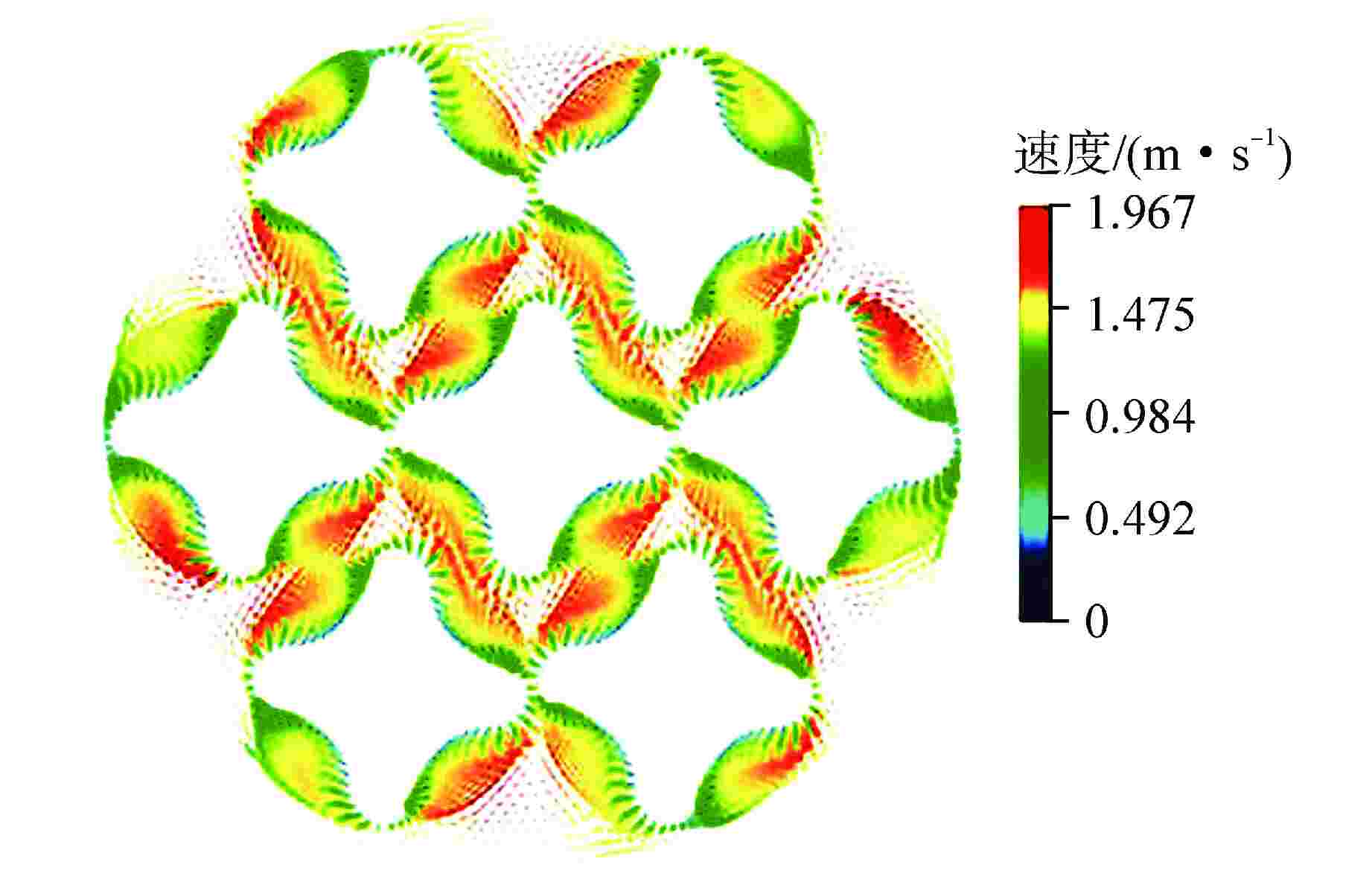

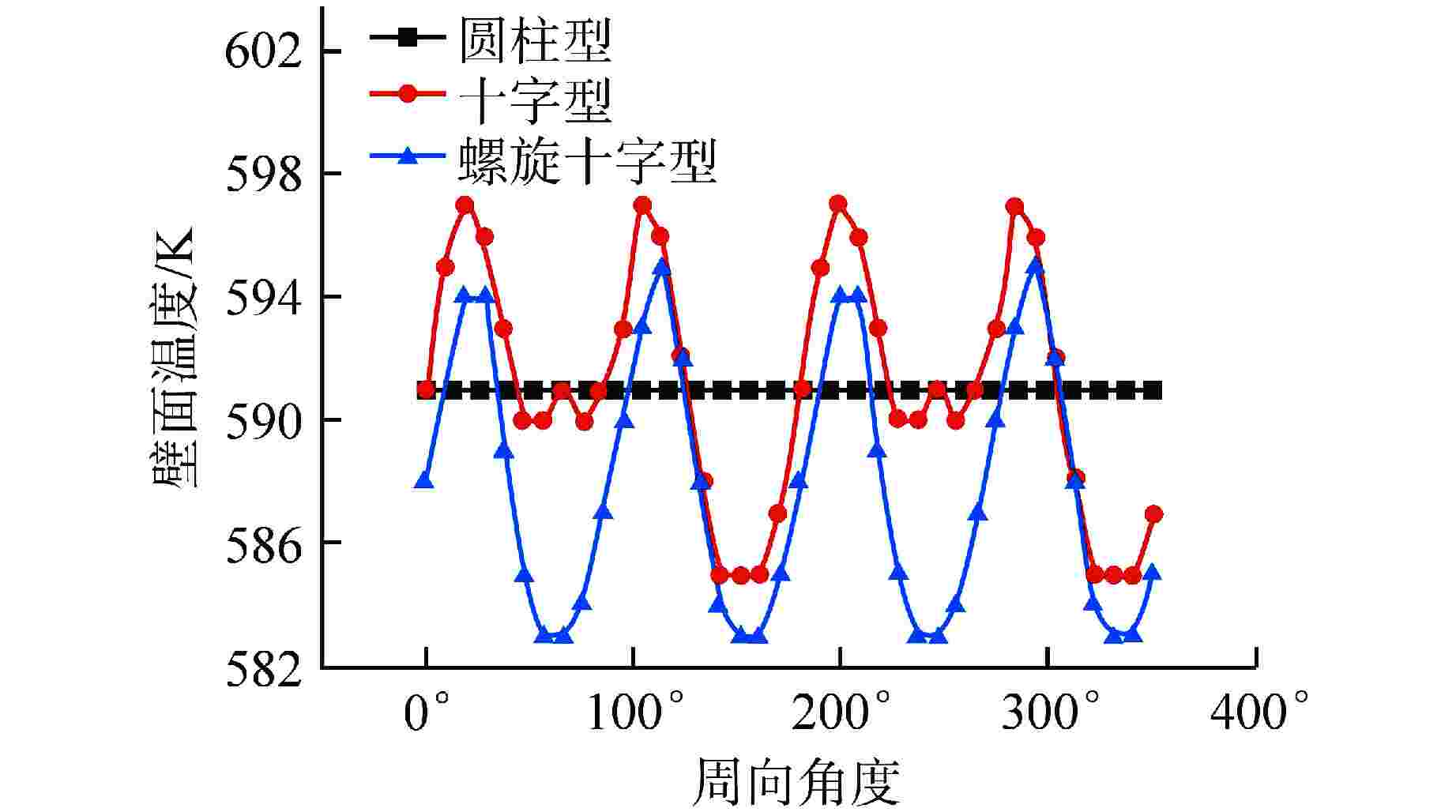

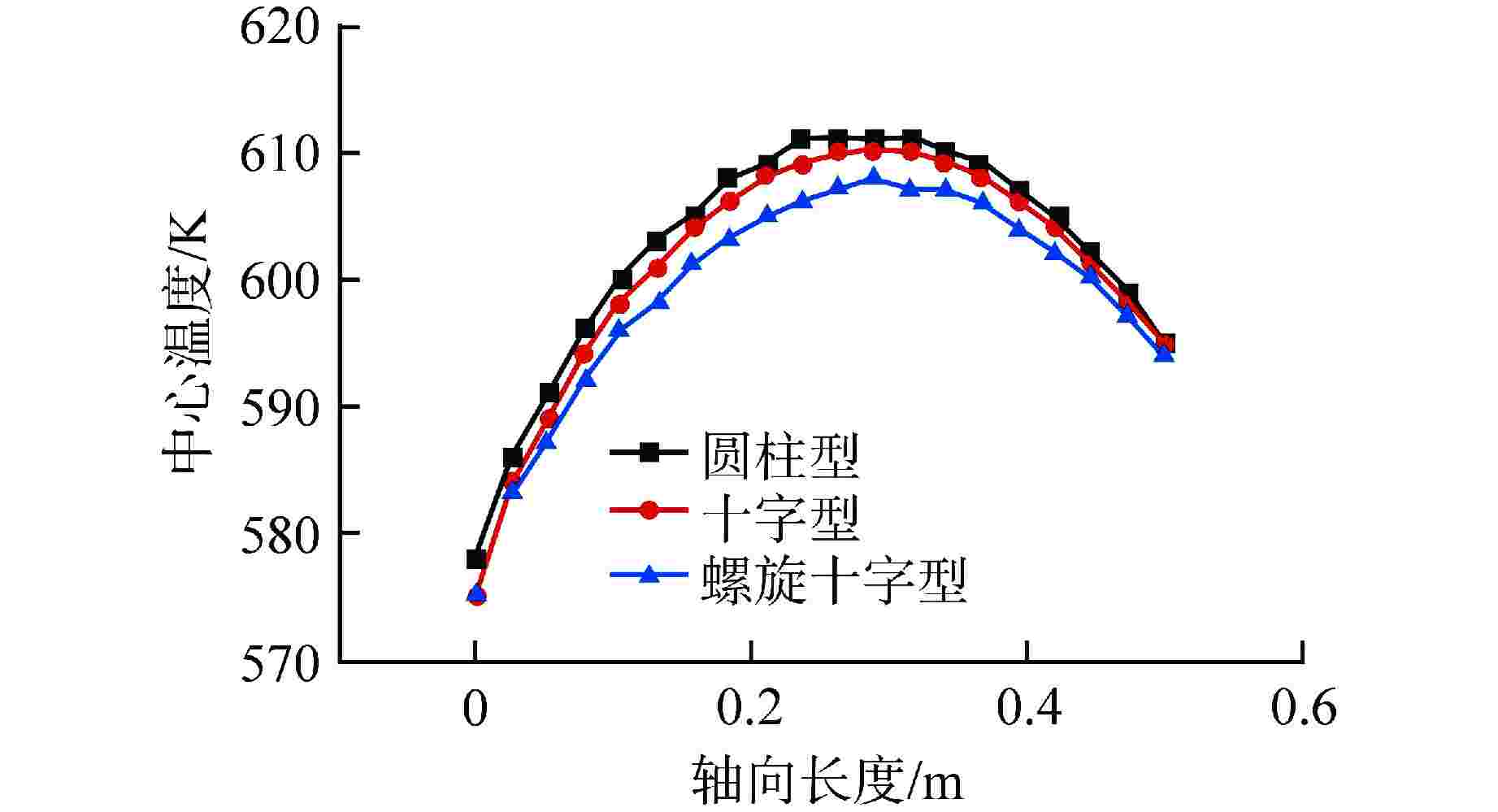

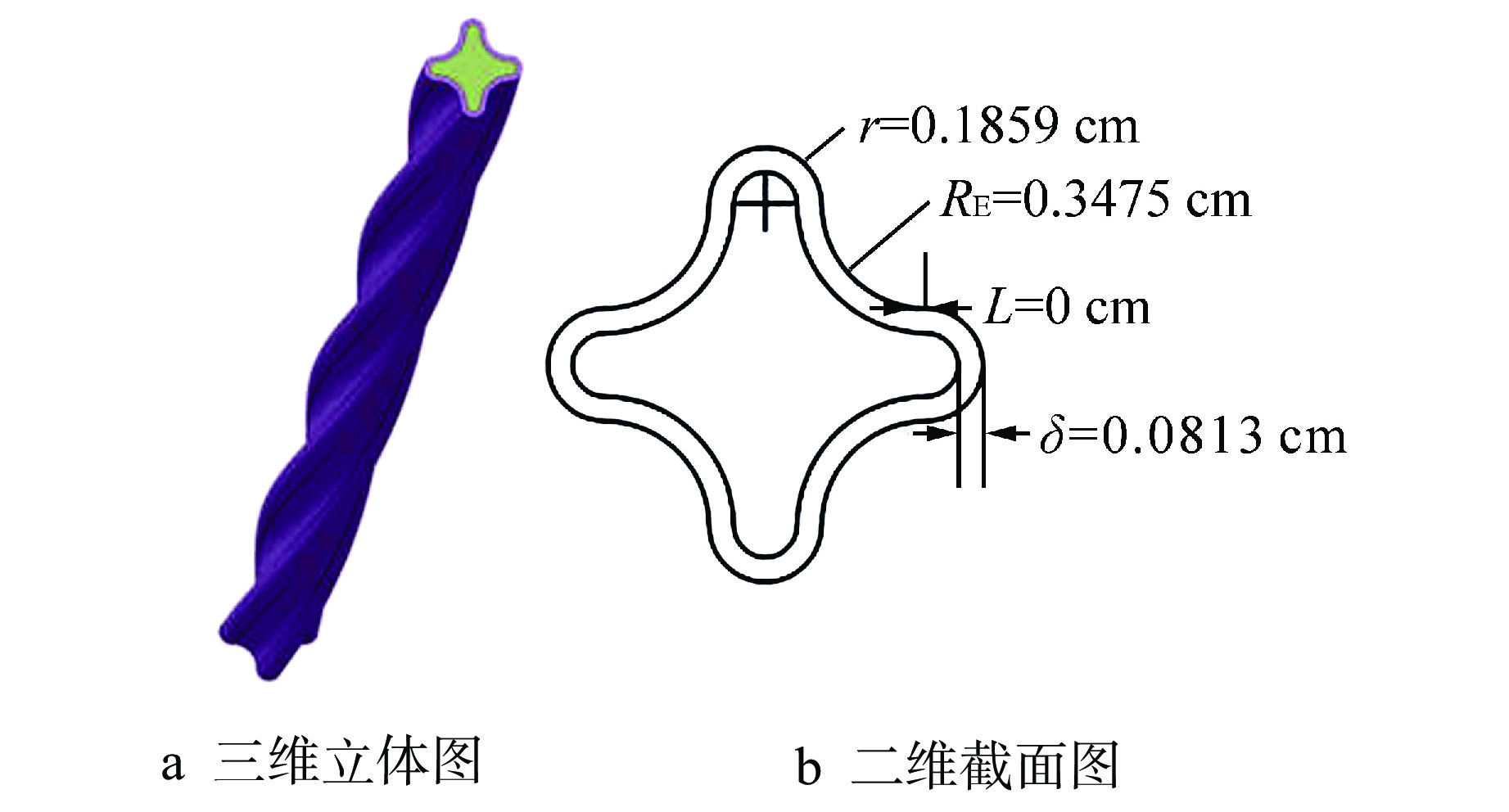

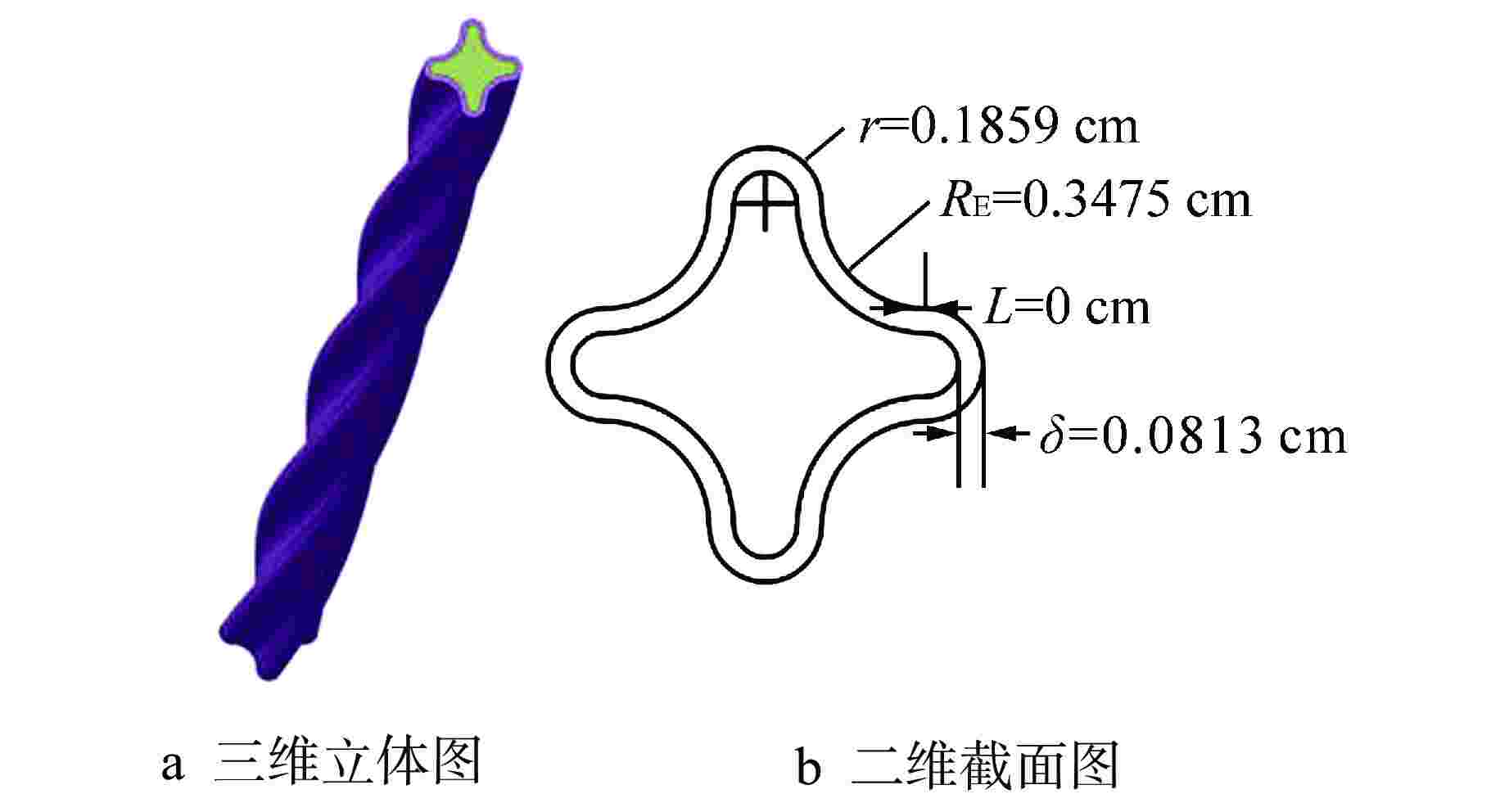

摘要: 为分析螺旋十字型燃料棒的中子物理及热工水力性能,使用基于计算机辅助设计(CAD)几何的反应堆蒙特卡罗程序RMC和商用计算流体力学(CFD)软件Fluent对螺旋十字型燃料棒进行数值模拟,并与传统圆柱型和无扭转十字型燃料棒进行对比。结果表明,螺旋十字型结构会略微降低反应性,增大径向功率峰因子;相较于圆柱型燃料棒,螺旋十字型燃料棒由于存在横向流动,能增强冷却剂交混,提升换热能力,在七棒束组件计算中,螺旋十字型燃料棒的平均温度和峰值温度都降低了约4 K。

-

关键词:

- 螺旋十字型燃料棒 /

- 蒙特卡罗方法 /

- 计算流体力学(CFD) /

- 流动换热特性

Abstract: To analyze the neutronic and thermal-hydraulic performance of helical cruciform fuel (HCF) rods, numerical simulations using the CAD (computer-aided design)-based Reactor Monte Carlo code RMC and the commercial computational fluid dynamics (CFD) software Fluent were conducted, and the results were compared with those of traditional cylindrical and untwisted cruciform fuel rods. The results show that the helical cruciform structure slightly reduces the reactivity and increases the radial power peaking factor. Compared with cylindrical fuel rods, the HCF rods can enhance coolant mixing and heat transfer due to their transverse flow characteristics. In the 7-rods assembly calculation, the mean and peak temperatures of HCF rods are reduced by about 4 K. -

表 1 CSG、CAD建模的计算结果对比

Table 1. Comparison of Results between CSG and CAD Model

建模方式 有效增殖系数(keff) CSG 1.308667±0.000148 CAD 1.308611±0.000144 表 2 二维临界计算结果

Table 2. Two-dimensional Critical Calculation Results

截面类型 文献[9] 计算 keff dk/k keff dk/k 圆型 1.3513 — 1.3874±0.0001 — 十字型 1.3456 −0.0043 1.3843±0.0001 −0.0022 十字型45° 1.3486 −0.0020 1.3856±0.0001 −0.0013 dk/k—其他截面相对于圆型截面keff的相对误差 表 3 三维临界计算结果

Table 3. Three-dimensional Critical Calculation Results

单栅元模型 keff 圆柱型 1.313672±0.000144 十字型 1.308667±0.000148 螺旋十字型 螺距50 cm 1.308946±0.000153 螺距100 cm 1.308981±0.000149 表 4 功率峰因子对比

Table 4. Power Peaking Factor Comparison

截面类型 轴向功率峰因子 整体功率峰因子 圆柱型 1.50 1.81 十字型 1.49 2.00 螺旋十字型 1.49 2.08 表 5 流动参数对比

Table 5. Comparison of Flow Parameters

物理量 圆柱型 十字型 螺旋十字型 $ {\bar V_{\text{R}}}/({\text{m}} \cdot {{\text{s}}^{ - 1}}) $ 0.00148 0.00151 0.02492 $ {{\Delta }}P{\text{/Pa}} $ 974.38 993.43 1087.02 -

[1] 邢继,高力,霍小东,等. “碳达峰、碳中和”背景下核能利用浅析[J]. 核科学与工程,2022, 42(1): 10-17. doi: 10.3969/j.issn.0258-0918.2022.01.002 [2] DIAKOV A C, DMITRIEV A M, KANG J, et al. Feasibility of converting Russian icebreaker reactors from HEU to LEU fuel[J]. Science & Global Security, 2006, 14(1): 33-48. [3] AGEENKOV V I, VOLKOV V S, SOLONIN M I, et al. Parameters and technology for fabricating PIK reactor fuel elements[J]. Atomic Energy, 2002, 92(6): 468-474. doi: 10.1023/A:1020262131193 [4] BOL’SHAKOV V V, BASHKIRTSEV S M, KOBZAR’ L L, et al. Experimental study of burnout in channels with twisted fuel rods[J]. Thermal Engineering, 2007, 54(5): 386-389. doi: 10.1134/S0040601507050096 [5] CONBOY T M. Assessment of helical-cruciform fuel rods for high power density LWRs[D]. Cambridge: Massachusetts Institute of Technology, 2010. [6] ZHANG Q, LIU L, XIAO Y, et al. Experimental study on the transverse mixing of 5 × 5 helical cruciform fuel assembly by wire mesh sensor[J]. Annals of Nuclear Energy, 2021, 164: 108582. doi: 10.1016/j.anucene.2021.108582 [7] SHIRVAN K, KAZIMI M S. Nuclear design of helical cruciform fuel rods[C]//PHYSOR 2012–Advances in Reactor Physics–Linking Research, Industry, and Education. Knoxville: American Nuclear Society, 2012. [8] SHIRVAN K, KAZIMI M S. Three dimensional considerations in thermal-hydraulics of helical cruciform fuel rods for LWR power uprates[J]. Nuclear Engineering and Design, 2014, 270: 259-272. doi: 10.1016/j.nucengdes.2014.01.015 [9] 蔡伟华,韦徵圣,李石磊,等. 5×5花瓣形燃料棒束组件内单相流动与换热特性数值模拟研究[J]. 原子能科学技术,2021, 55(11): 1939-1949. doi: 10.7538/yzk.2021.youxian.0593 [10] 刘畅. 螺旋型燃料棒束内流动与换热特性数值模拟[D]. 哈尔滨: 哈尔滨工业大学, 2020. [11] FANG Y L, QIN H, WANG C L, et al. Numerical investigation on thermohydraulic performance of high temperature hydrogen in twisted rod channels[J]. Annals of Nuclear Energy, 2021, 161: 108434. doi: 10.1016/j.anucene.2021.108434 [12] HARTMANN C, TOTEMEIER A, HOLCOMBE S, et al. Measurement station for interim inspections of Lightbridge metallic fuel rods at the Halden boiling water reactor[J]. EPJ Web of Conferences, 2018, 170: 04011. doi: 10.1051/epjconf/201817004011 [13] University of Wisconsin–Madison. DAGMC: direct accelerated geometry Monte Carlo[EB/OL]. (2021-07-08)[2022-05-05]. https://svalinn.github.io/DAGMC. [14] LOVECKÝ M, ZÁVORKA J, VIMPEL J. VVER-1000 fuel assembly model in CAD-based unstructured mesh for MCNP6[J]. Kerntechnik, 2019, 84(4): 262-266. doi: 10.3139/124.190041 [15] WU Y C, SONG J, ZHENG H Q, et al. CAD-based Monte Carlo program for integrated simulation of nuclear system SuperMC[J]. Annals of Nuclear Energy, 2015, 82: 161-168. doi: 10.1016/j.anucene.2014.08.058 [16] TALAMO A, GOHAR Y, LEPPÄNEN J. SERPENT validation and optimization with mesh adaptive search on stereolithography geometry models[J]. Annals of Nuclear Energy, 2018, 115: 619-632. doi: 10.1016/j.anucene.2018.01.012 [17] WANG K, LI Z G, SHE D, et al. RMC–a Monte Carlo code for reactor core analysis[J]. Annals of Nuclear Energy, 2015, 82: 121-129. doi: 10.1016/j.anucene.2014.08.048 [18] SHEN P F, LIANG J G, LIU S C, et al. Implementation and verification of the DAGMC module in Monte Carlo code RMC[C]//Proceedings of the 29th International Conference on Nuclear Engineering. New York: American Society of Mechanical Engineers, 2022. -

下载:

下载: