Research on U-Zr-based Metallic Fuel Additives and Performance Improvement for Fuel-Cladding Chemical Interaction and Phase Optimization

-

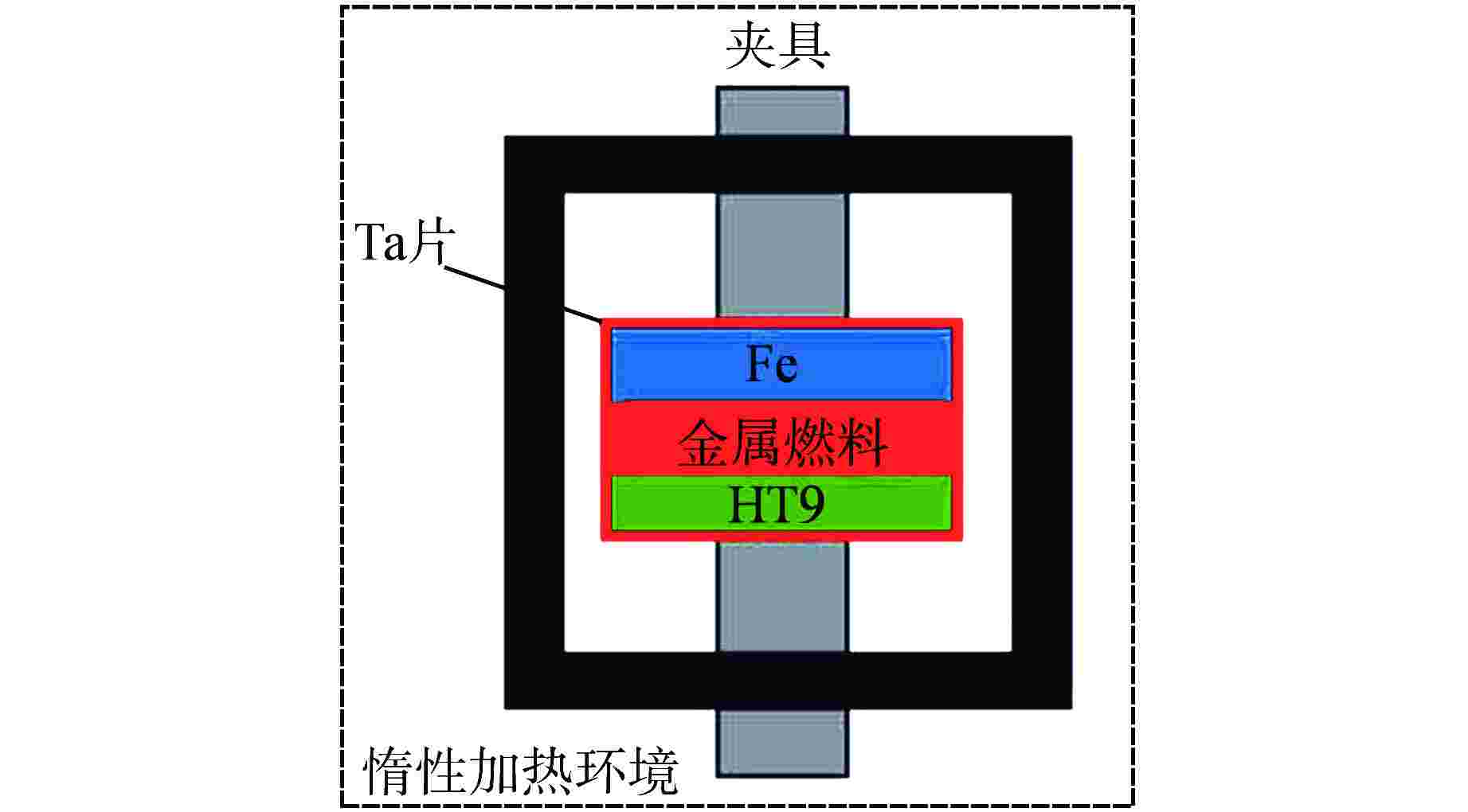

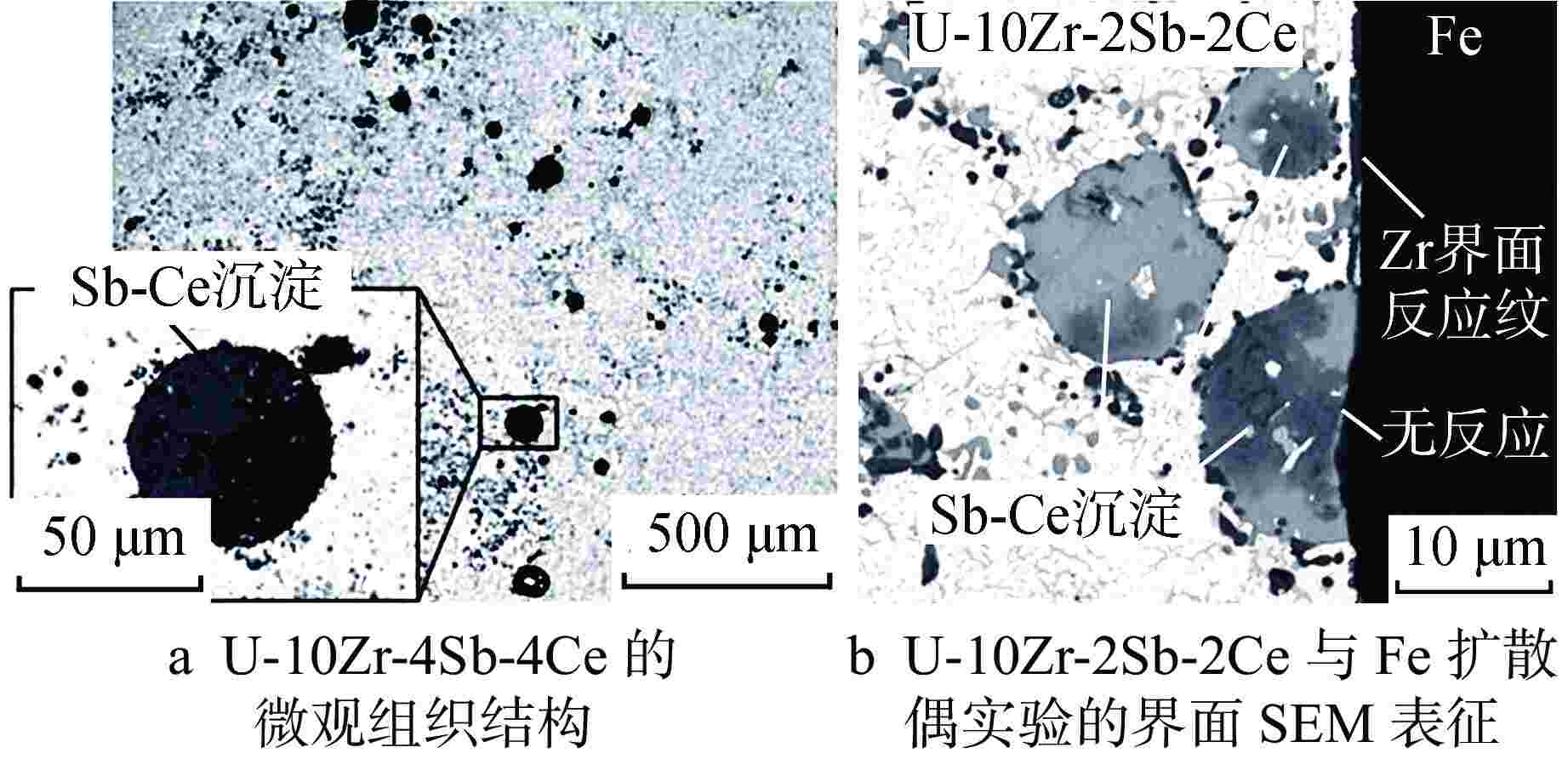

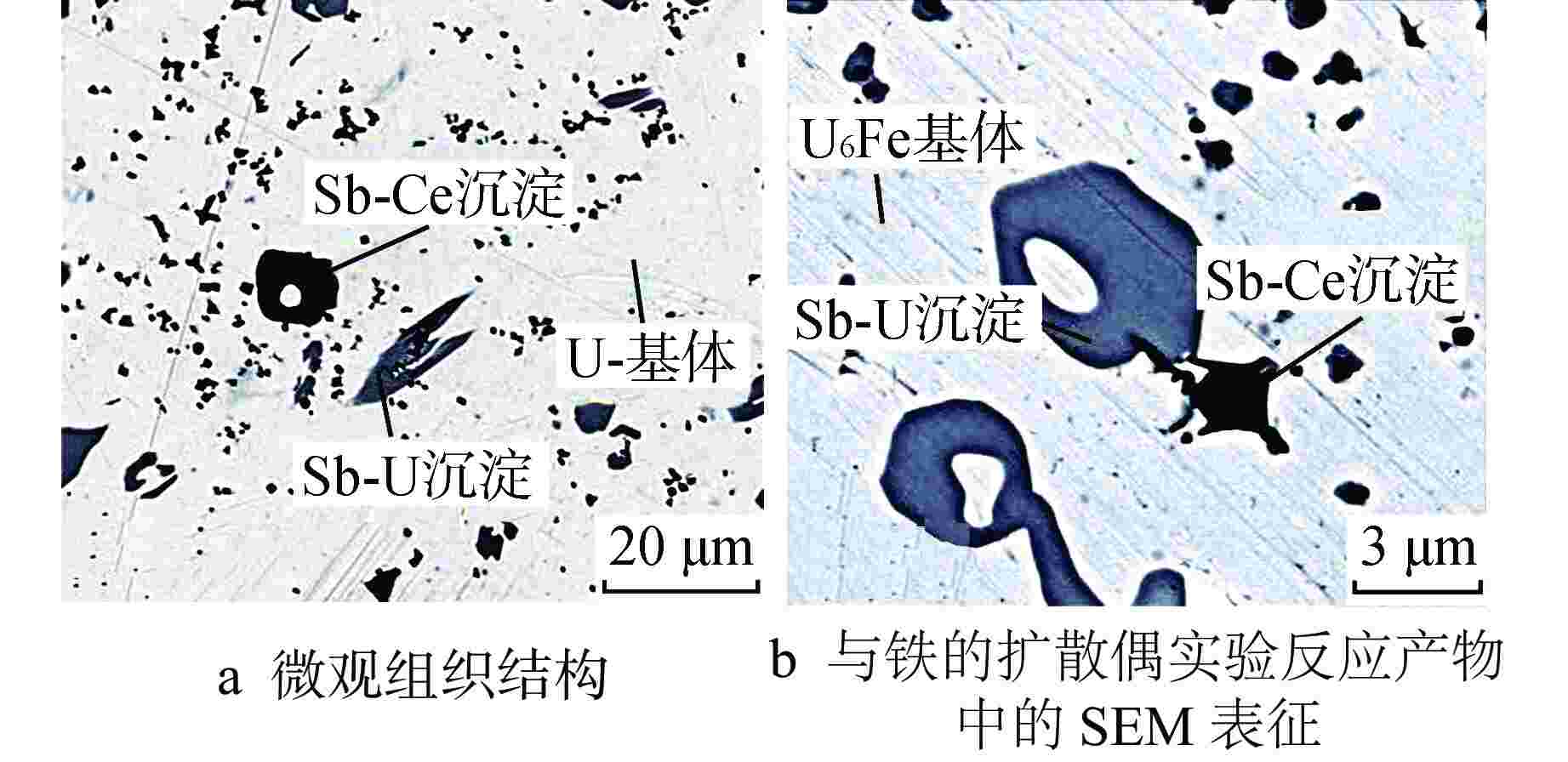

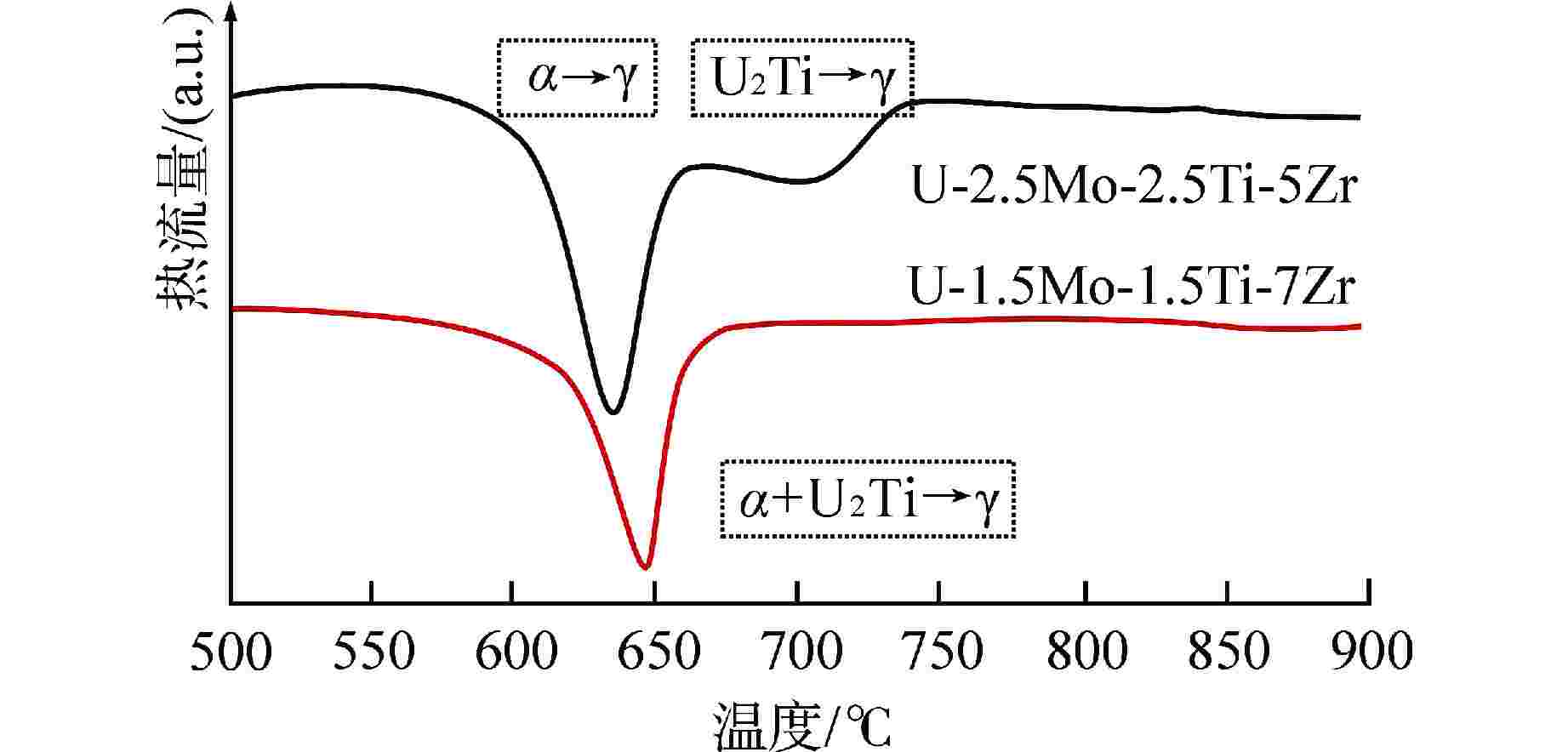

摘要: 针对U-Zr基金属燃料包壳化学反应(FCCI)和相优化问题,介绍了掺杂元素Sb、Mo、Nb和Ti对金属燃料的影响。结合扩散偶实验、高温加热实验,并利用扫描电子显微镜(SEM),X射线衍射(XRD)和热差仪分析(DSC)表征方法,对一系列U-Zr基金属燃料进行了堆外评价。掺杂元素Sb用于抑制金属燃料在高燃耗下的FCCI。研究结果表明,Sb和镧系元素Ce结合生成沉淀,并且其沉淀产物不与包壳反应,证明了Sb可以作为一种潜在的掺杂元素解决高燃耗下的FCCI问题;掺杂元素Mo、Nb和Ti用于相优化,其中Mo、Nb降低了γ相的转变温度,且Mo的效果优于Nb。研究结果可为未来先进金属燃料的设计和优化提供数据支撑。

-

关键词:

- U-Zr基金属燃料 /

- 元素掺杂 /

- 燃料包壳化学反应(FCCI) /

- 相优化 /

- 扫描电子显微镜(SEM) /

- X射线衍射(XRD) /

- 热差仪分析(DSC)

Abstract: The current work focuses on the fuel additives Sb, Mo, Nb, and Ti for U-Zr-based metallic fuel in order to mitigate fuel-cladding chemical interaction (FCCI) and optimize the fuel phase. A series of U-Zr-based fuel samples were evaluated out-of-pile by diffusion couple tests and annealing tests, and characterized by scanning electron microscope (SEM), X-ray diffraction (XRD) and differential scanning calorimetry (DSC). The additive Sb was used to mitigate FCCI under high burnup. The results showed that Sb formed precipitates with lanthanide Ce, and the precipitates did not react with cladding materials. This indicates that the additive Sb is a promising candidate to solve the FCCI problem under high burnup. The additives Mo, Nb and Ti were used to optimize the γ phase transition temperature of metallic fuel. It was found that Mo and Nb could reduce the transition temperature of γ phase, and the effect of Mo was better than that of Nb. The results in this work can provide fundamental data for the advanced fuel design in the future. -

表 1 金属燃料实验样品及研究方法

Table 1. Metallic Fuel Samples and Research Methods

针对性

问题样品名称 样品成分 实验方法 主要表

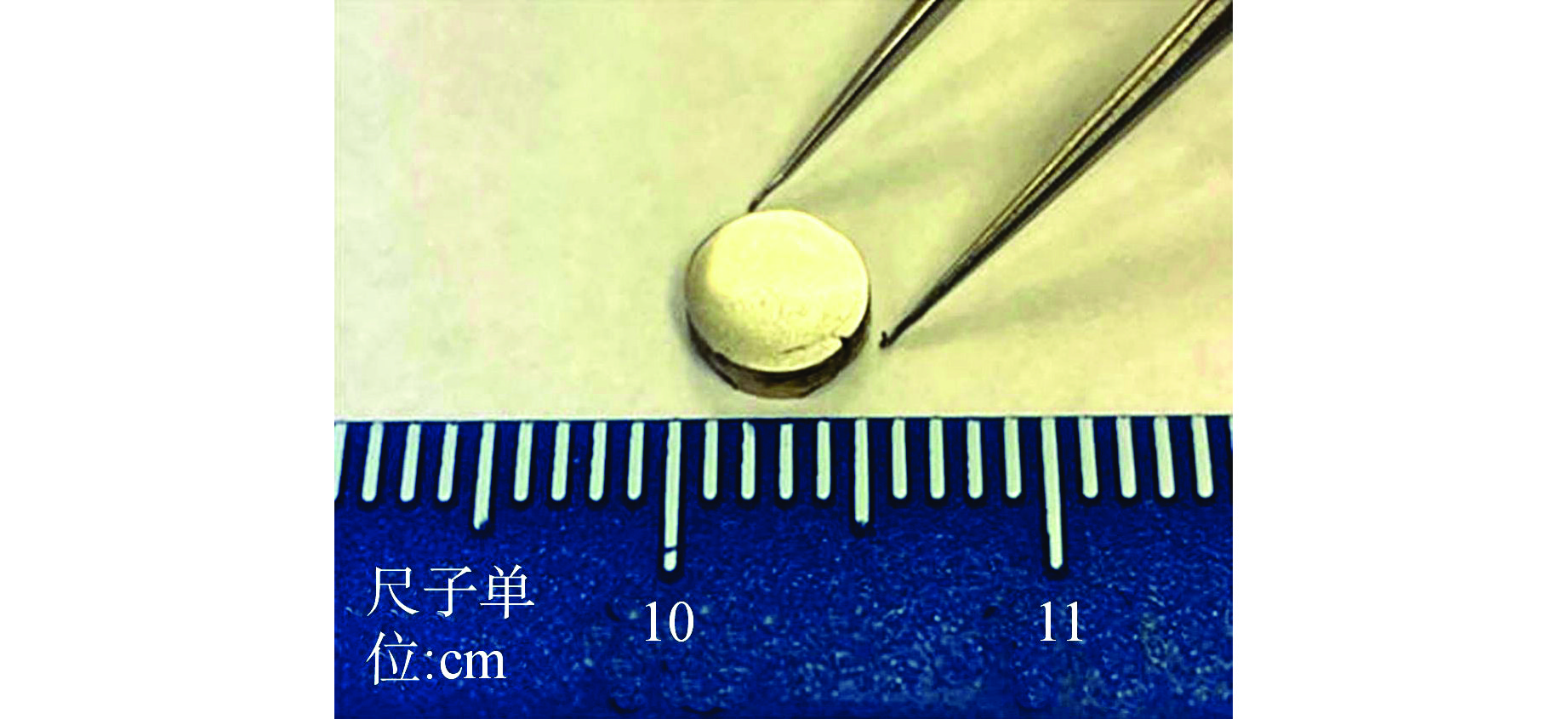

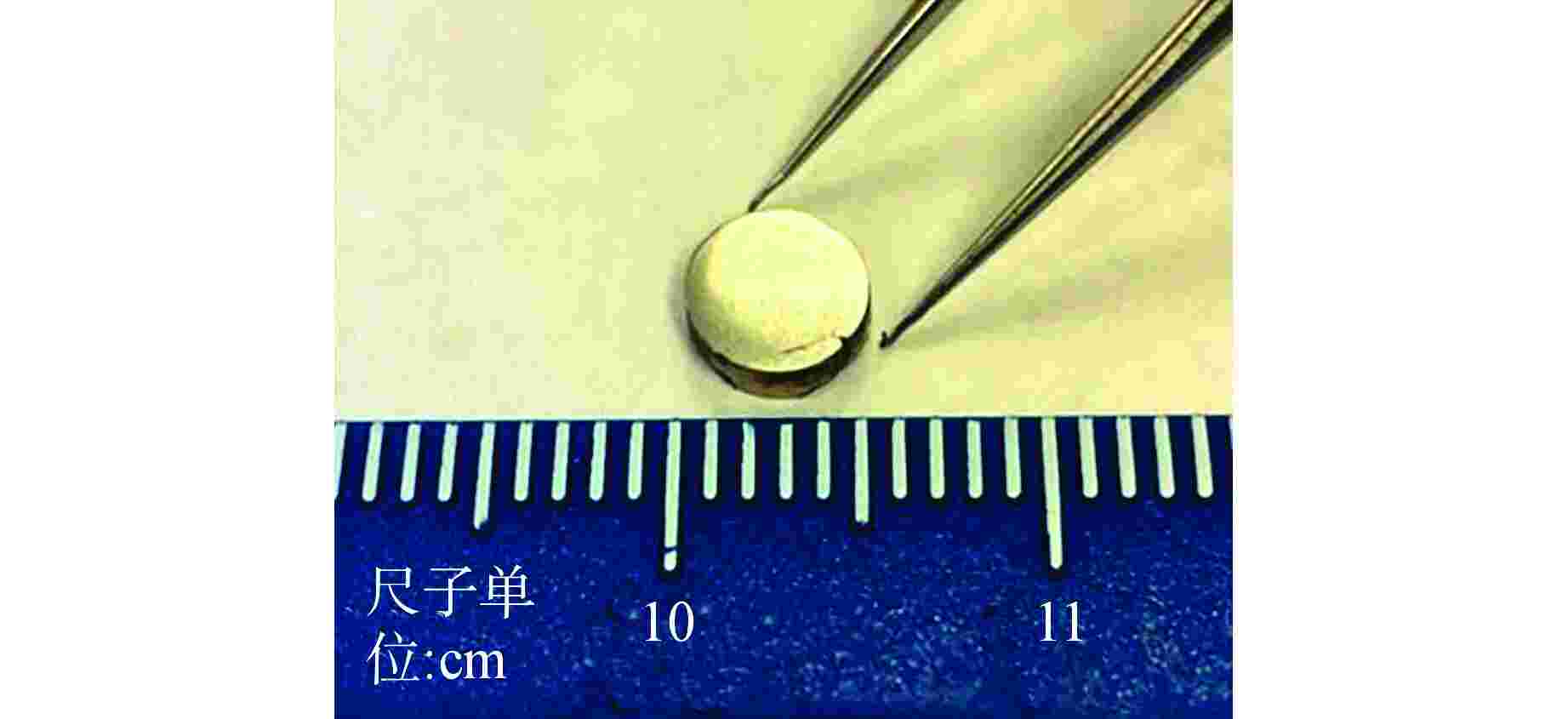

征方法FCCI U-Zr-Sb U-10Zr-4Sb 扩散偶实验 扫描电子

显微镜(SEM)U-10Zr-2Sb U-Zr-Sb-Ce U-10Zr-4Sb-4Ce U-10Zr-2Sb-2Ce U-Sb U-4Sb-4Ce U-Sb-Ce U-4Sb-4Ce 相优化 U-Mo-Ti-Zr U-2.5Mo-2.5Ti-5Zr 高温加热 X射线衍射

(XRD)、热差

仪分析(DSC)U-1.5Mo-1.5Ti-7Zr U-Nb-Ti-Zr U-2.5Nb-2.5Ti-5Zr U-1.5Nb-1.5Ti-7Zr -

[1] KITTEL J H, FROST B R T, MUSTELIER J P, et al. History of fast reactor fuel development[J]. Journal of Nuclear Materials, 1993, 204: 1-13. doi: 10.1016/0022-3115(93)90193-3 [2] HARP J M, CAPRIOTTI L, CAPPIA F. Postirradiation examination of recently irradiated metallic fuel concepts: INL/CON-18-51782-Rev000[R]. Idaho Falls: Idaho National Laboratory, 2018. [3] OGATA T. Metal fuel[J]. Comprehensive Nuclear Materials (Second Edition), 2020, 5: 1-42. [4] ZHUO W. Development of fuel additive and alloy for sodium-cooled fast reactor[D]. United States: Virginia Tech, 2022. [5] HOFMAN G L, WALTERS L C, BAUER T H. Metallic fast reactor fuels[J]. Progress in Nuclear Energy, 1997, 31(1-2): 83-110. doi: 10.1016/0149-1970(96)00005-4 [6] JANNEY D E, HAYES S L. Experimentally known properties of U-10Zr alloys: a critical review[J]. Nuclear Technology, 2018, 203(2): 109-128. doi: 10.1080/00295450.2018.1435137 [7] CARMACK W J, PORTER D L, CHANG Y I, et al. Metallic fuels for advanced reactors[J]. Journal of Nuclear Materials, 2009, 392(2): 139-150. doi: 10.1016/j.jnucmat.2009.03.007 [8] WRIGHT A E, HAYES S L, BAUER T H, et al. Development of advanced ultra-high burnup SFR metallic fuel concept – Project overview[J]. Transactions of the American Nuclear Society, 2012, 106: 1102-1105. [9] MATTHEWS C, UNAL C, GALLOWAY J, et al. Fuel-cladding chemical interaction in U-Pu-Zr metallic fuels: a critical review[J]. Nuclear Technology, 2017, 198(3): 231-259. doi: 10.1080/00295450.2017.1323535 [10] OKAMOTO H, SCHLESINGER M E, MUELLER E M. U (Uranium) binary alloy phase diagrams[M]. United States: ASM International, 2016, 3: 619. [11] OKAMOTO H, SCHLESINGER M E, MUELLER E M. Ti (Titanium) binary alloy phase diagrams[M]. United States: ASM International, 2016, 3: 615 [12] JIANG C, MARIANI R D. Status report on the development of a thermodynamic database for use with metallic fuel design: INL/EXT-18-51293-Rev000[R]. Idaho Falls: Idaho National Laboratory, 2018. [13] SOWA S, KIM-NGAN N T H, KRUPSKA M, et al. Superconductivity in U-T alloys (T = Mo, Pt, Nb, Zr) stabilized in the cubic γ-U structure[J]. Acta Physica Polonica A, 2016, 130(2): 521-526. doi: 10.12693/APhysPolA.130.521 [14] OKAMOTO H, SCHLESINGER M E, MUELLER E M. Nb (Niobium) binary alloy phase diagrams[M]. United States: ASM International, 2016, 3: 513. [15] XIE Y, BENSON M T, KING J A, et al. Characterization of U-Zr fuel with alloying additive Sb for immobilizing fission product lanthanides[J]. Journal of Nuclear Materials, 2018, 498: 332-340. doi: 10.1016/j.jnucmat.2017.10.039 [16] ZHUO W Q, XIE Y, BENSON M T, et al. Experimental investigation of FCCI using diffusion couple test between UZr fuel with Sb additive and cladding[J]. Nuclear Science and Engineering, 2020, 194(6): 462-476. doi: 10.1080/00295639.2020.1713656 [17] ZHUO W Q, XIE Y, BENSON M T, et al. Experimental assessment of antimony (Sb) in pure uranium for immobilizing fission product lanthanides[J]. Journal of Nuclear Materials, 2020, 534: 152135. doi: 10.1016/j.jnucmat.2020.152135 [18] ZHUO W Q, WU H L, XIE Y, et al. Solid-state phase transitions of two quaternary metallic fuel alloys (U-2.5Mo-2.5Ti-5.0Zr and U-1.5Mo-1.5Ti-7.0Zr in wt. %)[J]. Journal of Nuclear Materials, 2021, 555: 153134. doi: 10.1016/j.jnucmat.2021.153134 [19] ZHUO W Q, WU H L, BENSON M T, et al. An investigation of the phase behaviors for quaternary U-Nb/Mo-Ti-Zr metallic fuel alloys[J]. Materials Today Communications, 2022, 30: 103042. doi: 10.1016/j.mtcomm.2021.103042 -

下载:

下载: