Study on Characteristics of Xi’an Pulsed Reactor in Reflood Stage

-

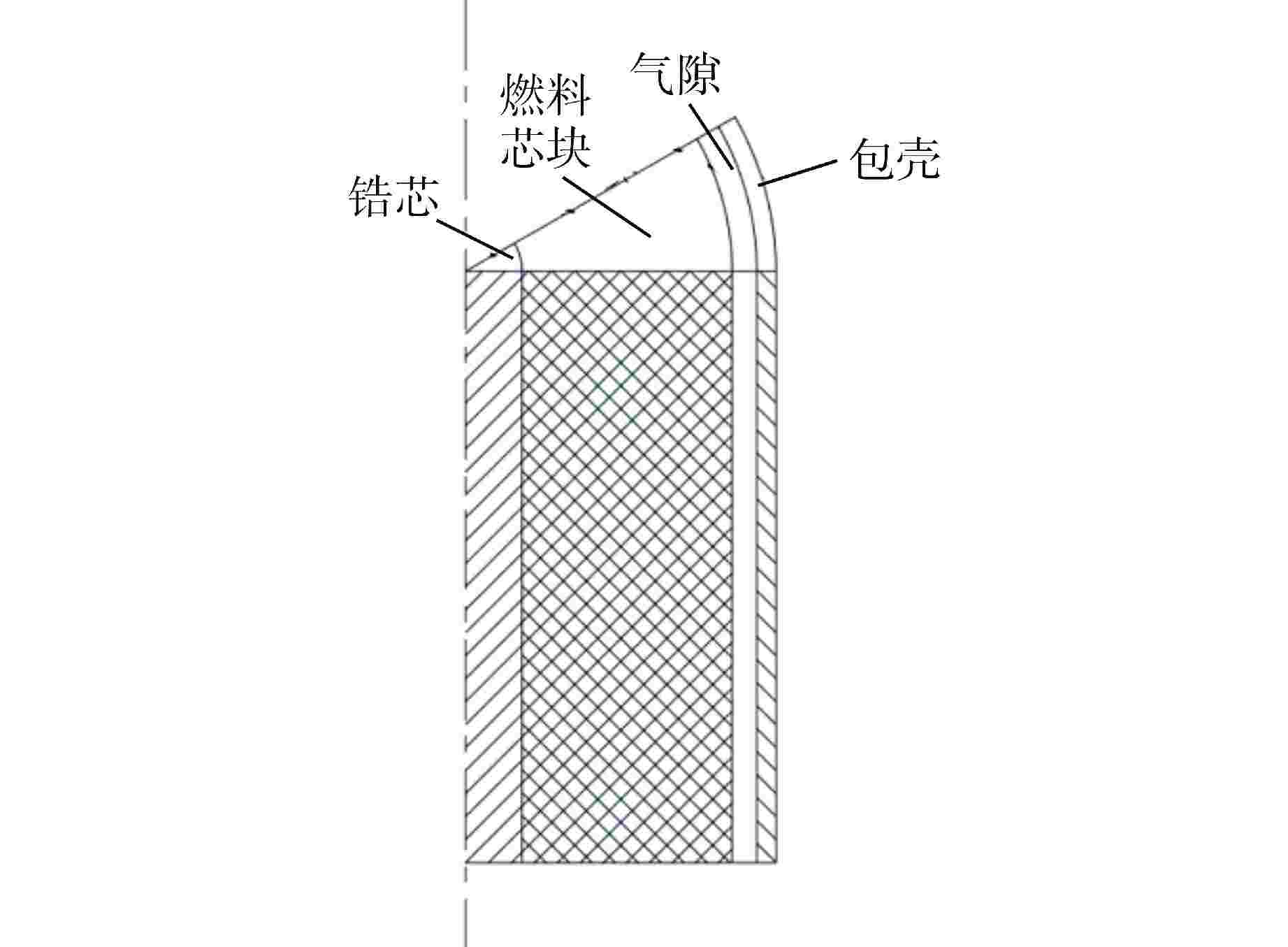

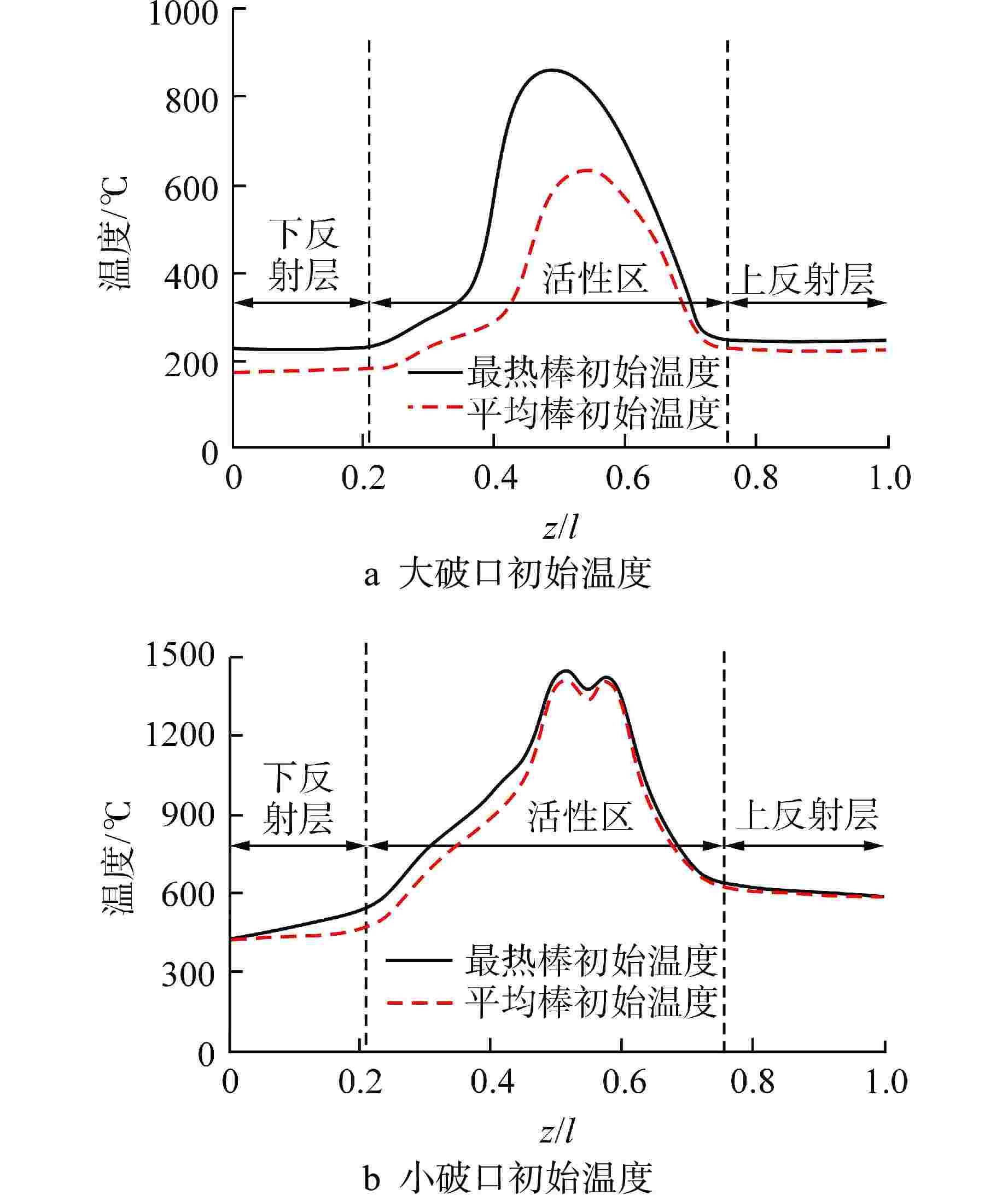

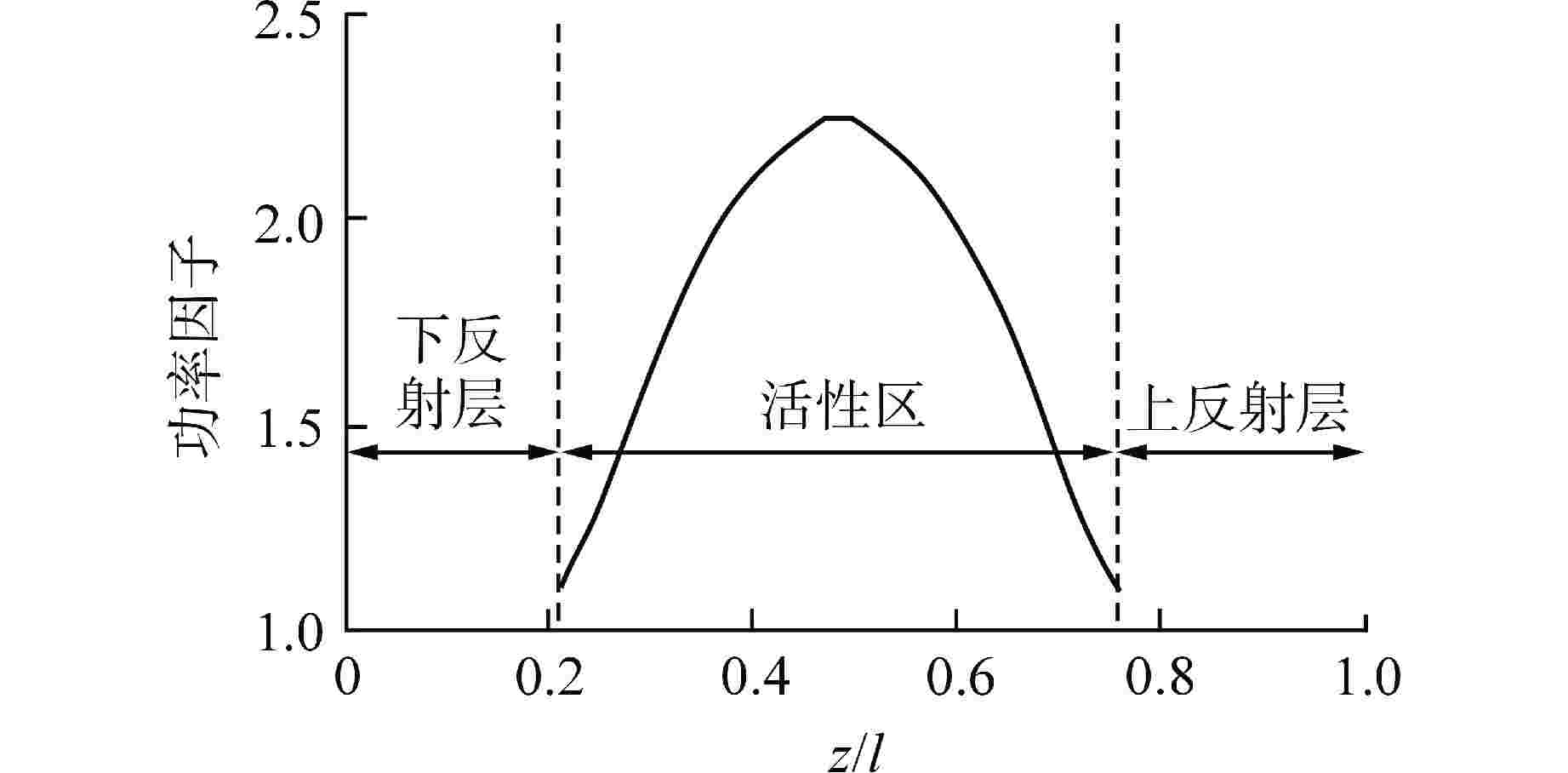

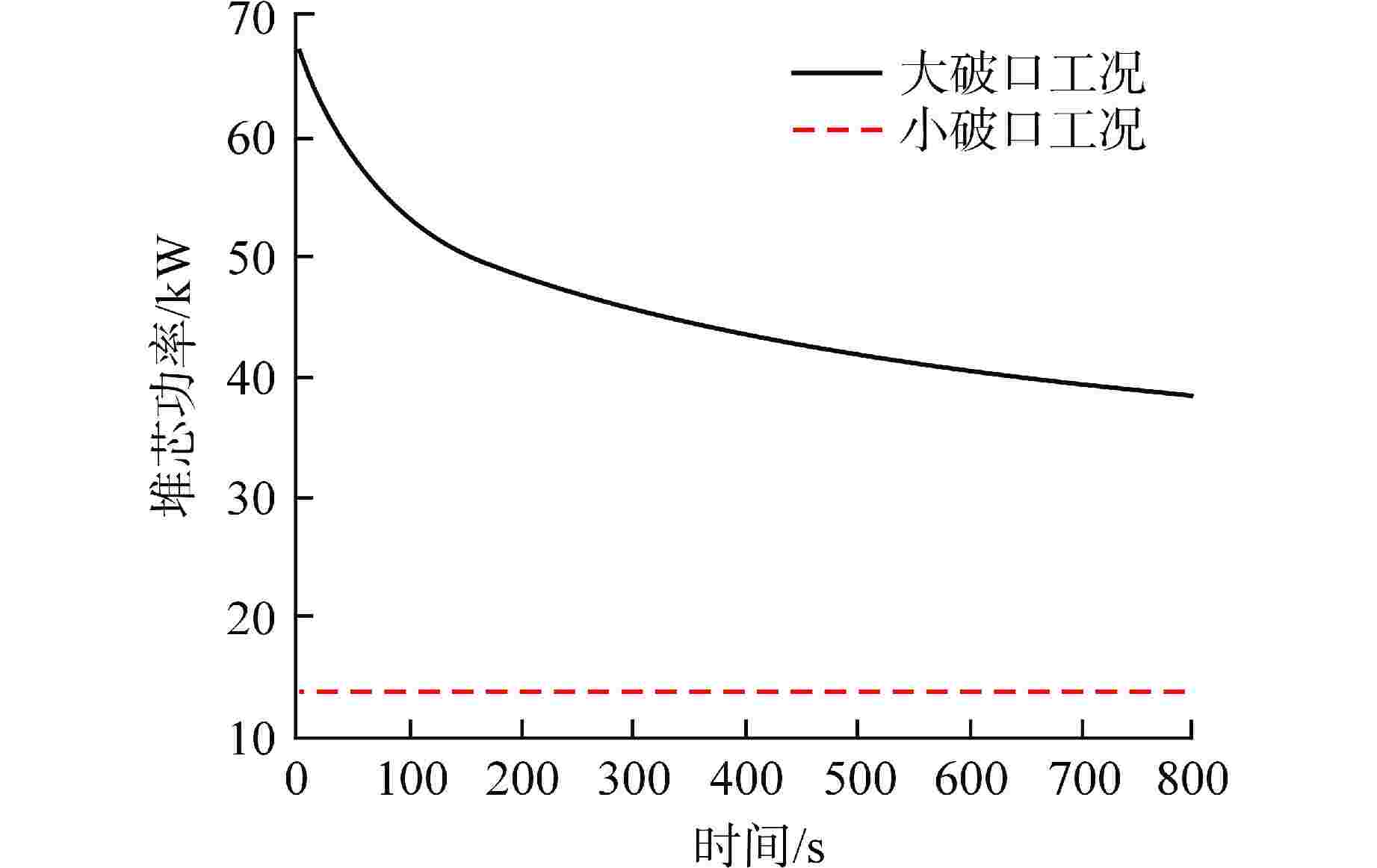

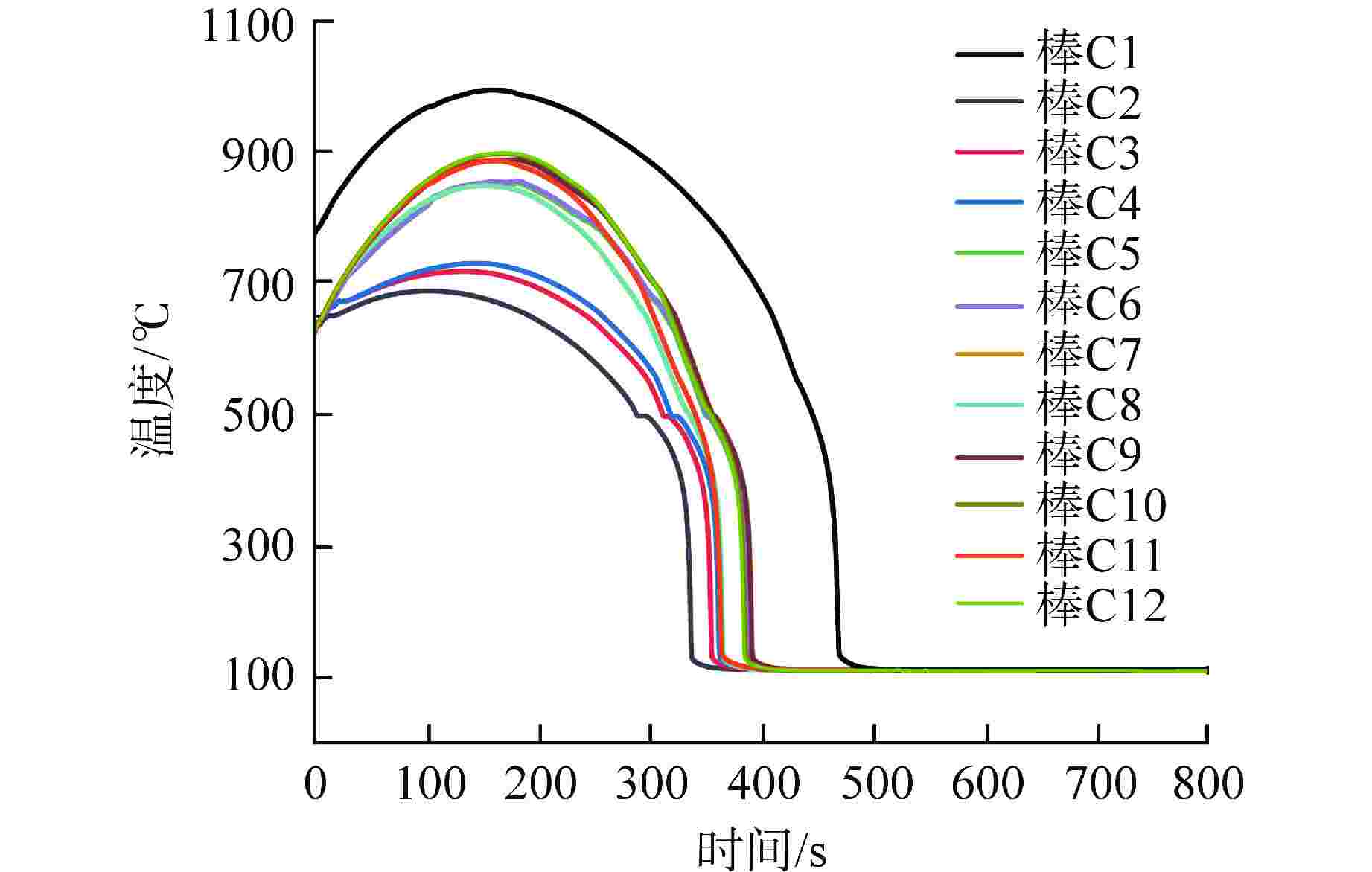

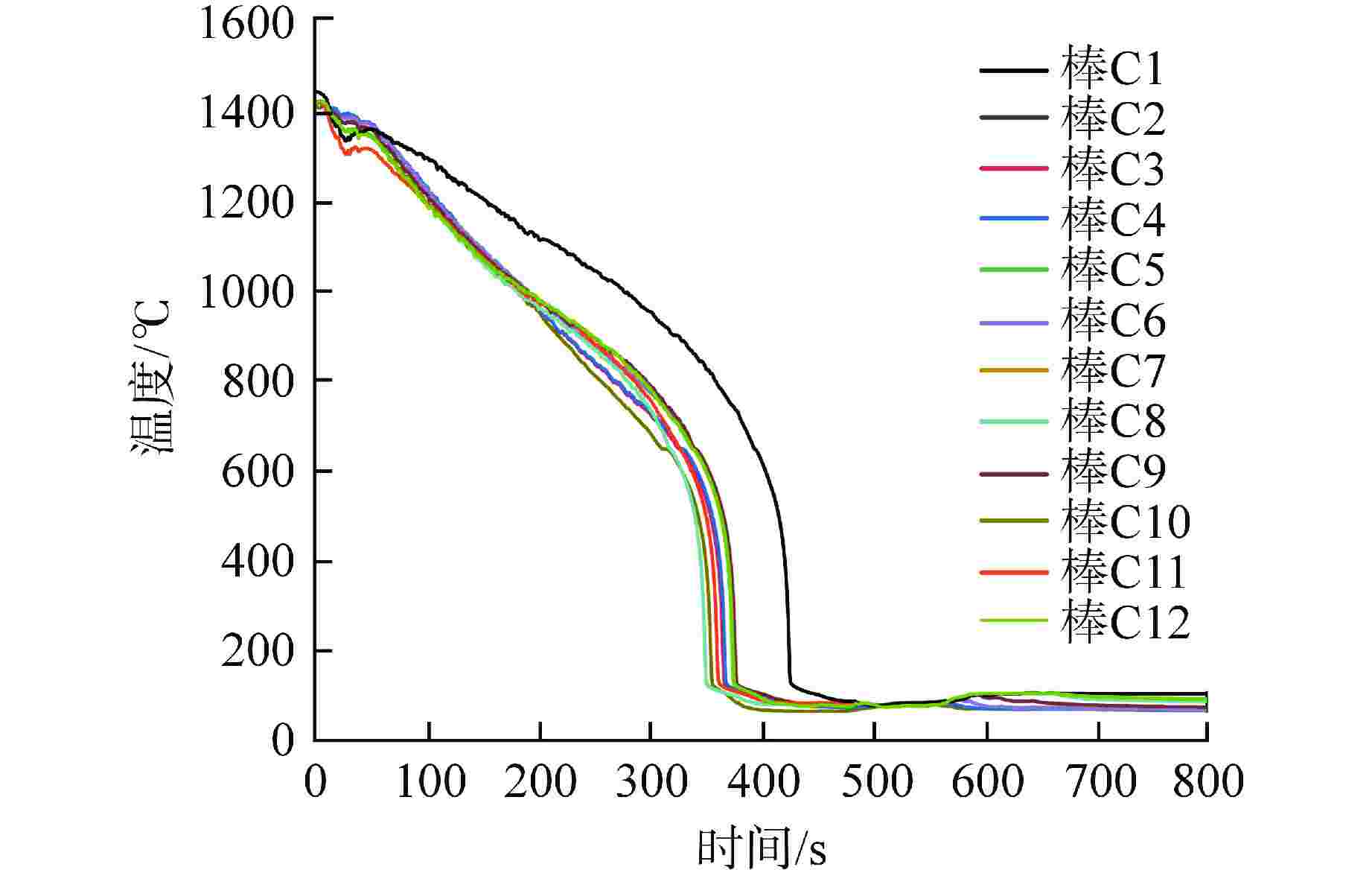

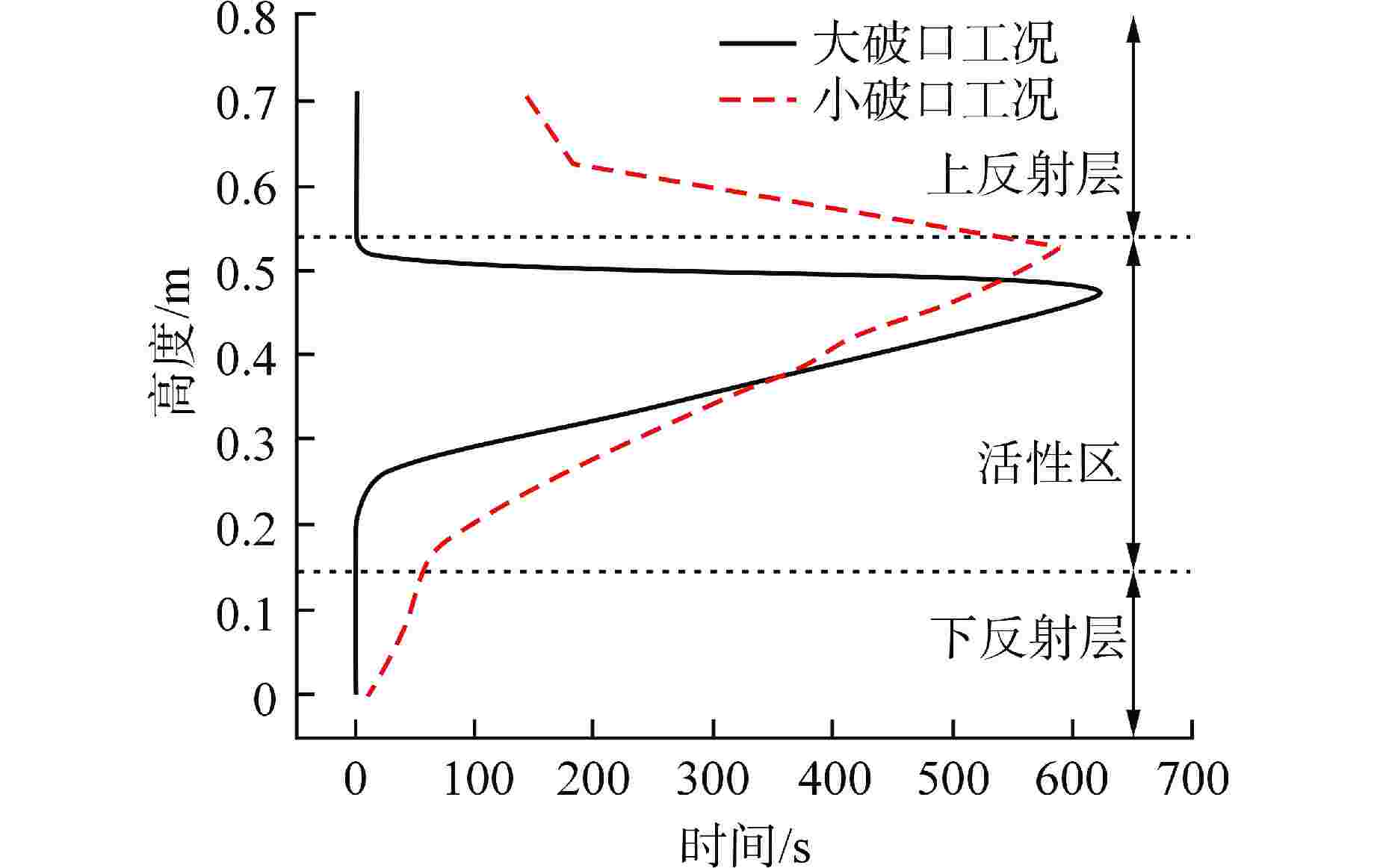

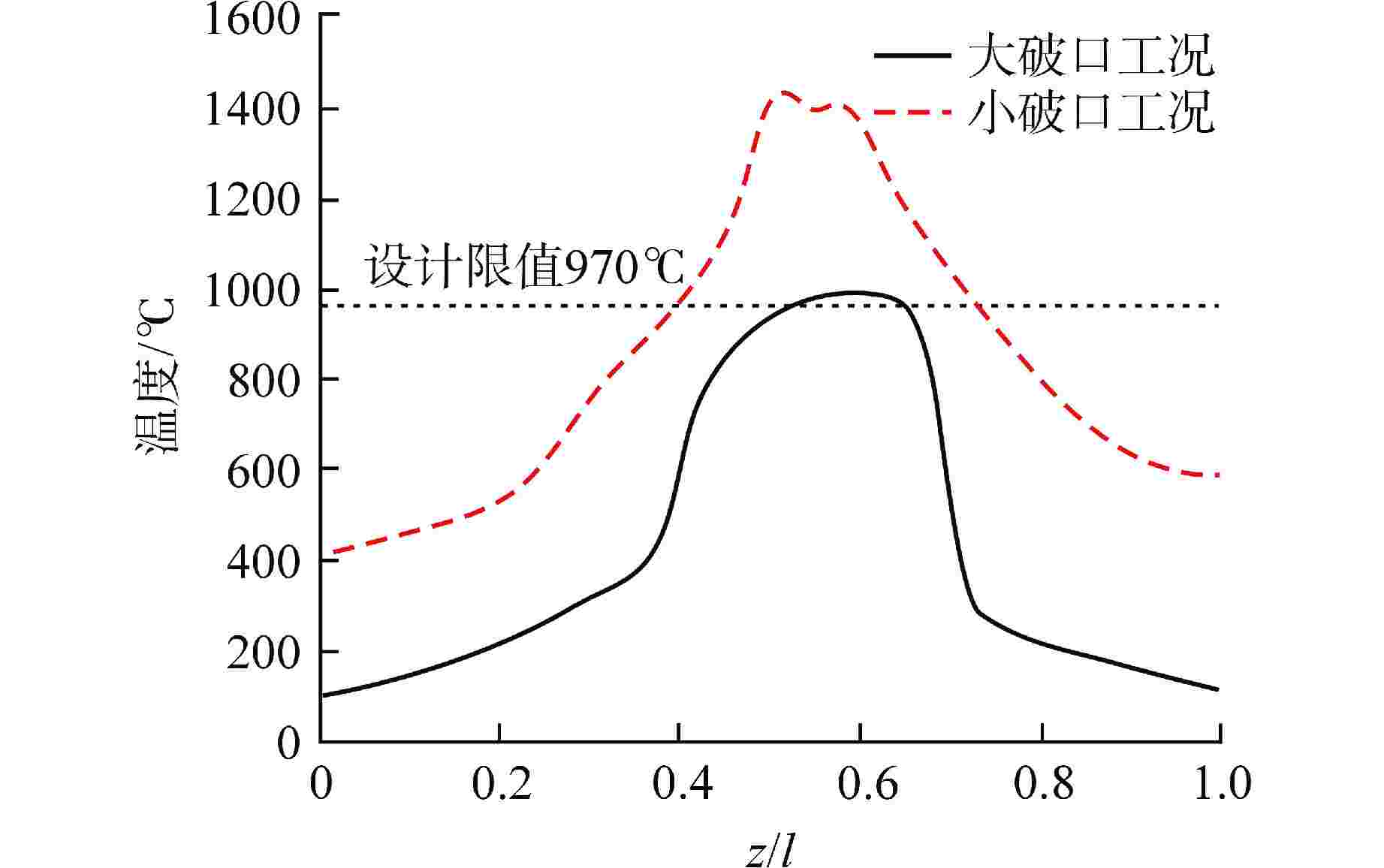

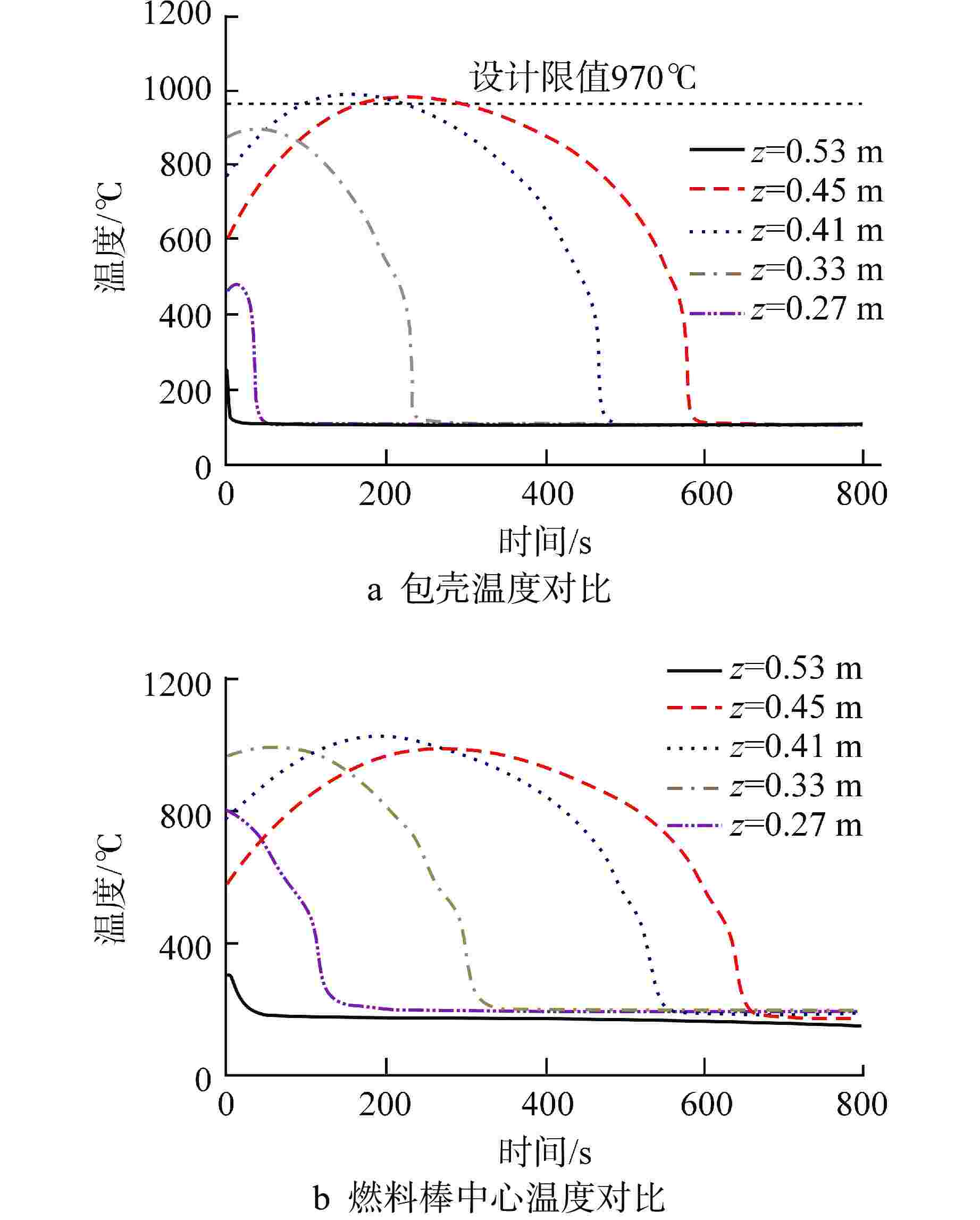

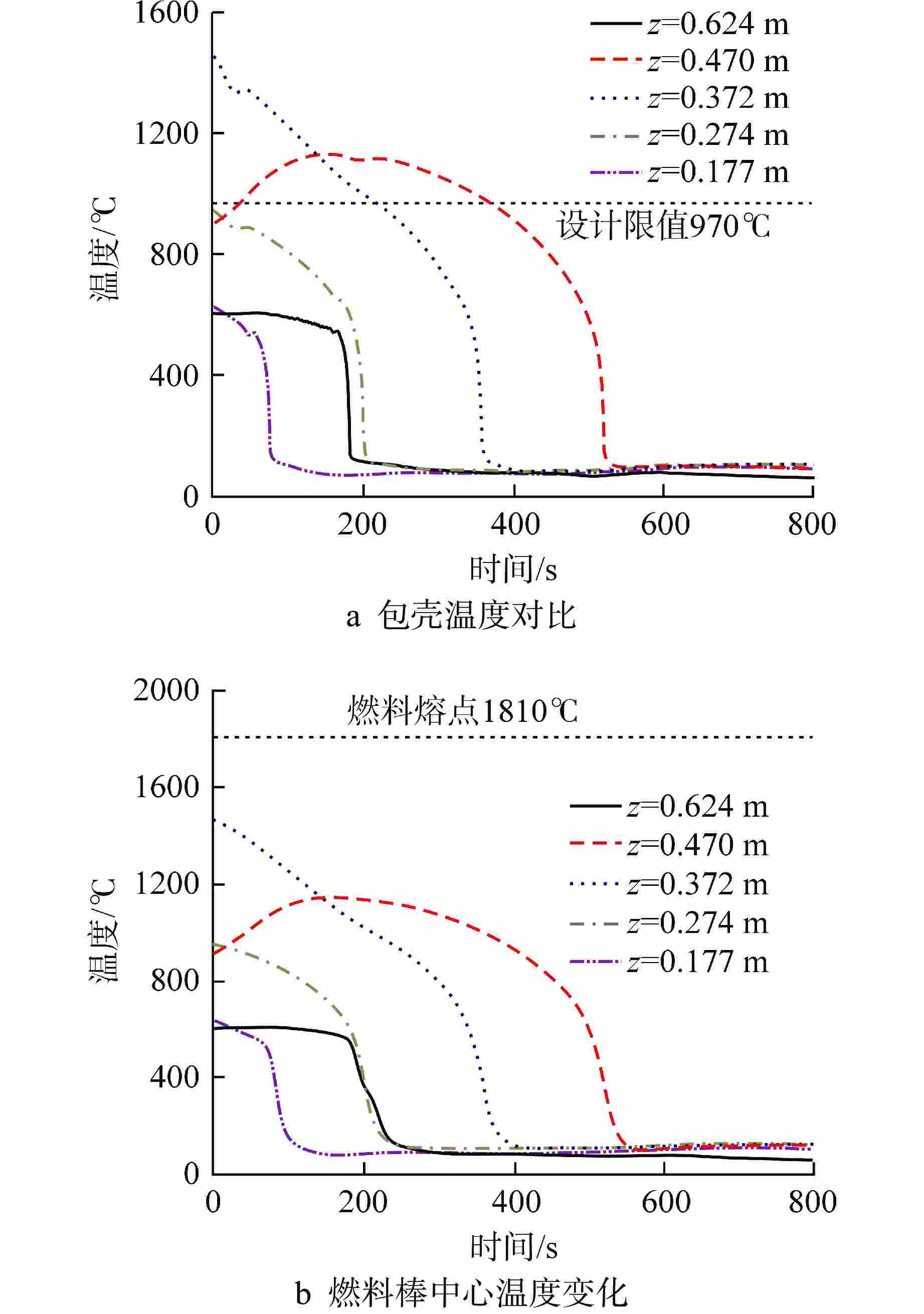

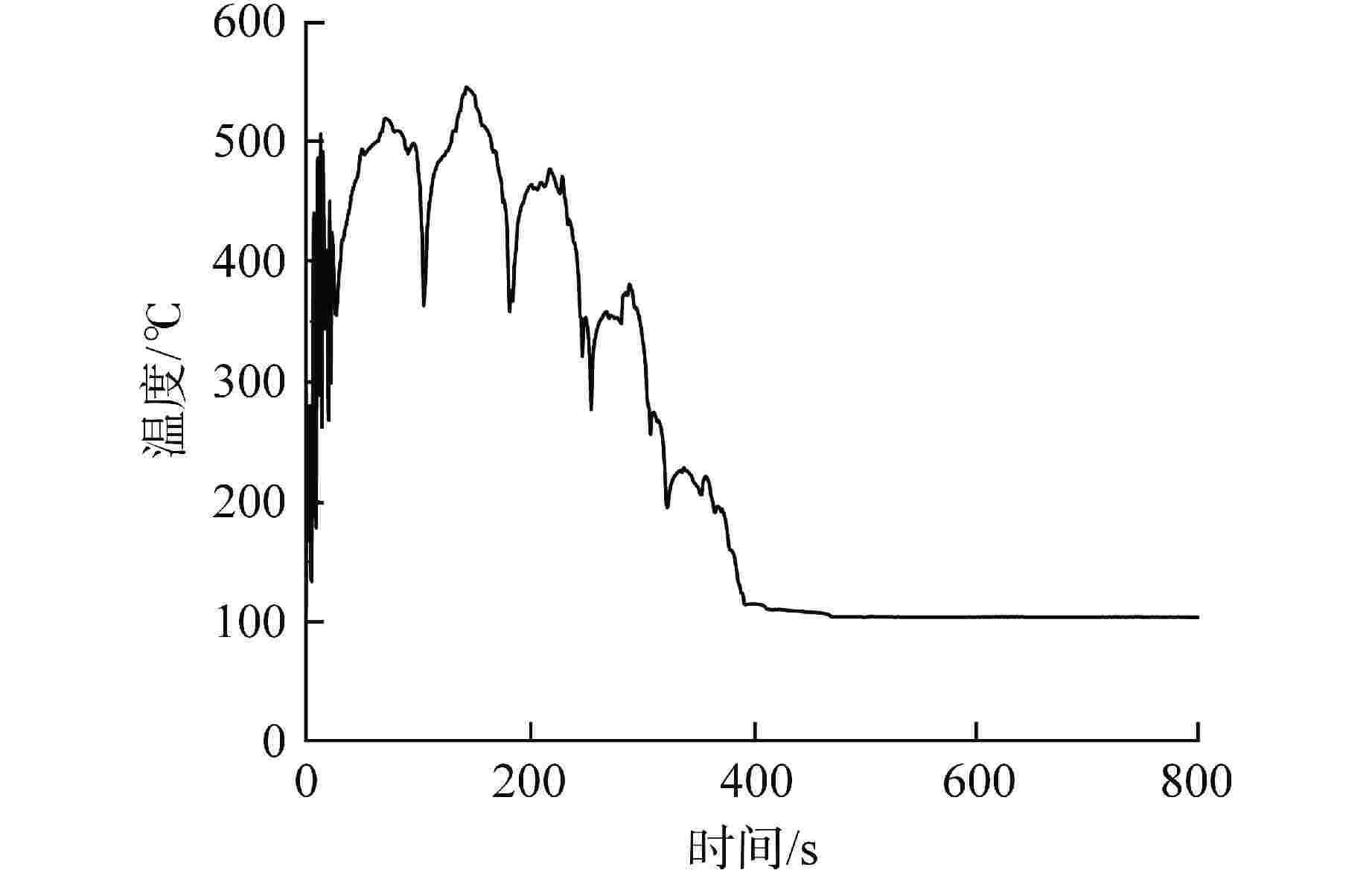

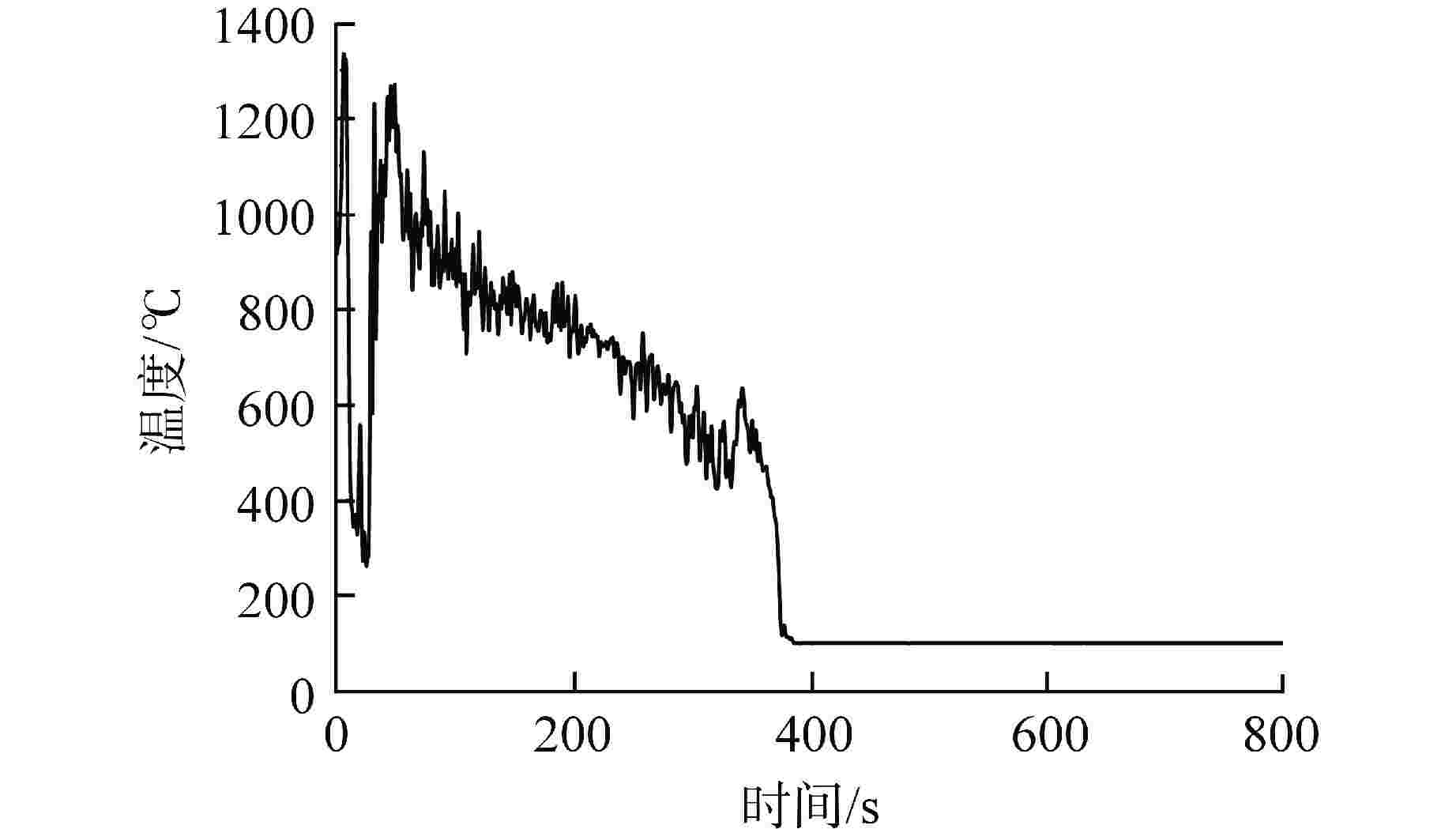

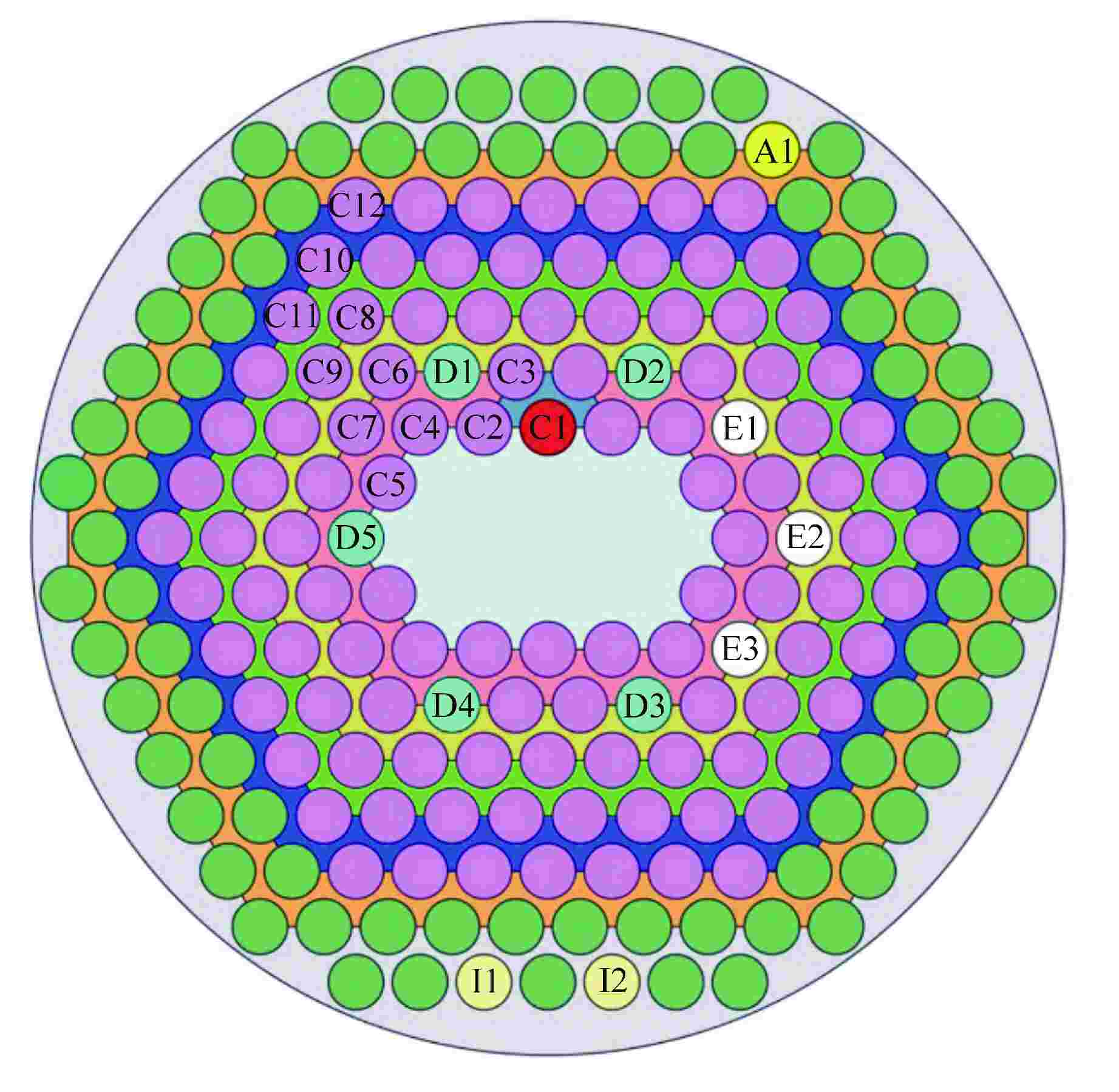

摘要: 再淹没过程是失水事故重要环节,明确再淹没过程中堆芯瞬态热工特性对破口失水事故安全分析极为关键。本研究基于子通道分析程序CTF,针对西安脉冲反应堆典型大、小破口失水事故中再淹没过程开展了瞬态分析计算。分析中将堆芯依据功率划分为8个通道,获得了骤冷前沿和堆芯温度的时空分布特性,分析了不同位置燃料棒在各高度的包壳与燃料棒中心温度变化规律。研究结果表明,外围燃料棒相较于中心最热棒温度更低且更早被完全冷却;大、小破口失水事故工况下冷却剂均能完全淹没堆芯,使堆芯完全冷却,大破口失水事故工况下因衰变功率更大,堆芯被完全冷却所需时间更长;大破口失水事故工况下包壳失效风险较小,小破口失水事故包壳失效风险相较于大破口失水事故工况更高,大、小破口失水事故工况下均不会发生燃料芯块熔毁。Abstract: Reflood process is an important part of LOCA, and it is crucial to identify the transient thermal characteristics of core during reflood process for the safety analysis of break accident. Based on the subchannel analysis code CTF, the transient analysis and calculation are carried out for the reflood process of Xi'an pulsed reactor in typical large and small break loss of coolant accidents. In the analysis, the core is divided into eight channels based on power. The spatiotemporal distribution characteristics of the quenching front and core temperature are obtained, and the temperature changes of the cladding and fuel rod center at different heights of fuel rods at different positions are analyzed. The results show that the temperature of the outer fuel rods is lower and completely cooled earlier than that of the hottest rod at the center. Under both large and small break conditions, the coolant can completely submerge the core, allowing it to cool completely. Under large break conditions, due to higher decay power, it takes longer for the core to be completely cooled. The risk of cladding failure is relatively low under large break conditions, while the risk of cladding failure in small break accidents is higher compared to large break conditions. Fuel pellet melting will not occur under both large and small break conditions.

-

Key words:

- Pulsed reactor /

- Reflood /

- Core temperature /

- Subchannel code /

- Safety features

-

表 1 堆芯几何参数

Table 1. Core Geometry Parameters

参数 数值 水池筒体内径/m 2.5 堆芯筒体内径/m 0.694 燃料棒间距/m 0.043 燃料棒长度/m 0.71 活性区长度/m 0.39 表 2 边界条件

Table 2. Boundary Conditions

参数 大破口失水事故 小破口失水事故 再淹没时间/s 5901 70374 再淹没压力/MPa 0.101 0.101 再淹没质量流量/(kg·s−1) 1.67 1.67 初始气体焓值/(kJ·kg−1) 682 1655 棒束表面平均

线功率密度/(kW·m−1)7.9 1.7 入口冷却剂温度/K 298 298 -

[1] 杨岐,卜永熙,李达忠,等. 西安脉冲反应堆[J]. 核动力工程,2002, 23(6): 1-7. doi: 10.3969/j.issn.0258-0926.2002.06.001 [2] 李莹,陈鑫,王金宇,等. 3×3棒束通道内再淹没过程实验研究[C]//中国核科学技术进展报告(第七卷)——中国核学会2021年学术年会论文集第2册(核能动力分卷). 烟台: 中国核学会,2021: 222-226. [3] 王宝生,唐秀欢,朱磊,等. XAPR中破口失水事故下堆芯自然循环冷却能力的功能可靠性研究[J]. 原子能科学技术,2019, 53(5): 844-852. [4] 王宝生,唐秀欢,沈志远,等. 西安脉冲堆概率安全分析技术要点及分析框架研究[J]. 核动力工程,2018, 39(3): 100-105. [5] 景春元,朱继洲,朱广宁,等. 脉冲反应堆失水事故分析[J]. 原子能科学技术,2000, 34(3): 199-204. [6] 陈立新,赵柱民,袁建新. 西安脉冲堆热工水力分析与脉冲特性分析[J]. 核动力工程,2006, 27(6): 1-4,17. [7] 陈立新,赵柱民,袁建新,等. 西安脉冲堆大破口失水事故分析[J]. 原子能科学技术,2009, 43(8): 678-682. doi: 10.7538/yzk.2009.43.08.0678 [8] 朱磊,陈立新,赵柱民,等. 西安脉冲反应堆超设计基准事故动态特性分析[J]. 原子能科学技术,2012, 46(S2): 800-806. [9] SALKO JR R, AVRAMOVA M, WYSOCKI A, et al. CTF 4.0 theory manual: ORNL/TM-2019/1145[R]. Oak Ridge: Oak Ridge National Laboratory, 2019. [10] 杨志林,李师新,徐明. COBRA-TF 程序的特点[J]. 核动力工程,1998, 19(3): 233-237. [11] ZUBER N. On the stability of boiling heat transfer[J]. Journal of Fluids Engineering, 1958, 80(3): 711-714. [12] YAMANOUCHI A. Effect of core spray cooling in transient state after loss of coolant accident[J]. Journal of Nuclear Science and Technology, 1968, 5(11): 547-558. doi: 10.1080/18811248.1968.9732513 [13] 张良,袁建新,赵巍,等. 西安脉冲反应堆在非脉冲瞬态工况下的动态特性研究[J]. 核动力工程,2020, 41(5): 1-7. [14] 郎雪梅,黄彦平. 管内顶部骤冷过程中骤冷前沿推进速度实验研究[J]. 核科学与工程,1998, 18(2): 109-118. [15] 黄彦平,郎雪梅. 骤冷前沿区域传热特性实验研究[J]. 核动力工程,1998, 19(2): 138-143. [16] 王金宇,王均,昝元峰,等. 环形通道内再淹没过程骤冷前沿推进速度实验研究[J]. 核动力工程,2018, 39(4): 63-66. [17] 李莹,王金宇,陈鑫,等. 圆管通道底部再淹没过程实验研究[J]. 原子能科学技术,2022, 56(6): 1180-1187. [18] 王金宇,王均,昝元锋,等. 环形通道内再淹没过程流动传热现象实验研究[J]. 核动力工程,2018, 39(4): 22-27. [19] 熊平. 圆柱骤冷沸腾表面热流密度反演及沸腾传热特性研究[D]. 北京: 北京化工大学,2021. [20] JIN Y, CHEUNG F B, SHIRVAN K, et al. Numerical investigation of rod bundle thermal–hydraulic behavior during reflood transients using COBRA-TF[J]. Annals of Nuclear Energy, 2020, 148: 107708. doi: 10.1016/j.anucene.2020.107708 -

下载:

下载: