Analysis of Potential Impact of ATFs on Reactor Safety under Shaft-Stuck Accident

-

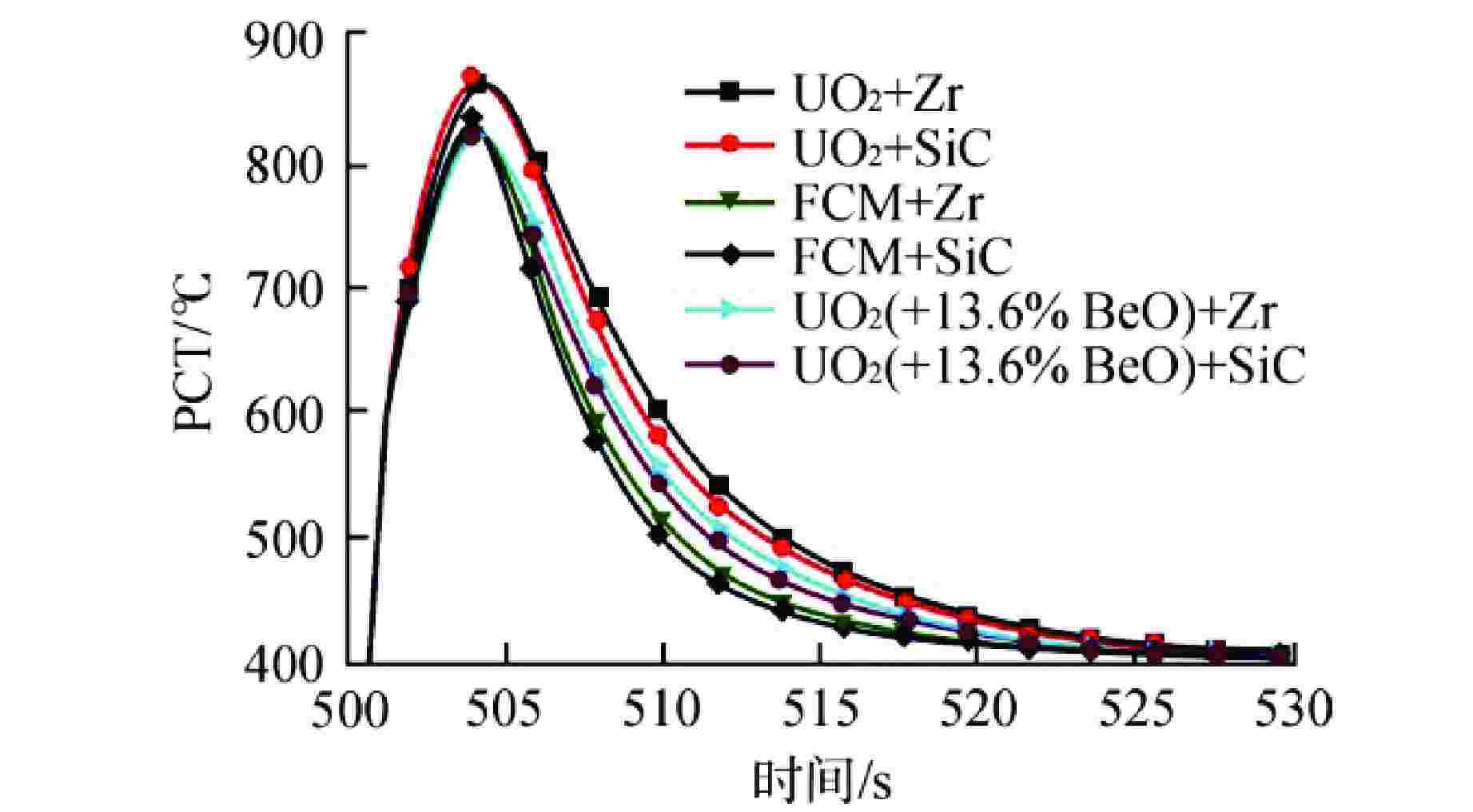

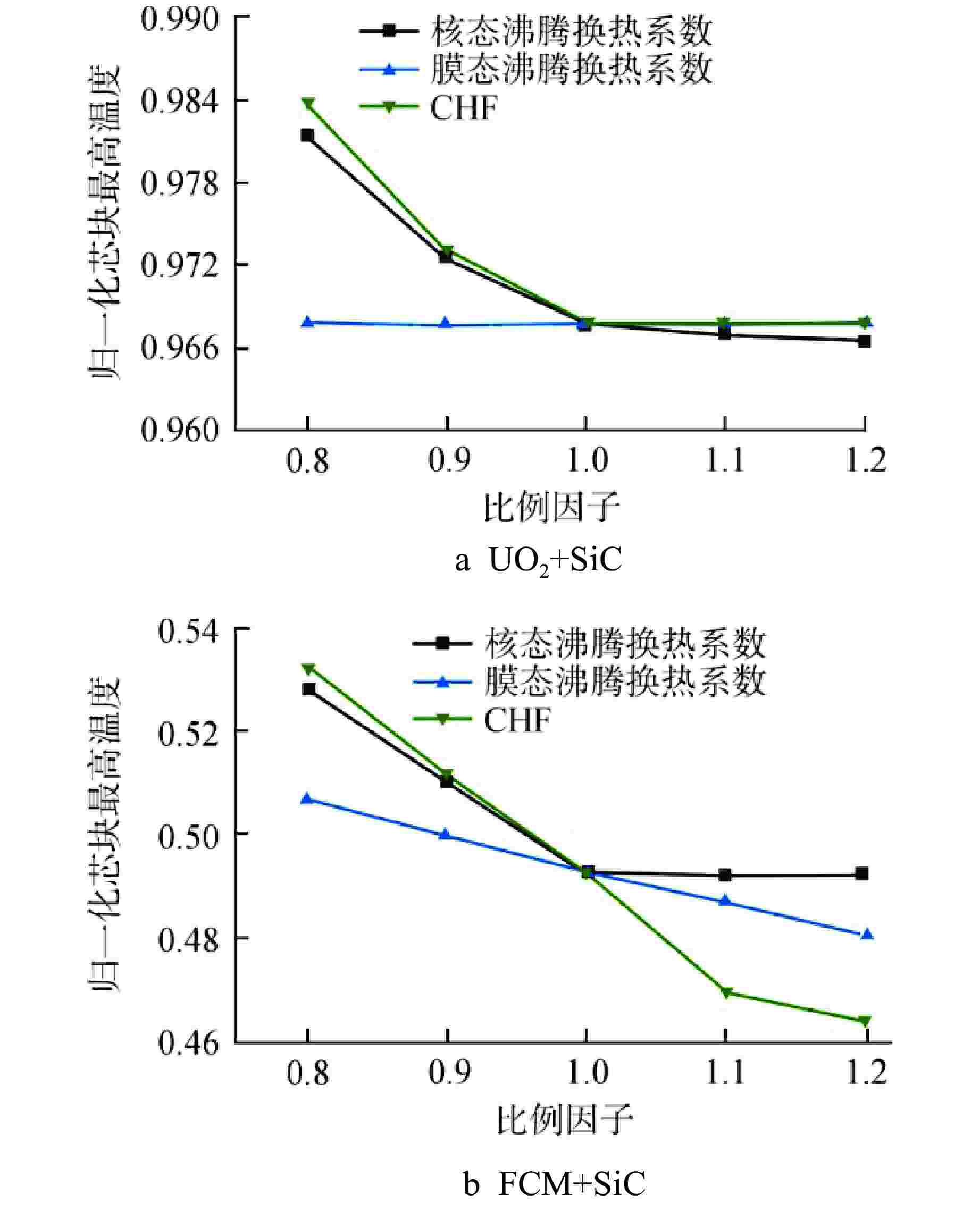

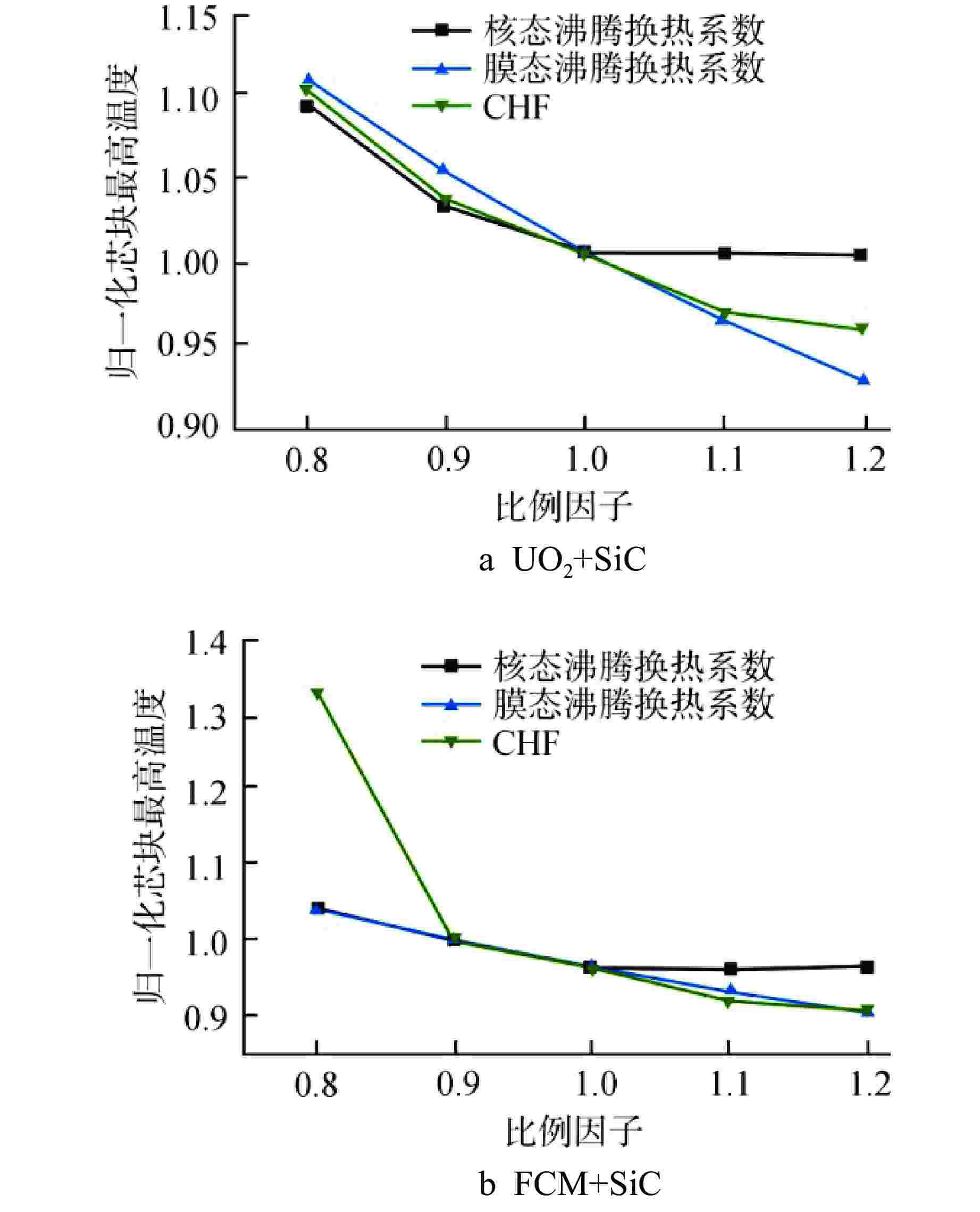

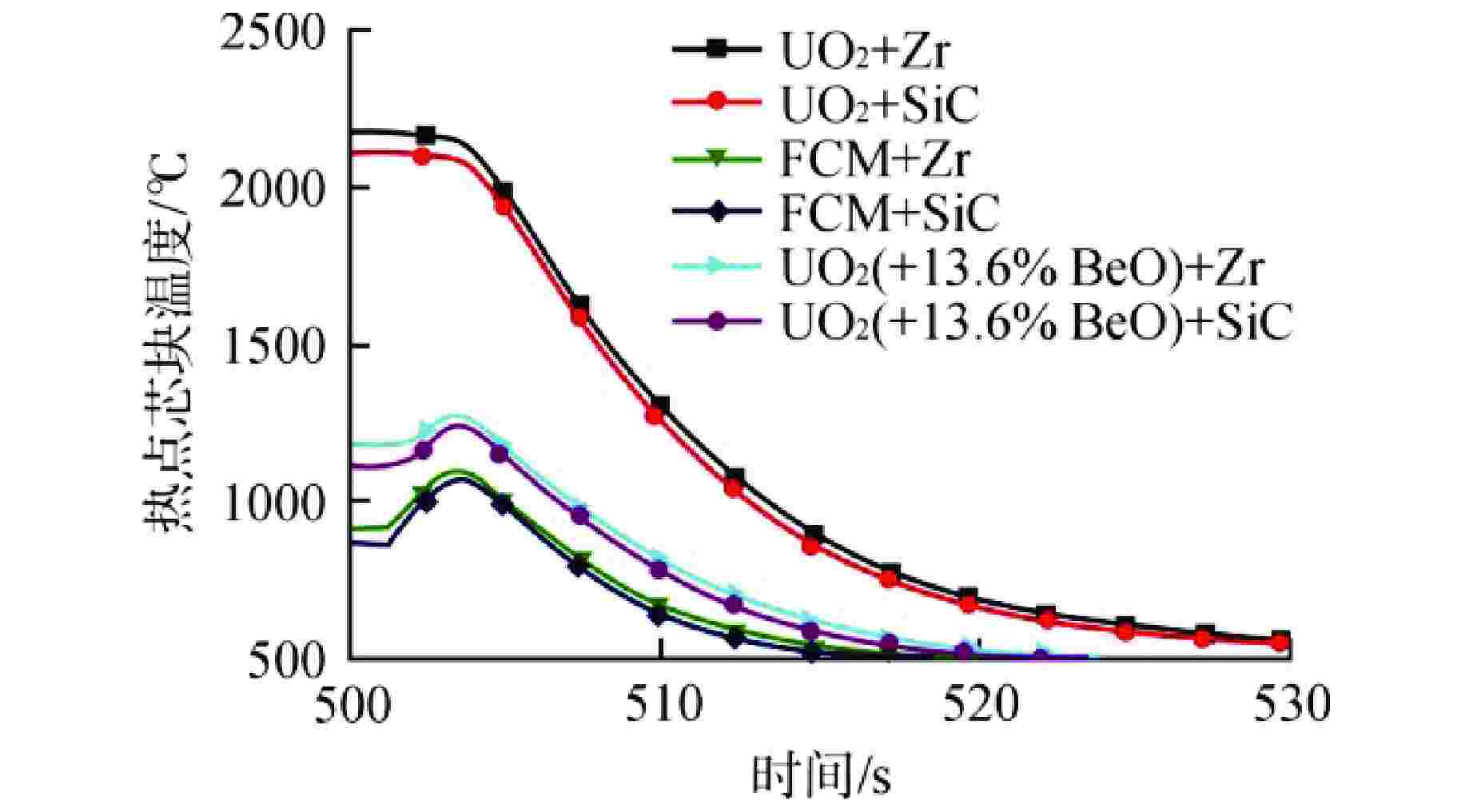

摘要: 为分析卡轴工况下事故容错燃料(ATF)对反应堆安全的潜在影响,以中国改进型三环路压水堆(CPR1000)为参考电站,基于系统分析程序NUSOL-SYS进行了二次开发,研究了不同ATF组合在卡轴工况下的表现,并对ATF包壳表面特性变化可能引起的换热系数和临界热流密度(CHF)变化开展了敏感性分析。分析结果表明,在卡轴工况下,ATF包壳表面特性变化导致的换热系数和CHF变化会对芯块最高温度和包壳峰值温度(PCT)产生较大影响,热导率大的ATF芯块能极大地降低芯块温度,比热容大的ATF材料能降低PCT。

-

关键词:

- 事故容错燃料(ATF) /

- 系统分析程序 /

- 事故分析

Abstract: To analyze the potential impact of accident tolerant fuel (ATF) on reactor safety under pump shaft-stuck accident, China's improved three-loop pressurized water reactor CPR1000 was used as reference power station to carry out second development based on the system analysis code NUSOL-SYS. The performance of CPR1000 with different ATF combinations under pump shaft-stuck accident was studied, and the sensitivity analysis was carried out to study the change of heat transfer coefficient and critical heat flux (CHF) caused by the change of ATF cladding surface characteristics. The results show that the change of heat transfer coefficient and CHF caused by the change of ATF cladding surface characteristics has a great influence on the maximum temperature of pellets and the peak cladding temperature (PCT). ATF pellets with high thermal conductivity can greatly reduce the pellet temperature, while ATF materials with high specific heat capacity can reduce the PCT.-

Key words:

- Accident tolerant fuel (ATF) /

- System analysis code /

- Accident analysis

-

表 1 CPR1000卡轴事故基本假设条件

Table 1. Basic Assumption of CPR1000 Pump Shaft-Stuck Accident

参数名 参数值 功率/MW 2953 一回路压力/MPa 15.29 热点因子 2.25 功率分布形式 顶部功率峰 停堆棒价值/pcm 4000 流量低信号 85.8%名义流量 1pcm=10−5 表 2 CPR1000卡轴事故序列

Table 2. Shaft-Stuck Accident Sequence of CPR1000

事故序列 触发时间/s 泵235转轴卡死 0 低流量触发停堆信号 0.04 控制棒开始下落 1.05 汽轮机脱扣 5.05 表 3 卡轴事故下不同ATF主要参数对比

Table 3. Key Paramaters of Different ATFs under Pump Shaft-Stuck Accident

芯块+包壳燃料组合 芯块最高温度/℃ PCT/℃ 热点氧化产热/W 气隙压力/MPa UO2+Zr 2183.13 868.55 326.54812 6.32197 UO2+SiC 2112.89 873.46 1.72287 6.31983 UO2+FeCrAl 2181.42 869.25 0.01207 6.32258 FCM+Zr 1095.15 832.38 272.38910 6.31787 FCM+SiC 1076.18 837.38 1.32034 6.31615 FCM+FeCrAl 1094.83 832.67 0.00788 6.31882 UO2(+13.6% BeO)+Zr 1278.63 824.70 234.96321 6.32043 UO2(+13.6% BeO)+SiC 1242.04 824.88 1.03070 6.31781 UO2(+13.6% BeO)+FeCrAl 1277.66 824.84 0.00629 6.31922 -

[1] OTT L J, ROBB K R, WANG D. Preliminary assessment of accident-tolerant fuels on LWR performance during normal operation and under DB and BDB accident conditions[J]. Journal of Nuclear Materials, 2014, 448(1-3): 520-533. doi: 10.1016/j.jnucmat.2013.09.052 [2] LIU R, ZHOU W, SHEN P, et al. Fully coupled multiphysics modeling of enhanced thermal conductivity UO2-BeO fuel performance in a light water reactor[J]. Nuclear Engineering and Design, 2015, 295: 511-523. doi: 10.1016/j.nucengdes.2015.10.019 [3] LATTA R, REVANKAR S T, SOLOMON A A. Modeling and measurement of thermal properties of ceramic composite fuel for light water reactors[J]. Heat Transfer Engineering, 2008, 29(4): 357-365. doi: 10.1080/01457630701825390 [4] SNEAD L L, NOZAWA T, KATOH Y, et al. Handbook of SiC properties for fuel performance modeling[J]. Journal of Nuclear Materials, 2007, 371(1-3): 329-377. doi: 10.1016/j.jnucmat.2007.05.016 [5] WU X, KOZLOWSKI T, HALES J D. Neutronics and fuel performance evaluation of accident tolerant FeCrAl cladding under normal operation conditions[J]. Annals of Nuclear Energy, 2015, 85: 763-775. doi: 10.1016/j.anucene.2015.06.032 [6] WU X L, LI W, WANG Y, et al. Preliminary safety analysis of the PWR with accident-tolerant fuels during severe accident conditions[J]. Annals of Nuclear Energy, 2015, 80: 1-13. [7] PAN D, ZHANG R Q, WANG H, et al. Formation and stability of oxide layer in FeCrAl fuel cladding material under high-temperature steam[J]. Journal of Alloys and Compounds, 2016, 684: 549-555. doi: 10.1016/j.jallcom.2016.05.145 [8] LI B S. Pellet Cladding mechanical interactions of ceramic claddings fuels under light water reactor conditions[D]. South Carolina: Univ. of South Carolina, 2013. [9] LEE S K, LIU M L, BROWN N R, et al. Comparison of steady and transient flow boiling critical heat flux for FeCrAl accident tolerant fuel cladding alloy, Zircaloy, and Inconel[J]. International Journal of Heat and Mass Transfer, 2019, 132: 643-654. doi: 10.1016/j.ijheatmasstransfer.2018.11.141 [10] SEO G H, JEUN G, KIM S J. Pool boiling heat transfer characteristics of zircaloy and SiC claddings in deionized water at low pressure[J]. Experimental Thermal and Fluid Science, 2015, 64: 42-53. doi: 10.1016/j.expthermflusci.2015.01.017 [11] 吴清,卢毅力. 秦山核电二期工程瞬态事故分析[J]. 核动力工程,2003, 24(S2): 56-60. -

下载:

下载: