Effect of Baffle on Flow Induced Vibration of Heat Exchange Tubes

-

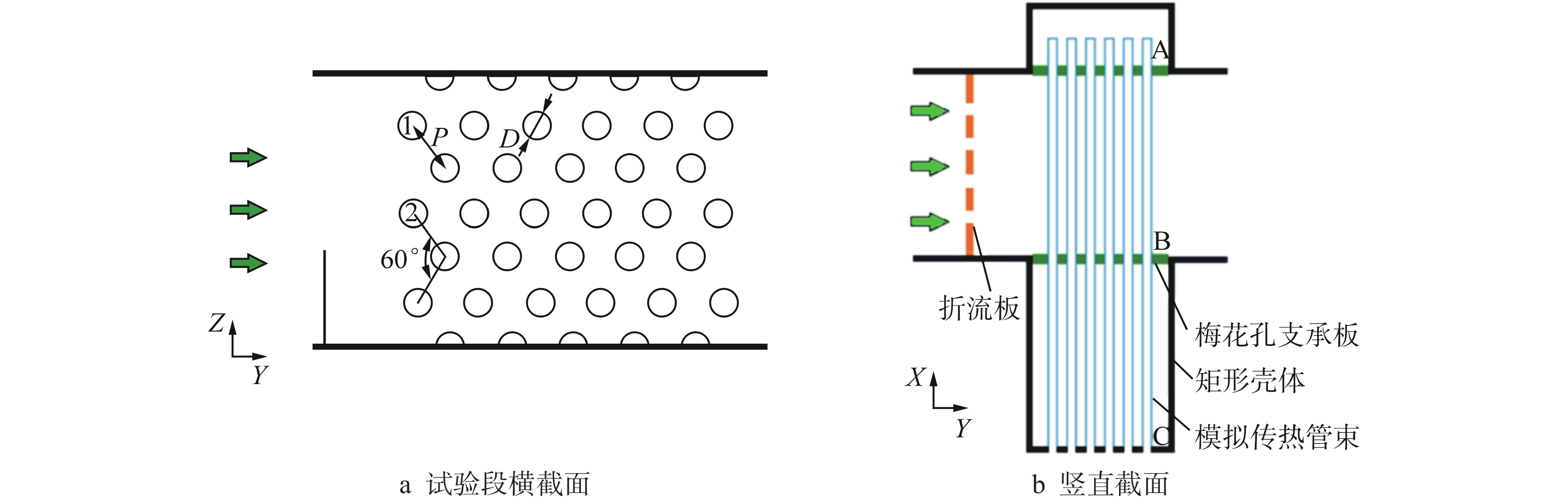

摘要: 传热管流致振动磨损是引起换热器性能衰退和运行故障的重要因素之一。本文针对换热器折流板形成的非均匀横流引起的振动,建立可视化三跨7×12传热管束流致振动试验装置,通过管内加速度传感器和高速相机视觉测振分别获得迎流首排中间跨管内振动加速度数据和管与支承板间隙变化数据,并开展数值模拟计算获得管间流场。对比横向全开口无折流板和2/3开口折流板形成横流引起的管振动试验和模拟结果,表明2种结构第三排后管间流速差异较小,发生流弹失稳临界速度较为相近,2/3开口折流板发生失稳临界速度略高于全开口无折流板结构。对比5种经典临界速度关系式,Chen公式能够较好地保守预测失稳发生。管与支承板的间隙可视化试验表明,极低流速时2种来流结构管均较稳定地依靠在支承板一侧孔上。在中等流速下,全开口来流作用下管在支承板孔中较大幅度往复运动而轻微敲击,而非均匀来流结构中管仍依靠在支承板上的梅花孔内缘上发生小幅度滑动。发生流弹失稳时,全开口结构以敲击为主,而2/3开口结构会发生显著滑动和敲击。2/3开口结构更易发生传热管-支承板的滑动磨损,将威胁传热管的完整性。Abstract: The wear of tubes caused by flow induced vibration is one of the most significant factors that cause performance attenuation and malfunction of the heat exchanger. In this paper, aiming at the vibration caused by the non-uniform cross flow formed by the heat exchanger baffle, a visualized three-span 7×12 heat transfer tube bundle flow-induced vibration test facility is established. The acceleration data of the vibration in the first row of midspan tubes and the change data of the gap between the tubes and the support plate were obtained by the acceleration sensor in the tube and the visual vibration measurement by the high-speed camera, respectively, and the flow field between the tubes was obtained by numerical simulation. By comparing the experimental and simulation results of cross-flow-induced vibration of tubes under non-baffle mode and 2/3 gap baffle mode, it is shown that the velocity difference between the two structures after the third row of tubes is small, and the fluid elastic instability (FEI) critical velocity is similar, and the critical velocity of 2/3-gap baffle is slightly higher than that of the structure without baffle. By comparing five classical critical velocity relationships, it is found that Chen’s correlation can conservatively predict the occurrence of instability. The visual test of the gap between the tube and the support plate shows that the two kinds of tubes with incoming flow structure are relatively stable against the hole on one side of the support plate at very low flow velocity. At a moderate flow rate, the tube reciprocates in the hole of the support plate with a large amplitude under the non-baffle mode, and slightly knocks, while in the non-uniform inflow structure, the tube still slides on the inner edge of the plum blossom hole on the support plate with a small amplitude. In the case of FEI, the non-baffle mode is mainly knocking, while the 2/3-gap baffle will obviously slide and knock. The 2/3-gap baffle is more prone to sliding wear between the heat transfer tube and the support plate, which will threaten the integrity of the heat transfer tube.

-

Key words:

- Baffle /

- Nonuniform flow /

- Visualization /

- Flow induced vibration /

- Tube baffle gap

-

表 1 4种简化结构的固有频率 Hz

Table 1. Natural Frequency of Four Simplified Structures

模态 简化结构1 简化结构2 简化结构3 简化结构4 湿模态1阶 49.8 3.3 8.4 60.8 湿模态2阶 86.2 21.1 55.2 194 湿模态3阶 58.0 83.5 表 2 经验式预测值和试验值对比表

Table 2. Comparison of Empirical Correlation and Experimental Results

关系式或试验 K b $ {v}_{\mathrm{c}} $/(m·s−1) Connors(1978) 2.90 0.50 1.45 Gorman(1976) 6.60 0.50 3.32 ASME 2.40 0.50 1.21 Chen(1981) 4.51 0.52 2.20 Weaver(1981) 6.20 0.29 4.24 横向全开口来流试验 2.27 横向2/3开口来流试验 2.43 -

[1] CHEN S S, ZHU S, CAI Y. Experiment of chaotic vibration of loosely supported tube rows in cross-flow[J]. Journal of Pressure Vessel Technology, 1995, 117(3): 204-212. doi: 10.1115/1.2842113 [2] CONNORS JR H J. Fluidelastic vibration of heat exchanger tube arrays[J]. Journal of Mechanical Design, 1978, 100(2): 347-353. doi: 10.1115/1.3453921 [3] CONNORS H J. Flow-induced vibration and wear of steam generator tubes[J]. Nuclear Technology, 1981, 55(2): 311-331. doi: 10.13182/NT55-311 [4] CHEN S S. Guidelines for the instability flow velocity of tube arrays in crossflow[J]. Journal of Sound and Vibration, 1984, 93(3): 439-455. doi: 10.1016/0022-460X(84)90340-7 [5] SCHRÖDER K, GELBE H. New design recommendations for fluidelastic instability in heat exchanger tube bundles[J]. Journal of Fluids and Structures, 1999, 13(3): 361-379. doi: 10.1006/jfls.1999.0208 [6] PRICE S J. An investigation on the use of Connors’ equation to predict fluidelastic instability in cylinder arrays[J]. Journal of Pressure Vessel Technology, 2001, 123(4): 448-453. doi: 10.1115/1.1403445 [7] 韩同行,左超平,秦加明,等. 蒸汽发生器传热管流弹失稳计算[J]. 压力容器,2014, 31(11): 39-44. doi: 10.3969/j.issn.1001-4837.2014.11.07 [8] 蒋庆磊,张坤,周继云,等. 蒸汽发生器传热管湍流激励功率谱密度计算[J]. 压力容器,2014, 31(7): 16-21. doi: 10.3969/j.issn.1001-4837.2014.07.004 [9] 冯志鹏,臧峰刚,张毅雄. 管束结构的流致振动特性研究[J]. 原子能科学技术,2015, 49(1): 51-57. [10] 丁林,张力,姜德义. 高雷诺数范围内不同形状柱体流致振动特性研究[J]. 振动与冲击,2015, 34(12): 176-181. doi: 10.13465/j.cnki.jvs.2015.12.030 [11] 姜乃斌,臧峰刚,张毅雄. 横掠水平管束间气-液两相流流型对流致振动激励的影响[J]. 核动力工程,2011, 32(4): 42-45, 71. [12] GORMAN D. Experimental Development of Design Criteria to Limit Liquid Cross-Flow-Induced Vibration in Nuclear Reactor Heat Exchange Equipment[J]. Nuclear science and engineering: the journal of the American Nuclear Society, 1976, 61(3): 324-336. [13] CHEN S S, JENDRZEJCYK J A. Experiments on fluid elastic instability in tube banks subjected to liquid cross flow[J]. Journal of Sound and Vibration, 1981, 78(3): 355-381. doi: 10.1016/S0022-460X(81)80145-9 [14] WEAVER D S, EL-KASHLAN M. The effect of damping and mass ratio on the stability of a tube bank[J]. Journal of Sound and Vibration, 1981, 76(2): 283-294. -

下载:

下载: