Verification and Validation of NECP-Bamboo Based on Measurement Data from Nuclear Power Plants

-

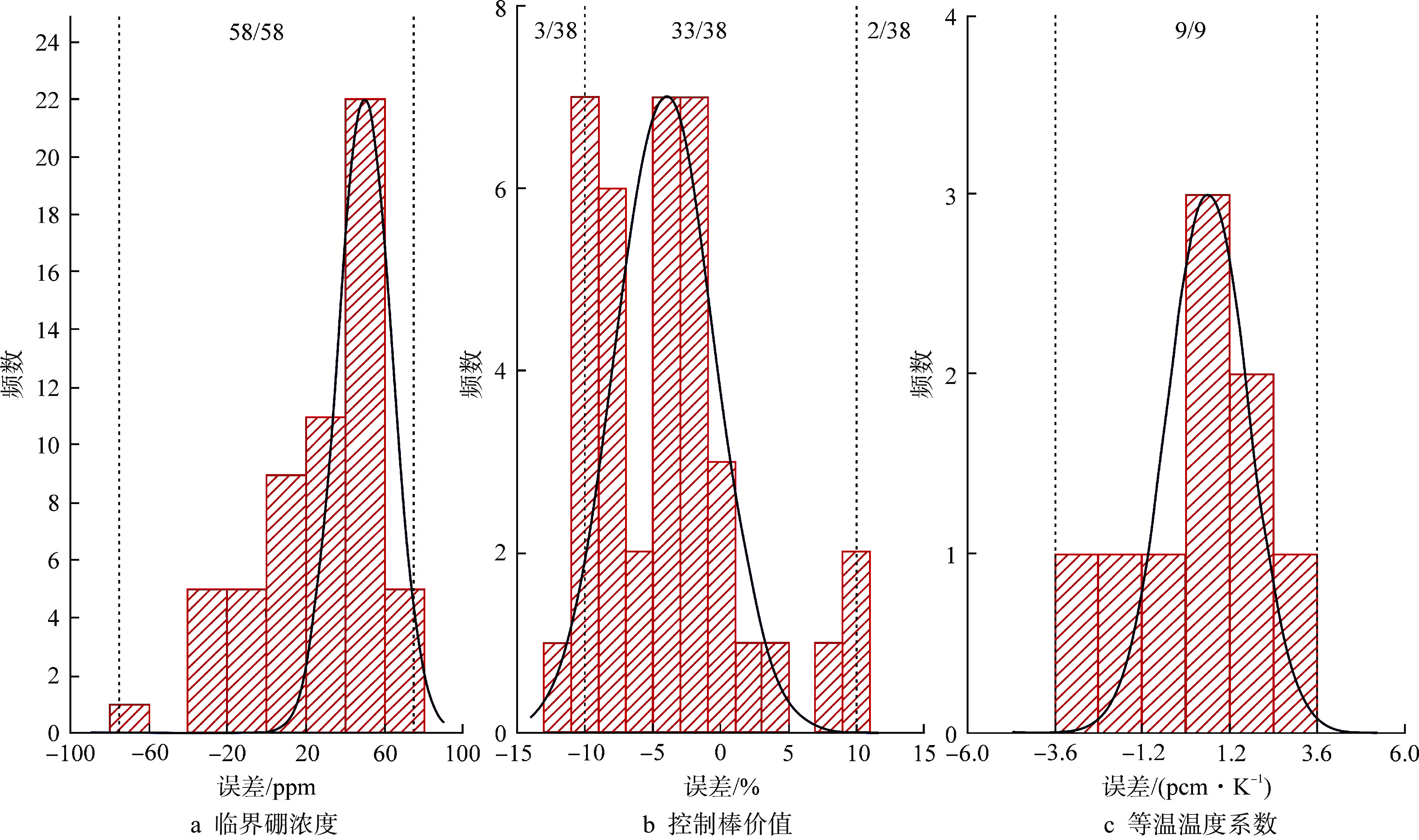

摘要: 验证与确认是软件生命周期中的重要环节,反映软件研发真正走向实际应用的过程,是软件从“书架”走向“货架”的重要标志。基于核电厂包括CNP300、M310、CNP650、BEAVRS和HPR1000在内的5种型号商用压水堆共计48个运行循环的实际测量数据,对NECP-Bamboo软件进行了验证与确认。结果表明,采用NECP-Bamboo软件计算获得的控制棒价值、温度系数、临界硼浓度和组件功率分布等堆型关键参数的计算值与实测值误差均能满足工业限值的要求。各个型号堆型相应关键参数误差的95%置信区间范围汇总如下:临界硼浓度为[−37.80,35.39]ppm,控制棒的价值为[−6.18%,3.68%],温度反应系数为[−3.27,2.99] pcm/K,组件相对功率在大于和小于0.9时分别为[−0.64%,−0.12%]和[1.18%,2.94%]。Abstract: The verification and validation (V&V) are important aspects in the life cycle of engineering software, and reflect the process of software development to practical application. They are also significant symbols of software from "bookshelf" to "goods shelf". In this paper, V&V for the software NECP-Bamboo were carried out based on the actual measurement data of five types of commercial pressurized water reactors, including CNP300, M310, CNP650, BEAVRS and HPR1000, for a total of 48 operation cycles. The results show that the errors between the calculated values and the measured values of the key reactor parameters, such as control rod worth, temperature coefficient, critical boron concentration and assembly power distribution, obtained by using NECP-Bamboo can meet the requirements of industrial limits. The 95% confidence interval range of the corresponding key parameter errors of various types of reactors is summarized as follows: [−37.80, 35.39]ppm for critical boron concentration, [−6.18%, 3.68%] for control rod worth, [−3.27, 2.99] pcm/K for the reactivity coefficient of temperature, [−0.64%, −0.12%] for the assembly power distribution when the relative power is greater than 0.9, and [1.18%, 2.94%] for that when the relative power is less than 0.9.

-

Key words:

- NECP-Bamboo /

- CNP300 /

- M310 /

- CNP650 /

- BEAVRS /

- HPR1000 /

- Verification and validation

-

表 1 BEAVRS启动物理试验计算结果

Table 1. Calculation Results of Start-up Physics Test for BEAVRS

参数 循环 控制棒状态 测量值 计算值 各参数计算误差 临界硼浓度 C1 棒组全提 975ppm 979ppm 4ppm C2 棒组全提 1405ppm 1378ppm −27ppm 控制棒价值 C1 D棒组 788pcm 802pcm 1.78% C棒组(D棒组插入) 1203pcm 1237pcm 2.83% B棒组(D、C棒组插入) 1171pcm 1220pcm 4.18% A棒组(D、C、A棒组插入) 548pcm 571pcm 4.20% SE棒组(D、C、B、A棒组插入) 461pcm 477pcm 3.47% SD棒组(D、C、B、A、SE棒组插入) 772pcm 784pcm 1.55% SC组(D、C、B、A、SE、SD棒组插入) 1099pcm 1120pcm 1.91% 等温温度系数 C1 棒组全提 −1.75 pcm/K −2.72 pcm/K −1.0 pcm/K C2 棒组全提 1.70 pcm/K 1.04 pcm/K −0.7 pcm/K 表 2 HPR1000机组启动物理试验计算结果

Table 2. Calculation Results of Start-up Physics Test for HPR1000

参数 循环 控制棒状态 各参数计算误差 临界硼浓度 U1 棒组全提 −23ppm R棒组插入 −24ppm U2 棒组全提 −1ppm R棒组插入(0步) −2ppm R棒组插入(5步) −2ppm 控制棒价值 U1 R棒组插入 −0.06% G1棒组插入 −2.11% G2棒组插入 −1.51% N1棒组插入 −1.64% N2棒组插入 2.86% SA棒组插入 2.40% SB棒组插入 −3.17% SC棒组插入 1.67% SD棒组插入 −2.90% U2 R棒组插入 2.12% G1棒组插入 −2.12% SB棒组插入 3.95% SA棒组插入 1.85% N2棒组插入 6.18% N1棒组插入 −3.11% 等温温度系数 U1 棒组全提 −3.4 pcm/K R棒组插入 −2.8 pcm/K U2 棒组全提 −1.1 pcm/K R棒组插入 −0.6 pcm/K -

[1] JONES A. ISO 12207 Software life cycle processes — fit for purpose?[J]. Software Quality Journal, 1996, 5(4): 243-253. doi: 10.1007/BF00209183 [2] 郑骈垚,钟柏,马象睿. 核电厂DCS软件验证与确认标准体系分析[J]. 自动化仪表,2017, 38(3): 13-17. doi: 10.16086/j.cnki.issn1000-0380.201703004 [3] 吴宏春,曹良志. 压水堆核电厂燃料管理[M]. 西安: 西安交通大学出版社,2021: 61-96. [4] LI Y Z, ZHANG B, HE Q M, et al. Development and verification of PWR-core fuel management calculation code system NECP-Bamboo: part I Bamboo-Lattice[J]. Nuclear Engineering and Design, 2018, 335: 432-440. doi: 10.1016/j.nucengdes.2018.05.030 [5] YANG W, WU H C, LI Y Z, et al. Development and verification of PWR-core fuel management calculation code system NECP-Bamboo: part Ⅱ Bamboo-Core[J]. Nuclear Engineering and Design, 2018, 337: 279-290. doi: 10.1016/j.nucengdes.2018.07.017 [6] LI Y Z, HE T, LIANG B N, et al. Development and verification of PWR-core nuclear design code system NECP-Bamboo: part III: Bamboo-Transient[J]. Nuclear Engineering and Design, 2020, 359: 110462. doi: 10.1016/j.nucengdes.2019.110462 [7] ZHOU Y C, LI Y Z, SHAO R Z, et al. Automatic modeling of PWR-core in the two-step reactor-core physics analysis code NECP-Bamboo[J]. Nuclear Engineering and Design, 2023, 414: 112546. doi: 10.1016/j.nucengdes.2023.112546 [8] 杨森涵,李云召,邵睿智,等. 基于NECP-Bamboo程序的商用压水堆乏燃料组件核素成分分析[J]. 原子能科学技术,2023, 57(3): 545-554. doi: 10.7538/yzk.2022.youxian.0333 [9] 田超,郑友琦,李云召,等. 基于组件模块化特征线方法的中子输运计算研究[J]. 核动力工程,2015, 36(3): 157-161. doi: 10.13832/j.jnpe.2014.03.0157 [10] 黄凯,吴宏春,李云召,等. 基于定量重要性分析的燃耗链压缩方法[J]. 强激光与粒子束,2017, 29(3): 036002. doi: 10.11884/HPLPB201729.160302 [11] ZHANG C, WAN C H, CAO L Z, et al. Method research and engineering validation of the improved homogenization for the heavy reflector in VVER[J]. Annals of Nuclear Energy, 2022, 173: 109119. doi: 10.1016/j.anucene.2022.109119 [12] 王永平,吴宏春,曹良志,等. 非均匀变分节块法[J]. 原子能科学技术,2016, 50(6): 1060-1064. [13] 梁博宁,吴宏春,李云召. 基于改进变分节块法的共轭中子通量密度计算技术[J]. 核动力工程,2023, 44(2): 24-29. [14] 贺涛,李云召,张文鑫,等. 预估校正的改进准静态方法在压水堆瞬态计算中的应用[J]. 科技视界,2020(17): 227-230. doi: 10.19694/j.cnki.issn2095-2457.2020.17.78 [15] 李云召,杨文,王思成,等. 压水堆堆芯Pin-by-pin燃料管理计算程序NECP-Bamboo2.0的设计与验证[J]. 核动力工程,2018, 39(S2): 29-32. doi: 10.13832/j.jnpe.2018.S2.0029 [16] 杨道广,陆双桐. 百万千瓦级核电站M310堆型国产化堆外核探测器综述[J]. 核电子学与探测技术,2013, 33(7): 860-864. doi: 10.3969/j.issn.0258-0934.2013.07.020 [17] RYU M, JUNG Y S, CHO H H, et al. Solution of the BEAVRS benchmark using the nTRACER direct whole core calculation code[J]. Journal of Nuclear Science and Technology, 2015, 52(7-8): 961-969. doi: 10.1080/00223131.2015.1038664 [18] XING J, SONG D Y, WU Y X. HPR1000: advanced pressurized water reactor with active and passive safety[J]. Engineering, 2016, 2(1): 79-87. doi: 10.1016/J.ENG.2016.01.017 -

下载:

下载: