Study on the Influence of Spacer Grid on Temperature Field Distribution at Rod Bundle Channel Outlet

-

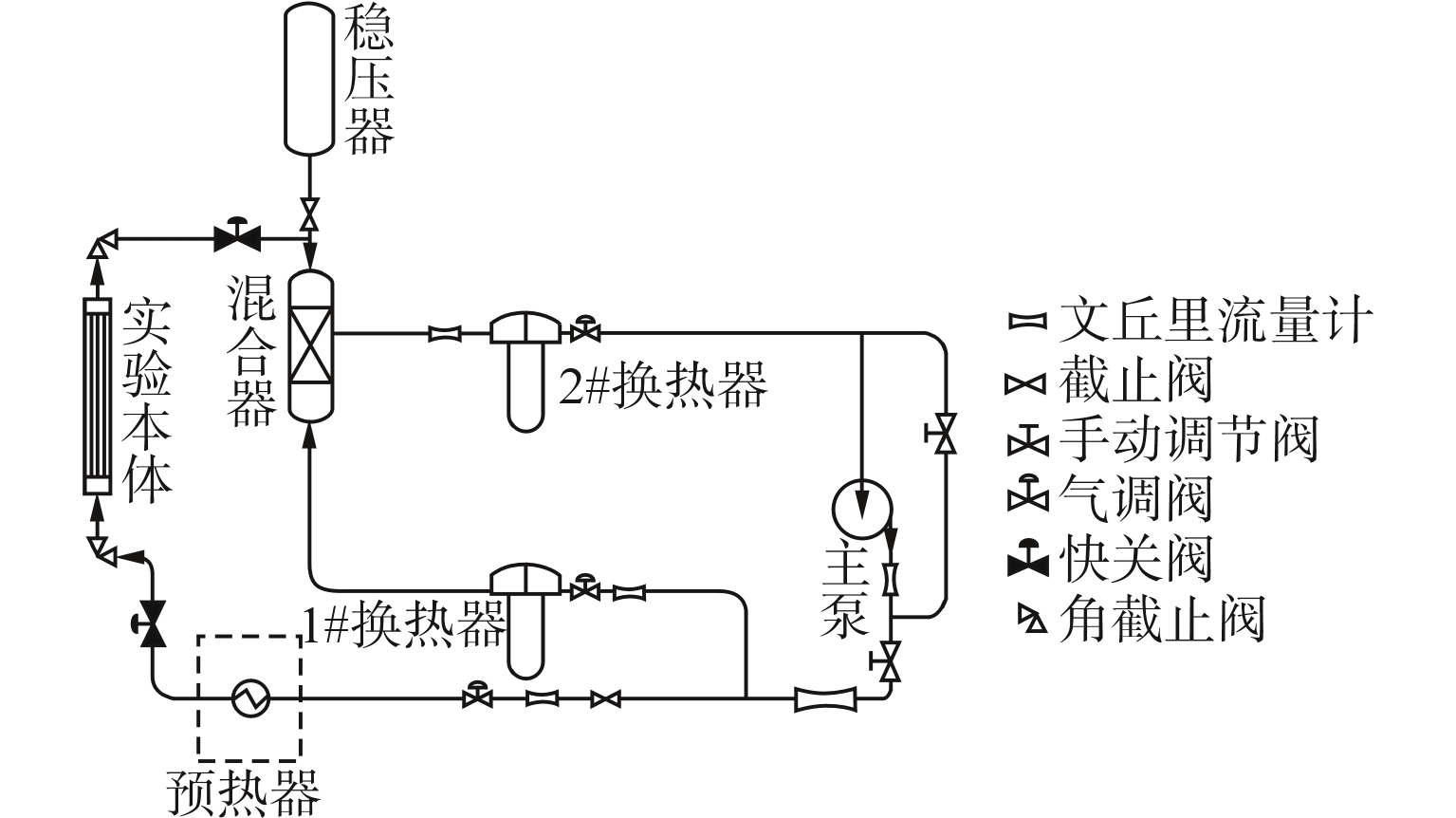

摘要: 为分析定位格架交混能力,进一步优化定位格架热工设计方法。本文通过实验研究不同结构定位格架对棒束通道出口温场分布的影响。实验中,系统压力为7.0~16.5 MPa,质量流速为900~4500 kg·m−2·s−1,实验段进出口温差为30~128℃。实验结果表明,在压水堆运行参数范围内,对于相同定位格架结构形式,不同压力、进出口温差、质量流速等热工参数条件下棒束通道出口截面子通道最高温度和最低温度的差值与进出口温差的比值没有明显变化趋势;交混翼主导了定位格架的交混作用,II型交混翼带来较强的交混作用;对于D型定位格架,非对称的条带结构会导致流场整体出现一定的偏转,一定程度上降低了定位格架的交混作用。Abstract: To analyze the mixing ability of the spacer grid and further optimize the thermal design method of the spacer grid, this article investigates the influence of spacer grid with different structures on the temperature field distribution at the outlet of rod bundle channel through experiments. In the experiments the system pressure is 7.0~16.5 MPa, the mass velocity is 900~4500 kg/m2s, and the temperature difference between the inlet and outlet of the experimental section is 30~128℃. The experimental results show that, within the range of PWR operating parameters, the ratio of the difference between the maximum and minimum temperatures of the sub-channel at the bundle channel outlet section to the temperature difference at the inlet and outlet has no obvious change trend under different thermal parameters such as pressure, inlet and outlet temperature difference and mass flow rate for the same spacer grid structure. The mixing wing dominates the mixing effect of the spacer grid, and Type II mixing wing has stronger mixing effect. For the D-type spacer grid, the asymmetric strip structure will lead to a certain deflection of the whole flow field, which will reduce the mixing effect of the spacer grid to some extent.

-

Key words:

- Spacer grid /

- Rod bundle channel /

- Temperature field distribution

-

表 1 大型热工实验装置参数汇总表

Table 1. Summary of Parameters of LS-THTF

参数名 参数值 设计压力/MPa 20 设计温度/℃ 370 主泵额定流量/(m3·h−1) 500 实验支路最大流量/(m3·h−1) 70 表 2 定位格架结构特点汇总表

Table 2. Structural Features of Spacer Grid

定位格架编号 边条带结构 交混翼结构 A 四边一致 无交混翼 B 四边一致 I型交混翼 C 四边一致 II型交混翼 D 两边(1、2)封闭,两边(3、4)开放 II型交混翼 表 3 主要测量参数及仪表配置表

Table 3. Main Measurement Parameters and Instrument Configuration

序号 参数 仪表型号 量程 精度 测点位置 1 出口压力 STG974压力变送器 0~20 MPa 0.1级 本体出口接管 2 压降 ST3000智能式差压变送器 0~200 kPa 0.1级 本体进出口接管 3 进出口温度 φ1N型铠装热电偶 0~300℃ ±1.0℃ 本体进出口接管 4 流量 文丘里管+ST3000差压变送器 0~45 t/h ±1.0% 实验支路管道 5 电流 直流电流传感器 0~30000 A 0.1级 本体电缆 6 电压 电压变送器 0~100 V 0.2级 本体上下接线 7 子通道温度 φ1N型铠装热电偶 0~300℃ ±1.0℃ 各子通道发热段末端中心位置 表 4 主要热工参数不确定度

Table 4. Uncertainties of Main Thermal Parameters

参数 不确定度/% 压力(P)/MPa 0.43 进出口温度(Tin/Tout)/℃ 0.72 子通道出口温度(T1~T36)/℃ 1.52 质量流速(G)/(kg·m−2·s−1) 1.88 热流密度(q)/(MW·m−2) 1.89 表 5 实验数据构成及参数范围

Table 5. Experimental Data Composition and Parameter Ranges

定位格架

编号出口压力

/MPa质量流速/

(kg·m−2·s−1)进出口温差

(Tout−Tin)/℃数据量

(组)A 10.0~15.6 900~3500 30~123 16 B 10.0~13.6 900~4500 30~126 18 C 7.0~16.5 900~3500 30~128 20 D 7.0~15.5 900~4500 30~128 26 合计 7.0~16.5 900~4500 30~128 80 表 6 典型工况各子通道出口温度 ℃

Table 6. Outlet Temperature of Each Sub-channel in Typical Condition

行 列 1 2 3 4 5 6 1 255.8 257.8 257.4 258.7 257.5 256.0 2 256.6 258.5 259.8 260.8 259.6 257.8 3 257.1 259.4 260.4 263.3 260.3 257.4 4 256.1 259.1 262.6 263.6 260.3 258.2 5 256.9 259.0 260.2 260.0 259.2 256.6 6 254.9 255.6 257.5 256.5 257.5 256.0 表 7 不同定位格架交混作用汇总表

Table 7. Summary of Mixing Effect for Different Spacer Grids

定位格架编号 交混翼结构 ΔT/℃ ΔT/(Tout−Tin) A 无交混翼 36.4 0.91 B I型交混翼 11.1 0.28 C II型交混翼 7.5 0.19 D II型交混翼 8.8 0.22 -

[1] KIM R K, STOUDT R H. Cross flow between rod bundles with spacer grids[J]. Transactions of the American Nuclear Society, 1975, 22: 584-585. [2] MAREK J, REHME K. Heat transfer in smooth and roughened rod bundles near spacer grids[C]//Proceedings of the ASME Winter Annual Meeting: Fluid Flow and Heat Transfer Over Rod or Tube Bundles. New York: ASME, 1979: 163-170. [3] DE CRÉCY F. The effect of grid assembly mixing vanes on critical heat flux values and azimuthal location in fuel assemblies[C]//International Topical Meeting on Nuclear Reactor Thermal Hydraulics. Grenoble: CEA Centre d`Etudes de Grenoble, 1993. [4] STOSIC Z. On the role of spacer grids on conditions of Dryout/rewetting and local thermal hydraulics in boiling water reactors[C]//Proceedings of the 9th International Topical Meeting on Nuclear Reactor Thermal Hydraulics. San Francisco: NURETH, 1999. [5] QIN S J, LANG X M, XIE S J, et al. Experimental investigation on repeatability of CHF in rod bundle with non-uniform axial heat flux distribution[J]. Progress in Nuclear Energy, 2016, 90: 151-154. doi: 10.1016/j.pnucene.2016.03.015 [6] 仇子铖,郎雪梅,谢士杰,等. 带定位格架棒束通道出口温场分布特性实验研究[C]//第十六届全国反应堆热工流体学术会议暨中核核反应堆热工水力技术重点实验室2019年学术年会论文集. 惠州: 中国科学院近代物理研究所,2019. -

下载:

下载: