Verification and Analysis of Fine Subchannel Rod Bowing Model

-

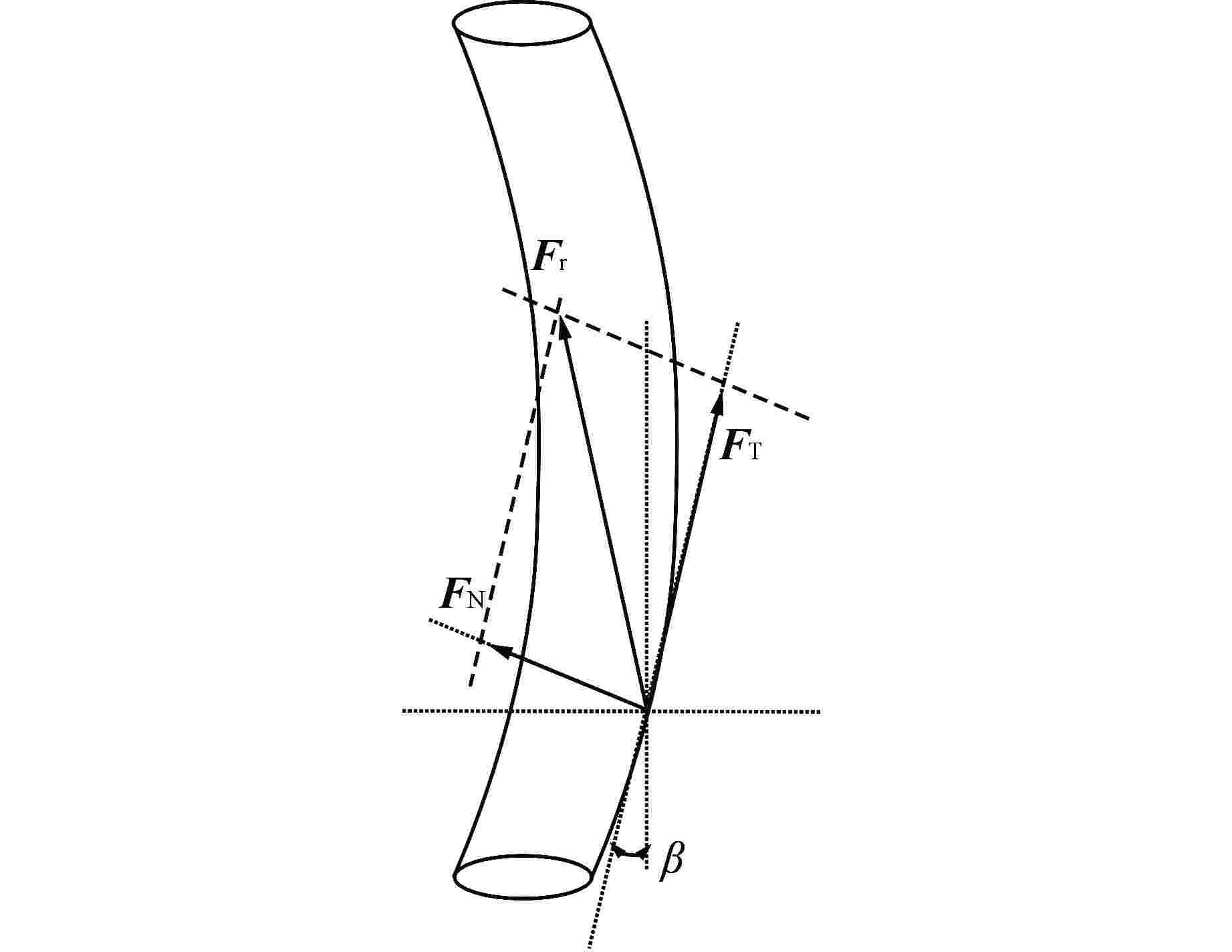

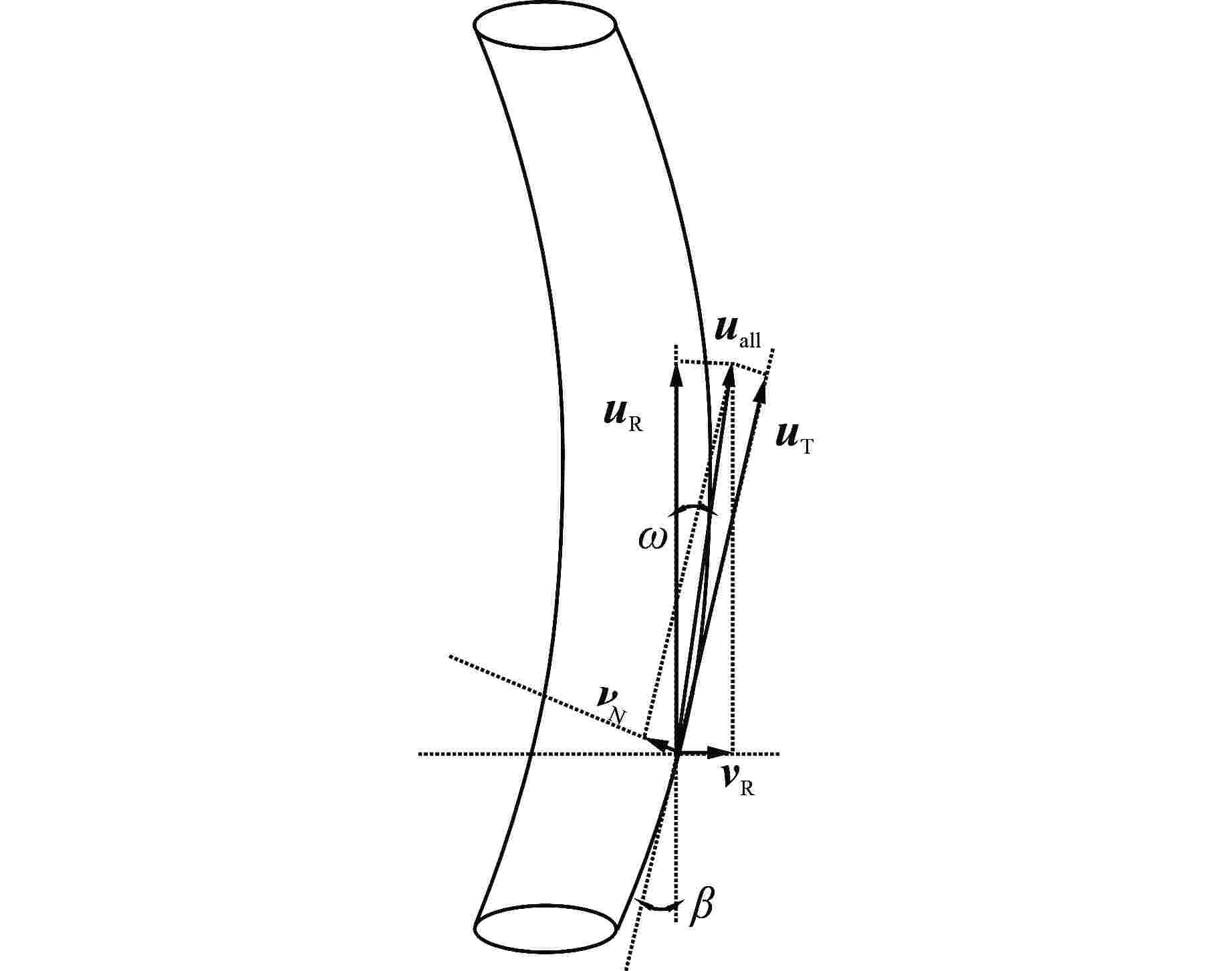

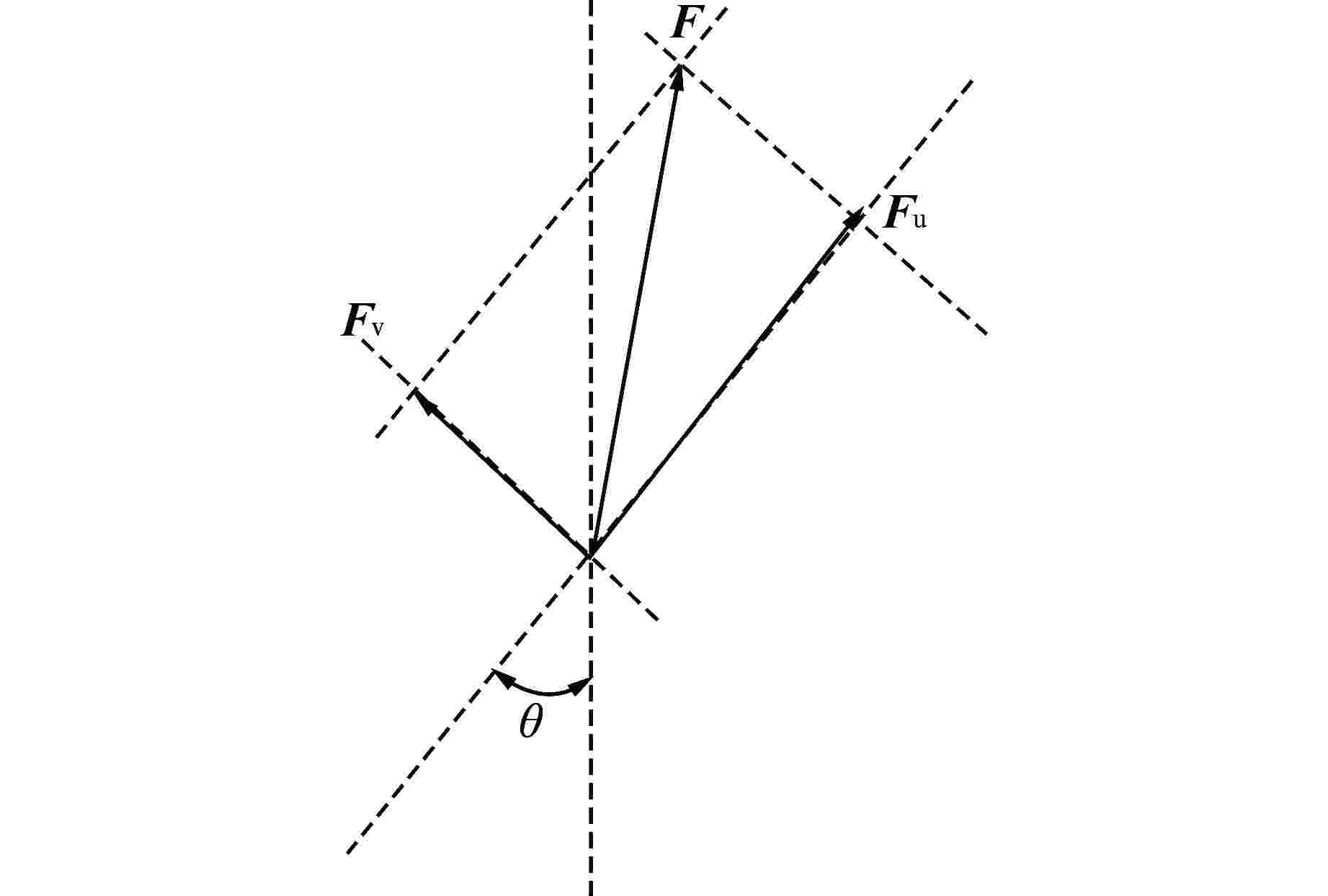

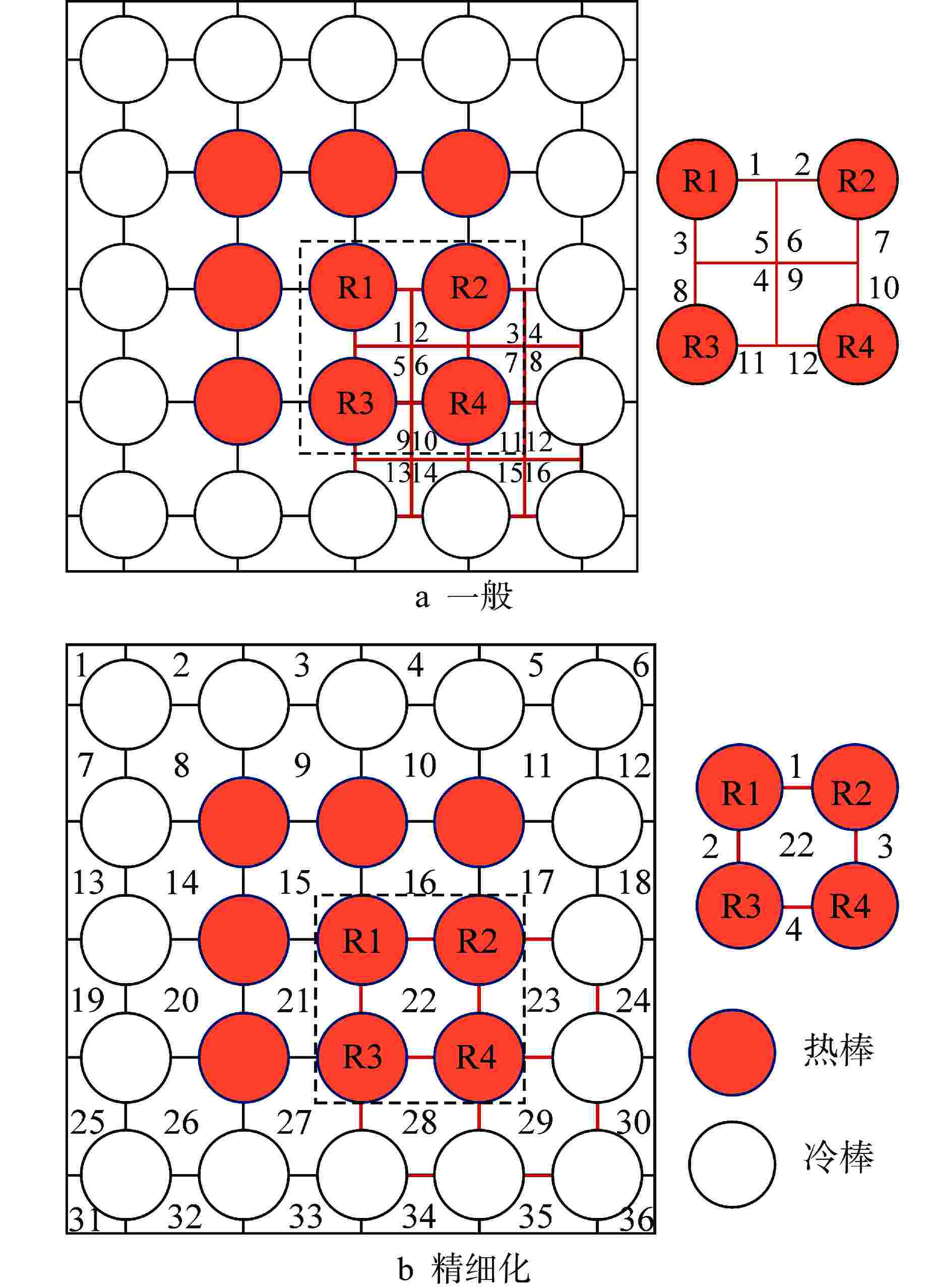

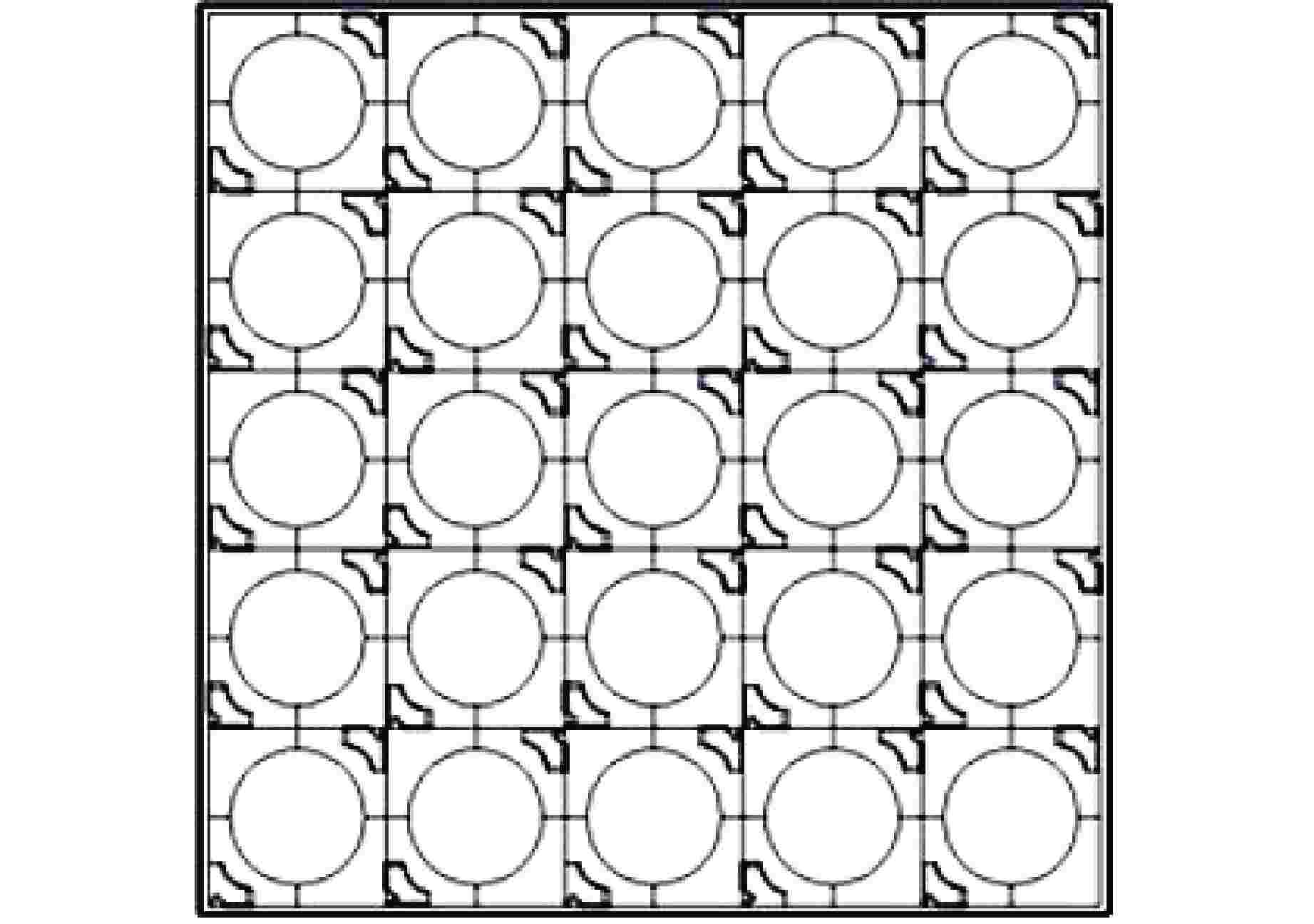

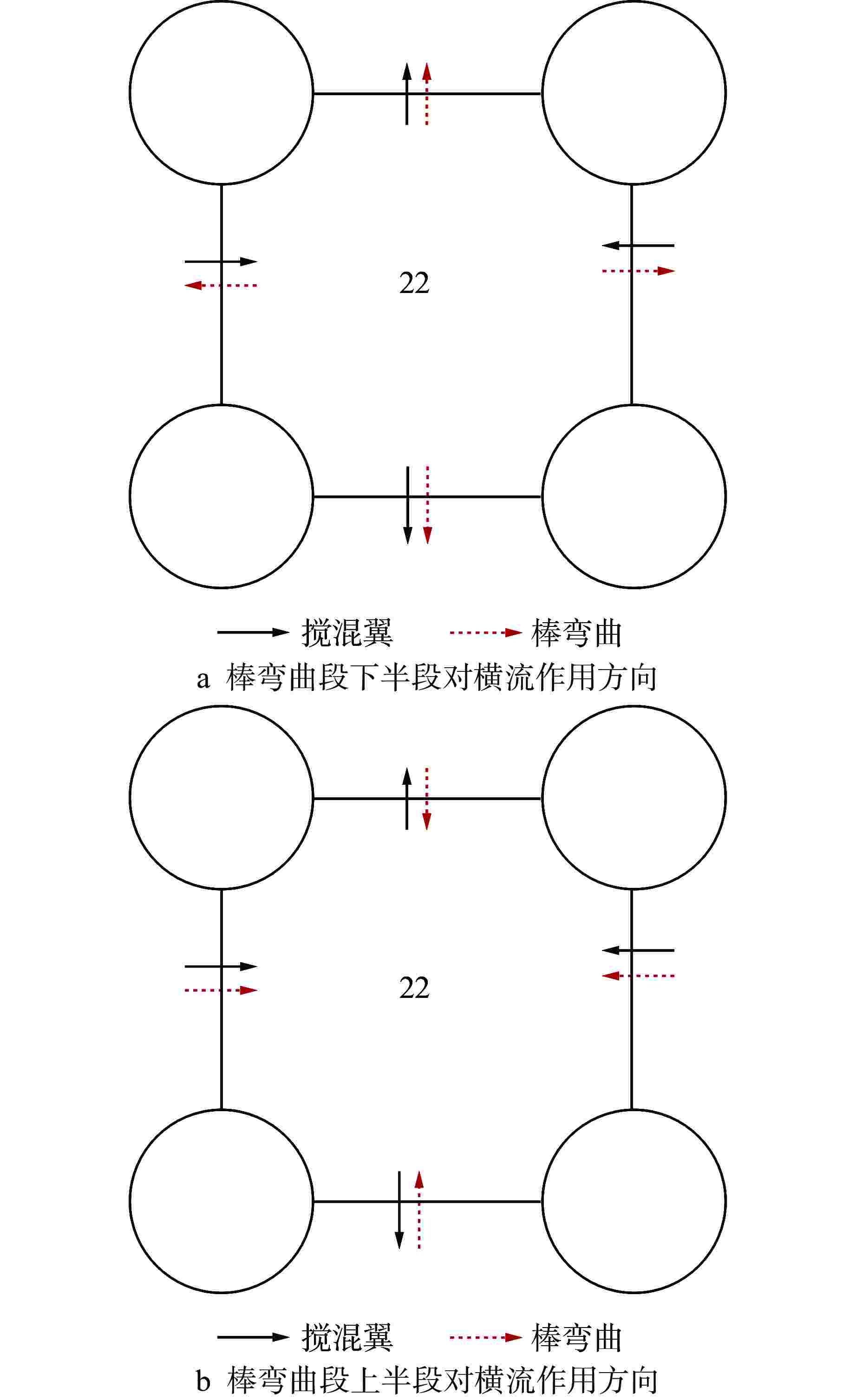

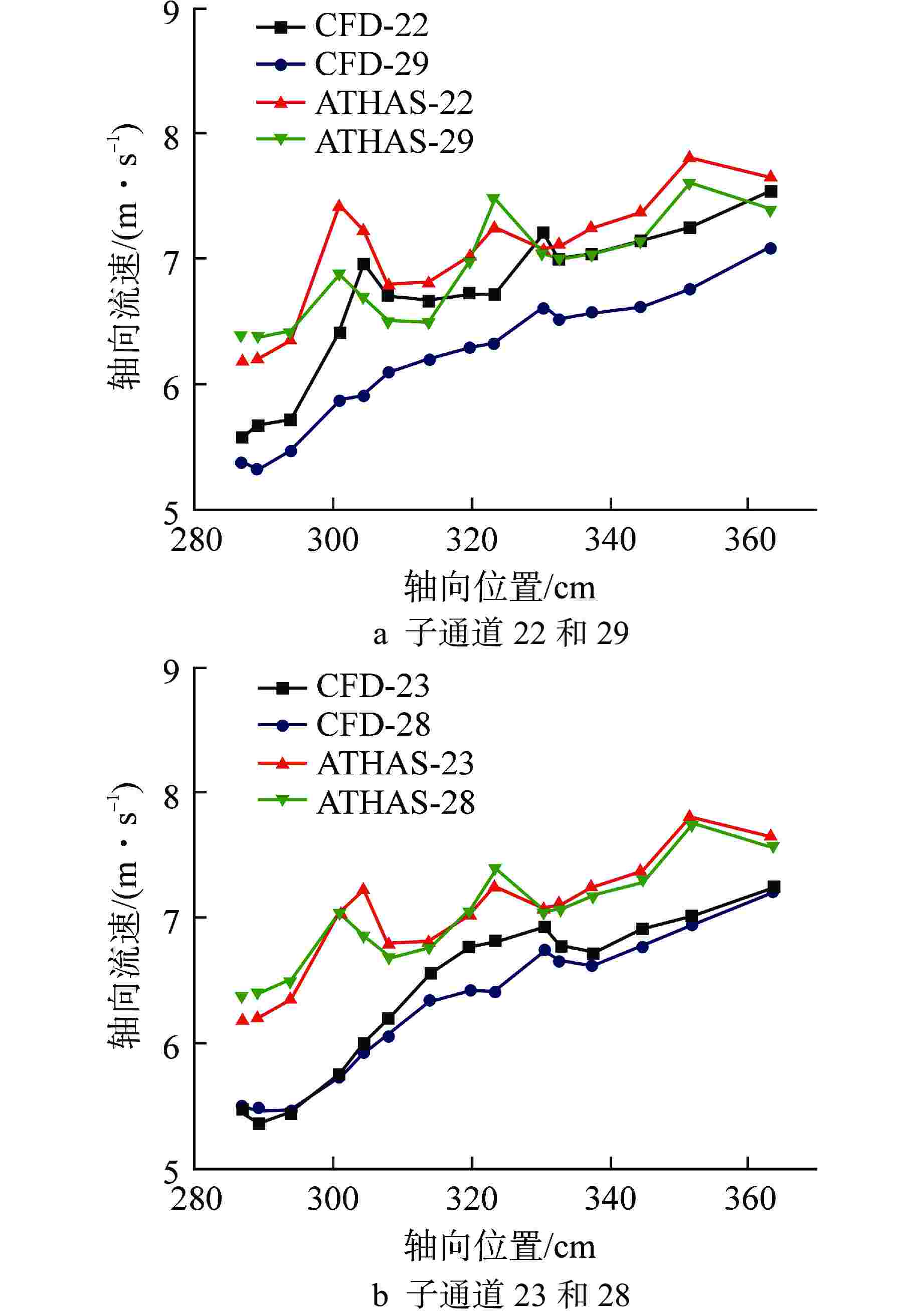

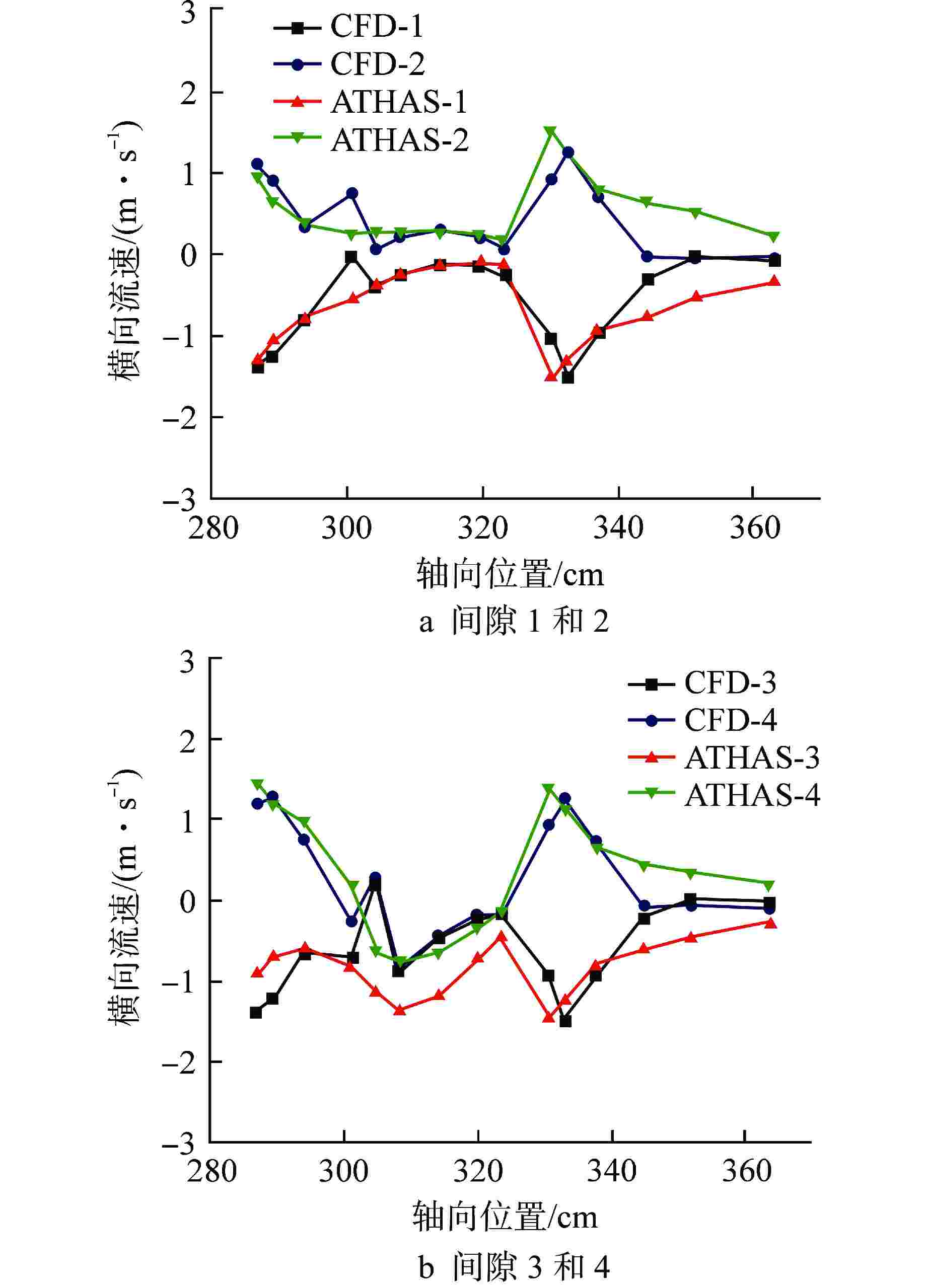

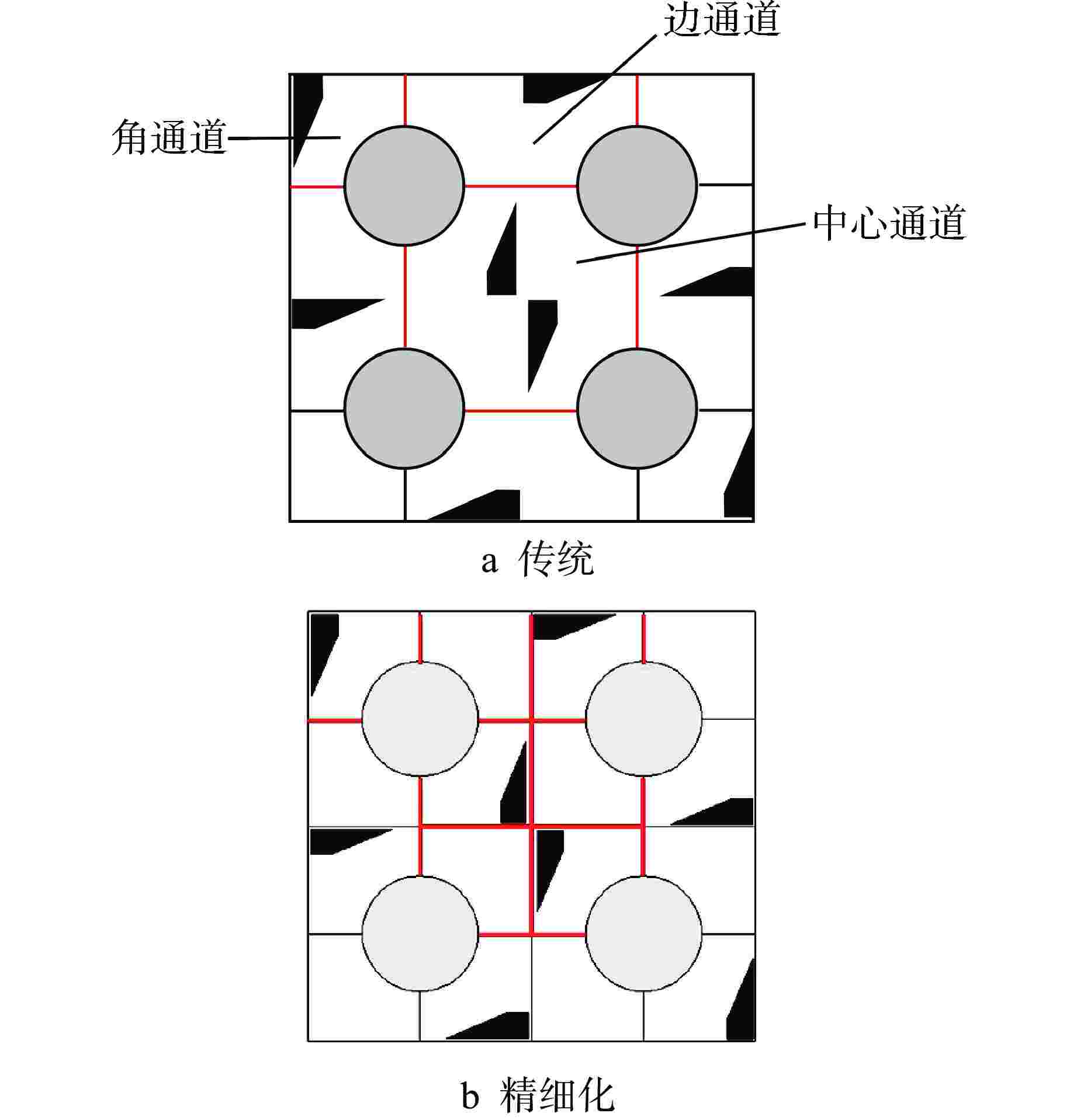

摘要: 为提高子通道程序在棒弯曲情况下对子通道局部参数变化的预测能力,本研究在对子通道进行精细划分的基础上,建立了精细化子通道棒弯曲模型对棒弯曲进行分析,并利用计算流体动力学(CFD)来验证精细化子通道棒弯曲模型对子通道轴流和横流的预测能力。通过CFD对模型进行验证,分析了棒弯曲段轴流和横流的变化趋势。结果表明,程序ATHAS和CFD对轴流和横流的变化趋势预测基本一致,精细化子通道棒弯曲模型可以较好地预测棒弯曲引起的轴流和横流的变化趋势。因此,精细化子通道棒弯曲模型可以预测弯曲棒对局部流场的影响,为临界热流密度的预测提供了基础。Abstract: In order to improve the prediction ability of the sub-channel code for the local parameter changes under rod-bowing condition, a fined sub-channel rod-bowing model was developed in this study. The model, based on a detailed division of the sub-channels, allows a comprehensive analysis of rod bowing. The prediction ability of the fined sub-channel rod-bowing model on the axial flow and cross flow of the sub-channel was validated by computational fluid dynamics (CFD). Based on the validity of the model by CFD, the analysis of the trends of axial and transverse flows in the rod-bowing section was conducted. The results show that the predictions of the changing trends of axial flow and cross flow by ATHAS and CFD are basically consistent, and the fined sub-channel rod bowing model can better predict the changing trend of axial flow and cross flow caused by rod bowing. Therefore, the fined sub-channel rod bowing model can predict the influence of bowing rod on local flow field, which provides a basis for the prediction of critical heat flux.

-

Key words:

- Fine sub-channels /

- Rod bowing /

- Distributed resistance model

-

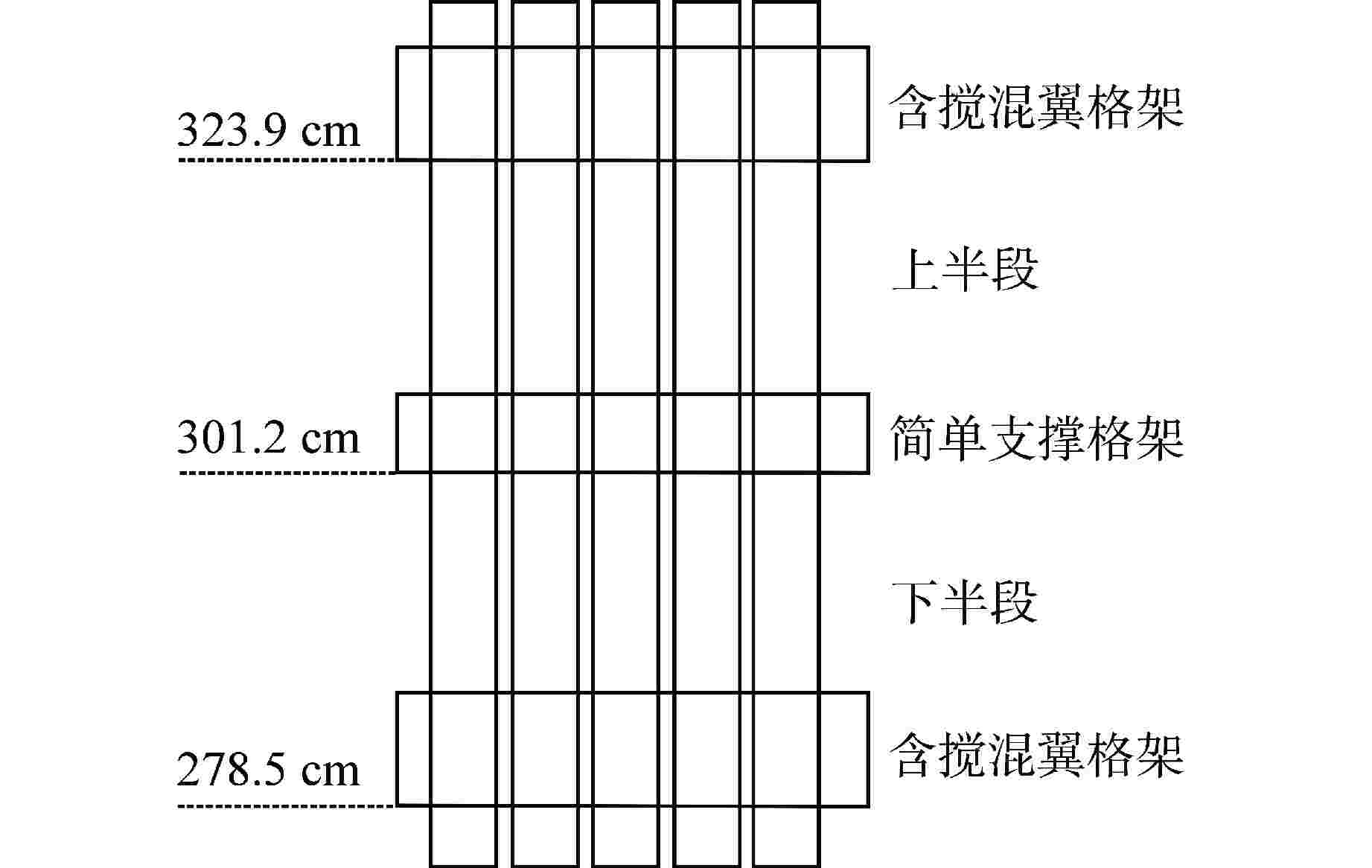

表 1 弯曲棒束几何参数

Table 1. Geometric Parameters of Bowing Rod Bundle

类型 参数值 燃料棒数目 25 燃料棒直径/mm 9.5 棒栅距/mm 12.6 棒到壁面距离/mm 2.5 通道流通面积/mm2 2440 加热长度/mm 3658 加热起始点/mm 500 棒束总长度/mm 4800 含搅混翼格架数目 7 含搅混翼格架轴向位置/mm 971、1425、1878、2332、

2785、3239、3747无搅混翼格架数目 2 无搅混翼格架轴向位置/mm 502.5、4255 简单支撑格架数目 8 简单支撑格架轴向位置/mm 737、1198、1651、2105、2559、3012、3493、4001 -

[1] DE LAMBERT S, CARDOLACCIA J, FAUCHER V, et al. Semi-analytical modeling of the flow redistribution upstream from the mixing grids in a context of nuclear fuel assembly bow[J]. Nuclear Engineering and Design, 2021, 371: 110940. doi: 10.1016/j.nucengdes.2020.110940 [2] MASTERSON R E, WOLF L. COBRA-IIIP: An improved version of COBRA for full-core light water reactor analysis[J]. Nuclear Engineering and Design, 1978, 48(2-3): 293-310. doi: 10.1016/0029-5493(78)90078-X [3] STEWART W C, WHEELER C L, CENA R J, et al. COBRA-IV: The Model and the Method, BNWL-2214[R]. Washington: Pacific Northwest Laboratories, 1977. [4] BLYTH T S. Improvement of COBRA-TF subchannel thermal-hydraulics code (CTF) using Computational fluid dynamics[R]. CASL Technical Report, 2015 [5] HWANG D H, KIM S J, SEO K W, et al. Accuracy and uncertainty analysis of PSBT benchmark exercises using a subchannel code MATRA[J]. Science and Technology of Nuclear Installations, 2012, 2012: 603752. [6] RAO Y F, ONDER E N, PODILA K. Assessment of subchannel code ASSERT-PV for supercritical applications[J]. The Journal of Supercritical Fluids, 2016, 117: 164-171. doi: 10.1016/j.supflu.2016.06.016 [7] HELLER A S, FARNSWORTH D A, MCGUINN E J. Statistical methods applied to fuel rod bow analysis[J]. Journal of Pressure Vessel Techn ology, 1987, 109(1): 147-152. doi: 10.1115/1.3264847 [8] DE LAMBERT S, CAMPIONI G, FAUCHER V, et al. Modeling the consequences of fuel assembly bowing on PWR core neutronics using a Monte-Carlo code[J]. Annals of Nuclear Energy, 2019, 134: 330-341. doi: 10.1016/j.anucene.2019.06.017 [9] PURAGLIESI R, MUKIN R, CLIFFORD I, et al. Comparison of computational fluid dynamics and subchannel numerical solutions of fuel assemblies characterised by bowing[C]//18th International Topical Meeting on Nuclear Reactor Thermal Hydraulics (NURETH-18). Portland: Curran Associates Inc., 2019. [10] MUKIN R, PURAGLIESI R, PECCHIA M, et al. Subchannel modeling of single rod bowing in a bundle geometry[J]. Nuclear Engineering and Design, 2018, 340: 347-369. doi: 10.1016/j.nucengdes.2018.09.032 [11] 刘伟,朱元兵,白宁,等. 热工水力子通道分析程序ATHAS的稳态验证[J]. 核科学与工程,2014, 34(2): 187-192. [12] NINOKATA H, EFTHIMIADIS A, TODREAS N E. Distributed resistance modeling of wire-wrapped rod bundles[J]. Nuclear Engineering and Design, 1987, 104(1): 93-102. doi: 10.1016/0029-5493(87)90306-2 [13] JIANG L, SHAN J Q. High-precision subchannel model for single and two phase flow in PWR rod bundles with mixing grids[C]//Proceedings of the 2022 29th International Conference on Nuclear Engineering. Shenzhen China: American Society of Mechanical Engineers (ASME), 2022. [14] REHME K. Simple method of predicting friction factors of turbulent flow in non-circular channels[J]. International Journal of Heat and Mass Transfer, 1973, 16(5): 933-950. doi: 10.1016/0017-9310(73)90033-1 [15] 张鸣远, 景思睿. 流体力学[M]. 西安: 西安交通大学出版社, 2013: 412-416 [16] 孔珑. 工程流体力学[M]. 第四版. 北京: 中国电力出版社, 2014: 118. [17] 董思莹,刘扬,单建强. 定位格架模型对子通道分析程序的影响研究[J]. 核动力工程,2017, 38(S1): 41-44. [18] REN B, XU S Y, GAN F J, et al. Numerical simulation of the effect of rod bowing on critical heat flux[J]. Kerntechnik, 2022, 87(1): 38-47. doi: 10.1515/kern-2021-0037 -

下载:

下载: