Numerical Simulation of Displacement Process of Liquid Scintillator and Ultrapure Water in a Large Diameter Spherical Tank

-

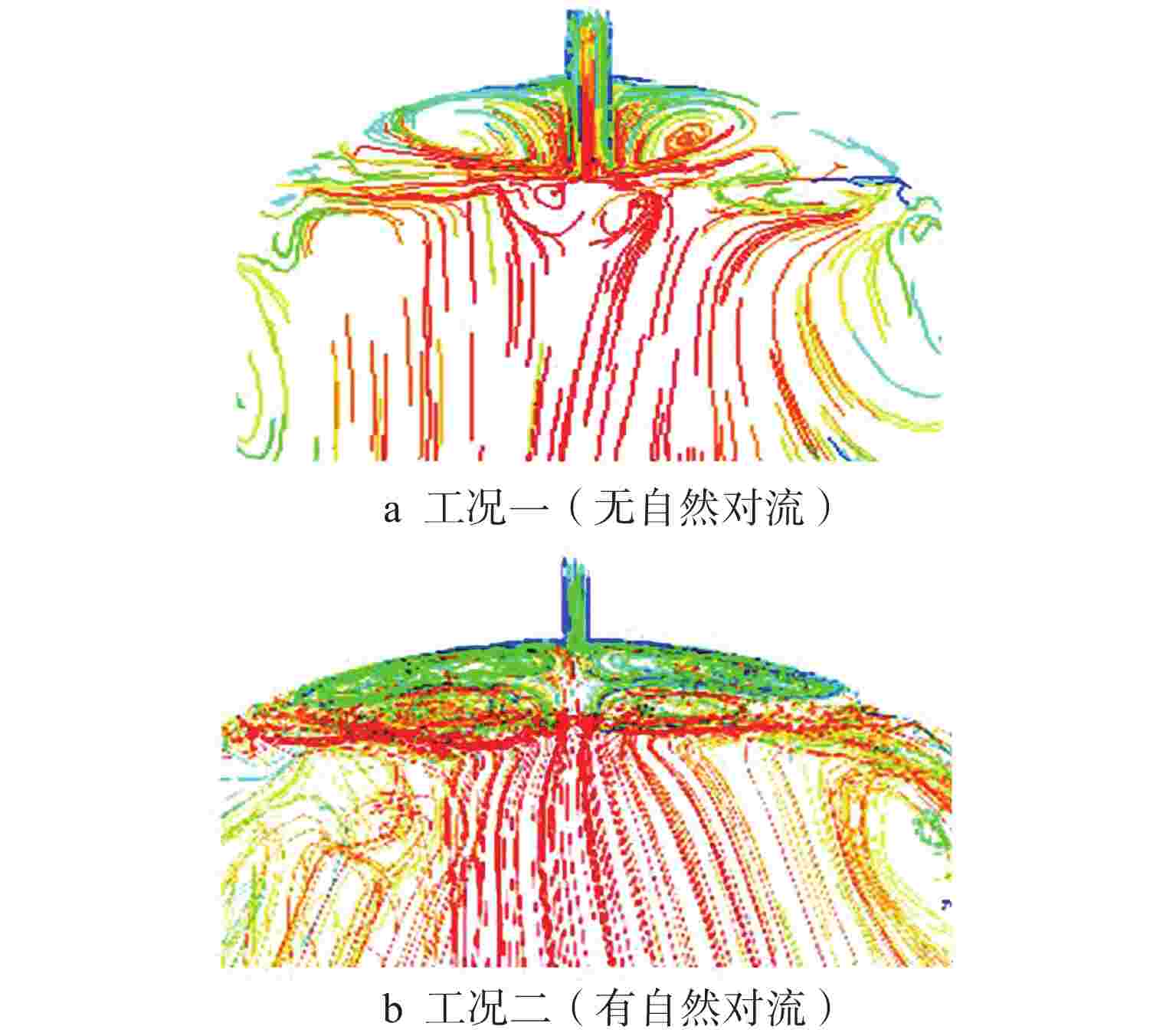

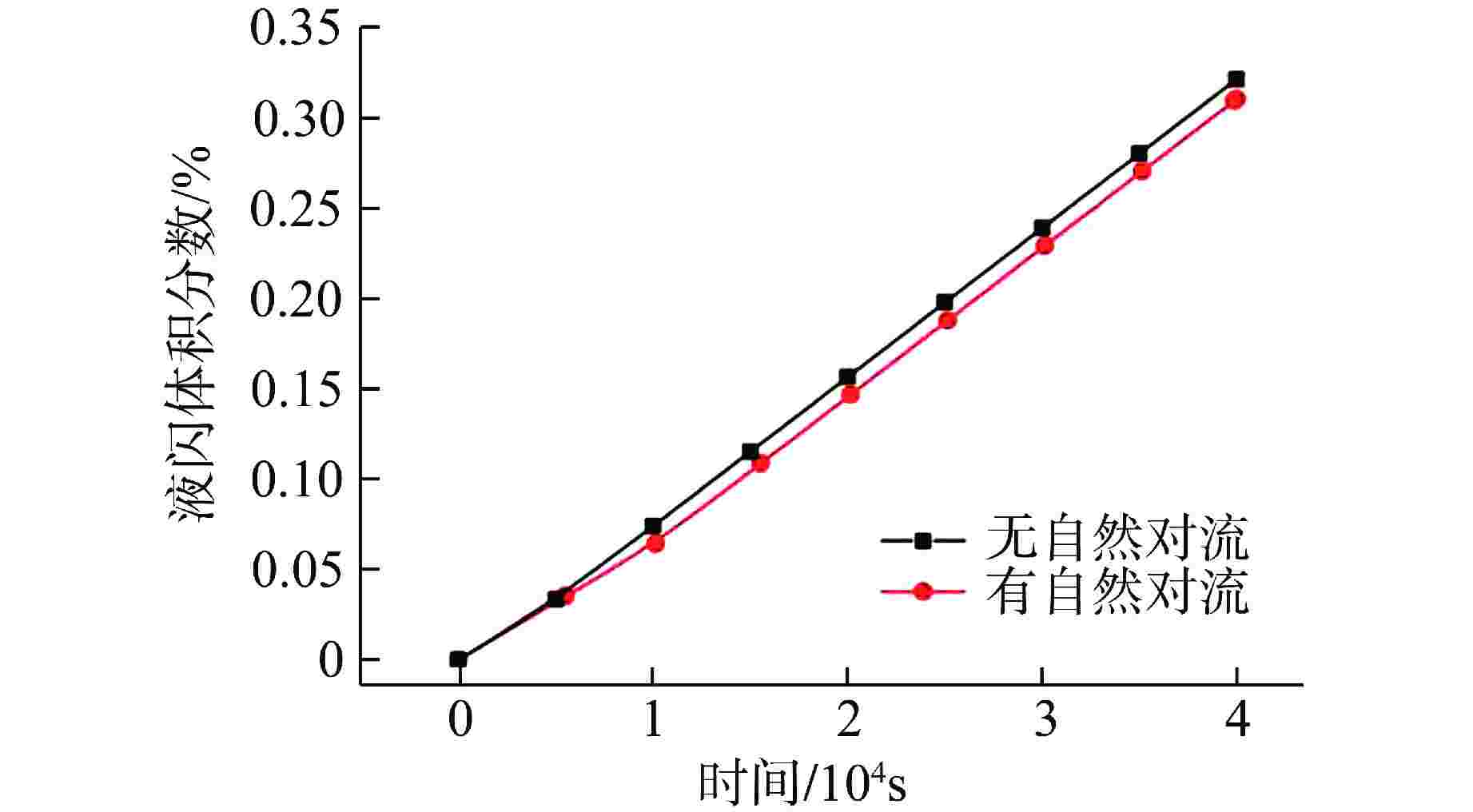

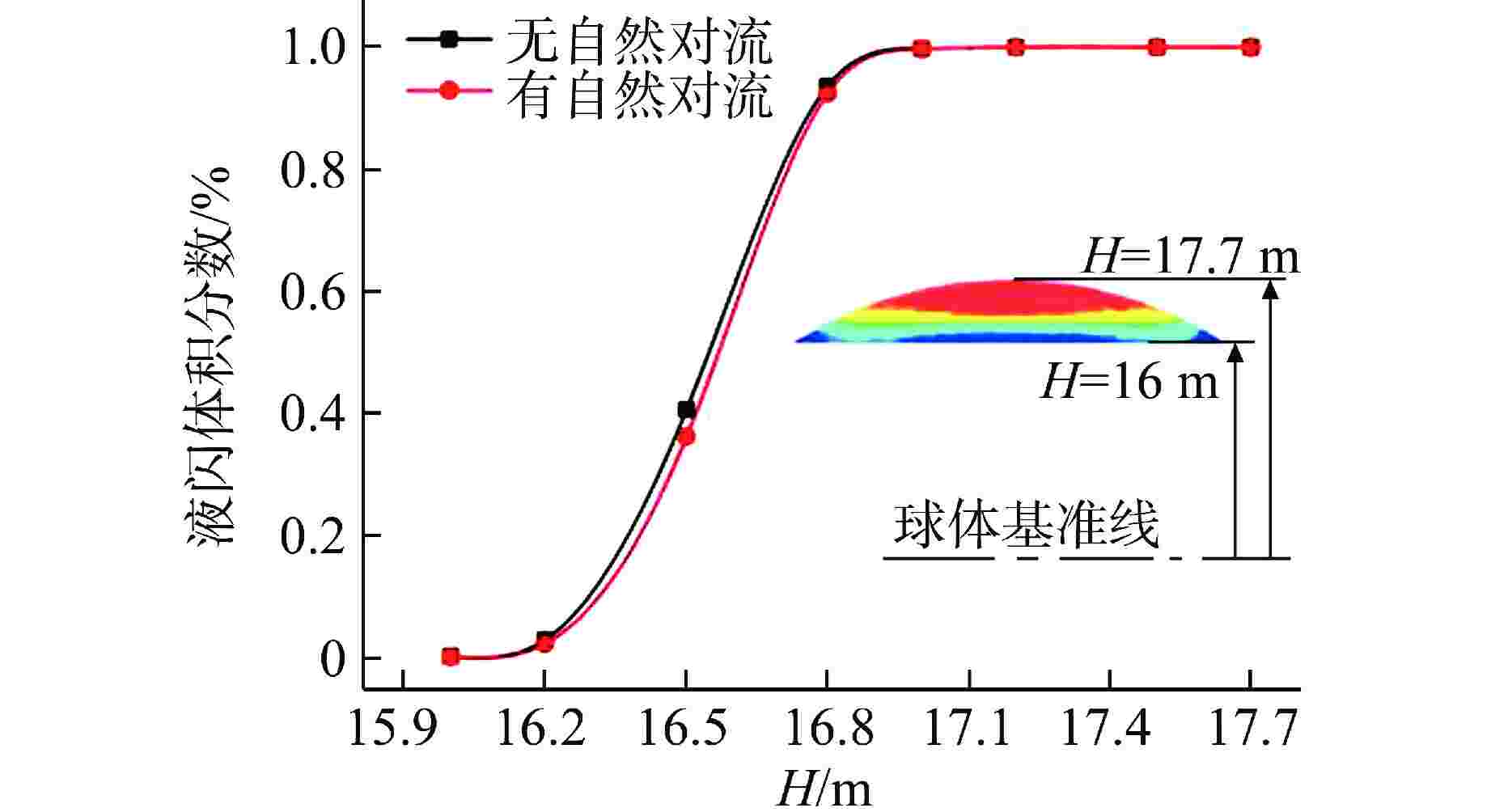

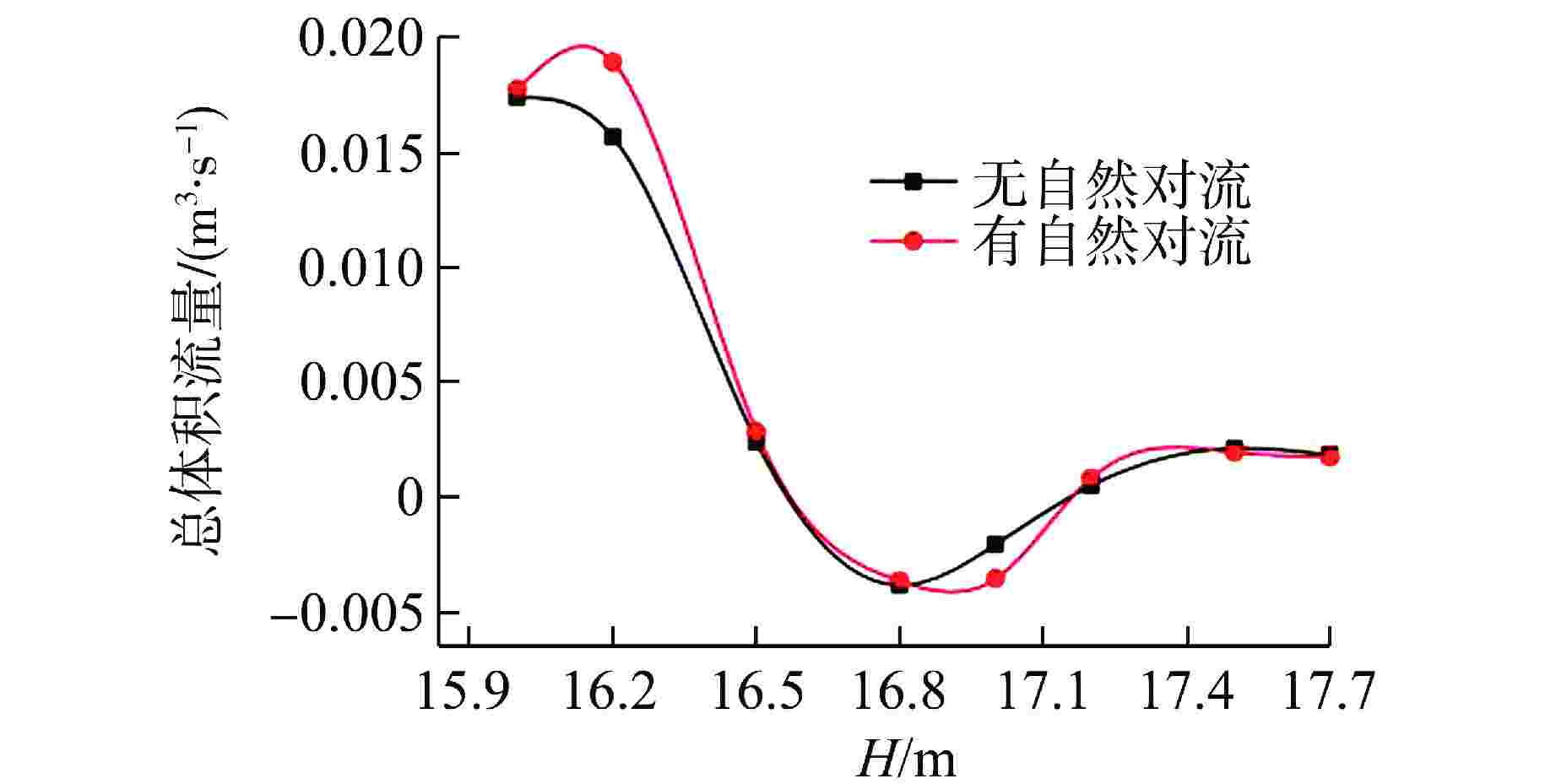

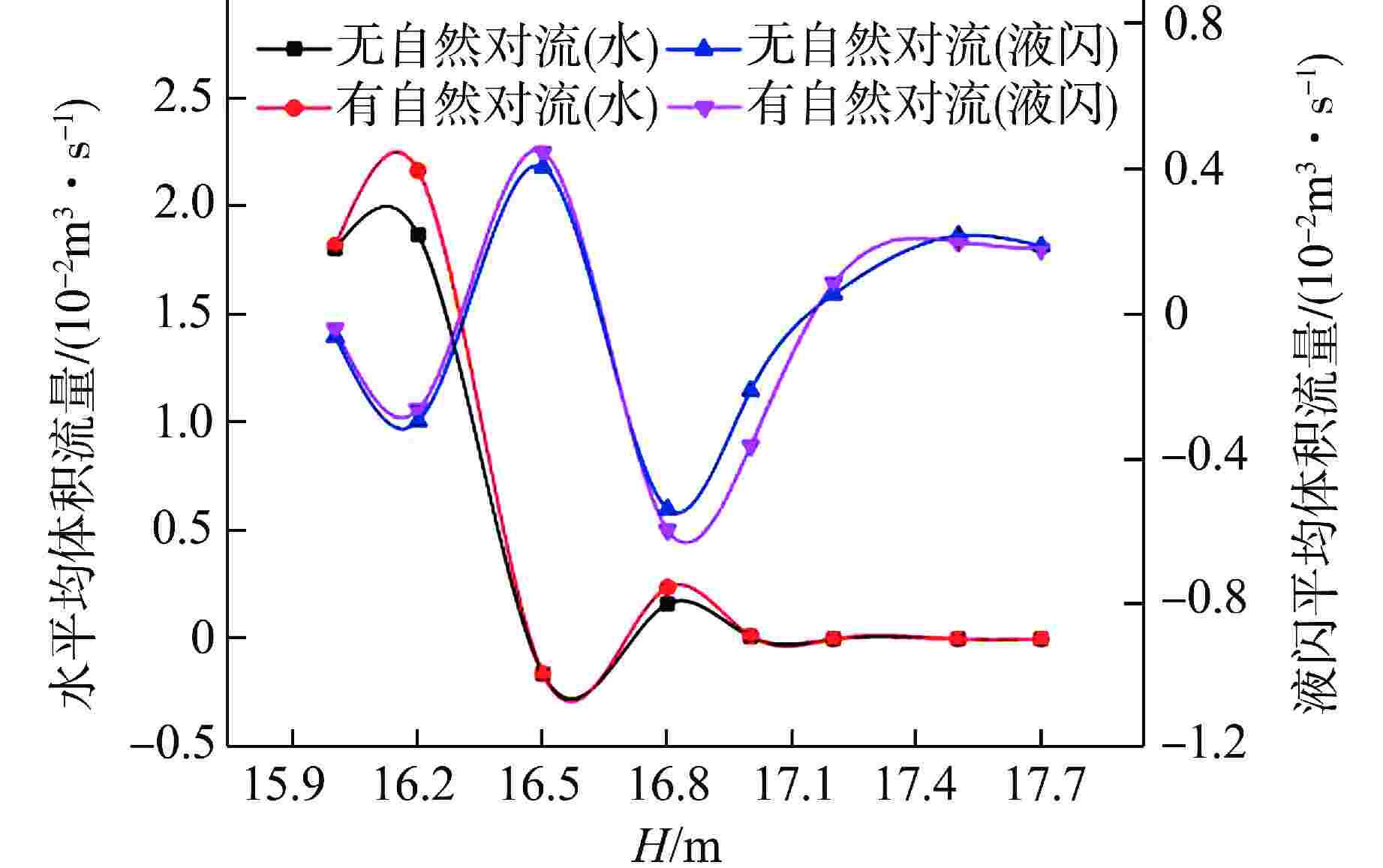

摘要: 中微子实验装置一方面需要屏蔽大量的宇宙射线和来自岩石、空气、灰尘的天然放射性;另一方面需要尽可能降低实验设施自身的放射性本底。本文利用计算流体动力学(CFD)软件模拟研究了中心探测器(大直径球罐)内液体闪烁体(简称液闪)和超纯水的置换过程,分析水中的放射性杂质进入液闪的情况,研究自然对流对置换过程中液闪本底的影响。通过模拟无自然对流和有自然对流2种工况,得到2种工况下液闪和水的相态与流态分布以及相含量随时间的变化情况,提取出相界面处竖直向上速度,并计算得出截面向上总流量,以判断自然对流对置换过程的影响。结果表明:在有自然对流工况下液闪向上的平均体积流量是小于无自然对流状态的,可知自然对流可以抑制水中放射性杂质进入液闪。

-

关键词:

- 大直径球罐 /

- 计算流体动力学(CFD) /

- 置换 /

- 自然对流

Abstract: On the one hand, the Neutrino experimental facility needs to shield a lot of cosmic rays and natural radioactivity from rocks, air and dust. On the other hand, it is necessary to reduce the radioactive background of the experimental facility as much as possible. In this paper, the displacement process of liquid scinulator (liquid flash) and ultrapure water in the central detector (large-diameter spherical tank) is studied by CFD simulation. The situation of radioactive impurities in the water entering the liquid scinulator is analyzed, and the effect of natural convection on the liquid flash background during the displacement is studied. By simulating the two conditions of "no natural convection" and "with natural convection", the phase and flow distribution under the two different conditions was obtained, and the changes in the phase content with time are also obtained. The vertical upward velocity at the phase interface was extracted, and the total upward flow of the section was calculated to judge the influence of natural convection on the displacement process. The results show that the upward average volume flow of the liquid scintillator in the natural convection is less than that under the condition of no natural convection, which shows that natural convection can inhibit radioactive impurities from entering the liquid scintillator.-

Key words:

- Large diameter spherical tank /

- CFD /

- Displacement /

- Natural convection

-

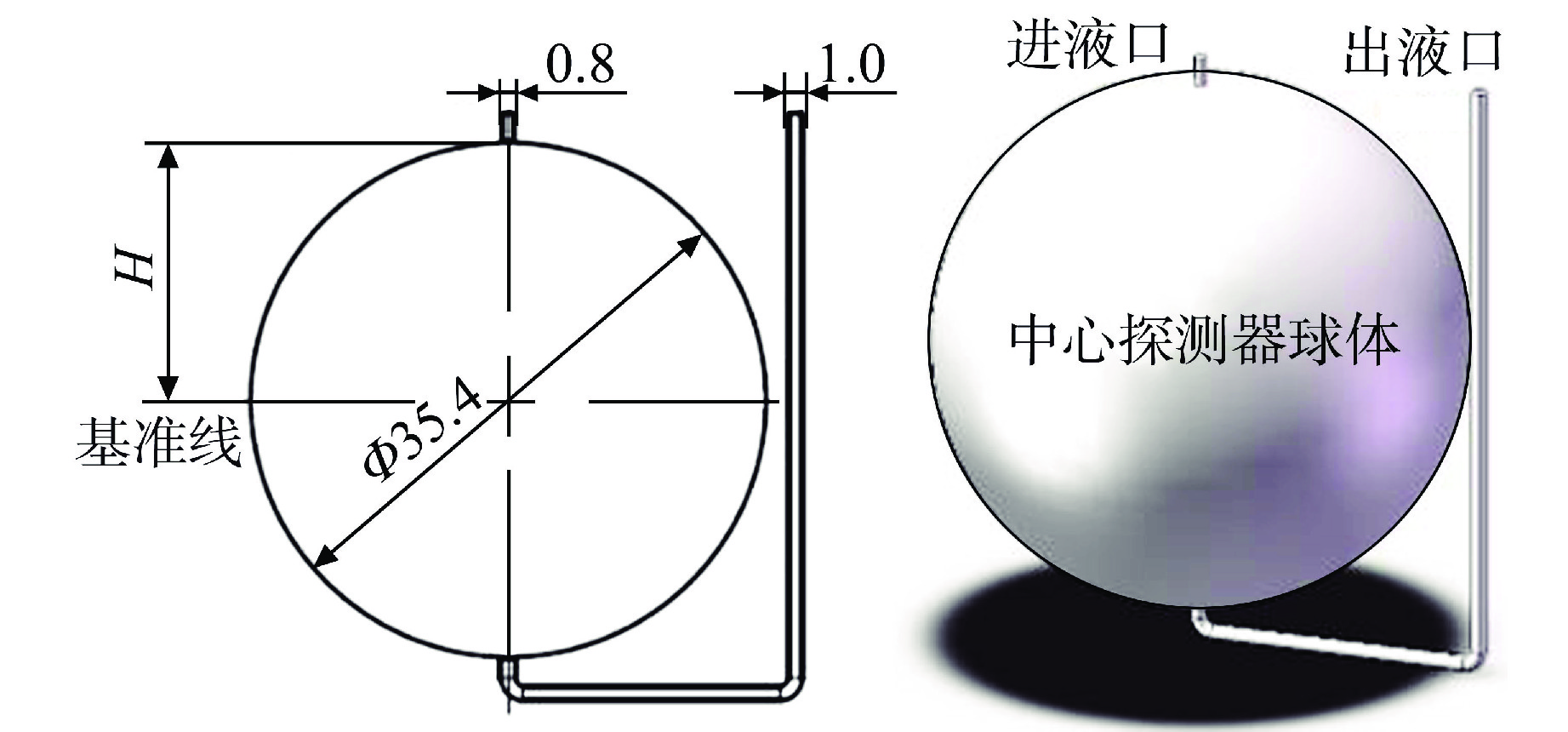

表 1 球形中心探测器尺寸

Table 1. Size of Spherical Center Detector

名称 进液管 中心探测器 出液管 内径/m 0.8 35.4 1.0 容积/m3 1.01 23228 48.77 表 2 液闪属性参数

Table 2. Properties of Liquid Scintillator

密度/

(kg·m−3)导热系数/

[W·(m·K)−1]比热容/

[J·(kg·K)−1]黏度/

[(kg·m)·s−1]体积膨胀

系数/K−1856 0.1426 2304 4.012×10−3 8.9×10−4 表 3 不同工况设置

Table 3. Settings of Different Operating Conditions

工况设置 工况一(无自然对流) 工况二(有自然对流) 相的数量 两相 两相 初始液闪体积分数 0 0 液闪密度/(kg·m−3) 不变 变化 入口温度/℃ 24 24 球壁面温度/℃ 24 20~22.74 计算工况 瞬态 瞬态 -

[1] 唐绍猛,刘德俊,文江波. 高黏油水两相流研究进展[J]. 化工进展,2017, 36(8): 2742-2747. [2] ABDUVAYT P, MANABE R, WATANABE T, et al. Analysis of oil/water-flow tests in horizontal, hilly terrain, and vertical pipes[J]. SPE Production & Operations, 2006, 21(1): 123-133. [3] 钱益斌,杨利民. 管道内油水两相流动研究进展[J]. 化工进展,2009, 28(4): 566-573. [4] 伞宇曦,吴明,张康南,等. 水平渐变管内油水两相流模拟研究[J]. 当代化工,2016, 45(1): 156-159,188. [5] 郭方圆,王丽军,成有为,等. 规整填料内高密度差液液两相流动模拟[J]. 化学反应工程与工艺,2020, 36(2): 97-107. [6] 白芳杰. 输油管道流场的仿真模拟[J]. 化学工程与装备,2013(1): 27-29. [7] 成战胜,行春丽,王拥军. 水置换法在化工生产中的应用[J]. 天然气化工,2005, 30(3): 38-40. [8] 刘一楠. 基于分子动力学模拟的天然气水合物分解和置换过程机理研究[D]. 天津: 天津大学,2017. [9] 张文豪. 大型LNG储罐间接置换过程及BOG排放研究[D]. 济南: 山东建筑大学,2022. [10] 赵国明. 大型LNG储罐氮气置换过程分析及优选研究[D]. 济南: 山东建筑大学,2021. [11] 彭宏恺,李建军,吴修鹏. 液化气船的罐体水置换法研究[C]//中国科学技术协会. 节能环保 和谐发展——2007中国科协年会论文集(三). 北京: 中国科学技术协会声像中心,2007: 1926-1930. [12] 骆碧君,樊在义,陈丽娜,等. 利用Fluent软件研究景观水体循环模式与流场优化[J]. 中国给水排水,2009, 25(19): 95-97. [13] 贾伟智,阎庆绂. 大型循环水体置换时间的实验研究[J]. 太原理工大学学报,2006, 37(1): 67-70. doi: 10.3969/j.issn.1007-9432.2006.01.020 [14] 杨晓宇,衡月昆,何伟,等. 江门中微子实验中心探测器小模型的结构设计[C]//中国力学学会. 第29届全国结构工程学术会议论文集(第I册). 北京: 《工程力学》杂志社,2020: 208-218. [15] 崔会敏. 顶部冷却三角形截面腔内的自然对流[D]. 北京: 北京交通大学,2016. [16] 乔曼曼. 通道及开口腔内外的自然对流[D]. 北京: 北京交通大学,2020. [17] 王福军. 计算流体动力学分析—CFD软件原理与应用[M]. 北京: 清华大学出版社,2004. [18] HIRT C W, NICHOLS B D. Volume of fluid (VOF) method for the dynamics of free boundaries[J]. Journal of Computational Physics, 1981, 39(1): 201-225. doi: 10.1016/0021-9991(81)90145-5 [19] BRACKBILL J U, KOTHE D B, ZEMACH C. A continuum method for modeling surface tension[J]. Journal of Computational Physics, 1992, 100(2): 335-354. doi: 10.1016/0021-9991(92)90240-Y -

下载:

下载: