Research of Ultimate Load Characteristics of Hoisting Structure Carrier for Equipment Hatch

-

摘要: 设备闸门起吊支架失稳发生在恒载荷和可变载荷共同作用的情况下,其极限承载力计算结果的准确性对设备闸门设计性能有重要影响。工程计算中原有不区分载荷类型直接求解特征值的计算方法导致结果过度保守。本文在原算法采用有限元分析软件ANSYS进行屈曲分析的基础上,将不应被特征值放大的载荷加以区别,将特征值作为目标函数,经优化迭代求得合理极限载荷,并在迭代过程中引入修正系数以加快收敛速度。通过非线性分析验证了改进后工程计算方法的准确性,找到了一种适用于工程计算的设备闸门起吊支架极限载荷计算方法。Abstract: Instability of the equipment hatch’s hoisting structure carrier occurs under the combined action of permanent and variable loads, and the accuracy of the ultimate load calculation results has an important influence on the design performance of equipment hatch. In engineering calculations, the traditional algorithm of directly solving eigenvalues without distinguishing load types resulted in overly conservative results. In this paper, on the basis of the original algorithm using ANSYS for buckling analysis, the loads that should not be amplified by the eigenvalues are distinguished. The eigenvalues are taken as the objective function, the reasonable ultimate loads are obtained through optimization iteration, and the correction coefficient is introduced in the iterative process to speed up the convergence. The accuracy of the improved engineering calculation method was verified through nonlinear analysis, and a suitable ultimate load algorithm for equipment hatch’s hoisting structure carrier was found for engineering calculations.

-

Key words:

- Equipment hatch /

- Ultimate load /

- Buckling /

- Nonlinear calculation /

- ANSYS

-

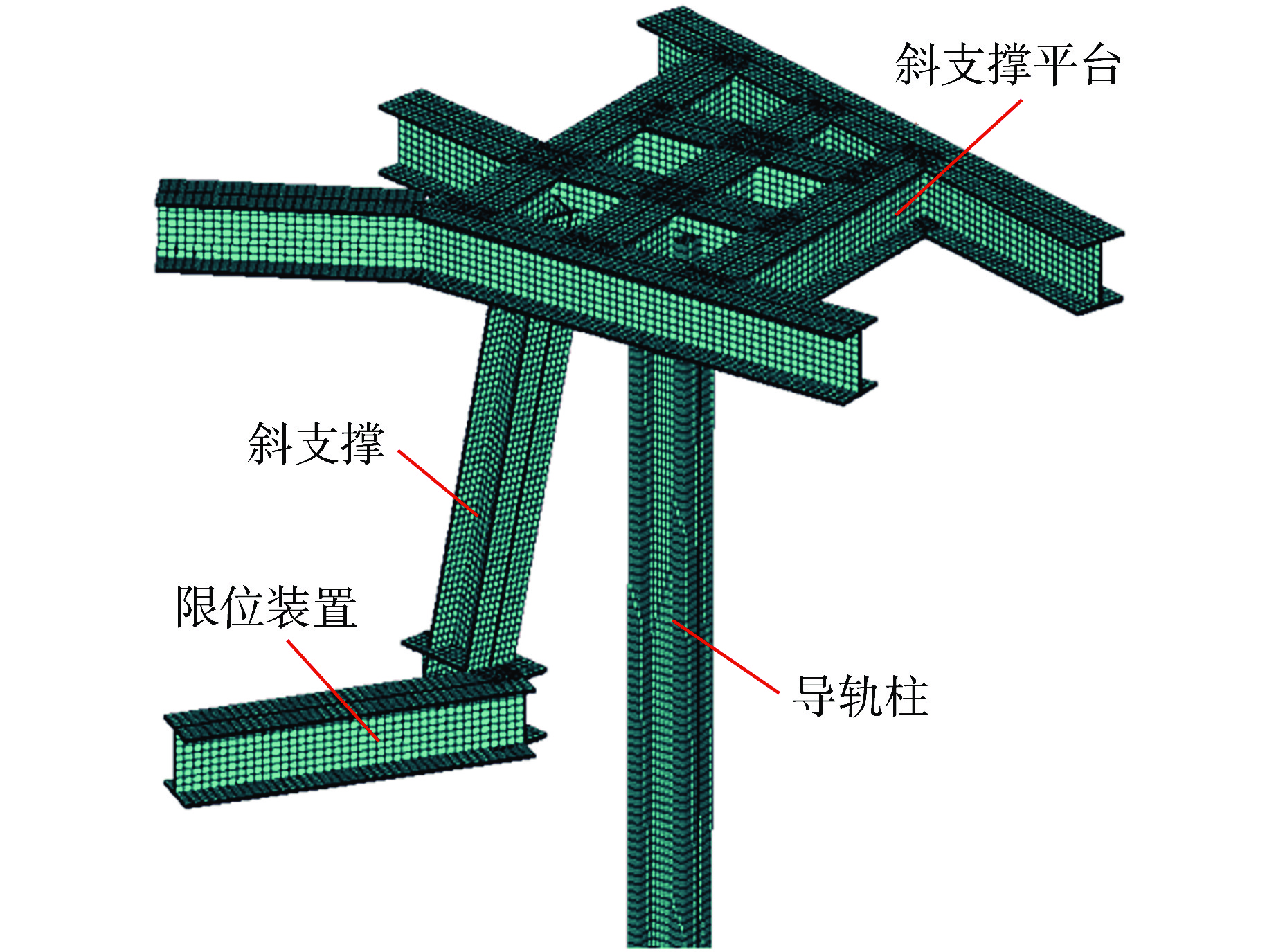

表 1 起吊支架主要部件参数

Table 1. Main Component Parameters of Hoisting Structure Carrier

部件名称 截面尺寸

(宽×高)/mm2翼缘厚

度/mm腹板厚

度/mm材料

牌号设计温

度/℃支撑平台 310×400 20 16 Q355C 150 斜支撑 300×360 20 16 Q355C 150 导轨柱(下段) 260×360 33 22 Q420C 150 导轨柱(下段) 260×360 73 22 Q420C 150 限位装置 330×400 20 20 Q355C 150 表 2 极限载荷计算结果

Table 2. Calculation Results of Ultimate Load

计算方法 极限载荷线性

计算结果/N极限载荷非线

性计算结果/N偏差率/% 原计算方法

(受特征值影响)1117500 1584585 −42 改进后计算方法

(不受特征值影响)2508520 2331286 7 -

[1] 杜坤,左永德,袁亮. 核电厂设备闸门外压极限承载特性研究[J]. 核动力工程,2020, 41(6): 106-110. doi: 10.13832/j.jnpe.2020.06.0106 [2] 谢洪虎,张峰,刘小华,等. 设备闸门提升与导向装置运行特性仿真分析[J]. 核动力工程,2020, 41(1): 180-184. doi: 10.13832/j.jnpe.2020.01.0180 [3] 吴晨晖. 基于热固耦合的安全壳设备闸门密封性分析[J]. 压力容器,2020, 37(8): 31-35. doi: 10.3969/j.issn.1001-4837.2020.08.006 [4] 徐芝纶. 弹性力学简明教程[M]. 第四版. 北京: 高等教育出版社,2013: 2. [5] 余伟炜,高炳军. ANSYS在机械与化工装备中的应用[M]. 北京: 中国水利水电出版社,2006: 90. [6] 张洪伟,高相胜,张庆余. ANSYS非线性有限元分析方法及范例应用[M]. 北京: 中国水利水电出版社,2013: 49. [7] 国家市场监督管理总局,国家标准化管理委员会. 压水堆核电厂核岛机械设备设计规范: GB/T 16702-2019[S]. 北京: 中国标准出版社,2020: 23, 243. [8] 包陈,王呼佳. ANSYS工程分析进阶实例[M]. 第二版. 北京: 中国水利水电出版社,2009: 169. [9] CRISFIELD M A. An arc‐length method including line searches and accelerations[J]. International Journal for Numerical Methods in Engineering, 1983, 19(9): 1269-1289. doi: 10.1002/nme.1620190902 [10] LAM W F, MORLEY C T. Arc-length method for passing limit points in structural calculation[J]. Journal of Structural Engineering, 1992, 118(1): 169-185. doi: 10.1061/(ASCE)0733-9445(1992)118:1(169) -

下载:

下载: