Numerical Analysis of Transient Process of HPR1000 Reactor Coolant Pump Shaft Jamming Accident Condition

-

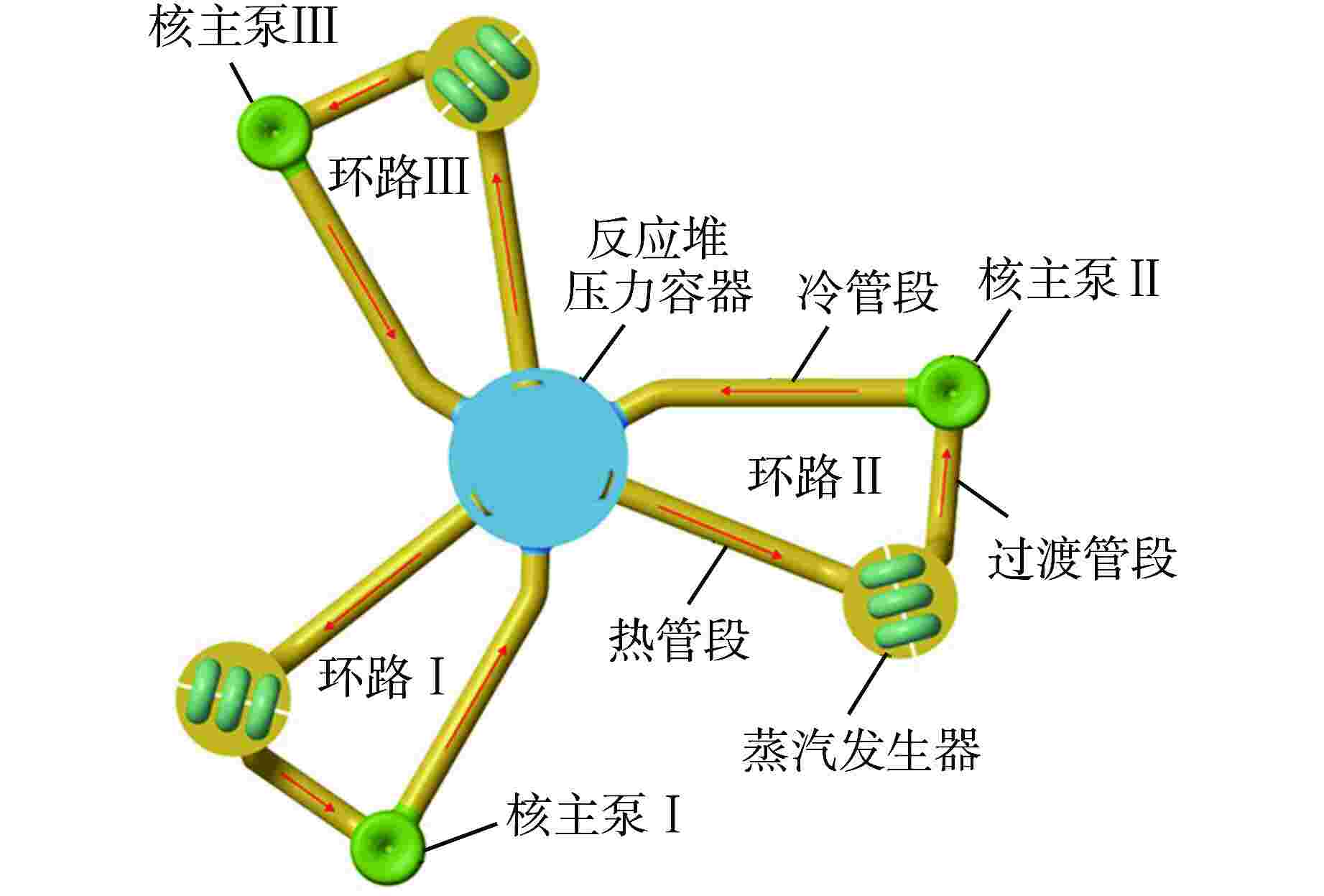

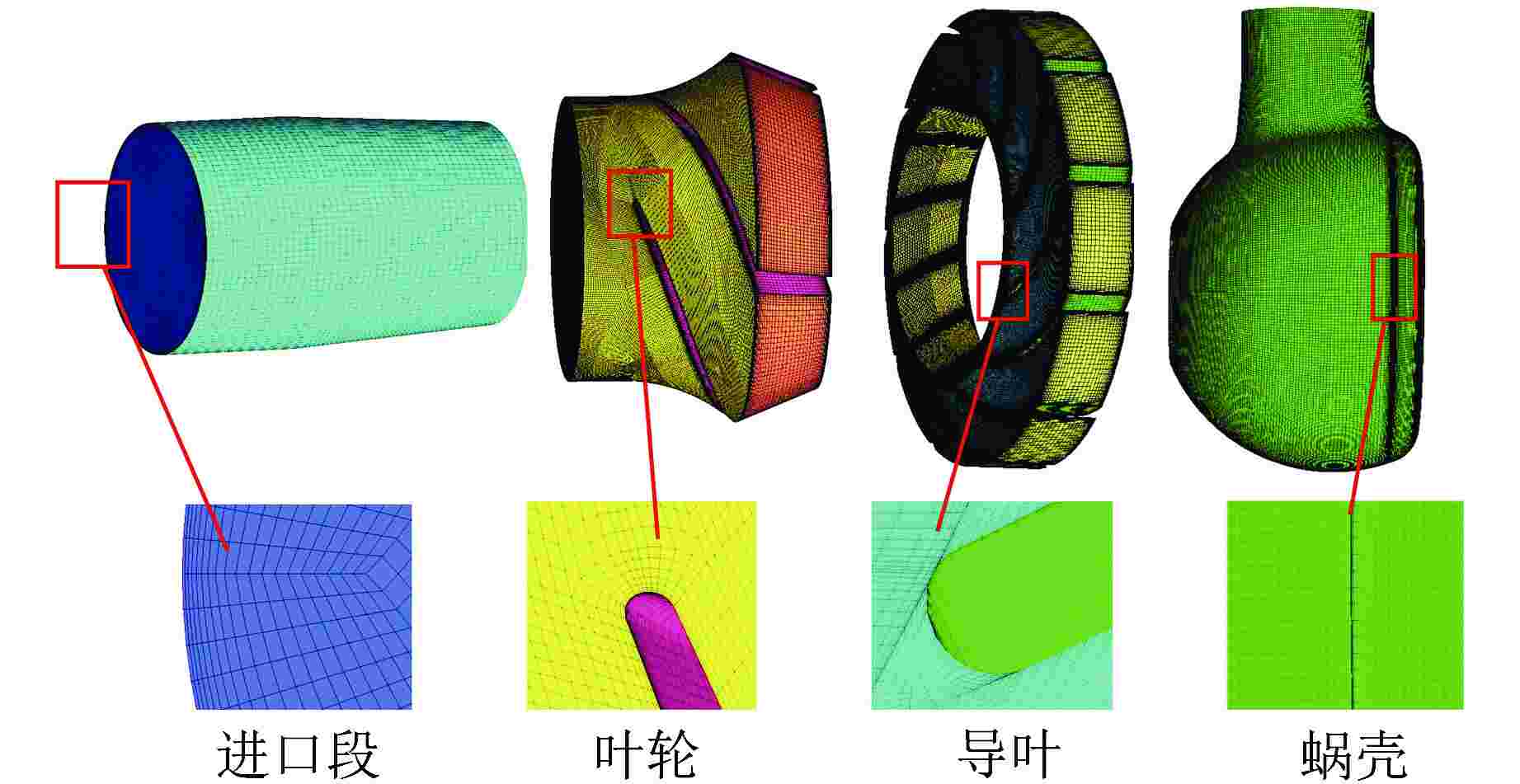

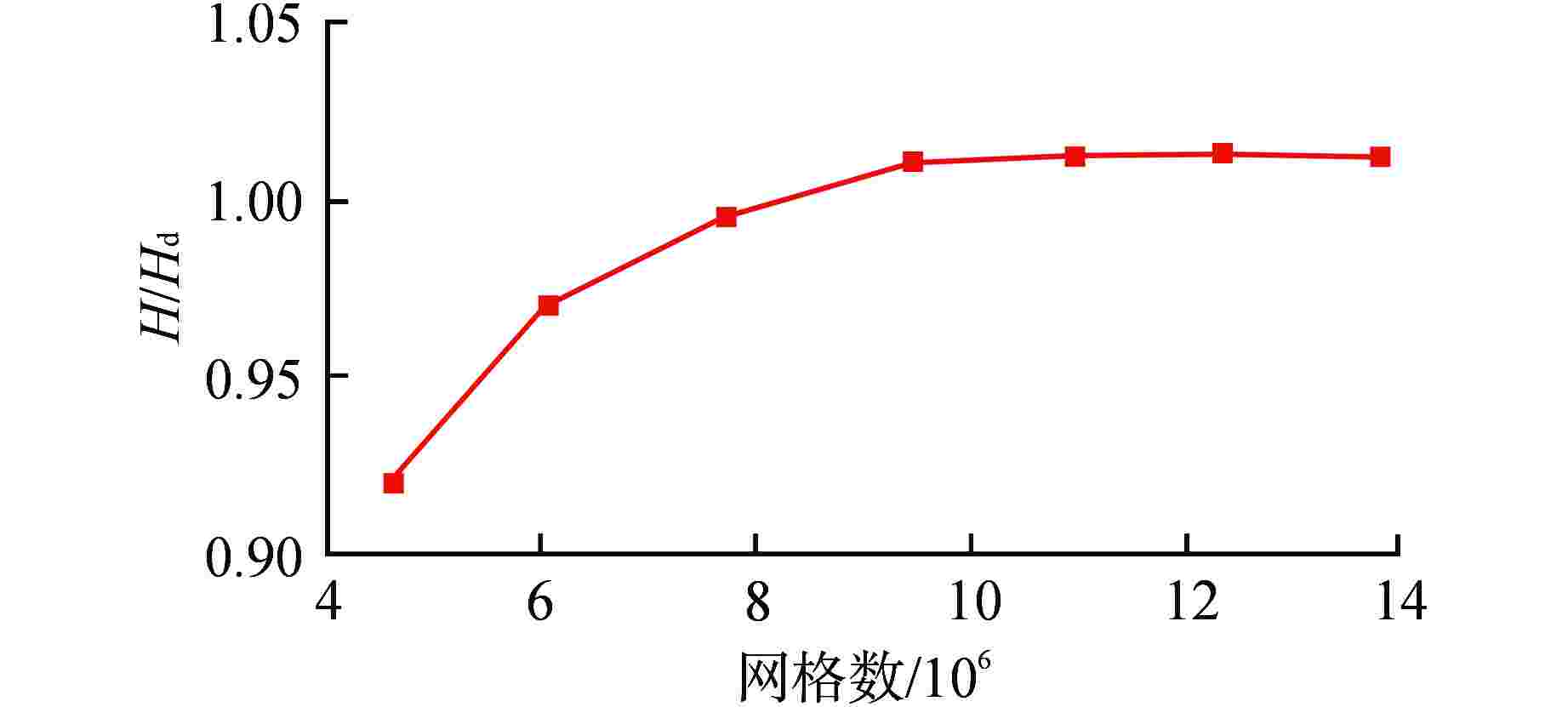

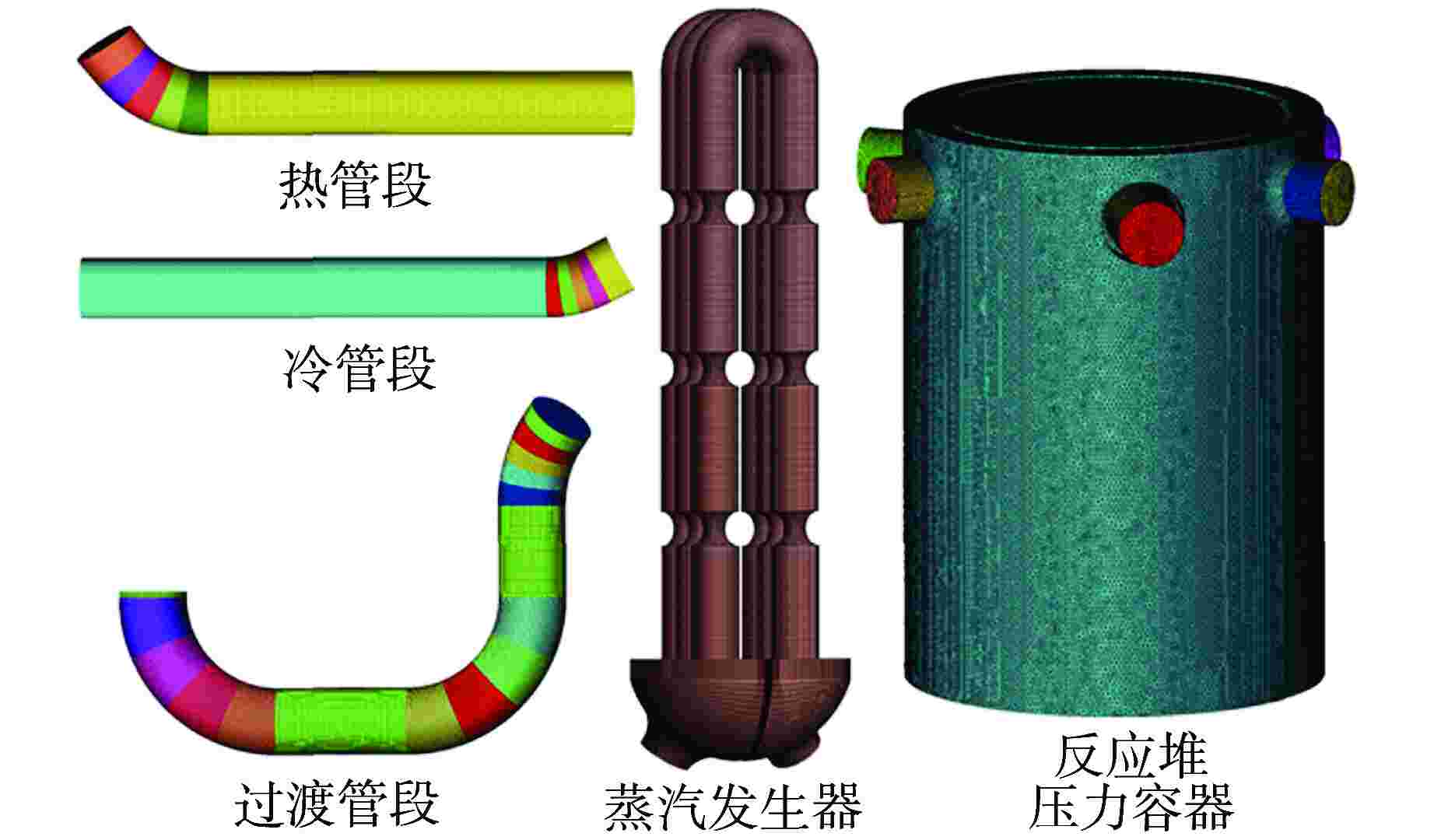

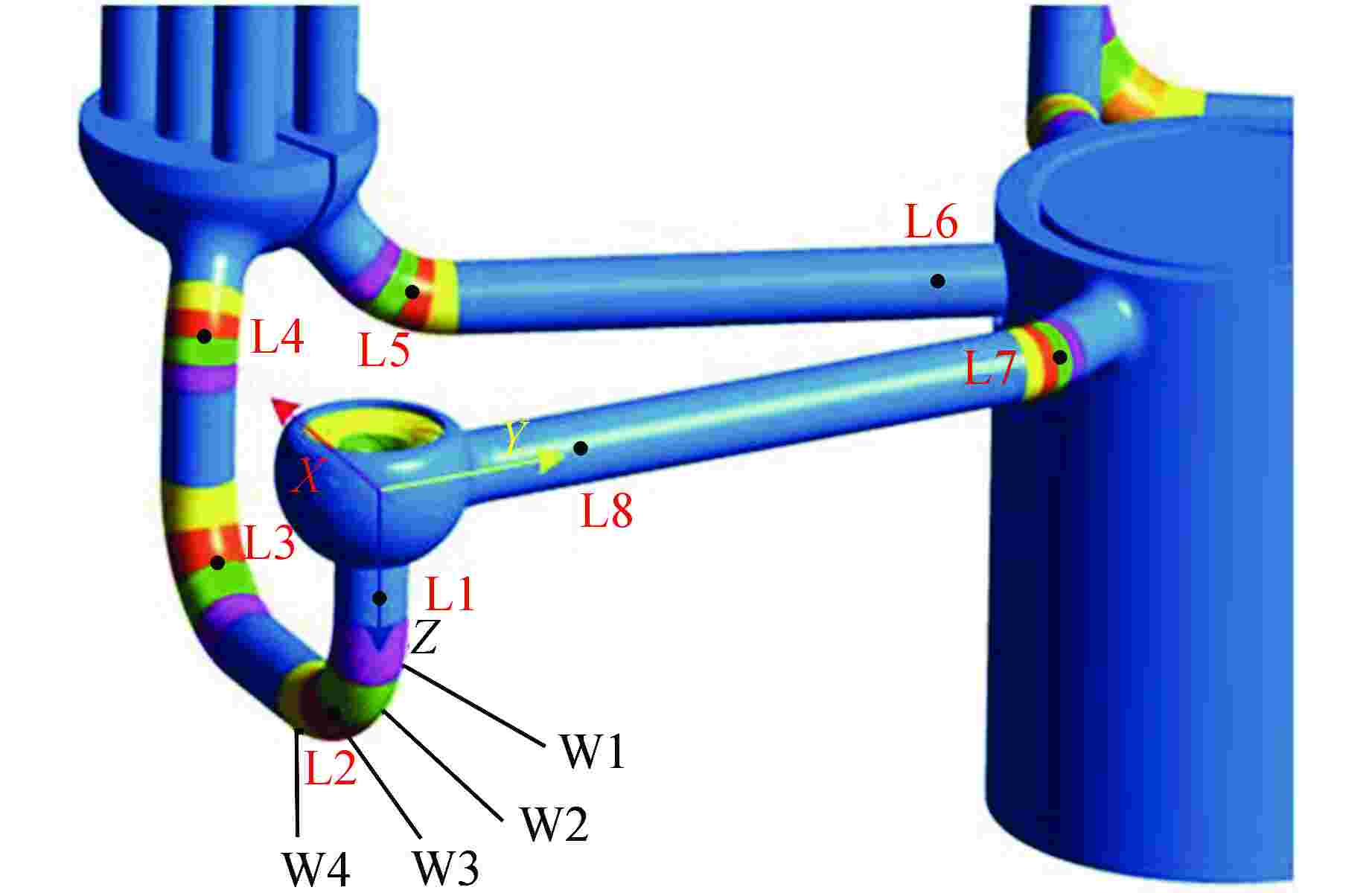

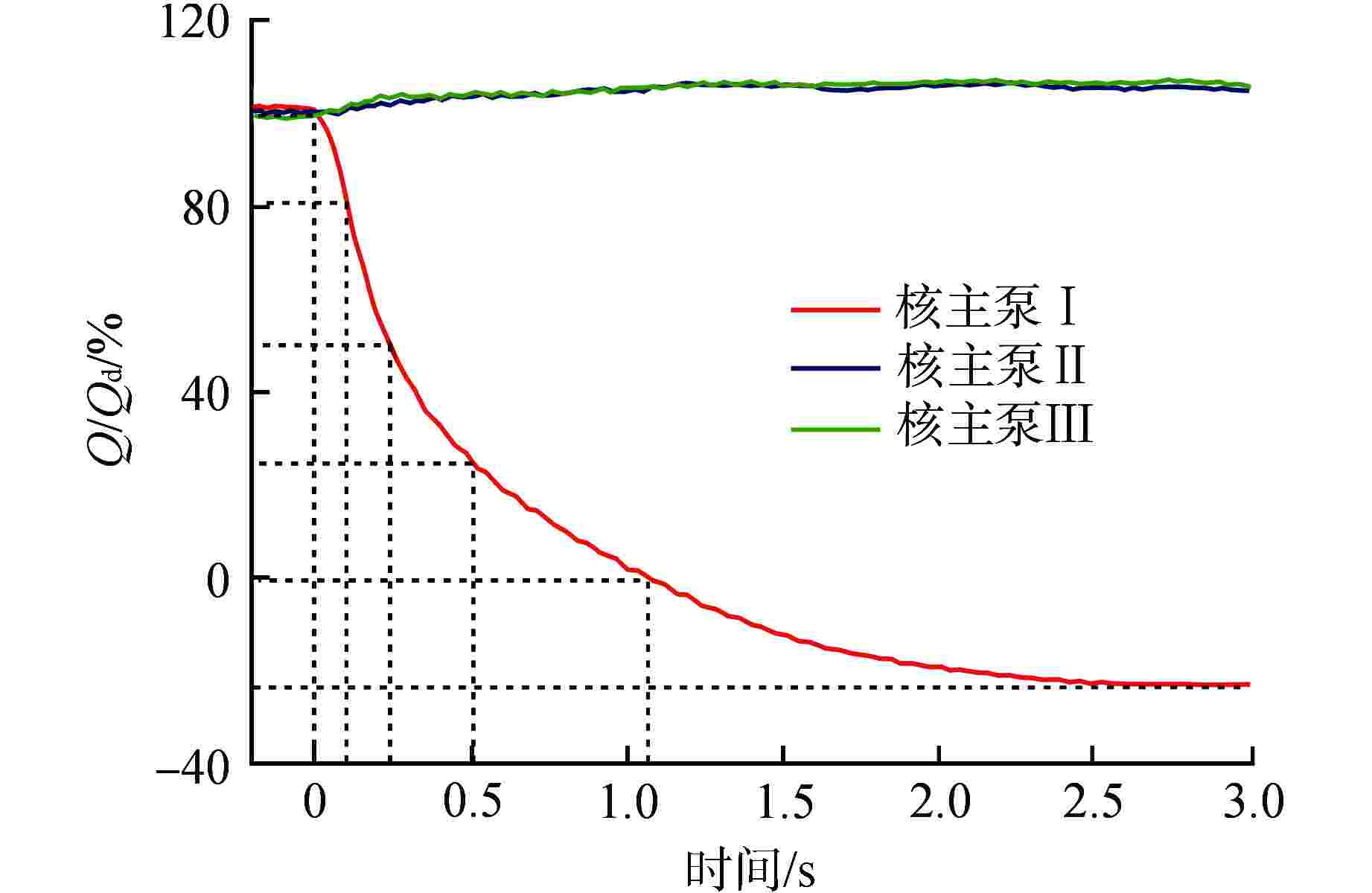

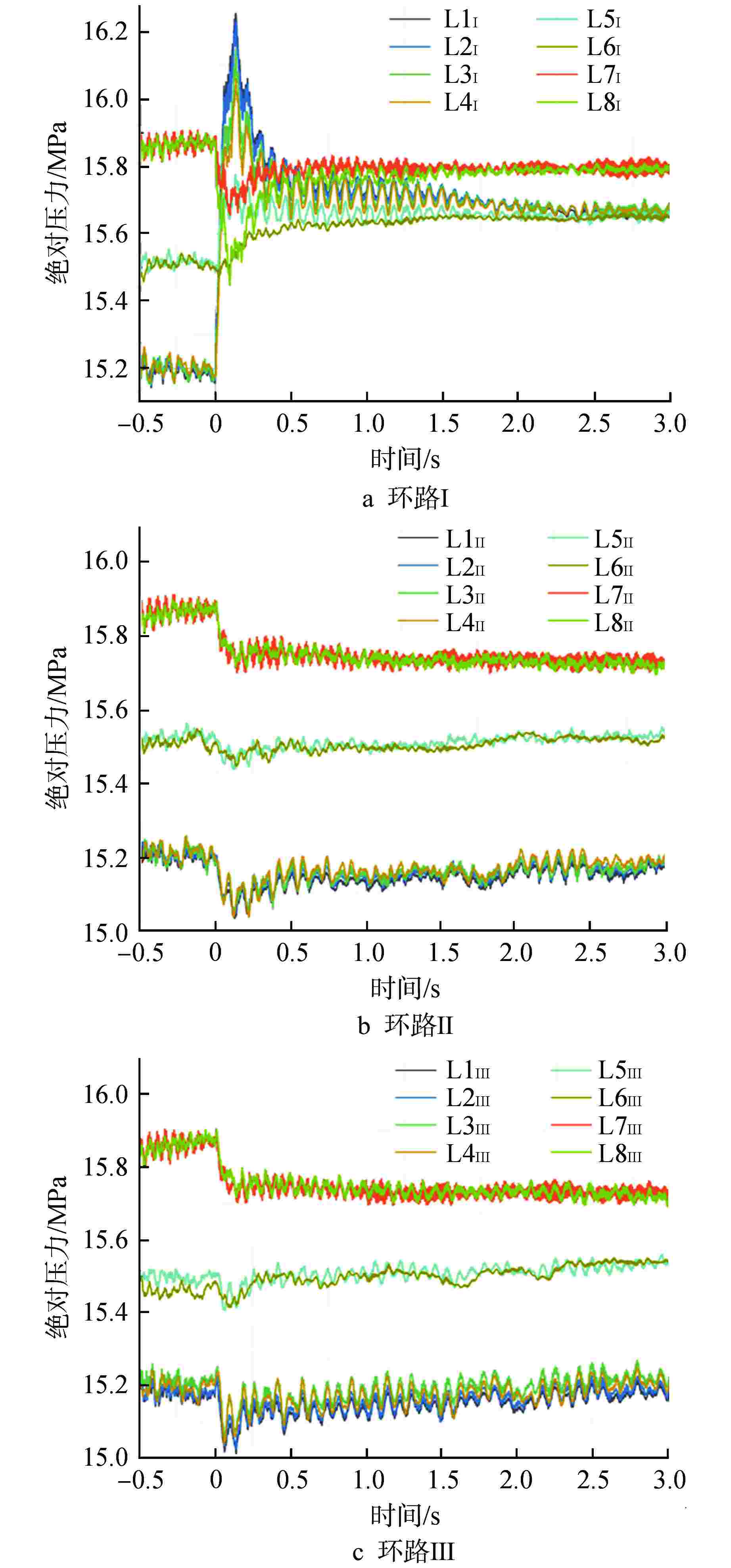

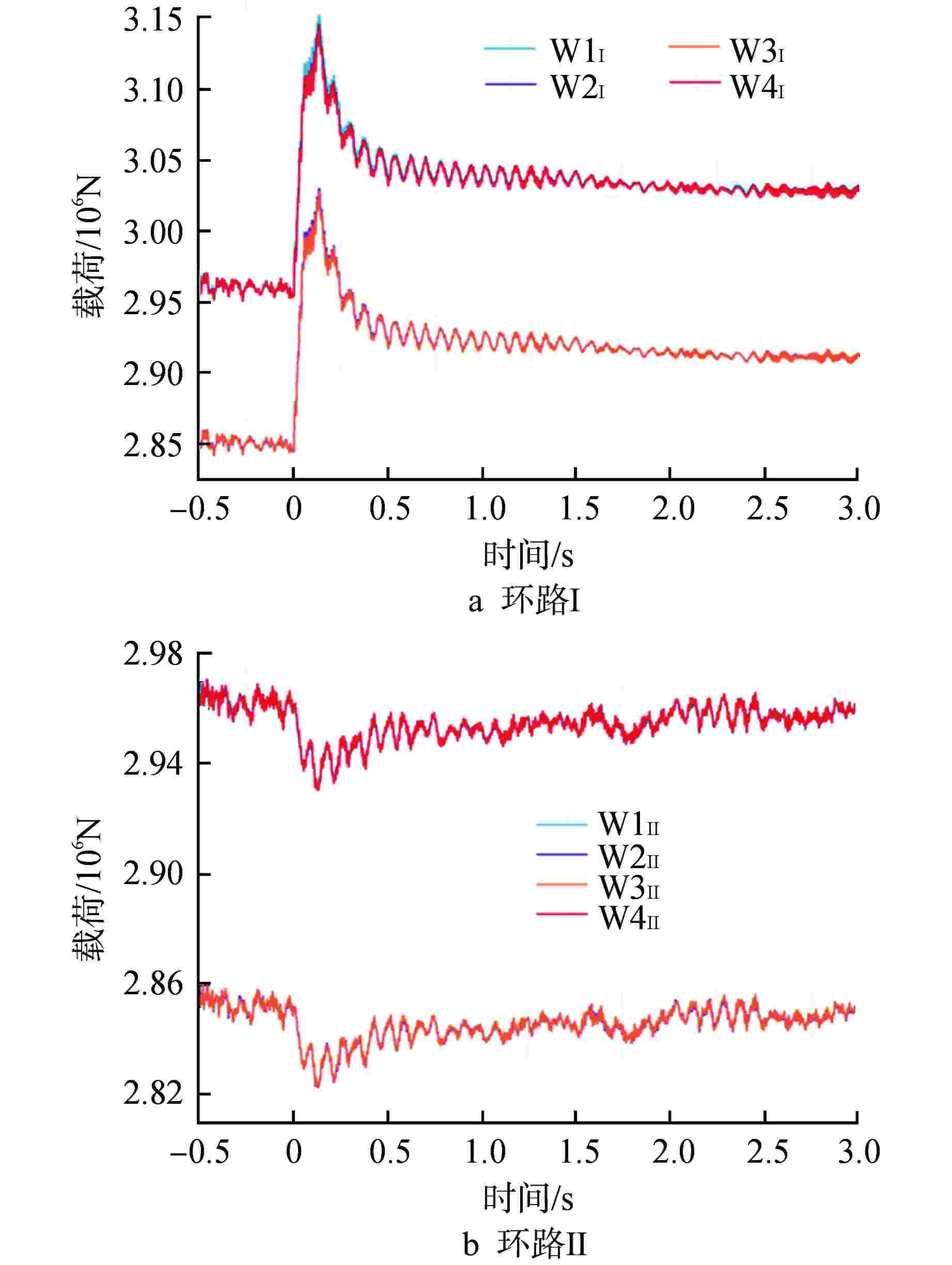

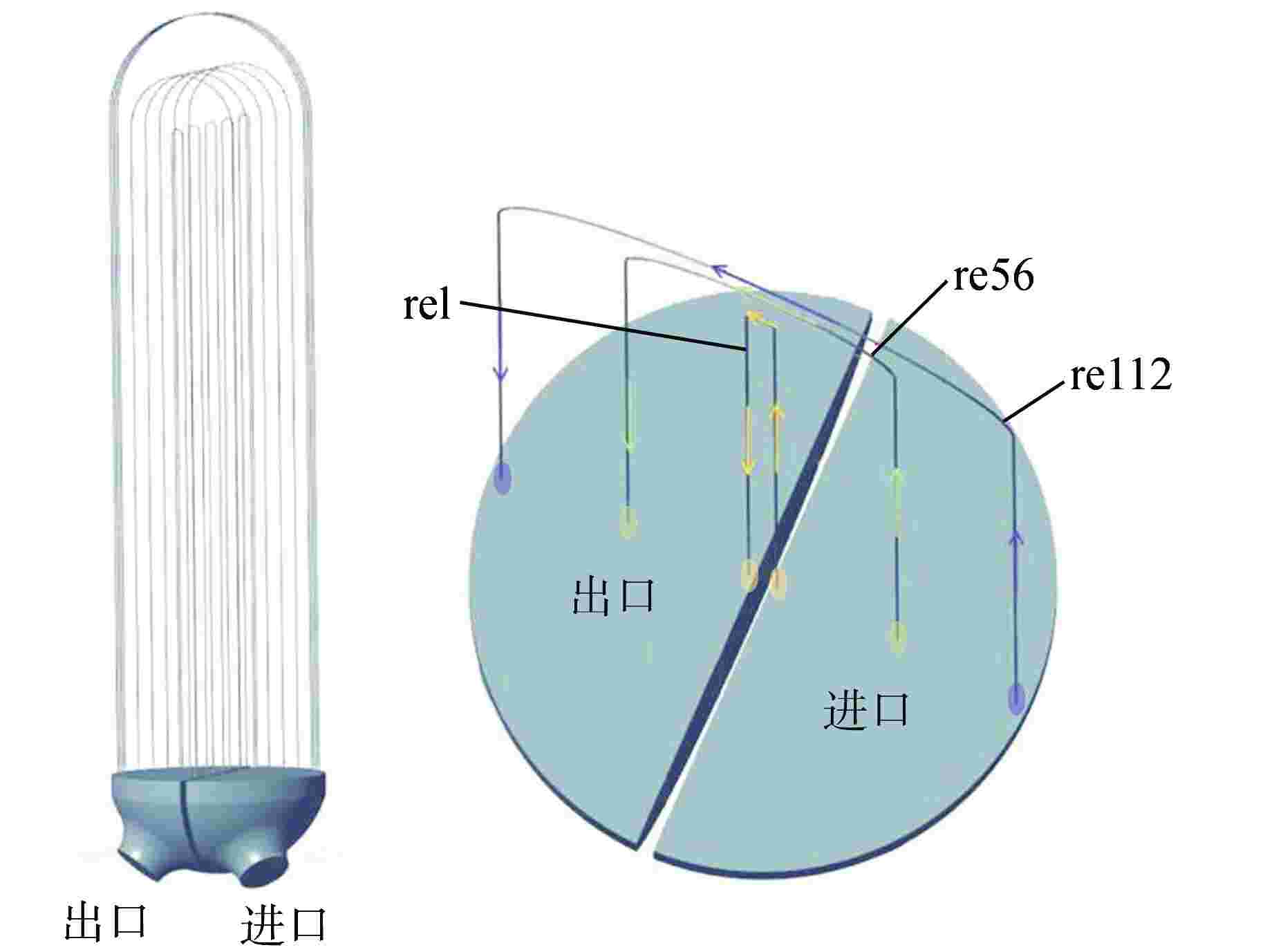

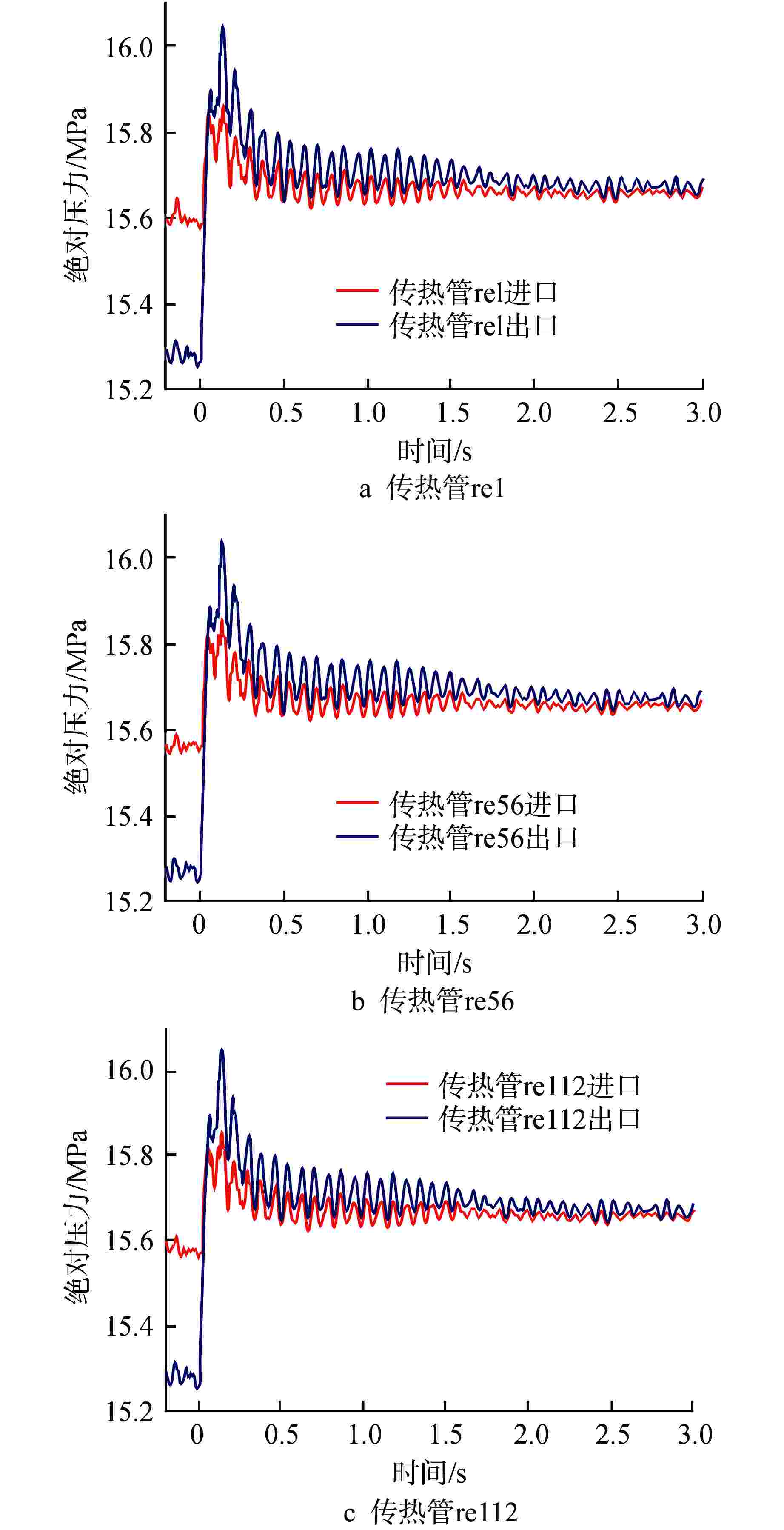

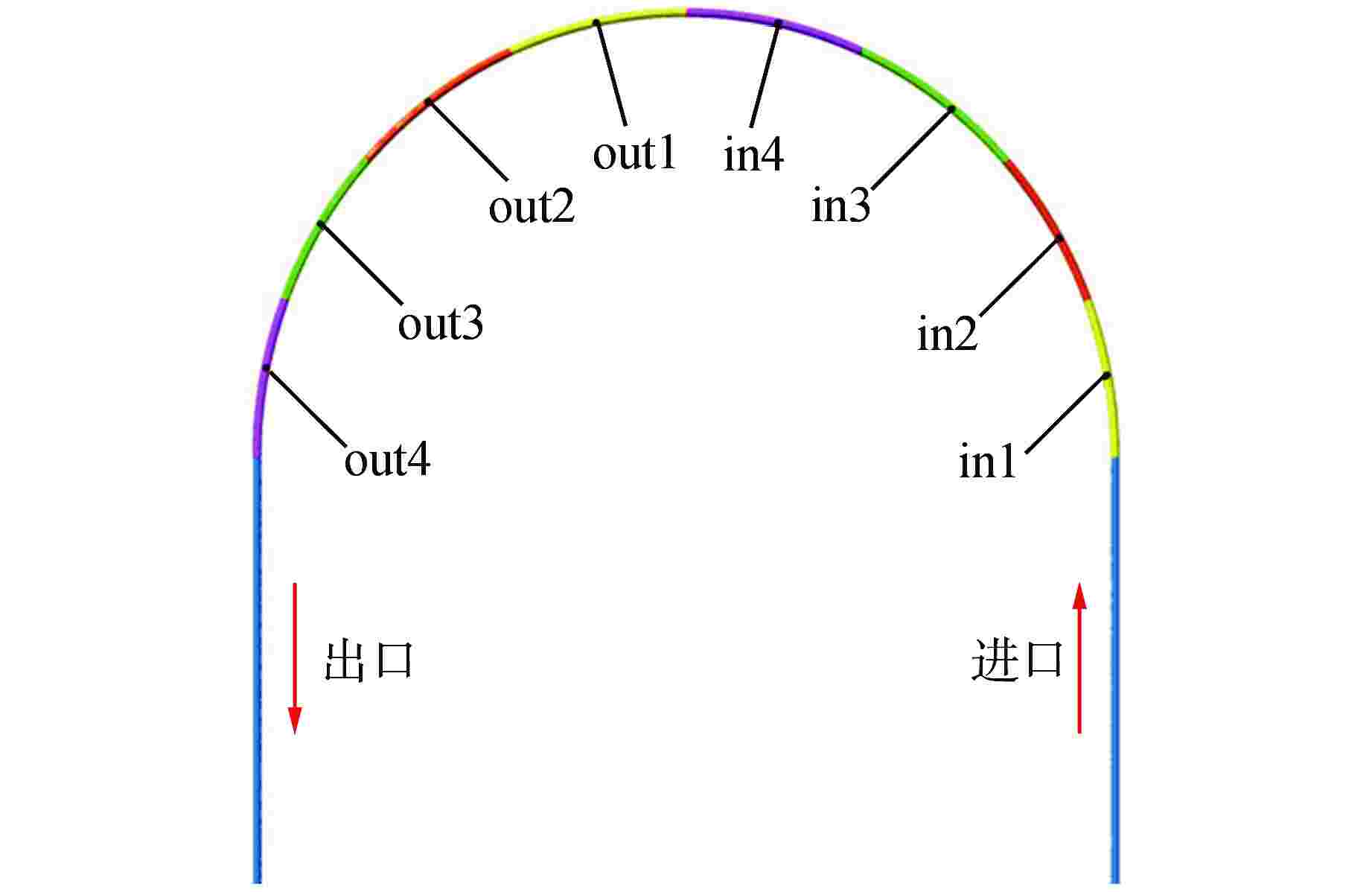

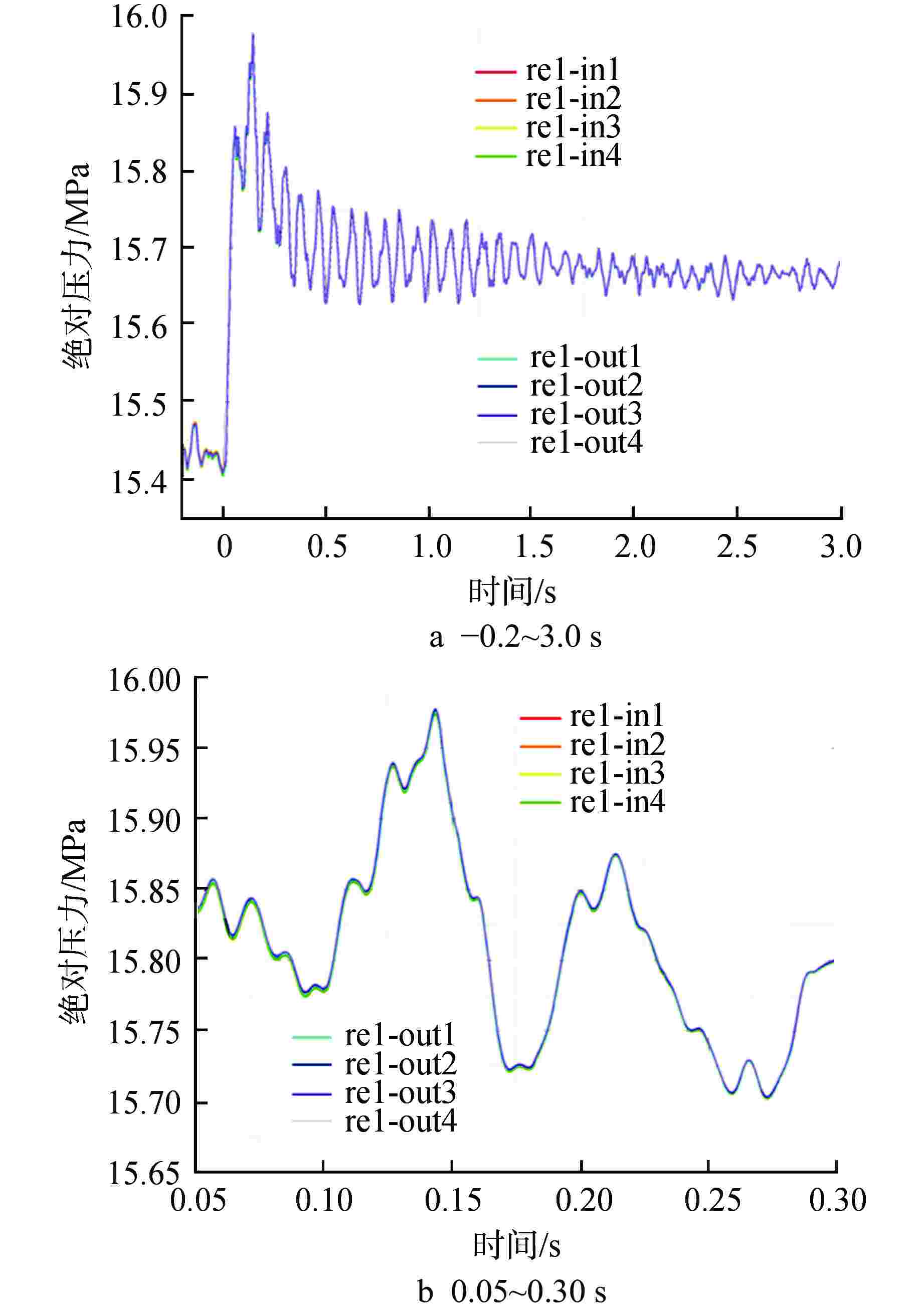

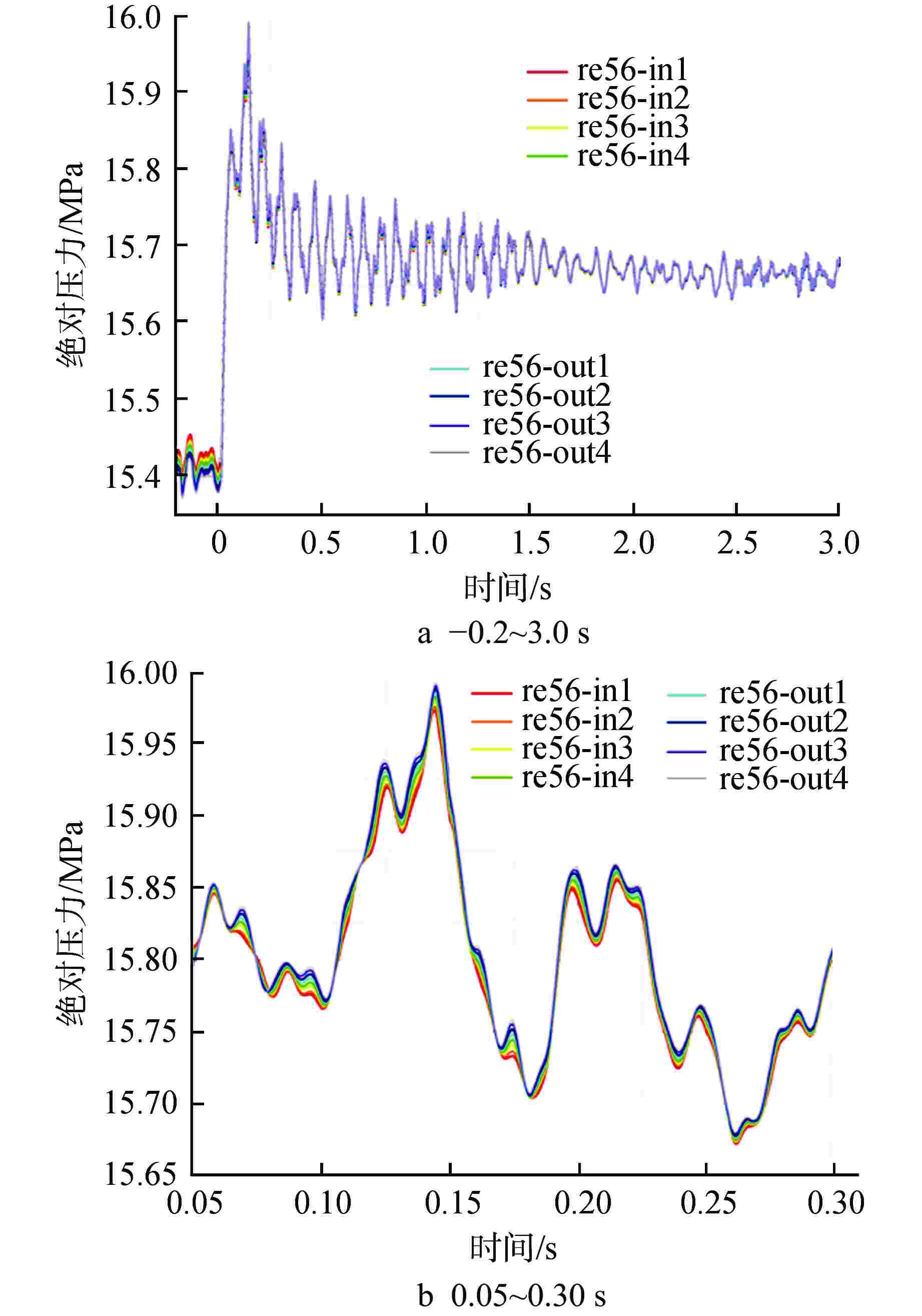

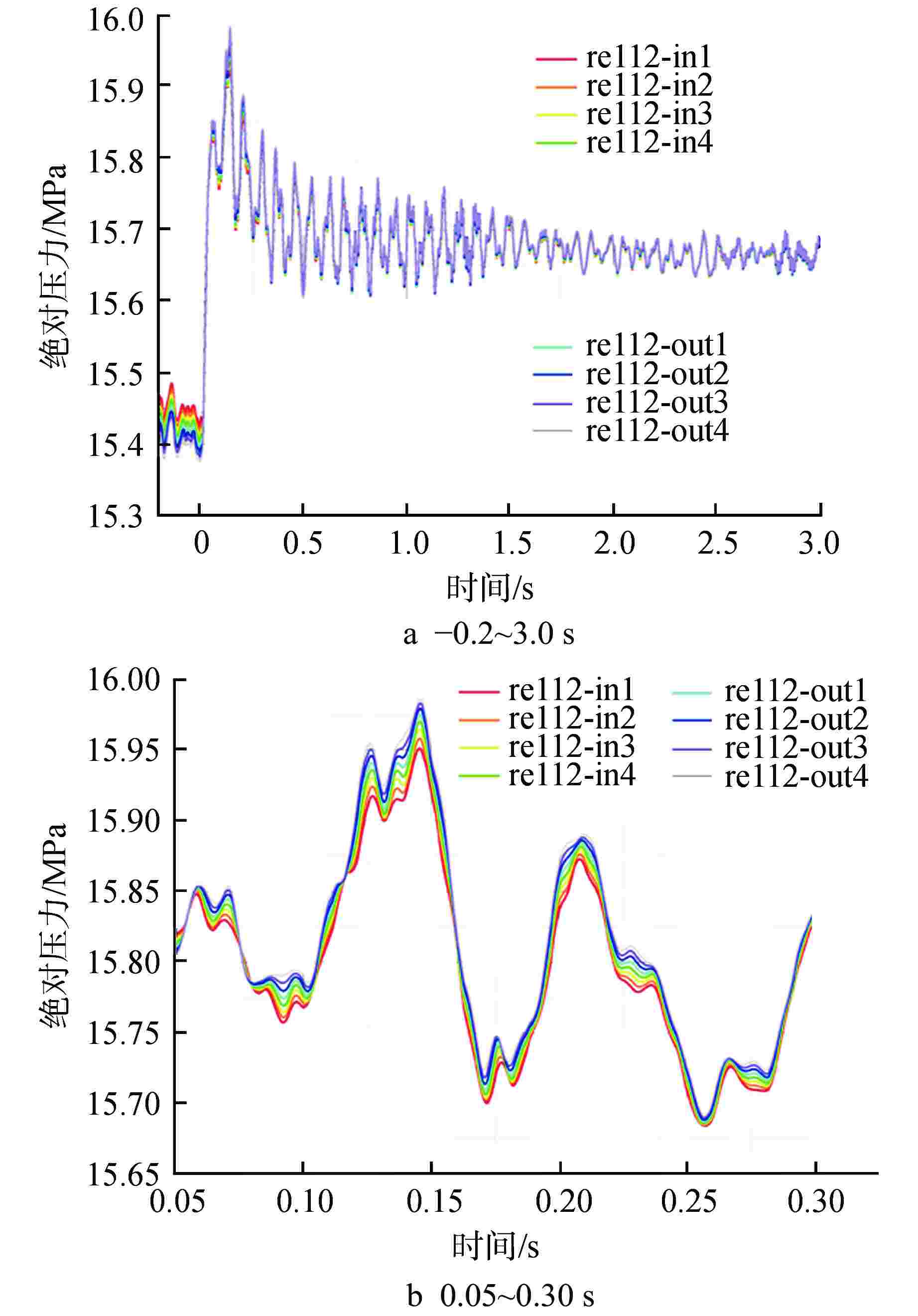

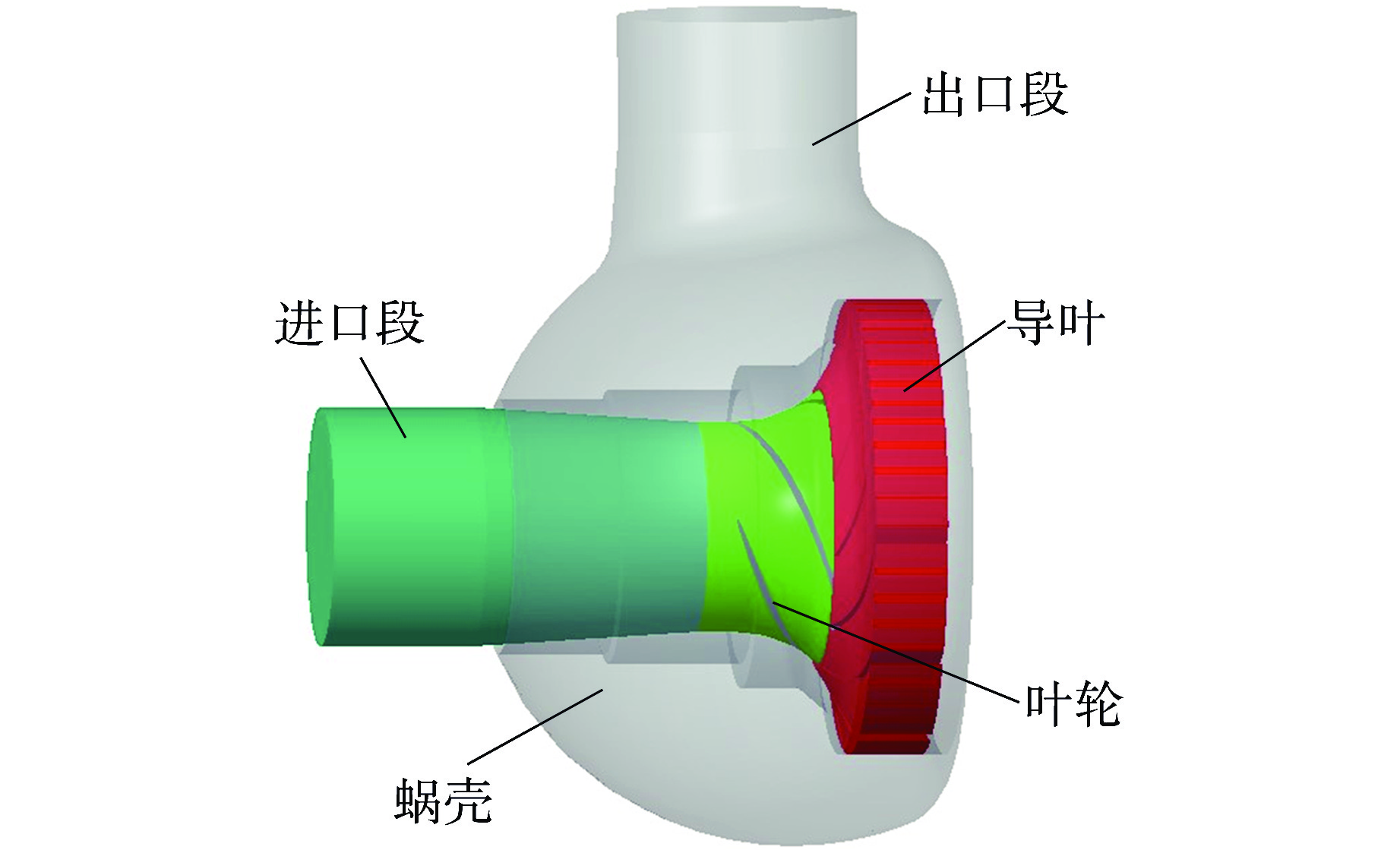

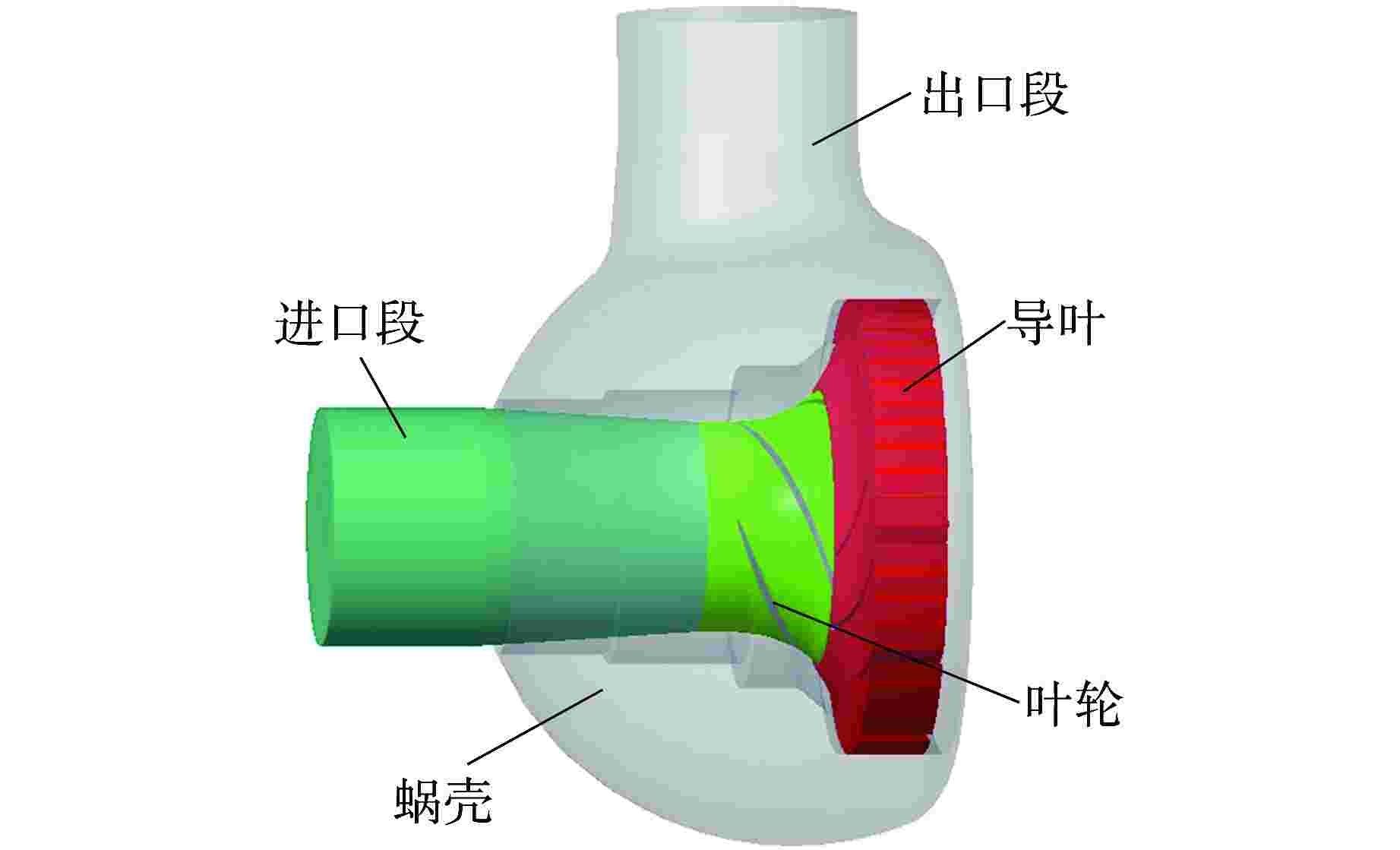

摘要: 为揭示核主泵卡轴事故工况管路瞬变机制,通过匹配核主泵和反应堆一回路系统管路阻力特性的关系,建立三环路反应堆冷却剂系统的简化水体模型。基于计算流体动力学(CFD)方法,再现了卡轴事故工况下系统内部的实际瞬态流动过程及其参数实时变化规律,构建了卡轴工况下反应堆冷却剂系统事故安全评估方法,对卡轴事故工况下系统主管路压力、过渡段弯头壁面载荷、三种典型曲率半径传热管压力的瞬态变化情况进行分析。研究表明:在卡轴事故过程中,事故环路中流量在下降至0 m3/h后反向增加,发生倒流现象;事故环路与其他环路的压力和壁面载荷在发生卡轴事故后均会发生剧烈变化后稳定,且事故环路变化程度更大;不同曲率半径传热管压力振荡规律基本一致,且沿各传热管进口至出口方向,监测点的压力峰值逐渐递增。Abstract: In order to reveal the pipeline transient mechanism under the shaft jamming accident condition of the reactor coolant pump (RCP), a simplified fluid domain model of the coolant system of the three-loop reactor was established by matching the relationship between the resistance characteristics of the reactor coolant pump and the pipeline of the primary system. Based on the computational fluid dynamics (CFD) method, the actual transient flow process and the real-time change rule of parameters in the reactor coolant system under shaft jamming accident condition were reproduced, and the accident safety evaluation method of reactor coolant system under shaft jamming accident condition was established. The transient changes of main pipeline pressure, wall load of transition bend and pressure of three typical heat transfer tubes with radius of curvature were analyzed under shaft jamming accident condition. The results show that: in the process of the shaft jamming accident, the flow in the accident loop decreases to 0 m³/h and then increases in reverse, and reverse flow occurs. The pressure and wall load of the accident loop and other loops will change dramatically after the shaft jamming accident, and the change degree of the accident loop is greater. The pressure oscillation law of the heat transfer tubes with different curvature radii is basically the same, and the peak pressure of the monitoring point increases gradually along the direction from the inlet to the outlet of each heat transfer tube.

-

表 1 核主泵额定参数

Table 1. Rated Parameters of Reactor Coolant Pump

参数名 参数值 额定流量/(m3·h−1) 24680 设计扬程/m 91 额定转速/(r·min−1) 1485 参考压力/MPa 15.5 水力效率/% 79 表 2 过渡段第一个弯头处的特殊时间壁面载荷值

Table 2. Wall Load Values at Special Time at the First Elbow of Transition Section

监测壁面 载荷/106 N 正常运行 峰值/谷值 卡轴结束 W1Ⅰ 2.960 3.152 3.031 W2Ⅰ 2.850 3.030 2.912 W3Ⅰ 2.850 3.028 2.912 W4Ⅰ 2.960 3.146 3.029 W1Ⅱ 2.962 2.931 2.959 W2Ⅱ 2.852 2.823 2.850 W3Ⅱ 2.852 2.823 2.850 W4Ⅱ 2.962 2.931 2.959 表 3 不同曲率半径传热管各监测点瞬态压力波峰值

Table 3. Peak Value of Transient Pressure Wave at Each Monitoring Point of Heat Transfer Tube with Different Radius of Curvature

监测点位置 压力/MPa Re1-3 Re56-3 Re112-2 in1 15.9743 15.9737 15.9510 in2 15.9750 15.9765 15.9581 in3 15.9754 15.9804 15.9643 in4 15.9757 15.9833 15.9700 out1 15.9763 15.9863 15.9750 out2 15.9772 15.9889 15.9793 out3 15.9778 15.9911 15.9830 out4 15.9783 15.9928 15.9860 -

[1] LONG Y, WANG D Z, YIN J L, et al. Numerical investigation on the unsteady characteristics of reactor coolant pumps with non-uniform inflow[J]. Nuclear Engineering and Design, 2017, 320: 65-76. doi: 10.1016/j.nucengdes.2017.04.027 [2] LONG Y, WANG D Z, YIN J L, et al. Experimental investigation on the unsteady pressure pulsation of reactor coolant pumps with non-uniform inflow[J]. Annals of Nuclear Energy, 2017, 110: 501-510. doi: 10.1016/j.anucene.2017.07.010 [3] 叶道星,赖喜德,文海罡,等. 核主泵断电惰转停机过渡过程性能特性研究[J]. 动力工程学报,2020, 40(7): 593-599. doi: 10.19805/j.cnki.jcspe.2020.07.011 [4] 黎义斌,瞿泽晖,郭艳磊,等. 核主泵卡轴事故瞬变过程的水动力特性研究[J]. 核动力工程,2023, 44(2): 177-184. doi: 10.13832/j.jnpe.2023.02.0177 [5] 黄晨,胡嘉杨,赖旭. 三机式抽水蓄能电站三机运行方式下水泵停泵过渡过程研究[J]. 水电能源科学,2018, 36(11): 148-152. [6] 刘金昊,吴建华. 西山供水工程事故停泵水力过渡过程计算及水锤防护[J]. 水电能源科学,2021, 39(7): 113-116. [7] 钟伟源. 卡轴事故工况下核主泵流固耦合瞬变特性研究[D]. 镇江: 江苏大学,2018. [8] QU Z H, LI Y B, PAN J, et al. Study on pressure surge characteristics of reactor coolant pump shaft stuck accident condition based on wavelet analysis[J]. Nuclear Engineering and Design, 2022, 397: 111921. doi: 10.1016/j.nucengdes.2022.111921 [9] LI D H, LI Y B, ZHANG F, et al. Study on hydraulic characteristics of reactor coolant pump shutdown transition process based on primary circuit closed system[J]. Frontiers in Energy Research, 2022, 9: 808393. doi: 10.3389/fenrg.2021.808393 [10] FARHADI K. Transient behaviour of a parallel pump in nuclear research reactors[J]. Progress in Nuclear Energy, 2011, 53(2): 195-199. doi: 10.1016/j.pnucene.2010.05.001 [11] FARHADI K, BOUSBIA-SALAH A, D’AURIA F. A model for the analysis of pump start-up transients in Tehran research reactor[J]. Progress in Nuclear Energy, 2007, 49(7): 499-510. doi: 10.1016/j.pnucene.2007.07.006 [12] KIM S G, LEE K B, KIM K Y. Water hammer in the pump-rising pipeline system with an air chamber[J]. Journal of Hydrodynamics, 2014, 26(6): 960-964. doi: 10.1016/S1001-6058(14)60105-0 [13] TANG J J, LU D G, LIANG J T, et al. Numerical simulation on asymmetrical three-dimensional thermal and hydraulic characteristics of the primary sodium pool under the pump stuck accident in CEFR[J]. Nuclear Science and Engineering, 2021, 195(5): 478-495. doi: 10.1080/00295639.2020.1834314 [14] BEHROOZI A M, VAGHEFI M. Numerical investigation of water hammer due to transient in parallel pumps[J]. International Journal of Civil Engineering, 2021, 19(12): 1415-1425. doi: 10.1007/s40999-021-00640-w [15] LIU Y F, ZHOU J X, GUO Q, et al. 3-D CFD simulation of transients in multiple pump system with some pumps being stopped[J]. Journal of Hydrodynamics, 2021, 33(3): 583-592. doi: 10.1007/s42241-021-0042-8 [16] 黄伟,张文其,陶文铨,等. 蒸汽发生器下封头/主泵连接处流动特性试验研究[J]. 核动力工程,2004, 23(S1): 38-42. [17] 余红星,黄代顺. 秦山核电二期工程设计基准事故水力学载荷分析[J]. 核动力工程,2003, 24(S2): 102-105. [18] 李文姬,吕红,张洁. LOCA水力载荷分析软件HLPS的开发与验证[J]. 核动力工程,2021, 42(4): 159-165. doi: 10.13832/j.jnpe.2021.04.0159 -

下载:

下载: