Study on Long-Term High Temperature Creep Properties of 12Cr-1.5W-0.6Si Alloy Pipe

-

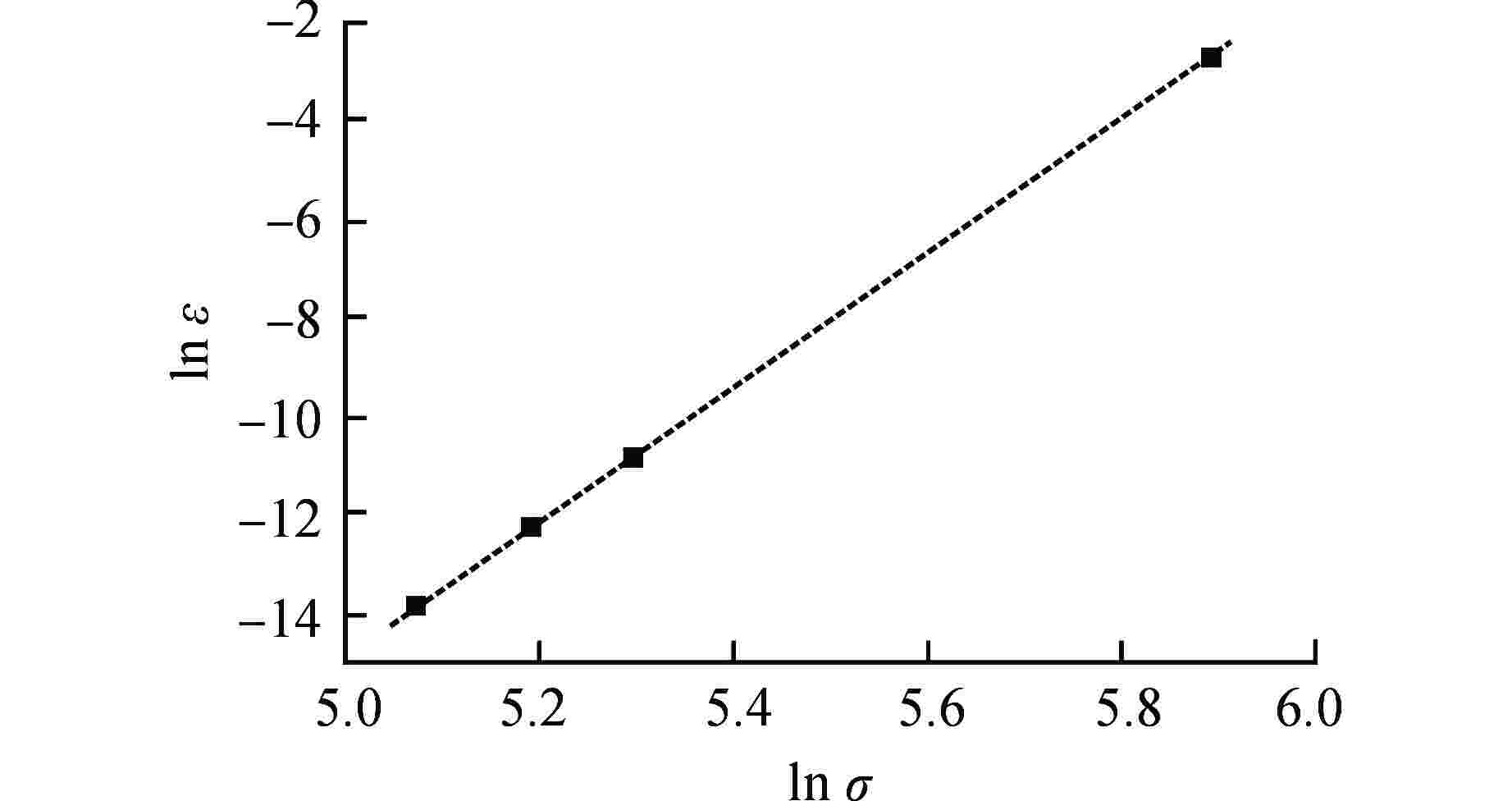

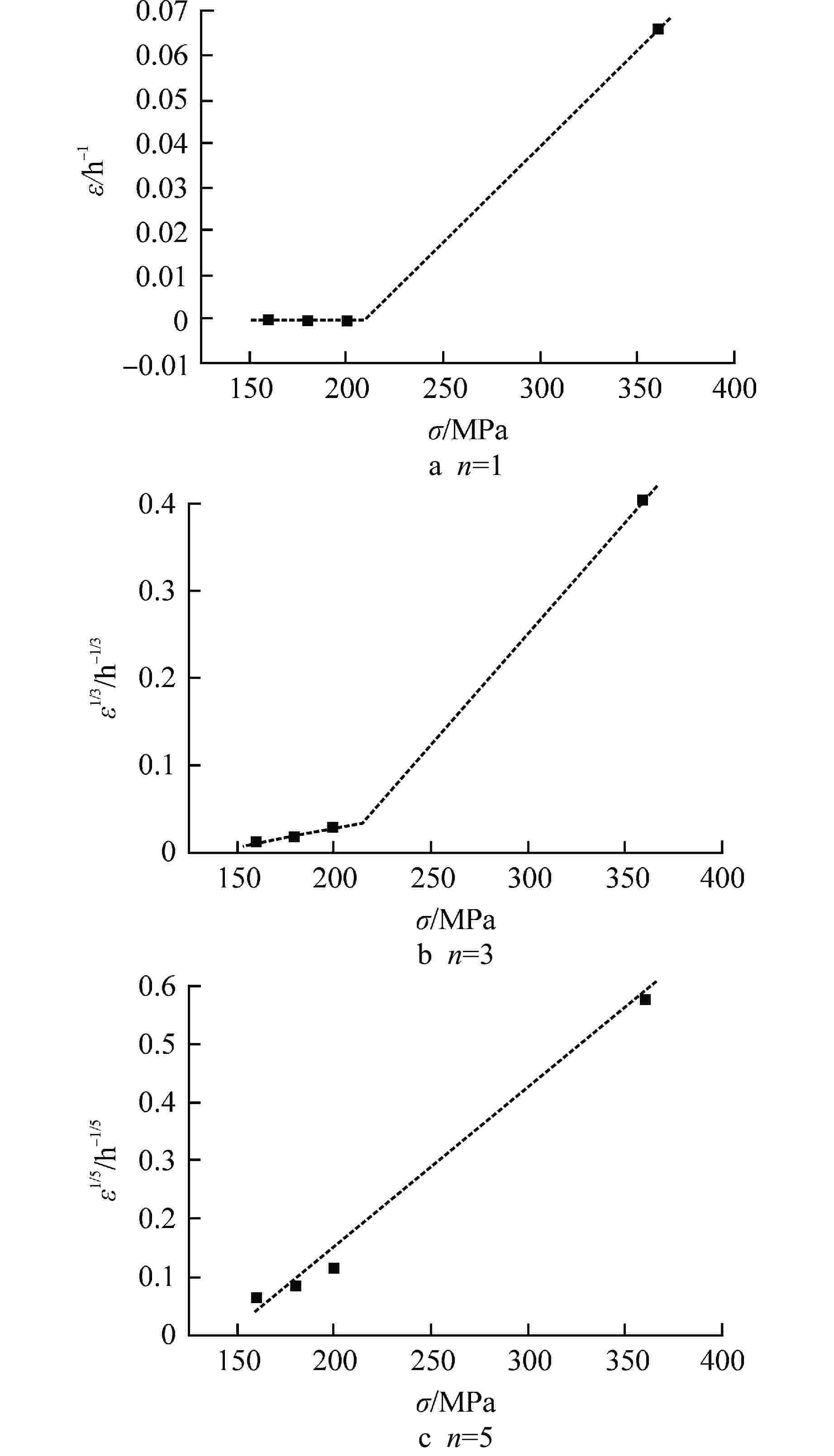

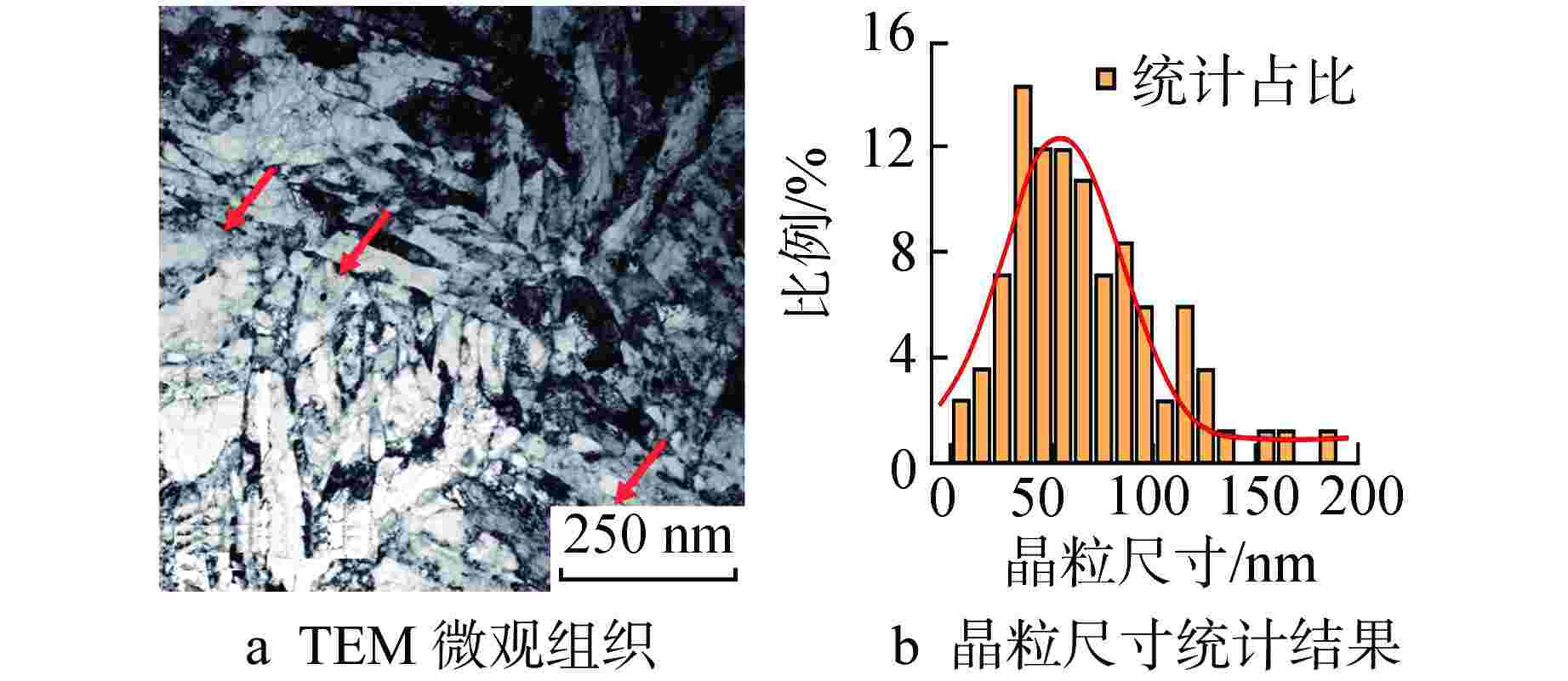

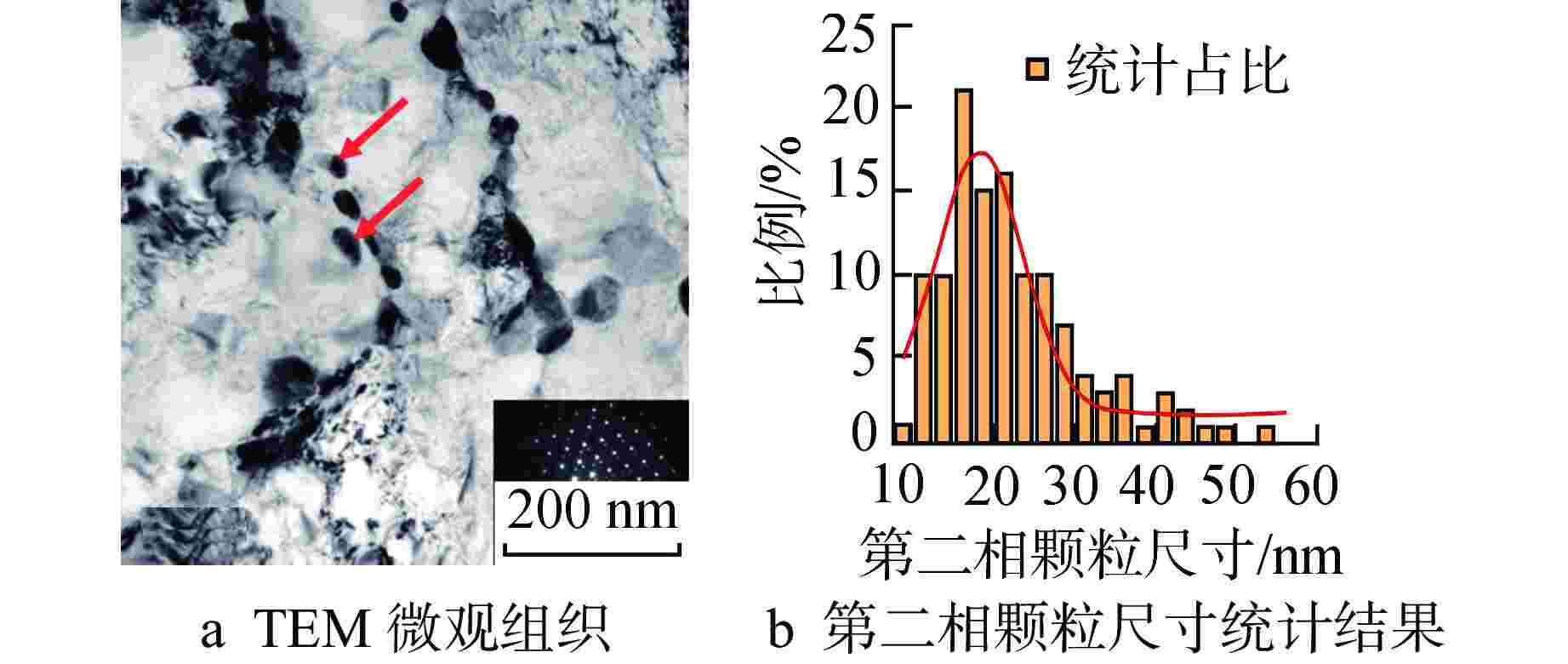

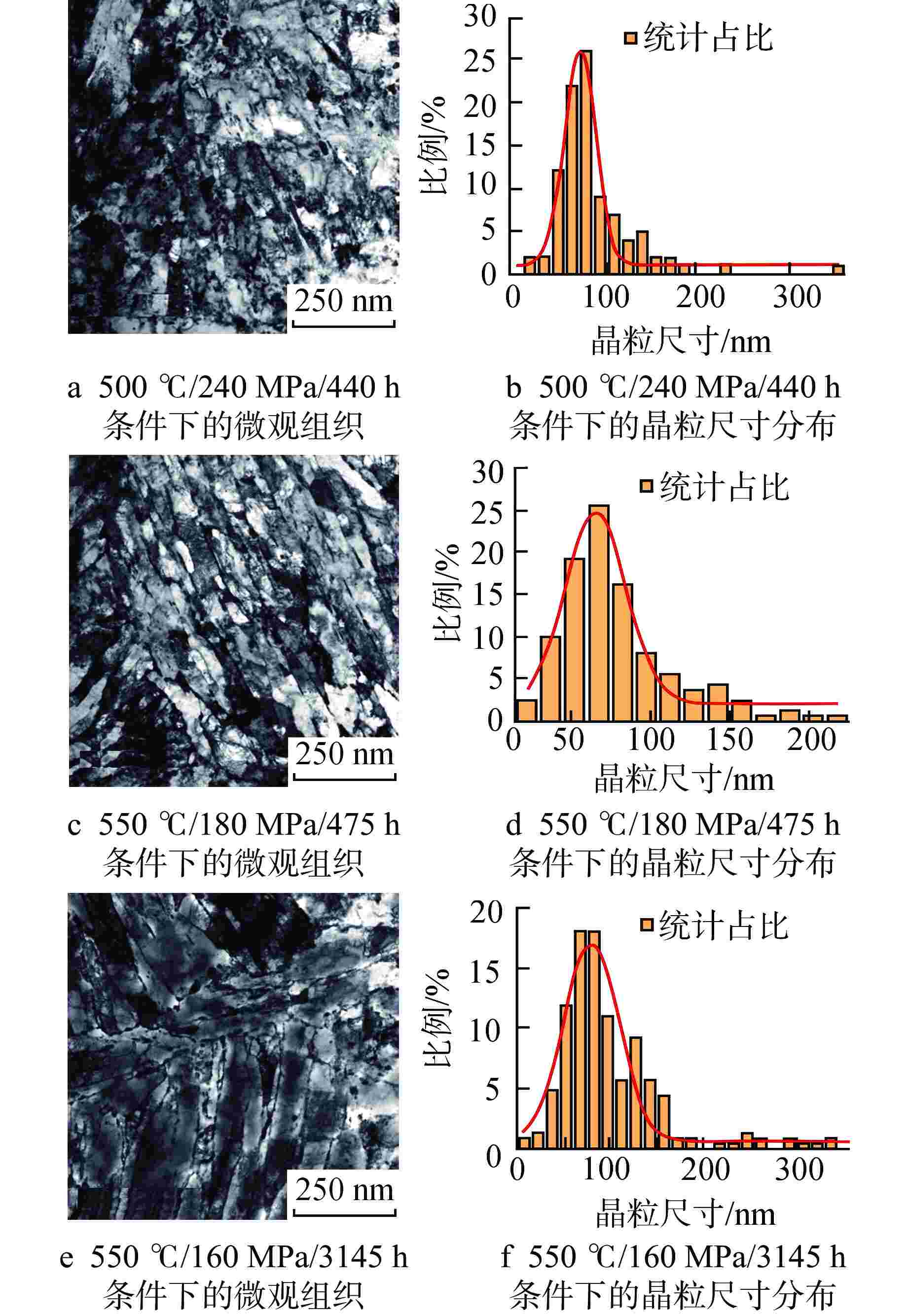

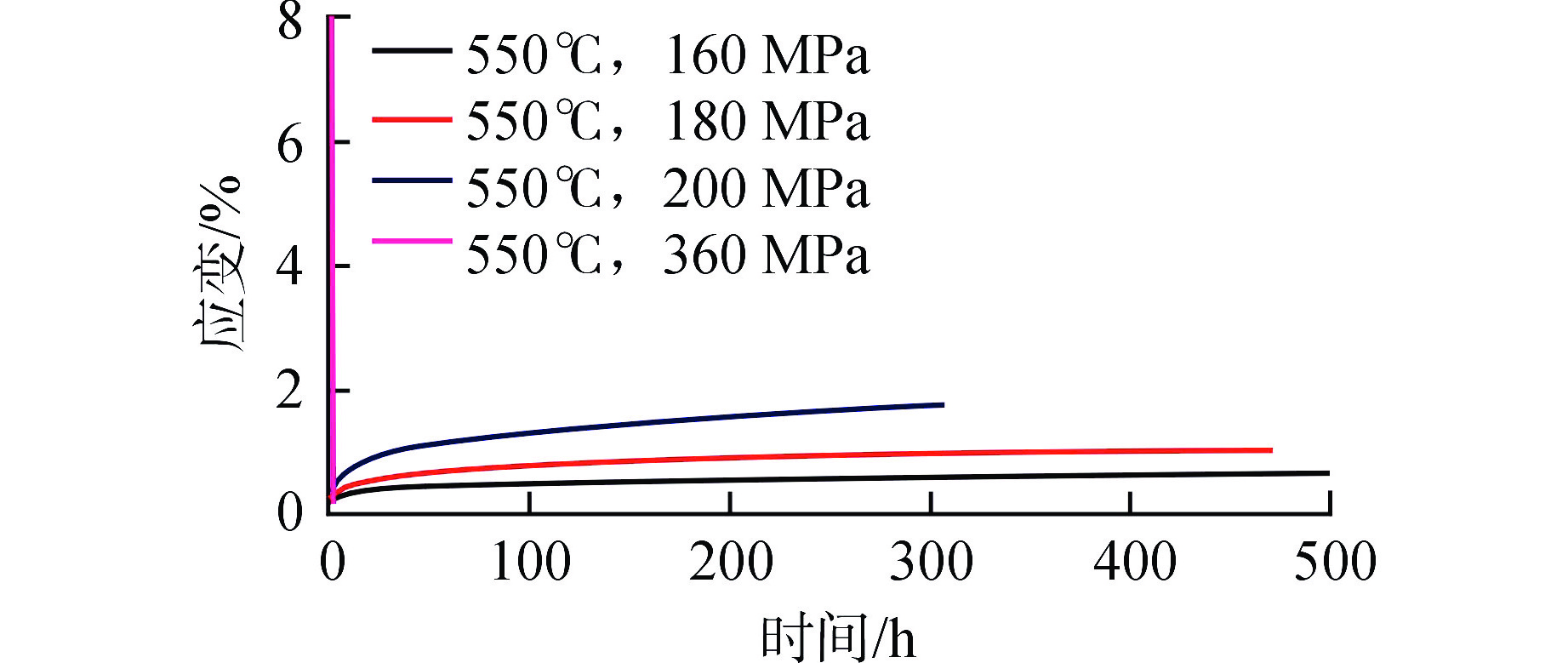

摘要: 为获得铁素体/马氏体合金的高温蠕变性能,采用蠕变试验装置对12Cr-1.5W-0.6Si合金管材开展了450、500和550℃在空气环境下的蠕变试验,获得了蠕变时间-应变曲线和稳态蠕变速率。研究表明:合金的应力指数较高,通过引入门槛应力获得真实应力指数,其蠕变机制是位错攀移机制;经过550℃、160 MPa、3145 h蠕变试验后,第二相仍沿晶界分布,但合金出现了板条晶粒宽化、第二相颗粒粗化现象,且长时间蠕变对微观组织的影响更为显著。

-

关键词:

- 12Cr-1.5W-0.6Si合金 /

- 高温蠕变 /

- 第二相

Abstract: To obtain the creep properties of Ferritic/Martensitic alloy, creep tests for 12Cr-1.5W-0.6Si pipes in the air environment at 450°C, 500°C and 550°C were carried out to obtain the creep time-strain curve and steady-state creep rate by using the creeptesting device. The results show that the stress index is relatively high, and the true stress index is obtained by introducing threshold stress. The creep mechanism is dislocation climbing mechanism. After creep tests at 550°C and 160MPa for 3145 h, the precipitated phase is still distributed along the grain boundary, but the lath grain widens and the precipitated phase grain coarsens, and the effect of long-term creep on the microstructure is more significant.-

Key words:

- 12Cr-1.5W-0.6Si alloy /

- High temperature creep /

- Precipitated phase

-

表 1 成品管材蠕变试验参数及试验结果

Table 1. Creep Test Parameters and Test Results of Finished Pipe

温度/

℃屈服强

度/MPa应力/

MPa屈服强

度占比/%蠕变

时间/hε/h−1 备注 550 396.5 360 91 4 6.60×10−2 应变11%断裂 200 50 311 1.93×10−5 未断裂 180 45 475 4.90×10−6 未断裂 160 40 3145 9.63×10−7 未断裂 500 463.5 430 93 0.12 1.80×10−2 应变11.5%断裂 280 60 459 8.11×10−5 未断裂 240 52 440 5.07×10−6 未断裂 220 47 1109 7.25×10−7 未断裂 450 493.5 450 91 0.11 1.18×10−3 应变11%断裂 340 69 459 2.13×10−5 未断裂 300 61 460 4.81×10−6 未断裂 260 53 1008 1.12×10−6 未断裂 表 2 蠕变前后12Cr-1.5W-0.6Si合金板条晶粒尺寸和第二相尺寸对比

Table 2. Lath Grain Size and Precipitated Phase Size Statistics of 12Cr-1.5W-0.6Si before and after Creep

选取试样条件 板条晶粒

宽度/nm第二相颗粒

半径/nm第二相数

密度/m−3原始态 54.3±2.9 18.3±0.7 6.82×1019 500℃/240 MPa/440 h 57.2±1.5 22.6±1.4 6.16×1019 550℃/180 MPa/475 h 65.8±1.3 25.7±2.0 5.67×1019 550℃/160 MPa/3145 h 78.9±2.4 38.9±0.6 4.73×1019 -

[1] QIAO Y Q, LI M Y, GUO X P. Development of silicide coatings over Nb-NbCr2 alloy and their oxidation behavior at 1250℃[J]. Surface and Coatings Technology, 2014, 258: 921-930. doi: 10.1016/j.surfcoat.2014.07.058 [2] CHENG J C, YI S, PARK J S. Oxidation behavior of Nb-Si-B alloys with the NbSi2 coating layer formed by a pack cementation technique[J]. International Journal of Refractory Metals and Hard Materials, 2013, 41: 103-109. doi: 10.1016/j.ijrmhm.2013.02.010 [3] PENG L, TAKIZAWA S, IKEDA K I, et al. Effect of Si on the stability of NbCr2 laves phase in Cr-Mo-Nb system[J]. Intermetallics, 2019, 110: 106457. doi: 10.1016/j.intermet.2019.03.020 [4] XUE Y L, LI S M, WU Y T, et al. Strengthening and toughening effects in laves phase Cr2Ta/Cr in-situ composites by Si additions[J]. Vacuum, 2020, 174: 109202. doi: 10.1016/j.vacuum.2020.109202 [5] CHEN S H, RONG L J. Effect of silicon on the microstructure and mechanical properties of reduced activation ferritic/martensitic steel[J]. Journal of Nuclear Materials, 2015, 459: 13-19. doi: 10.1016/j.jnucmat.2015.01.004 [6] PANDEY A B, MISHRA R S, MAHAJAN Y R. Creep behaviour of an aluminium-silicon carbide particulate composite[J]. Scripta Metallurgica et Materialia, 1990, 24(8): 1565-1570. doi: 10.1016/0956-716X(90)90433-H [7] LATHA S, NANDAGOPAL M, SELVI S P, et al. Tensile and creep behaviour of modified 9Cr-1Mo steel cladding tube for fast reactor using metallic fuel[J]. Procedia Engineering, 2014, 86: 71-79. doi: 10.1016/j.proeng.2014.11.013 [8] KIMURA K, KUSHIMA H, SAWADA K. Long-term creep deformation property of modified 9Cr–1Mo steel[J]. Materials Science and Engineering:A, 2009, 510-511: 58-63. doi: 10.1016/j.msea.2008.04.095 [9] GUGULOTH K, ROY N. Study on the creep deformation behavior and characterization of 9Cr-1Mo-V-Nb steel at elevated temperatures[J]. Materials Characterization, 2018, 146: 279-298. doi: 10.1016/j.matchar.2018.10.011 [10] LI Y, MOHAMED F A. An investigation of creep behavior in an SiC-2124 Al composite[J]. Acta Materialia, 1997, 45(11): 4775-4785. doi: 10.1016/S1359-6454(97)00130-4 [11] YANG C, CAO L F, GAO Y H, et al. Nanostructural Sc-based hierarchy to improve the creep resistance of Al–Cu alloys[J]. Materials & Design, 2020, 186: 108309. [12] VO N Q, BAYANSAN D, SANATY-ZADEH A, et al. Effect of Yb microadditions on creep resistance of a dilute Al-Er-Sc-Zr alloy[J]. Materialia, 2018, 4: 65-69. doi: 10.1016/j.mtla.2018.08.030 [13] HU X B, LI L, WU X C, et al. Coarsening behavior of M23C6 carbides after ageing or thermal fatigue in AISI H13 steel with niobium[J]. International Journal of Fatigue, 2006, 28(3): 175-182. doi: 10.1016/j.ijfatigue.2005.06.042 [14] DUDOVA N, KAIBYSHEV R. On the precipitation sequence in a 10%Cr steel under tempering[J]. ISIJ International, 2011, 51(5): 826-831. doi: 10.2355/isijinternational.51.826 -

下载:

下载: