Numerical Simulation of Pressure and Temperature Fields in Rectangular Narrow Channel under Blistering Condition

-

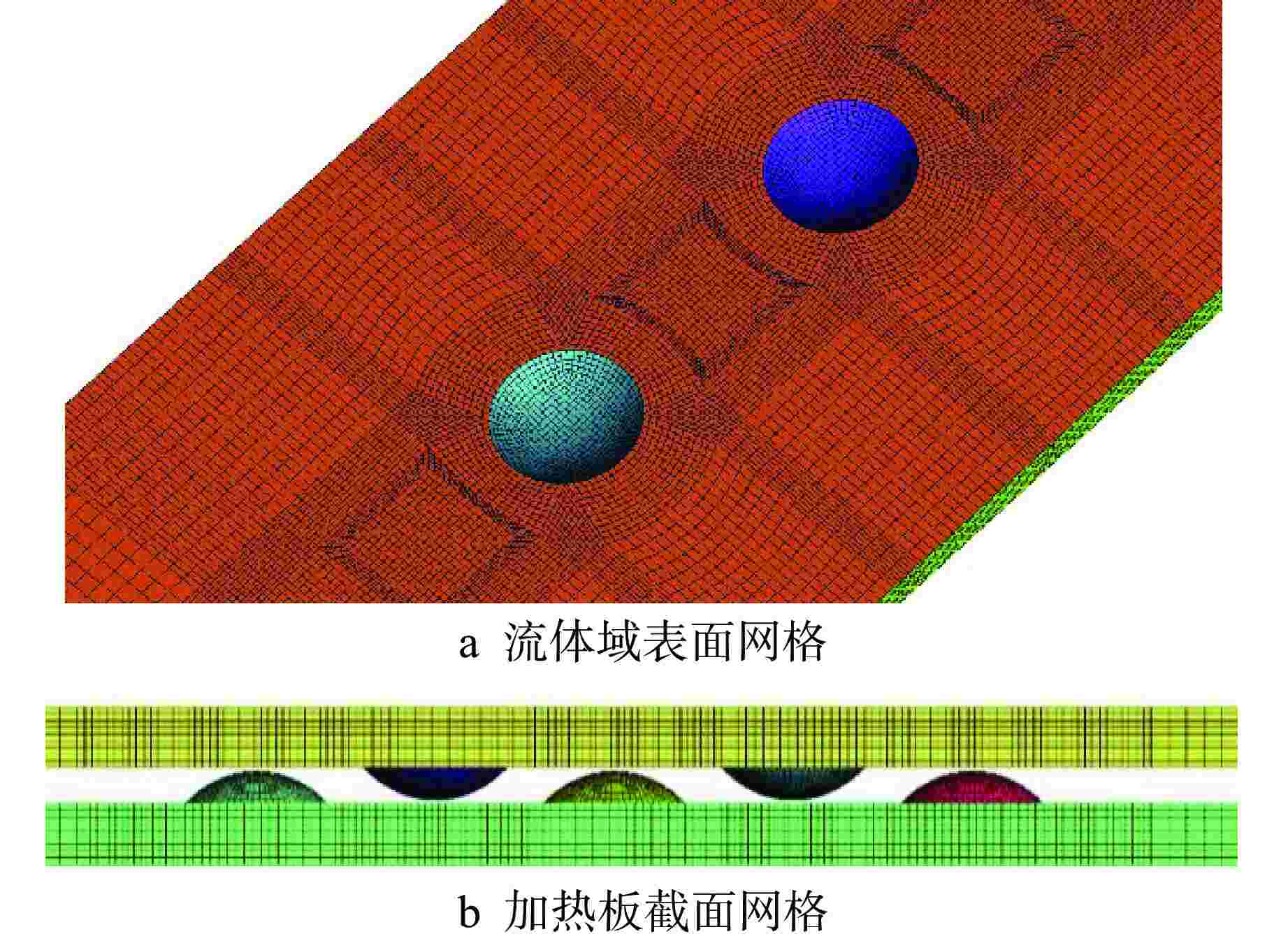

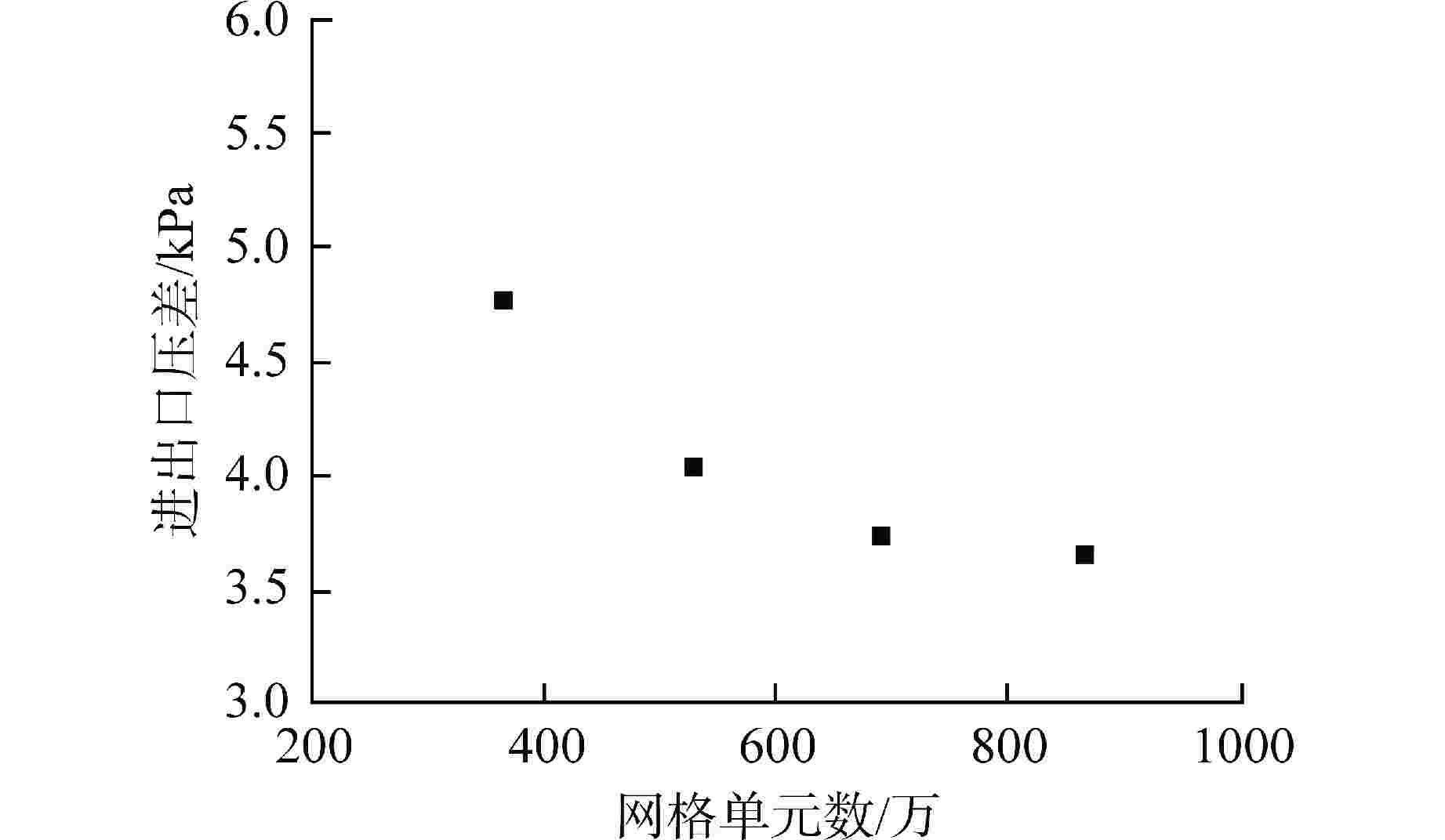

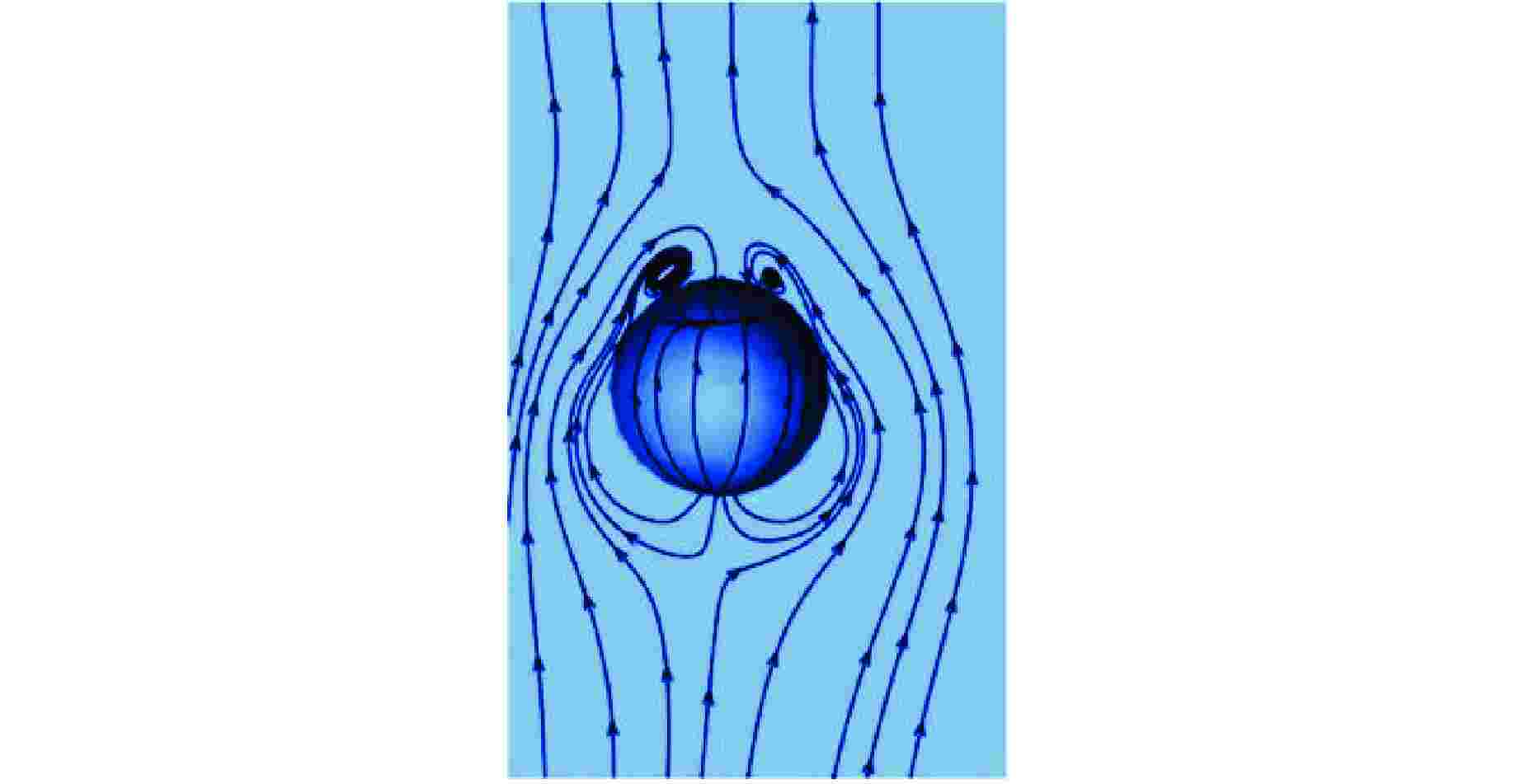

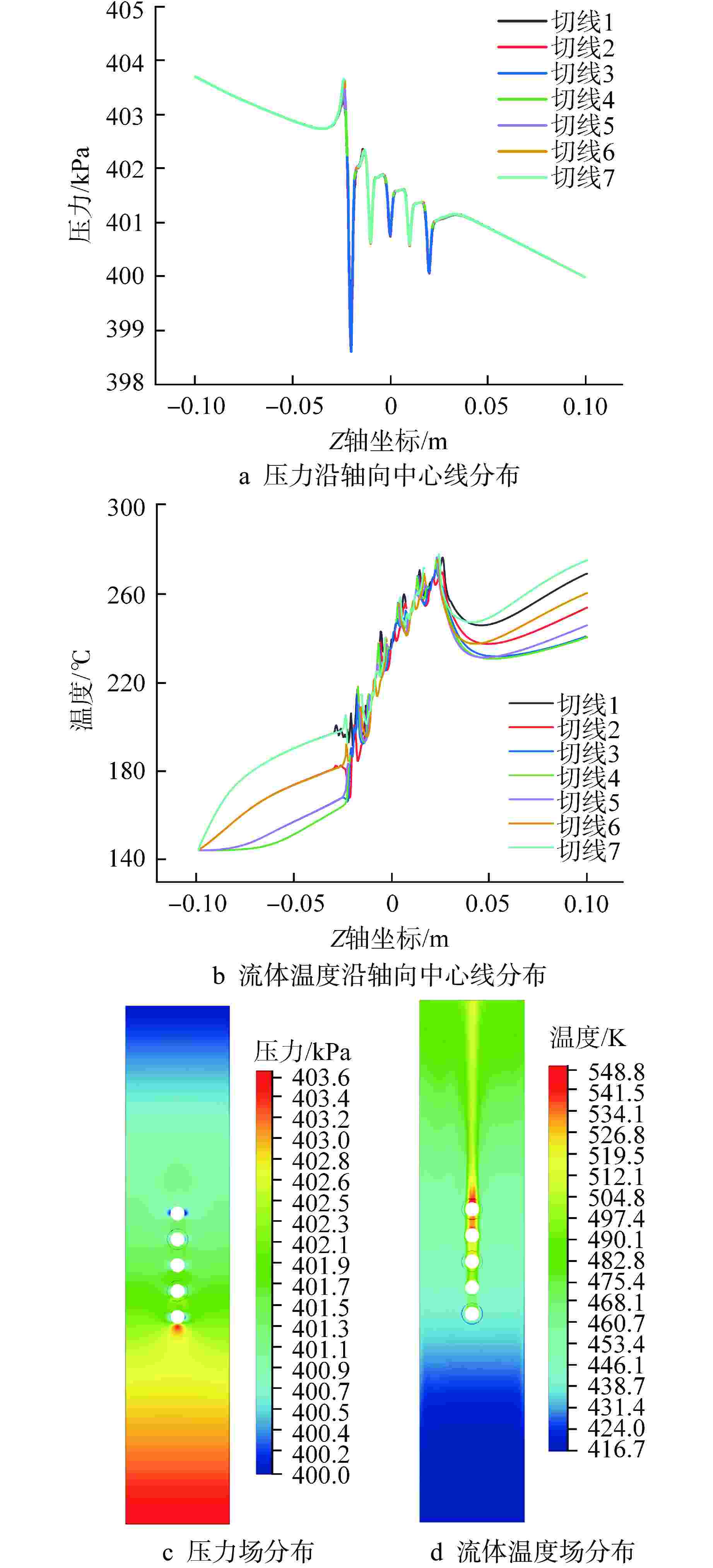

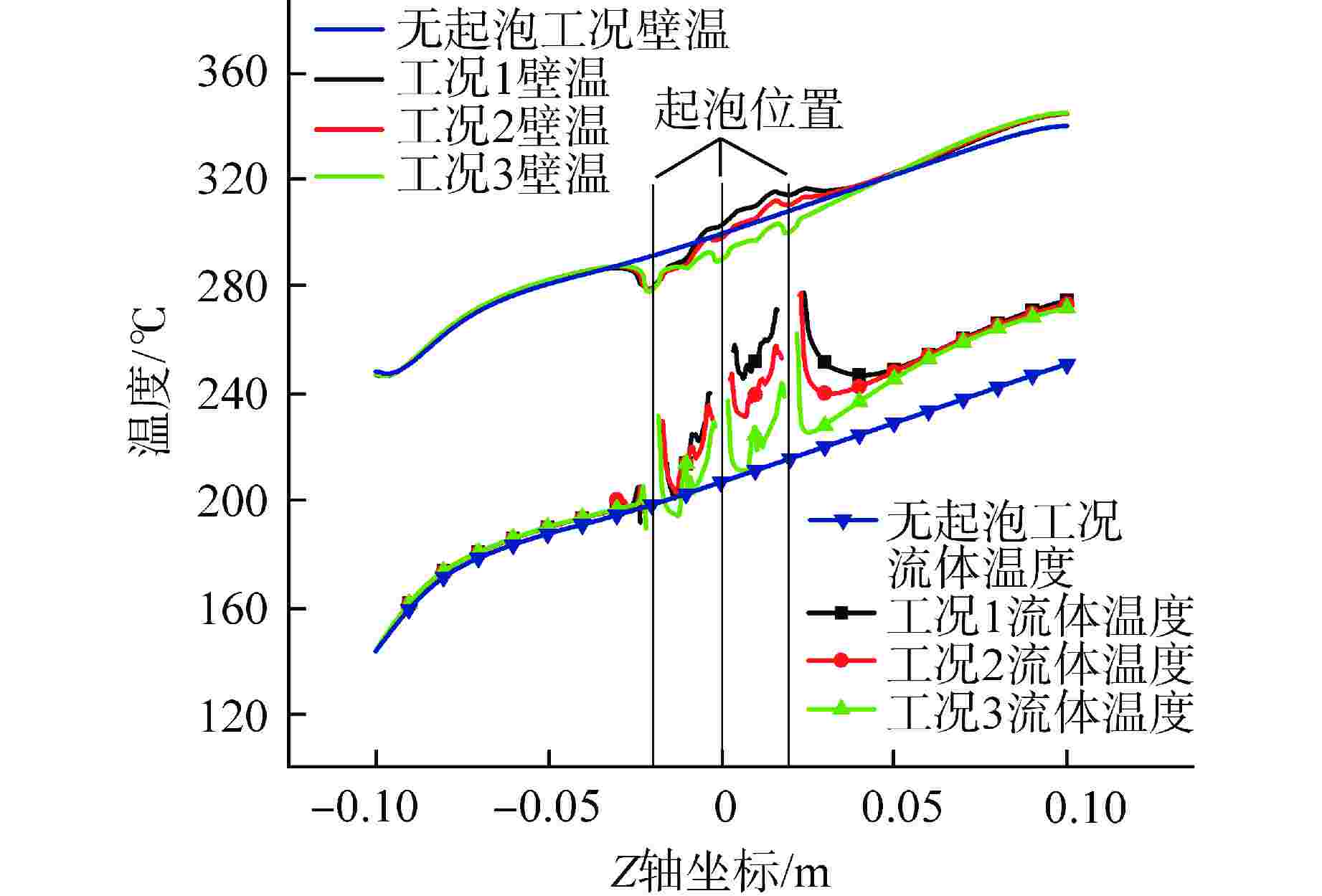

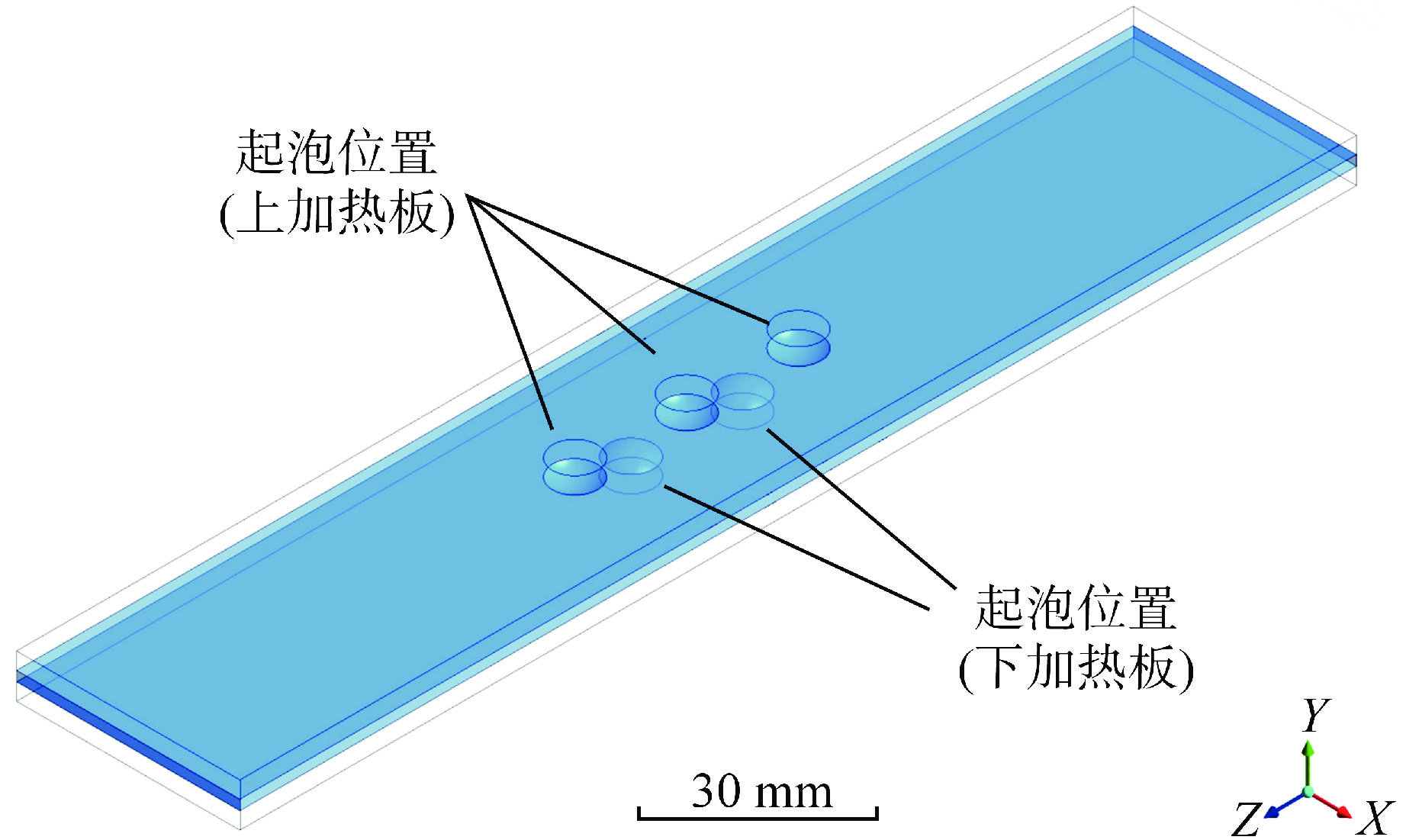

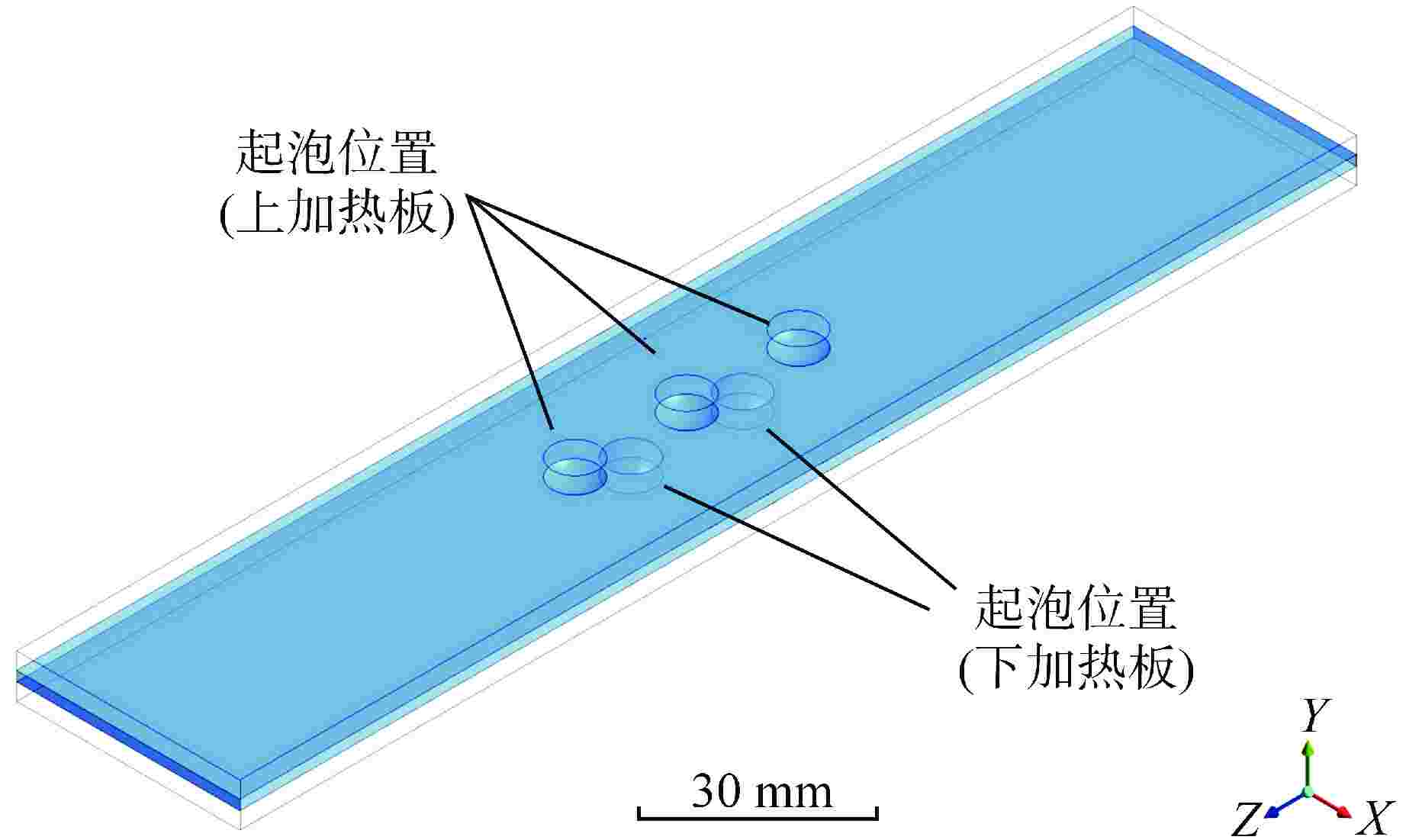

摘要: 当矩形窄缝通道由于辐照肿胀产生形变出现起泡结构时,通道内流动传热特性会发生改变。本文采用数值计算方法分析了起泡条件下矩形窄缝通道内流体压力场和温度场分布。结果表明,起泡对流体的阻碍作用会导致流体在第一个起泡前出现压力高点。经过每一个起泡,局部压降均会先飞升后突降,起泡处流体温度上升,壁面温度下降。通过模型计算分析获得了起泡条件对压力场和温度场的影响规律。Abstract: When the rectangular narrow channel is deformed due to radiation blistering, the flow heat transfer characteristics in the channel will be changed. In this study, the fluid pressure field and temperature field in the rectangular narrow channel under blistering condition is analyzed by numerical calculation method. The results show that the blocking effect of blistering on the fluid leads to a high pressure point before the first blistering. After each blistering, the local pressure drop suddenly rises first and then suddenly drops, causing the fluid temperature at the blistering to rise and the wall temperature to decrease. The influence of blistering conditions on the pressure and temperature fields is obtained through model calculation and analysis.

-

Key words:

- Blistering /

- Rectangular narrow channel /

- Pressure field /

- Temperature field /

- Numerical simulation

-

表 1 起泡几何参数

Table 1. Blistering Geometric Parameters

工况 起泡直径/mm 起泡高度/mm 起泡间距/mm 矩形通道高度/mm 矩形通道宽度/mm 加热板厚度/mm 矩形通道长度/mm 1 8 1.6 20 2.0 40 3 200 2 6 1.6 20 2.0 40 3 200 3 4 1.6 20 2.0 40 3 200 4 8 1.3 20 2.0 40 3 200 5 8 1.0 20 2.0 40 3 200 无起泡 2.0 40 3 200 表 2 热工工况

Table 2. Thermal Conditions

系统压力/

MPa入口温度/℃ 入口质量流速/

(kg·m−2·s−1)功率/W 工质 0.4 142.85 81.8 555×2 饱和水蒸气 -

[1] YE C T. China Advanced Research Reactor (CARR): a new reactor to be built in China for neutron scattering studies[J]. Physica B:Condensed Matter, 1997, 241-243: 48-49. doi: 10.1016/S0921-4526(97)00509-7 [2] GONG D X, HUANG S F, WANG G B, et al. Heat transfer calculation on plate-type fuel assembly of high flux research reactor[J]. Science and Technology of Nuclear Installations, 2015, 2015: 198654-198666. [3] HEDAYAT A, DAVILU H, JAFARI J. Loss of coolant accident analyses on Tehran research reactor by RELAP5/MOD3.2 code[J]. Progress in Nuclear Energy, 2007, 49(7): 511-528. doi: 10.1016/j.pnucene.2007.07.009 [4] 丁丽,骆贝贝,花晓,等. 板状燃料元件流道堵塞事故预防与探测技术研究[J]. 核技术,2020, 43(4): 040002. [5] MOON H K, O’CONNELL T, SHARMA R. Heat transfer enhancement using a convex-patterned surface[J]. Journal of Turbomachinery, 2003, 125(2): 274-280. doi: 10.1115/1.1556404 [6] CHEN Y, CHEW Y T, KHOO B C. Heat transfer and flow structure in turbulent channel flow over protrusions[J]. International Journal of Heat and Mass Transfer, 2013, 66: 177-191. doi: 10.1016/j.ijheatmasstransfer.2013.07.014 [7] HWANG S D, KWON H G, CHO H H. Local heat transfer and thermal performance on periodically dimple-protrusion patterned walls for compact heat exchangers[J]. Energy, 2010, 35(12): 5357-5364. doi: 10.1016/j.energy.2010.07.022 [8] BHATT M S, SHAH R K. Turbulent and transition flow convective heat transfer in ducts, Handbook of Single-Phase Convective Heat Transfer [M]. New York: Wiley, 1987:63-64. -

下载:

下载: