Finite Element Analysis of a Special Multi-bar Detection Manipulator

-

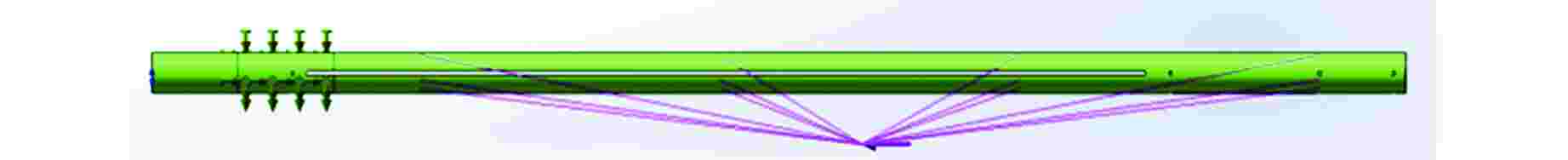

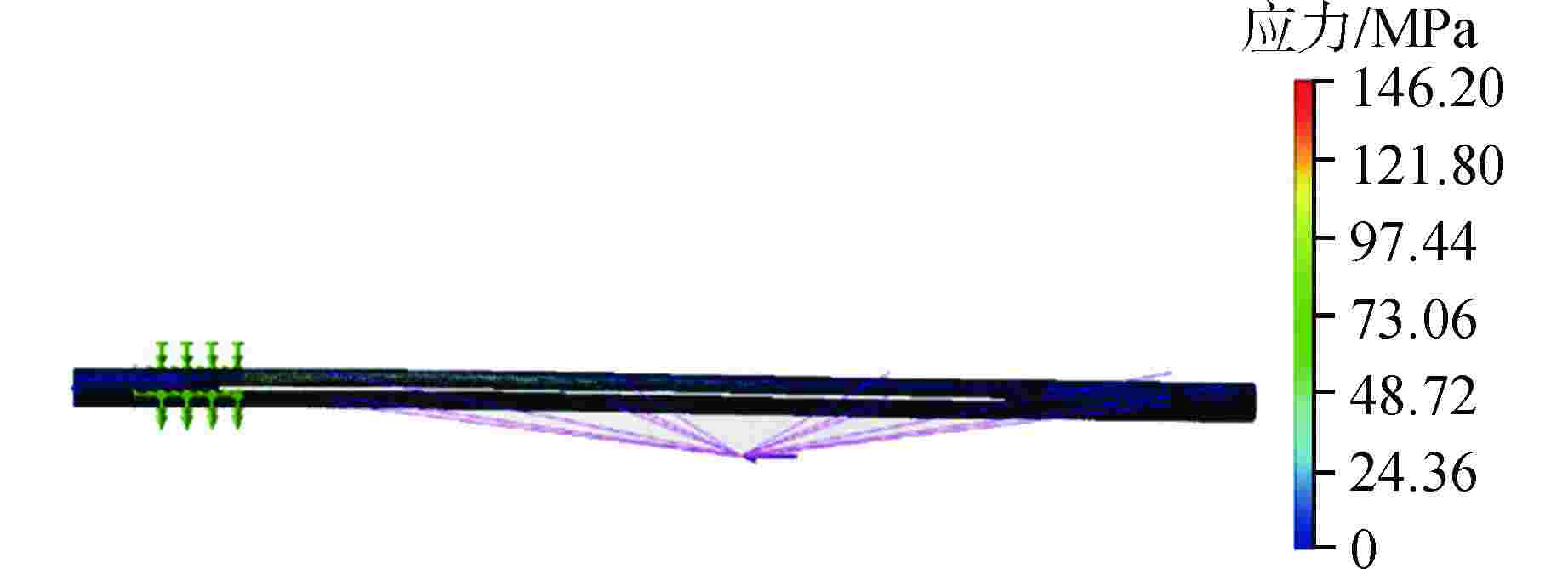

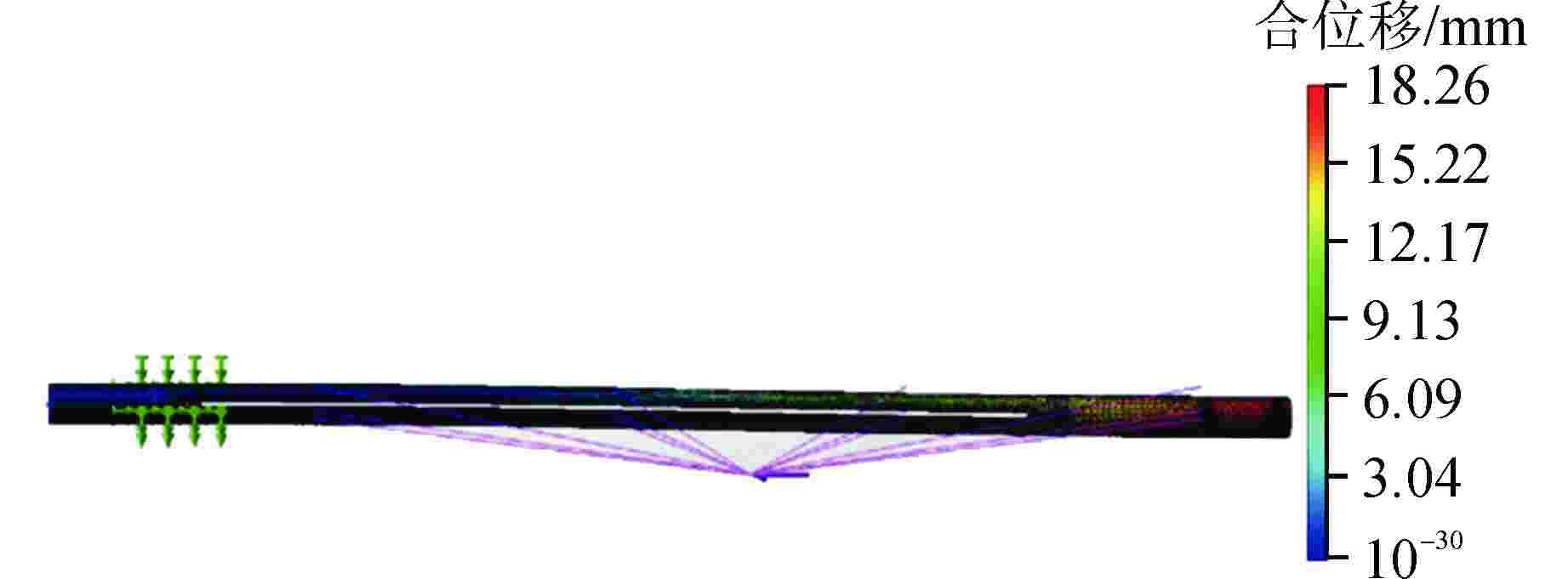

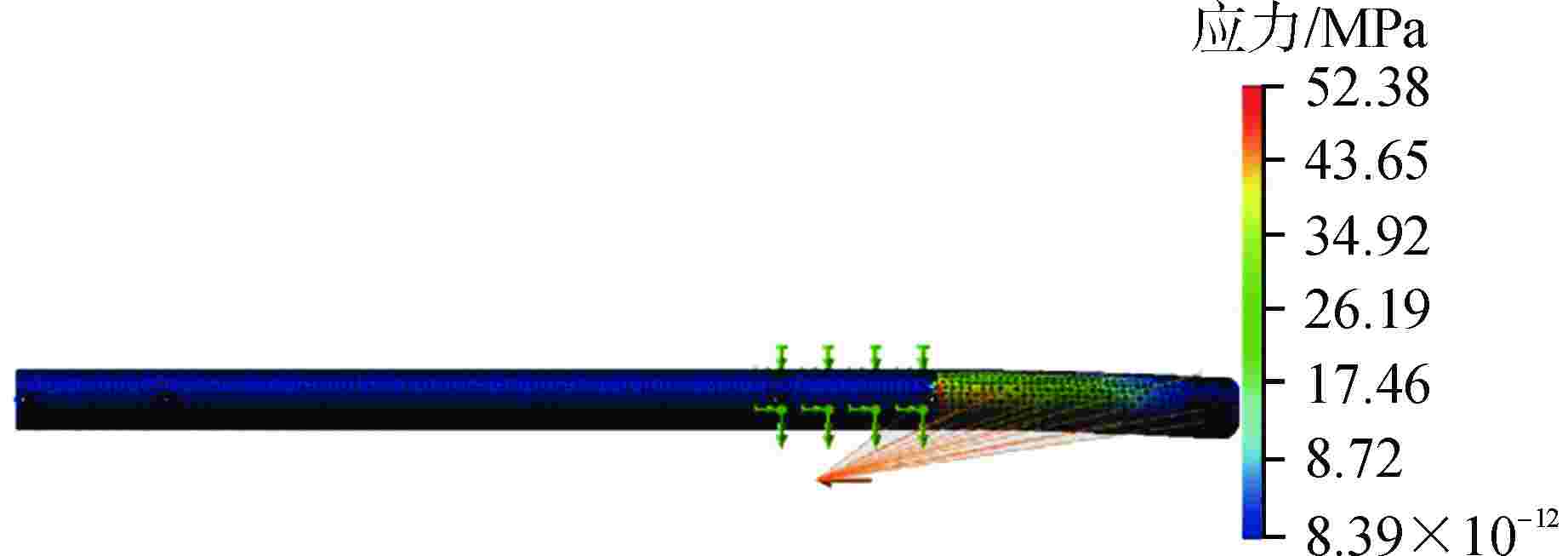

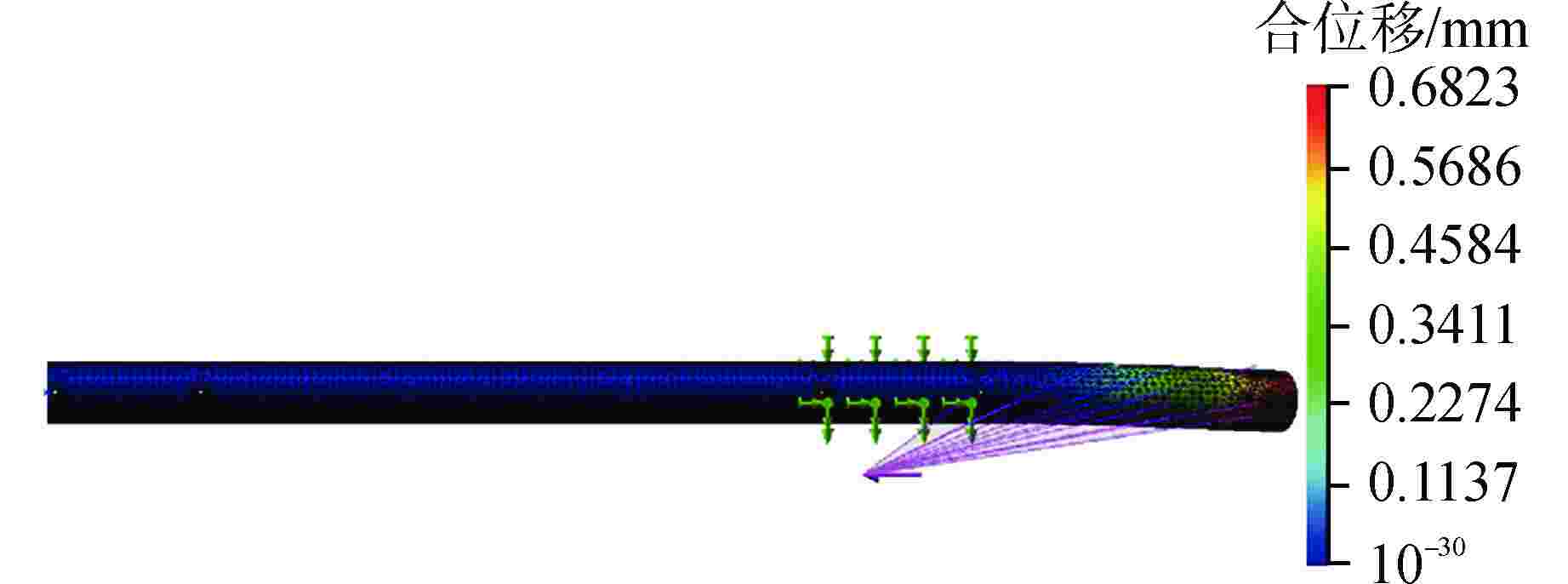

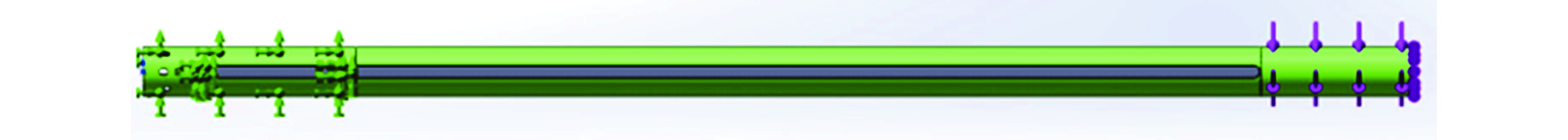

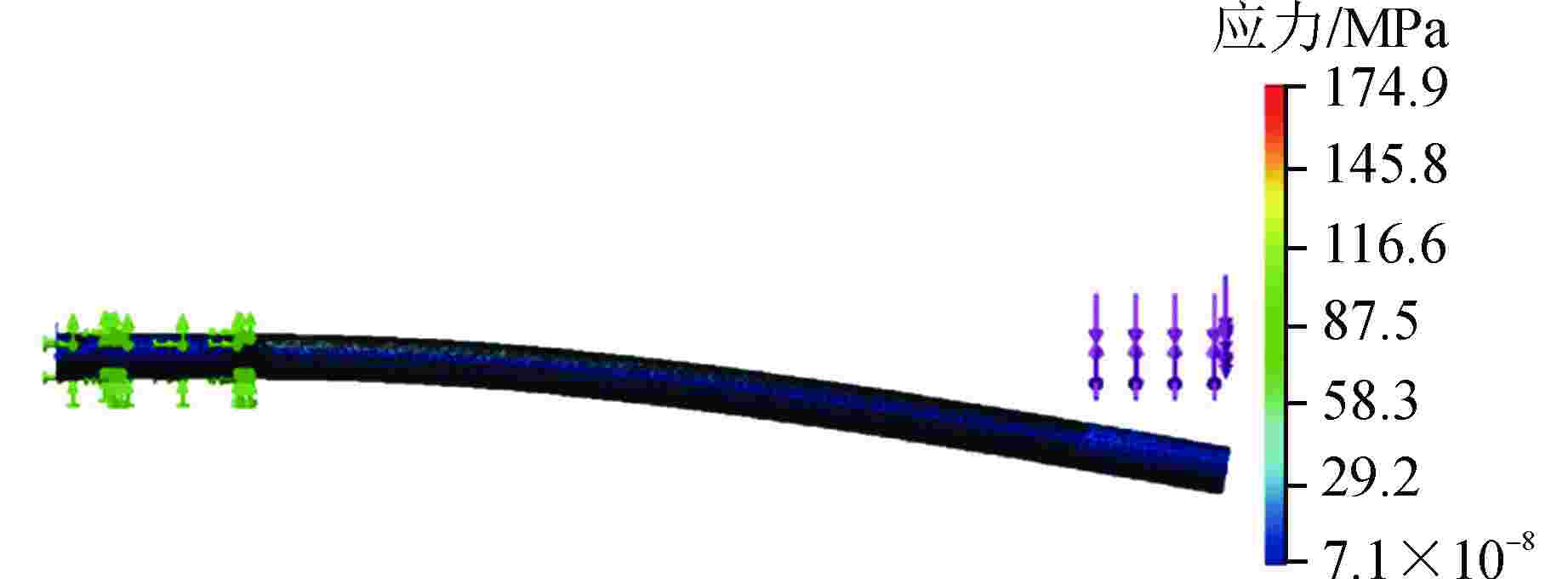

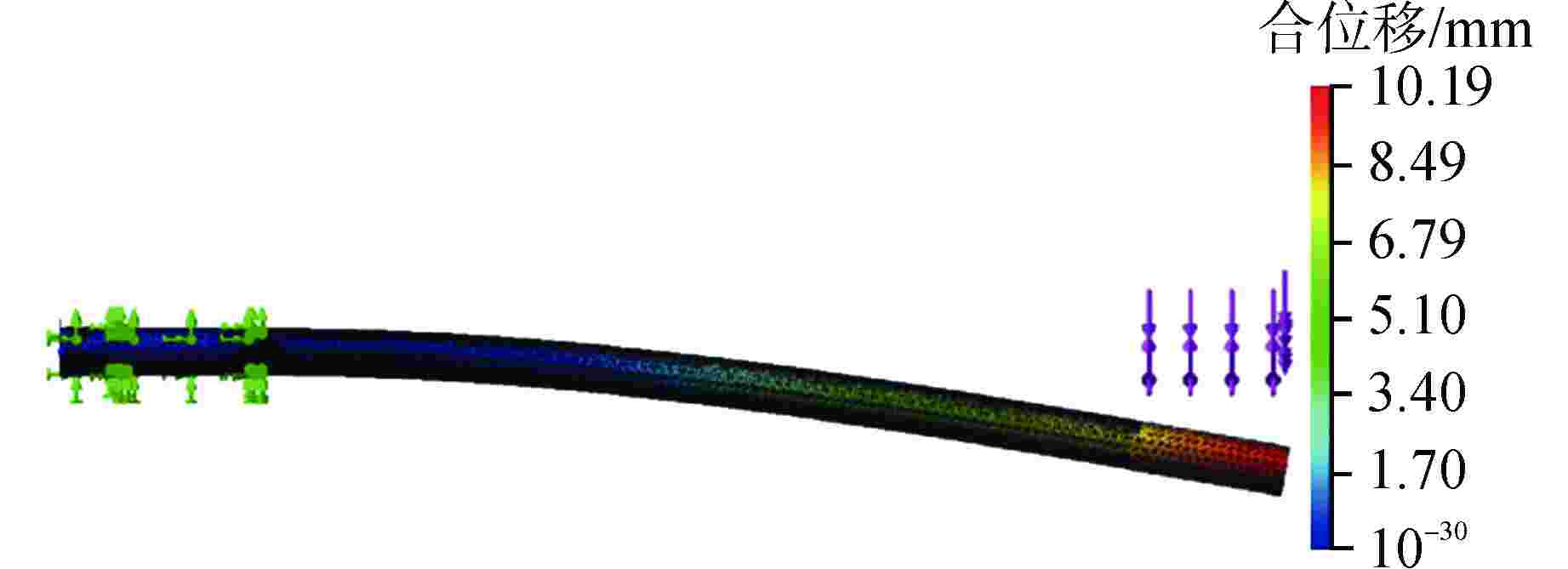

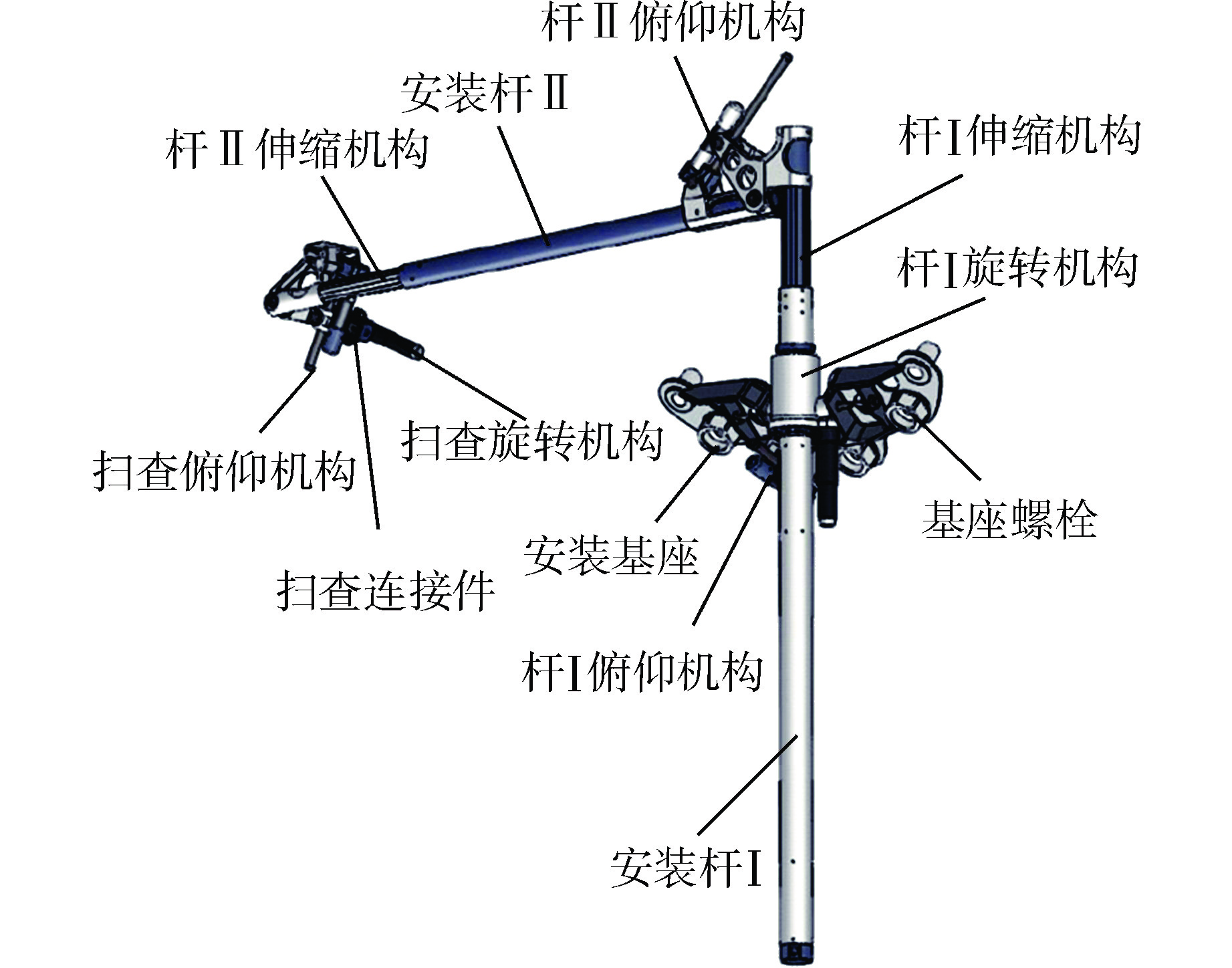

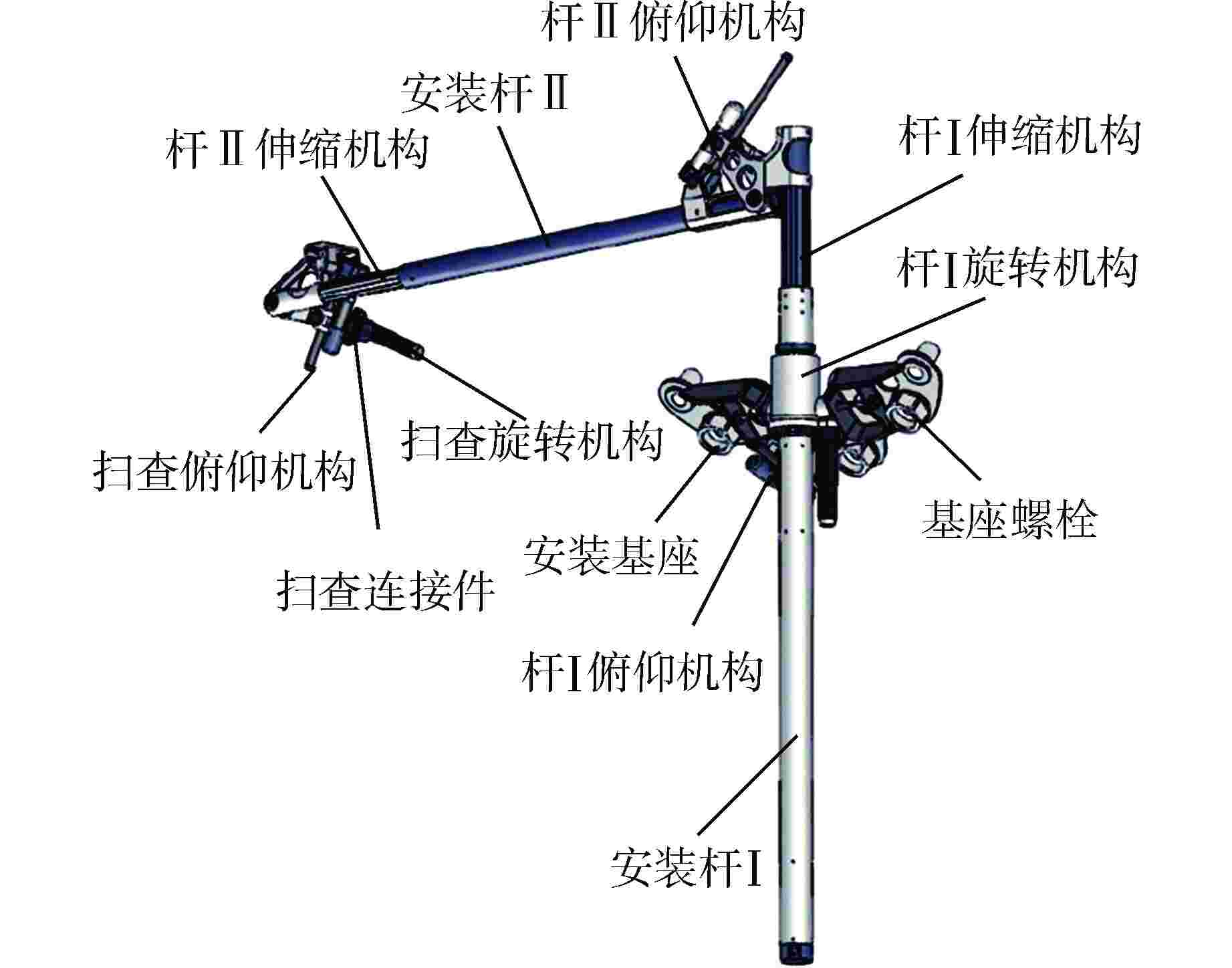

摘要: 为满足核电厂蒸汽发生器(SG)出水接管与主冷却泵连接焊缝内部的超声检测需求,开发了一套具有多自由度的特种多杆检测机械臂。使用Solidworks软件的Simulation模块对特种多杆检测机械臂的关键构件进行了有限元分析,结果发现采用铝杆制造的特种多杆检测机械臂仅满足服役时的强度要求,不能达到刚度要求,对其运载和扫查时的定位精度造成很大影响。采用铝管对特种多杆检测机械臂进行结构优化,结果表明改进后的设备能够满足服役时的强度要求,且刚度得到明显提升,进一步轻量化后,运载和扫查过程中的定位精度明显提高,有利于后期检测的操作。Abstract: In order to satisfy the need of ultrasonic detection of the welding seam between the steam generator (SG) outlet pipe and the main cooling pump in nuclear power plant, a set of special multi-bar detection manipulators with multi-degree of freedom is developed. A finite element analysis is conducted on the special multi-bar detection manipulator using Solidwork’s Simulation module. The results show that the special multi-bar detection manipulator made of aluminum bars only meets the strength requirements during service and could not meet the stiffness requirements, which greatly affects the positioning accuracy during transportation and scanning. Subsequently, an aluminum tube is used to optimize the structure of the special multi-bar detection manipulator. The results show that the improved equipment can meet the strength requirements during service, and the stiffness has been significantly improved. After further lightweighting, the positioning accuracy during transportation and scanning is significantly improved, which is conducive to the operation of later detection.

-

表 1 铝合金7075-T6性能

Table 1. Properties of Aluminum Alloy 7075-T6

抗拉强度/MPa 560 弹性模量/MPa 7.2×104 屈服强度/MPa 495 泊松比 0.33 硬度/HB 150 抗剪模量/MPa 2.69×104 延伸率/% 6 质量密度/(kg·m−3) 2810 -

[1] 朱性利,田婷,周礼峰,等. 在役检查设备运载过程的运动仿真[J]. 核动力工程,2016, 37(1): 113-116. [2] 朱性利,周礼峰,罗玉文,等. AP1000蒸汽发生器接管焊缝内部超声检测系统[J]. 机械工程师,2016(3): 136-138. [3] 陈永当,鲍志强,任慧娟,等. 基于SolidWorks Simulation的产品设计有限元分析[J]. 计算机技术与发展,2012, 22(9): 177-180. [4] 刘鸿文. 材料力学Ⅰ[M]. 第五版. 北京: 高等教育出版社,2011: 221-265. [5] 杨国良. 工业机器人动力学仿真及有限元分析[D]. 武汉: 华中科技大学,2007. -

下载:

下载: