Analysis of Steady and Transient Characteristics of Once-through Steam Generator for Lead Bismuth Fast Reactor

-

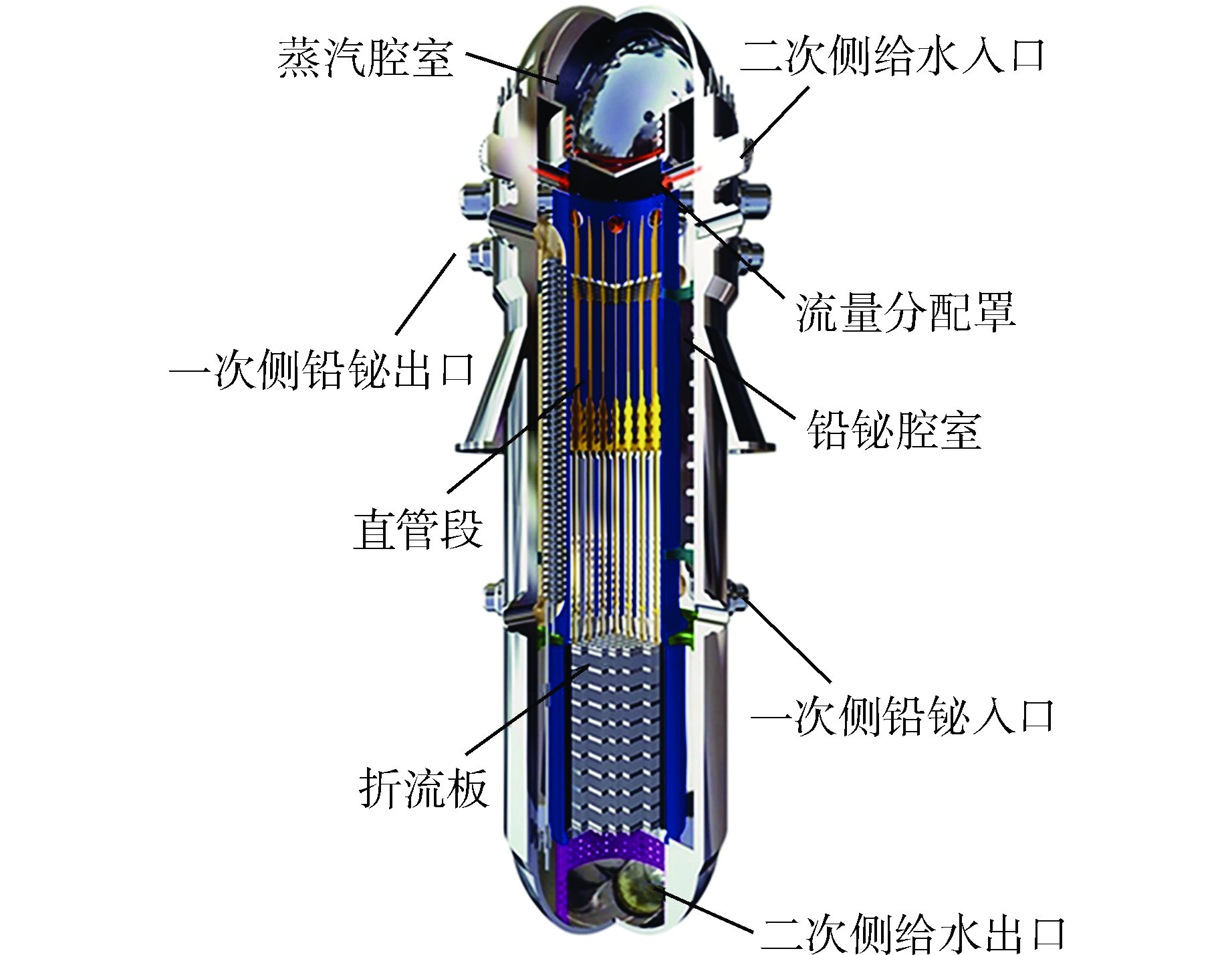

摘要: 铅铋快堆的安全稳定运行与换热器一二次侧间的散热性能密切相关。本研究通过建立基于铅铋快堆的直流蒸汽发生器(OTSG)稳态与瞬态耦合分布参数模型,分析对比了不同负荷条件下OTSG内部热工水力特性的分布差异,并进一步揭示了铅铋快堆一次侧焓值及流量扰动对换热器动态散热性能的影响。结果表明:稳态传热时铅铋快堆一次侧温降主要集中在过冷沸腾及核态沸腾区,二次侧负荷减小将导致管壁面温度飞升前移;动态调节显示在设计工况下一次侧入口焓值仅下降5%,就可能导致铅铋快堆循环在90 s后进入事故工况。研究结果为铅铋快堆的OTSG动态流动换热特性研究及结构设计优化提供了有价值的建议。Abstract: The safe and stable operation of lead bismuth fast reactor is closely related to the heat dissipation performance between the primary and secondary sides of the heat exchanger. In this study, the steady-state and transient coupled distribution parameter model of once-through steam generator (OTSG) based on lead bismuth fast reactor is established. The distribution difference of thermal and hydraulic characteristics in OTSG under different load conditions is analyzed and compared, and the influence of primary enthalpy and flow disturbance of lead bismuth fast reactor on the dynamic heat dissipation performance of heat exchanger is further revealed. The steady-state results show that the temperature drop on the primary side of the lead bismuth fast reactor was mainly concentrated in the subcooled boiling and nucleate boiling regions, and the decrease in the secondary side load can cause the temperature jump on the tube wall. The dynamic results show that the primary side inlet enthalpy only decreases by 5% under design conditions, which may lead to the lead bismuth reactor cycle entering accident conditions after 90 seconds. The relevant results provide valuable suggestions for the study of OTSG flow and heat transfer characteristics and structural design optimization of the lead bismuth fast reactor.

-

表 1 铅铋合金热工物性计算

Table 1. Calculation of Thermal Properties of LBE

铅铋物性 经验关系式 ρ/(kg·m−3) $ {\rho_{_{{\text{LBE}}}}} = 11096 - 1.3236T $ cp/[J·(kg·K)−1] $ {c_{p\;,_{\text{LBE}}}} = 159 - 2.72 \times {10^{ - 2}}T + 7.12 \times {10^{ - 6}}{T^2} $ η/(Pa·s) $ {\eta _{{\text{LBE}}}} = 4.94 \times {10^{ - 4}}{\text{exp}}\left(\dfrac{{754.1}}{T}\right) $ λ/[W·(m·K)−1] $ {\lambda _{{\text{LBE}}}} = 3.61 + 1.517 \times {10^{ - 2}}T - 1.741 \times {10^{ - 6}}{T^2} $ $ T $—温度;$ \rho $—密度;$ {c_{p\;}} $—比热容;$ \eta $—动力粘度 表 2 求解程序中各传热区域分段的判别条件

Table 2. Discriminant Conditions for Segmentation of Each Heat Transfer Region in the Numerical Code

表 3 设计点的计算边界条件

Table 3. Boundary Conditions for Design Points

参数名 参数值 堆芯功率/MW 1284 一次侧运行压力/MPa 15.17 二次侧运行压力/MPa 6.38 一次侧质量流量/(kg·s−1) 8273 二次侧质量流量/(kg·s−1) 680.4 一次侧入口温度/℃ 237.8 二次侧入口温度/℃ 317.7 -

[1] OECD Nuclear Energy Agency for the Generation IV International Forum. Technology roadmap update for generation IV nuclear energy systems: gif-tru2014[R]. Paris: OECD, 2014. [2] 赵孝,白宇飞,张震,等. 直流蒸汽发生器稳态与瞬态特性数值模拟[J]. 核动力工程,2020, 41(6): 8-13. doi: 10.13832/j.jnpe.2020.06.0008 [3] 朱景艳,张志俭,郭赟. 套管式直流蒸汽发生器动态实时仿真研究[J]. 原子能科学技术,2011, 45(8): 937-942. [4] ZHANG G L, ZHANG Y, YANG Y L, et al. Dynamic heat transfer performance study of steam generator based on distributed parameter method[J]. Annals of Nuclear Energy, 2014, 63: 658-664. doi: 10.1016/j.anucene.2013.09.005 [5] CIONCOLINI A, SANTINI L. Two-phase pressure drop prediction in helically coiled steam generators for nuclear power applications[J]. International Journal of Heat and Mass Transfer, 2016, 100: 825-834. doi: 10.1016/j.ijheatmasstransfer.2016.05.027 [6] OSAKABE M. Thermal-hydraulic study of integrated steam generator in PWR[J]. Journal of Nuclear Science and Technology, 1989, 26(2): 286-294. doi: 10.1080/18811248.1989.9734304 [7] TZANOS C P. A movable boundary model for once-through steam generator analysis[J]. Nuclear Technology, 1988, 82(1): 5-17. doi: 10.13182/NT88-A34113 [8] 干依燃. 基于均相流模型的直流蒸汽发生器换热性能仿真[D]. 哈尔滨: 哈尔滨工程大学,2016. [9] 杨宇鹏,王成龙,张大林,等. 液态金属螺旋管式直流蒸汽发生器数值模拟研究[J]. 原子能科学技术,2021, 55(7): 1288-1295. doi: 10.7538/yzk.2020.youxian.0514 [10] YANG Y P, LI Y, WANG C L, et al. Parametric sensitivity analysis of liquid metal helical coil once-through tube steam generator[J]. Nuclear Engineering and Design, 2021, 383: 111427. doi: 10.1016/j.nucengdes.2021.111427 [11] KROMER D, CHANDRASEKARAN S, GARIMELLA S. Microchannel steam generators for design for integral inherently safe light water reactors[J]. Nuclear Engineering and Design, 2020, 370: 110867. doi: 10.1016/j.nucengdes.2020.110867 [12] 丁雪友. 基于两流体架构的铅铋快堆螺旋管直流蒸汽发生器流动与传热模型研究[D]. 重庆: 重庆大学,2021. [13] CHENG X, BATTA A, CHEN H Y, et al. Turbulent heat transfer to heavy liquid metals in circular tubes[C]//ASME 2004 Heat Transfer/Fluids Engineering Summer Conference. Charlotte: ASME, 2004: 115-125. [14] CONCETTA F. Handbook on lead-bismuth eutectic alloy and lead properties, materials compatibility, thermal-hydraulics and technologies: 2015 edition[M].Paris, France: OECD, 2015: 28-132. [15] 陶文铨. 传热学[M]. 第五版. 北京: 高等教育出版社,2019: 230-238. [16] ZAMBRANA J, LEO T J, PEREZ-DEL-NOTARIO P. Vertical tube length calculation based on available heat transfer coefficient expressions for the subcooled flow boiling region[J]. Applied Thermal Engineering, 2008, 28(5-6): 499-513. doi: 10.1016/j.applthermaleng.2007.05.003 [17] 赵兆颐,朱瑞安. 反应堆热工流体力学[M]. 北京: 清华大学出版社,1992. [18] 许余,皇甫泽玉,胥建群,等. 直流蒸汽发生器建模与仿真研究[J]. 核动力工程,2021, 42(1): 154-160. doi: 10.13832/j.jnpe.2021.01.0154 [19] 吴鸽平,吴埃敏,郭贇,等. 环形窄缝通道内流动沸腾干涸点的研究[J]. 西安交通大学学报,2004, 38(7): 686-689,697. doi: 10.3321/j.issn:0253-987X.2004.07.007 [20] WANG L Z, WU G W, WANG J, et al. Numerical investigation of the core outlet temperature fluctuation for the lead-based reactor[J]. Annals of Nuclear Energy, 2018, 117: 194-201. doi: 10.1016/j.anucene.2018.03.020 [21] 杨若楠. 池式铅基堆自然循环特性的数值模拟研究[D]. 兰州: 中国科学院大学(中国科学院近代物理研究所),2019. -

下载:

下载: