Experiment Study on Critical Heat Flux of 19-Pin Helical Cruciform Fuel Assembly

-

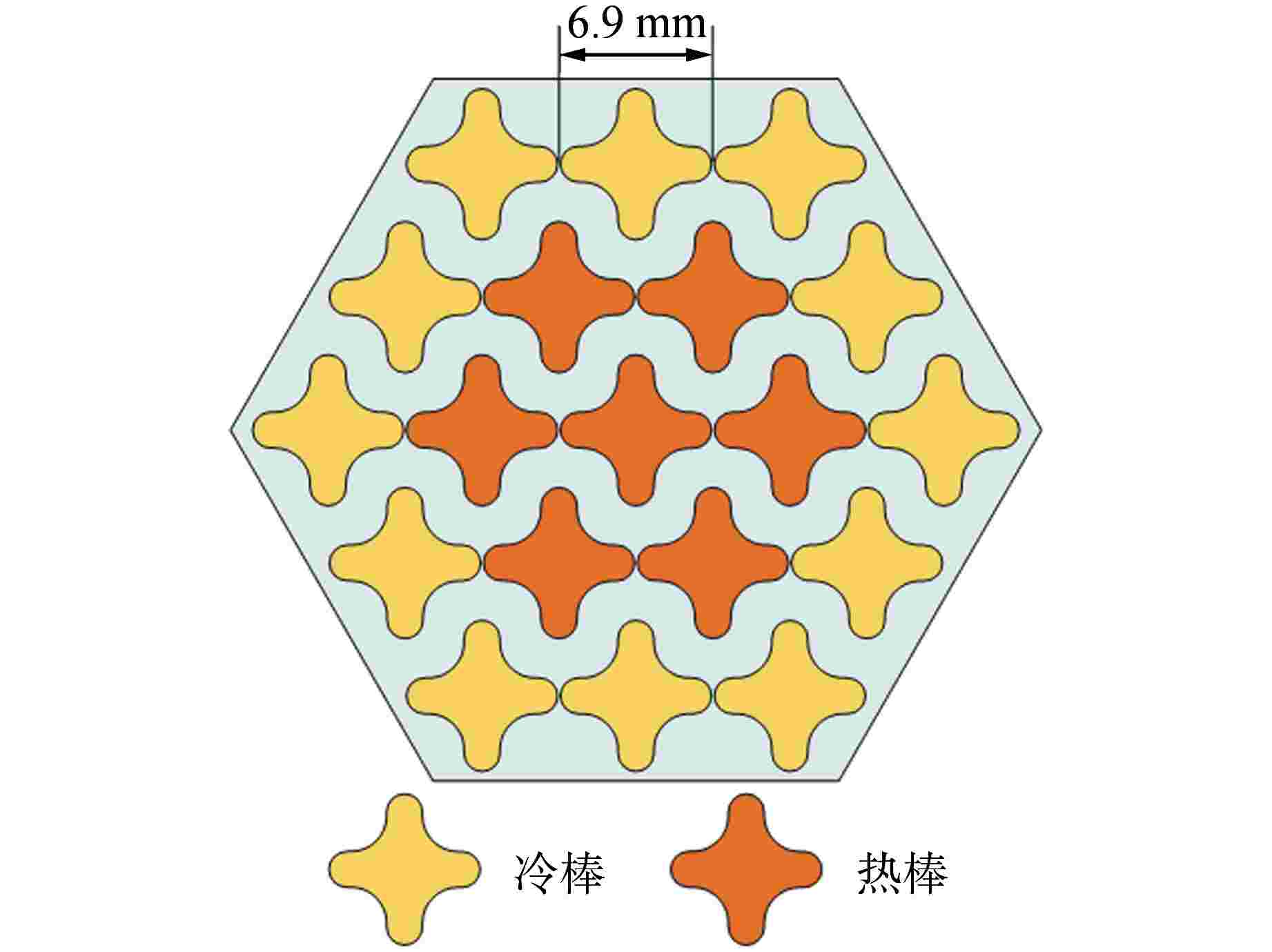

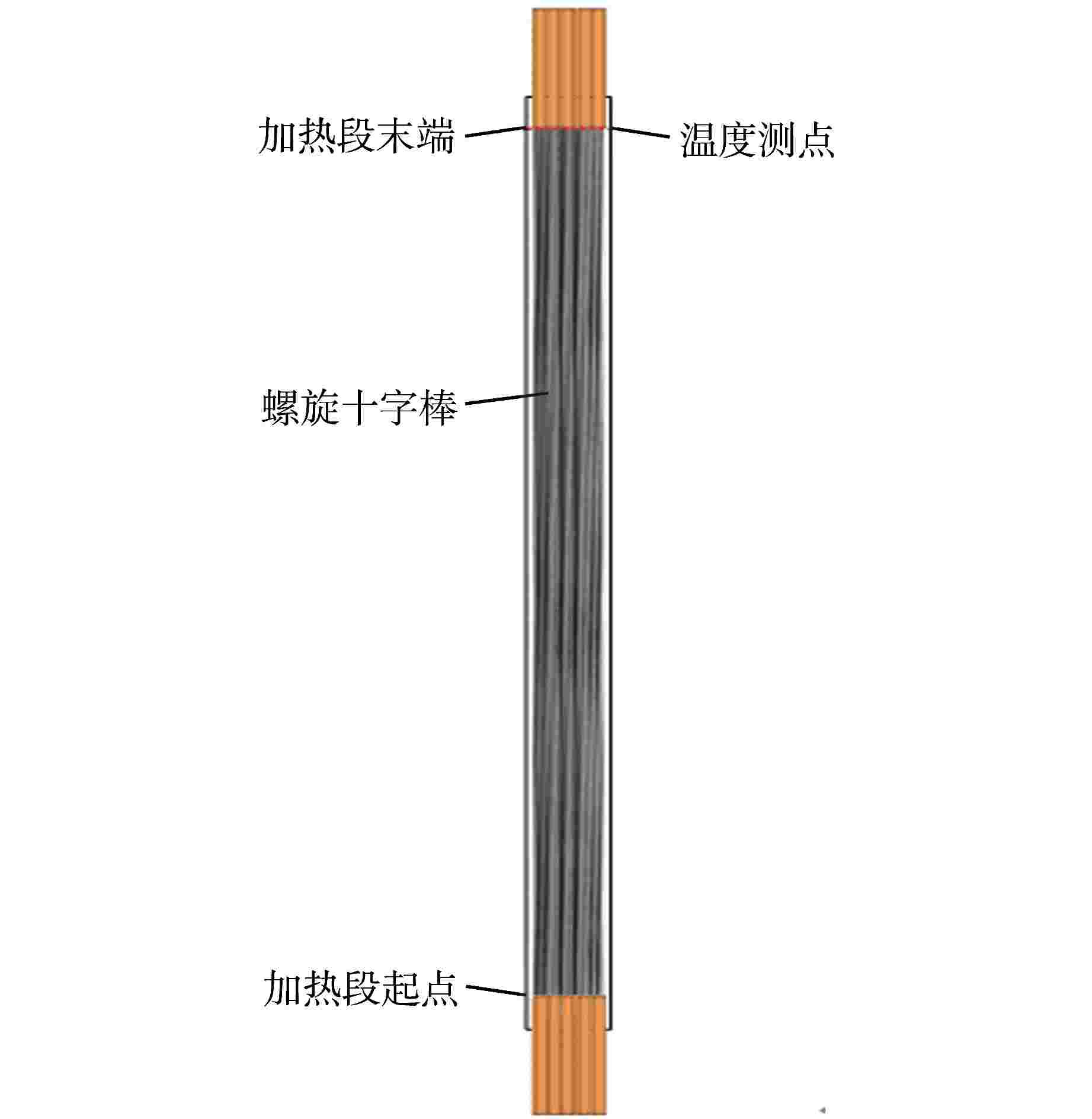

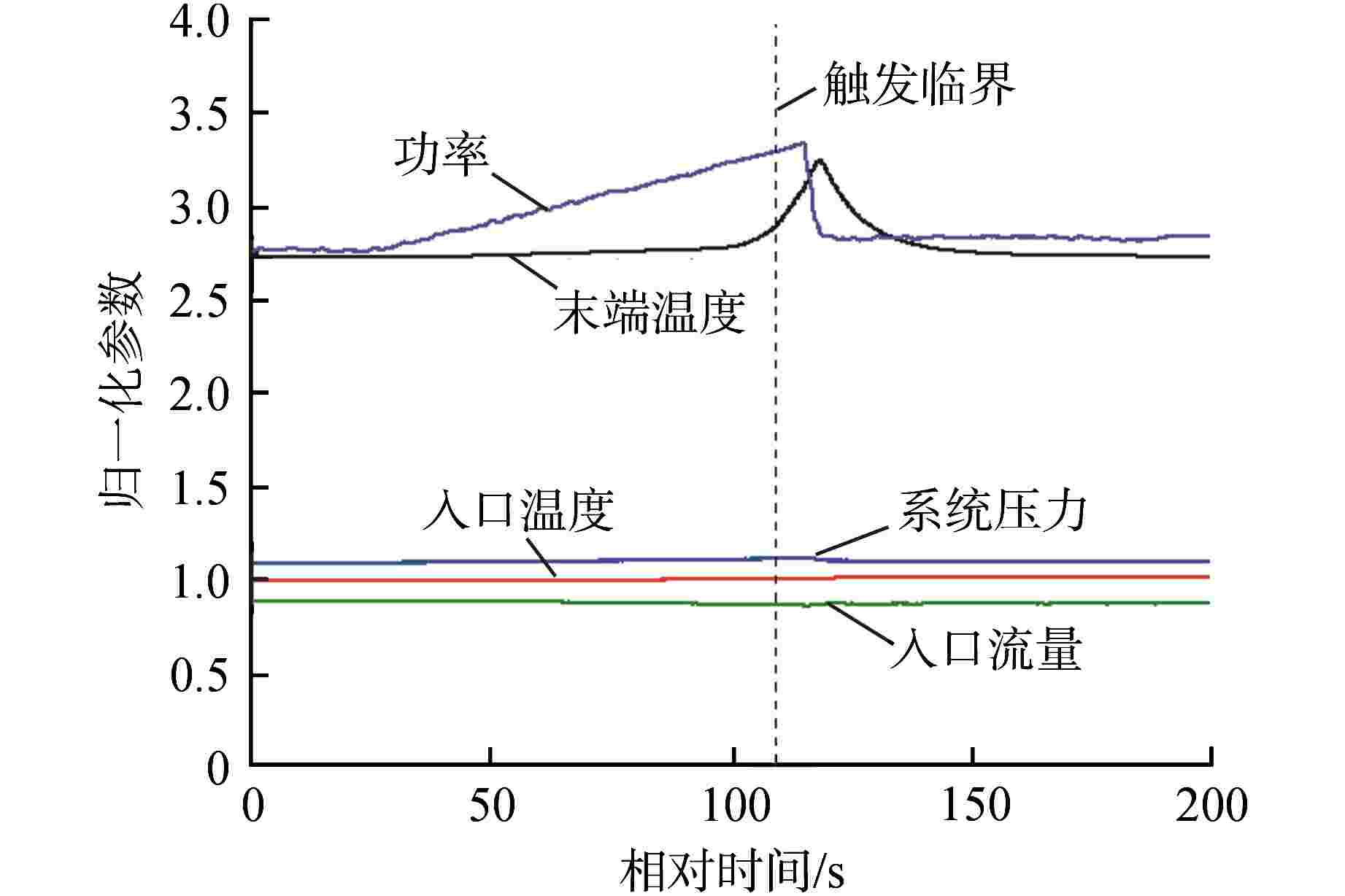

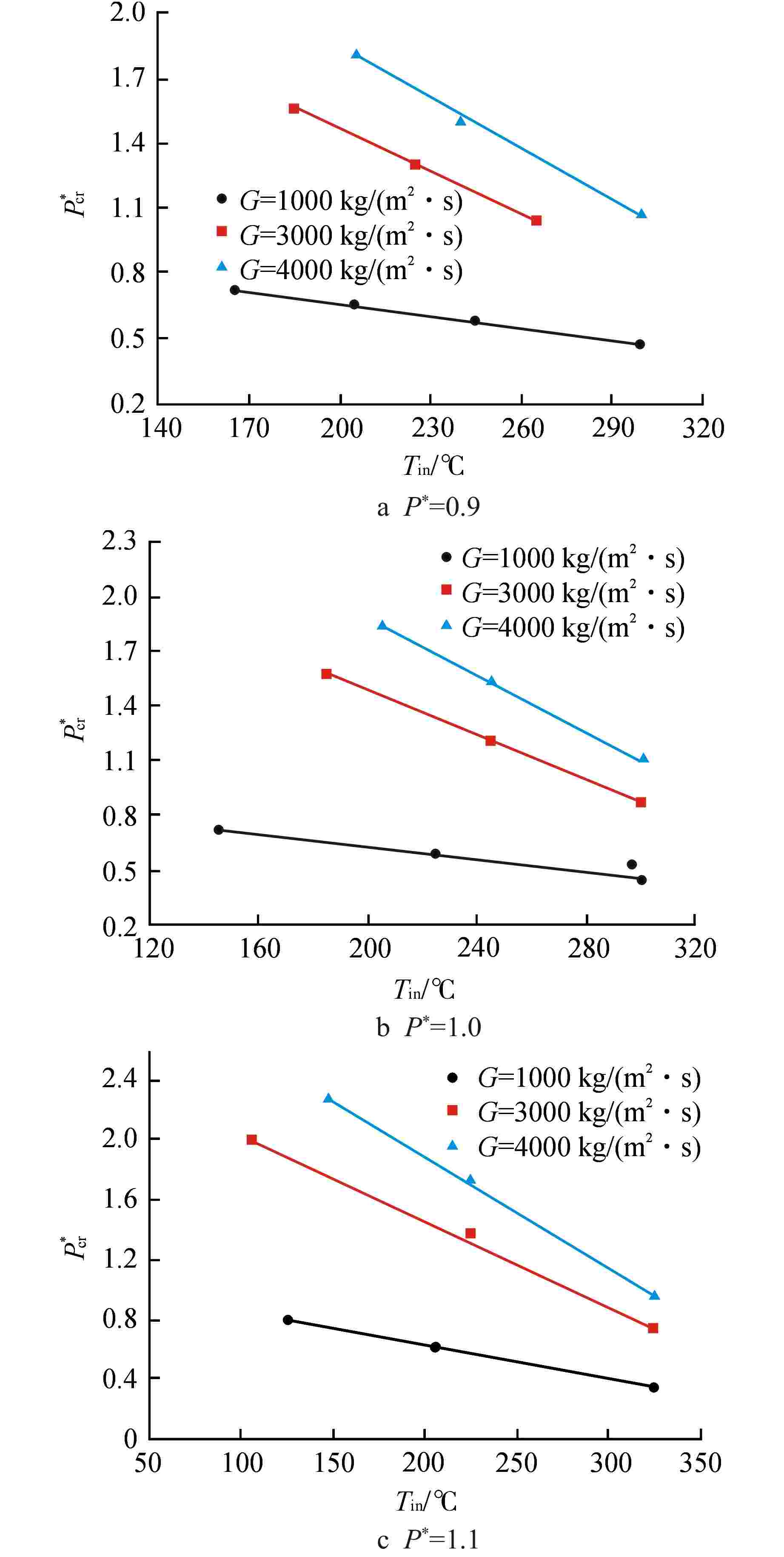

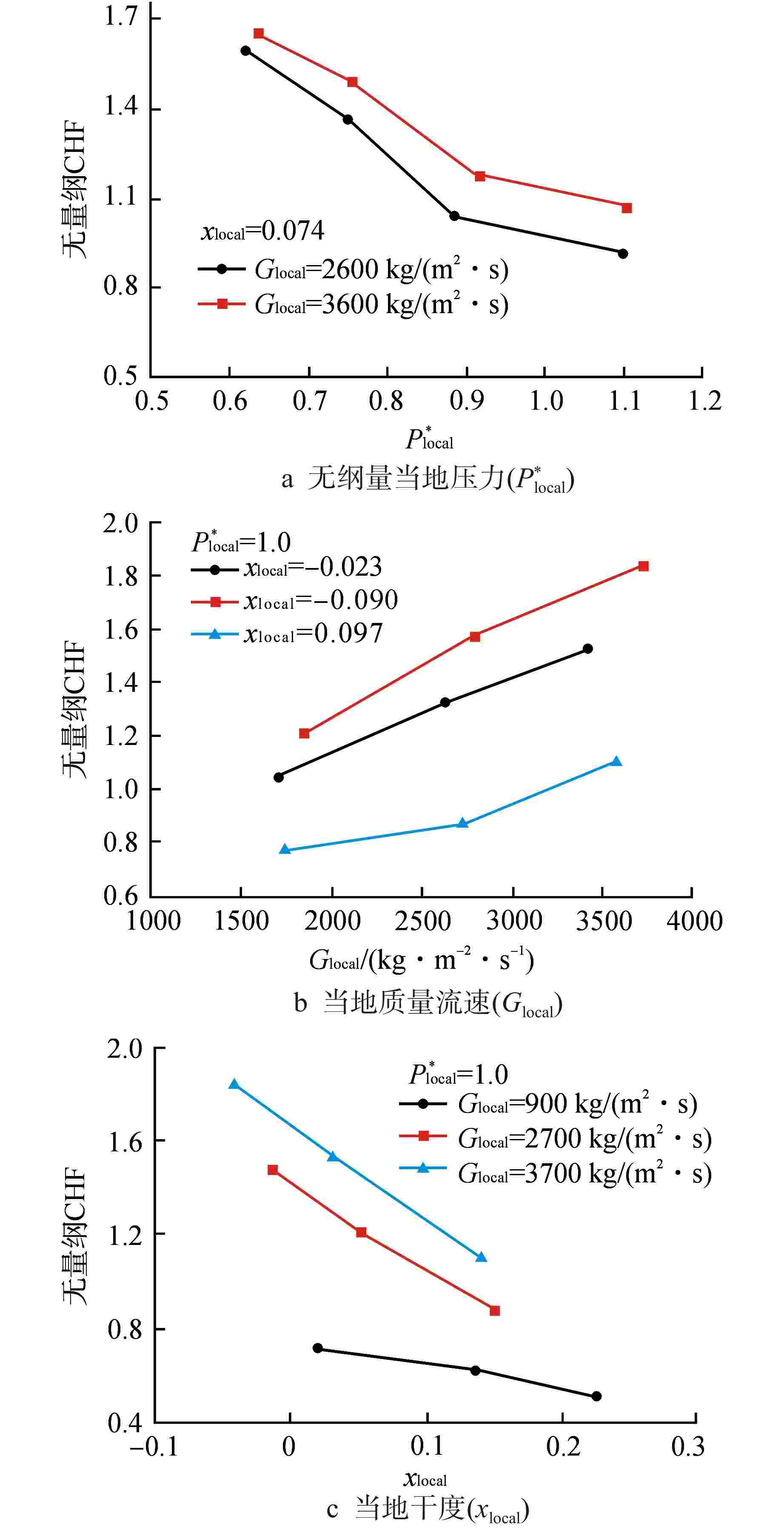

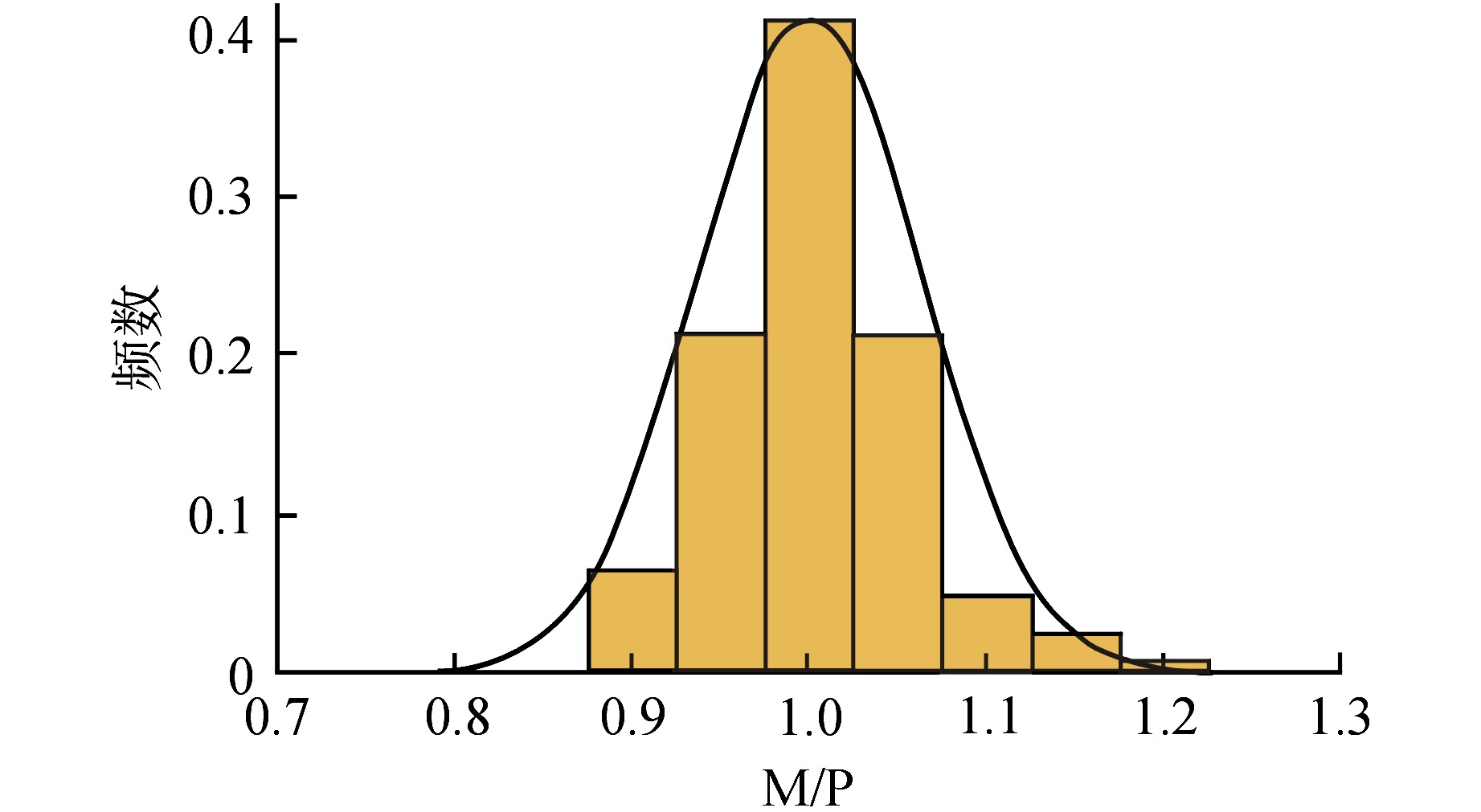

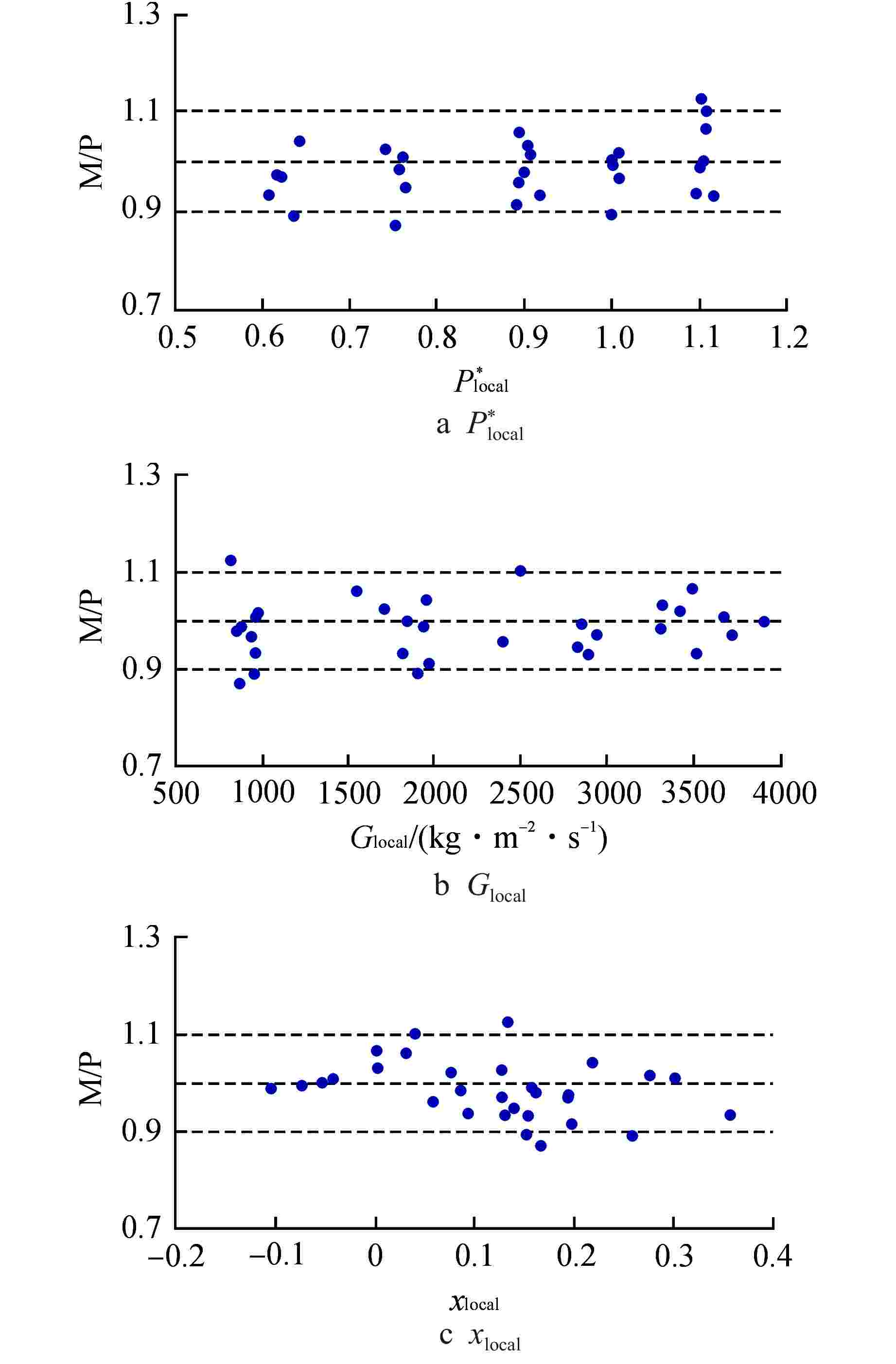

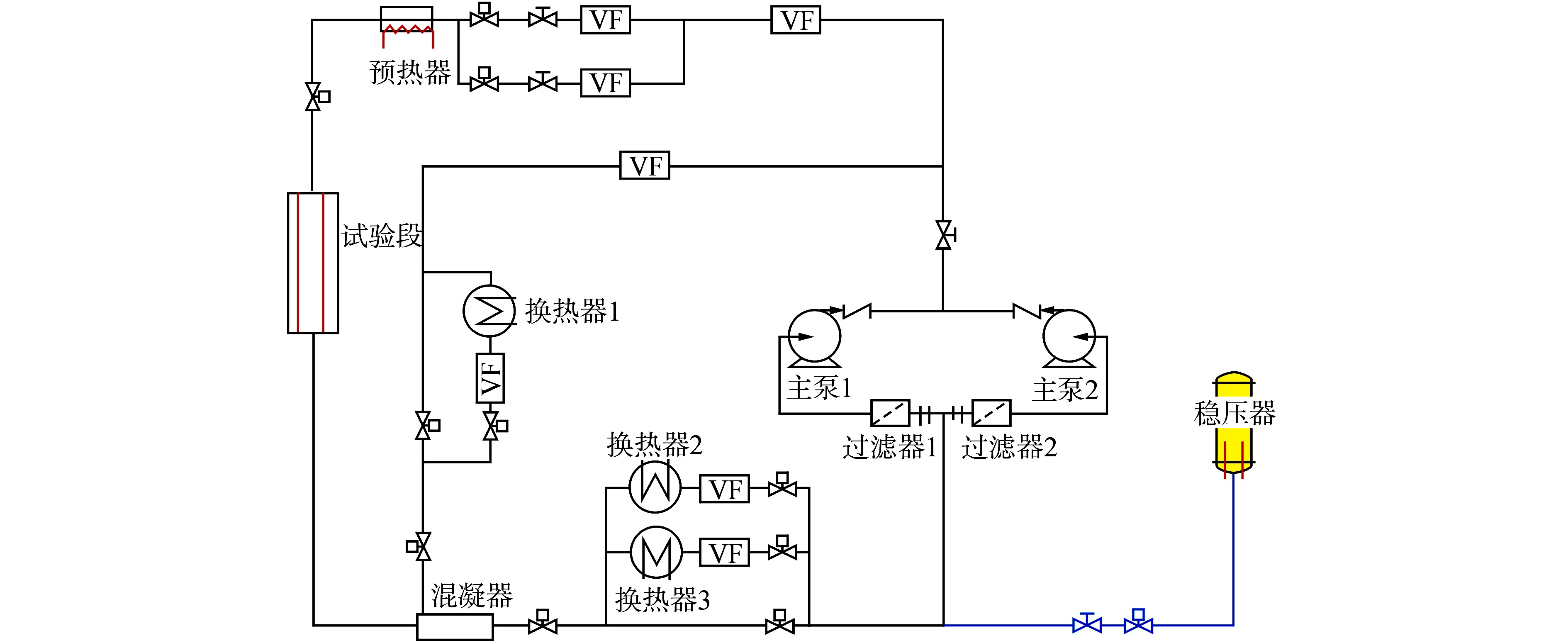

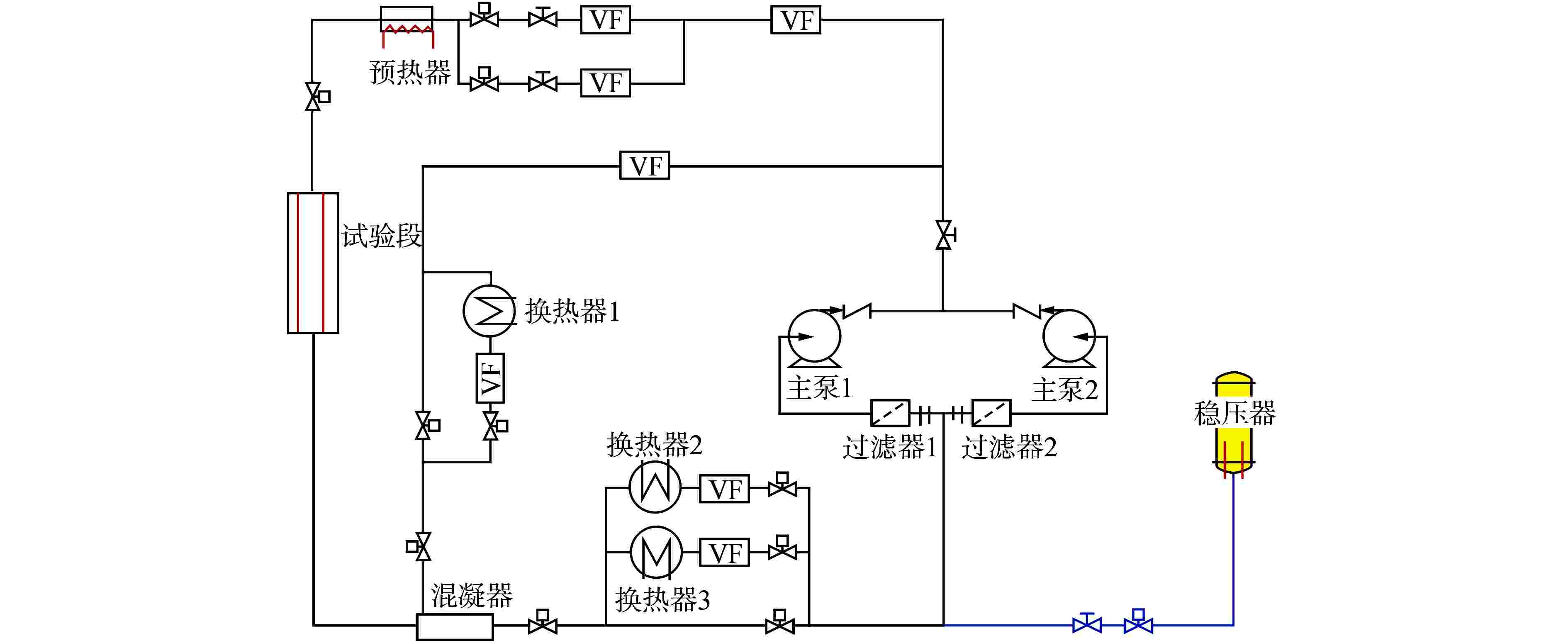

摘要: 燃料组件是反应堆的重要组成部件,临界热流密度是决定燃料组件性能的最关键参数之一。参考上海交通大学热工水力实验室的螺旋十字燃料元件参数,设计了19棒束螺旋十字燃料组件并开展临界热流密度特性实验研究,建立了一套适用于均匀发热全长螺旋燃料组件棒束临界热流密度测量方法,获得了螺旋燃料组件临界热流密度数据库,并对实验结果进行了分析。结果表明:临界功率随入口温度升高而线性降低,随着压力和干度的增大而减小,随质量流速的增大而增大。引入周向不均匀因子,建立了螺旋燃料临界热流密度预测模型,实验值(M)/预测值(P)数据的统计分布呈现正态分布,且均匀分布在1附近,证明了关系式的可靠性和准确性。所用实验技术和模型开发方法具有通用性,可应用于同类螺旋燃料组件临界热流密度特性研究。Abstract: The fuel assembly is an important component of the reactor, and the critical heat flux (CHF) is one of the most critical parameters that determine the performance of the fuel assembly. With reference to the parameters of helical cruciform fuel elements in the Nuclear Engineering Thermal-Hydraulic Laboratory of Shanghai Jiao Tong University, a 19-pin helical cruciform fuel assembly was designed and the CHF experiment was carried out. A measurement method for the CHF of uniformly heated full-length helical fuel rod bundle was developed. The CHF database of helical fuel assemblies was obtained, and the experimental results were analyzed. The results show that the critical power decreases linearly with the increase of inlet temperature, pressure and dryness, and increases with the increase of mass flow rate. A CHF prediction model for helical fuel assembly is established by introducing a circumferential non-uniform factor. The statistical distribution of experimental value (M)/predicted value (P) data presents normal distribution and is uniformly distributed around 1, which proves the reliability and accuracy of the relationship. The proposed experimental technique and model development method are universal, and can be applied to the study of CHF characteristics of similar helical fuel assemblies.

-

表 1 重复性实验验证结果

Table 1. Verification Results of Repeatability Test

参数 参数值 相对偏差/% 重复0 重复1 无量纲系统压力P* 1.106 1.111 −0.45 入口温度Tin/℃ 244.89 245.95 −0.43 质量流速G/(kg·m–2·s−1) 2999.46 3001.65 −0.073 无量纲临界功率$ P_{{\text{cr}}}^* $ 1.28 1.29 −0.78 -

[1] 宋丹戎,李庆,秦冬,等. “玲龙一号”反应堆研发关键技术——堆芯设计与安全设计[J]. 核动力工程,2021, 42(4): 1-5. doi: 10.13832/j.jnpe.2021.04.0001 [2] BOL’SHAKOV V V, BASHKIRTSEV S M, KOBZAR’ L L, et al. Experimental study of burnout in channels with twisted fuel rods[J]. Thermal Engineering, 2007, 54(5): 386-389. doi: 10.1134/S0040601507050096 [3] SHIRVAN K. Numerical investigation of the boiling crisis for helical cruciform-shaped rods at high pressures[J]. International Journal of Multiphase Flow, 2016, 83: 51-61. doi: 10.1016/j.ijmultiphaseflow.2016.03.014 [4] CONG T L, XIAO Y, WANG B C, et al. Numerical study on the boiling heat transfer and critical heat flux in a simplified fuel assembly with 2×2 helical cruciform rods[J]. Progress in Nuclear Energy, 2022, 145: 104111. doi: 10.1016/j.pnucene.2021.104111 [5] FU J S, XIAO Y, LI J L, et al. Development of a refined helical fuel mixing model and application to a helical fuel rod bundle[J]. Science China Technological Sciences, 2023, 66(2): 586-598. doi: 10.1007/s11431-022-2278-2 [6] XIAO Y, FU J S, ZHANG Q, et al. Development of a flow sweeping mixing model for helical fuel rod bundles[J]. Annals of Nuclear Energy, 2021, 160: 108428. doi: 10.1016/j.anucene.2021.108428 [7] CONG T L, ZHANG Q, ZHU J Z, et al. Transverse mixing characteristics of single-phase flow in the helical cruciform fuel assembly[J]. Annals of Nuclear Energy, 2023, 180: 109427. doi: 10.1016/j.anucene.2022.109427 [8] CONG T L, ZHANG R, WANG B C, et al. Single-phase flow in helical cruciform fuel assembly with conjugate heat transfer[J]. Progress in Nuclear Energy, 2022, 147: 104199. doi: 10.1016/j.pnucene.2022.104199 [9] ZHANG Q, LIU L, XIAO Y, et al. Experimental study on the transverse mixing of 5×5 helical cruciform fuel assembly by wire mesh sensor[J]. Annals of Nuclear Energy, 2021, 164: 108582. doi: 10.1016/j.anucene.2021.108582 [10] 陈硕,郭明,马岩,等. 5×5全长棒束组件临界热流密度验证试验[C]. 重庆: 第一届全国核反应堆热工流体力学学术年会暨中核核反应堆热工水力技术重点实验室学术年会, 2021. [11] ZHANG C, SONG Q F, GUO H, et al. Reactivity control optimization of boron-free small modular pressurized water reactor with helical-cruciform metallic fuel[J]. Nuclear Engineering and Design, 2023, 414: 112593. doi: 10.1016/j.nucengdes.2023.112593 [12] PARK H Y, KIM K H, PARK E J, et al. Verification of omega-2 CHF loop reliability via benchmarking chf test[C]. Jeju Island: International Congress on Advances in Nuclear Power Plants, ICAPP 2013, 2013. [13] 张玉相,席炎炎,庞铮铮,等. CHF关系式开发与DNBR限值确定方法研究[J]. 核动力工程,2016, 37(5): 130-134. doi: 10.13832/j.jnpe.2016.05.0130 [14] FRAMATOME. FC-FRAMATOME critical heat flux collation for AFA-2G and AFA-3G fuel assemblies: topical report EPD/DC-454[R]. Paris: Areva, 2000. [15] 刘伟,彭诗念,江光明,等. 基于最小DNBR点法和BO点法的棒束CHF预测研究[J]. 核动力工程,2018, 39(5): 172-175. doi: 10.13832/j.jnpe.2018.05.0172 -

下载:

下载: