Research on Vibration Measurement Method of Nuclear Power Plant Pipeline Based on Unmarked Vision Algorithm

-

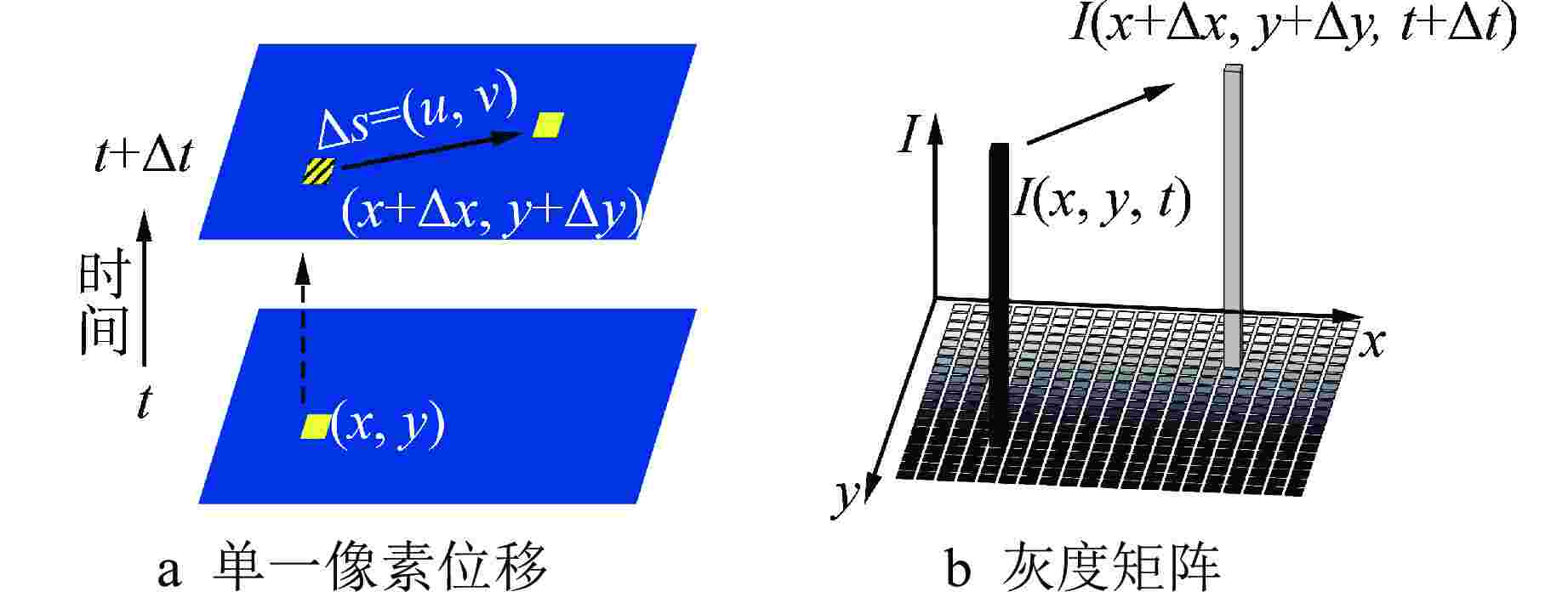

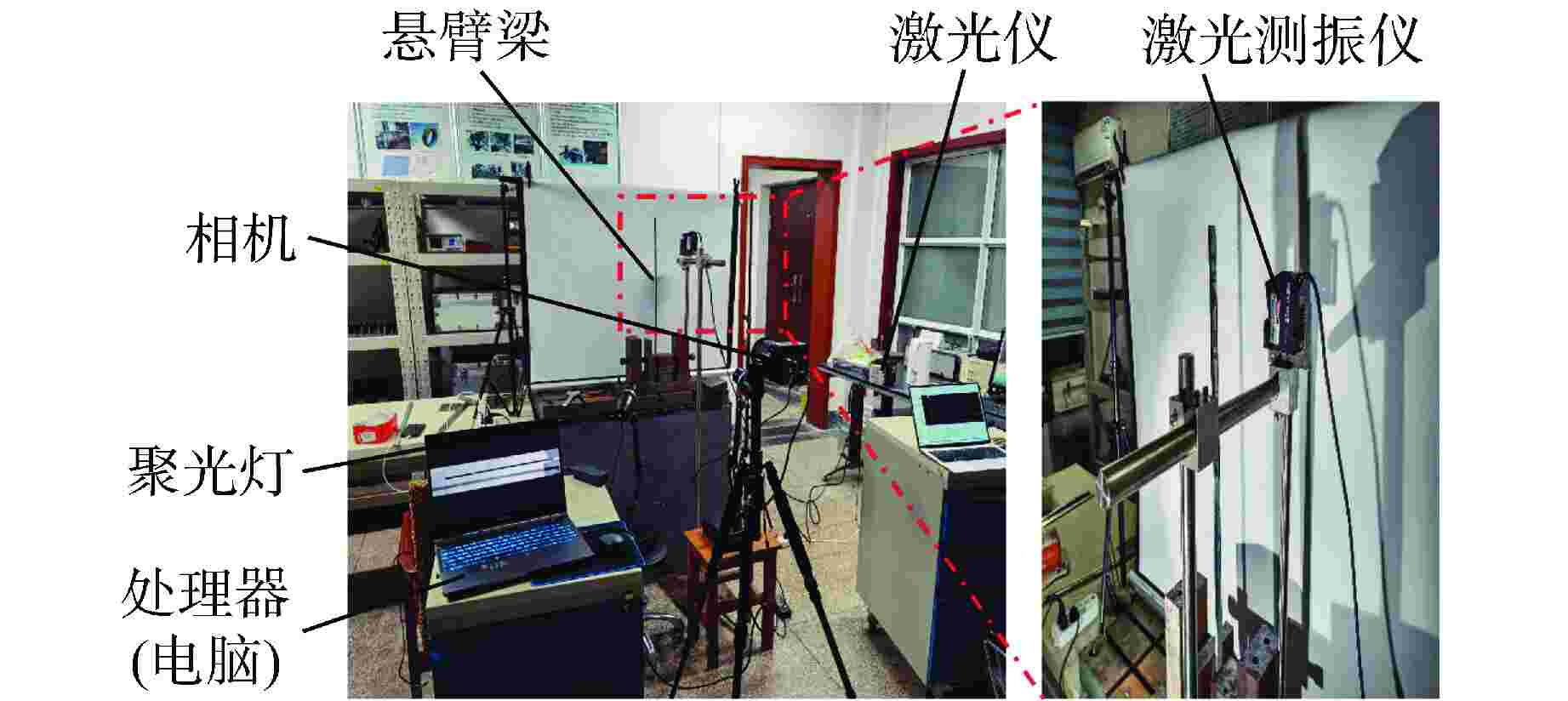

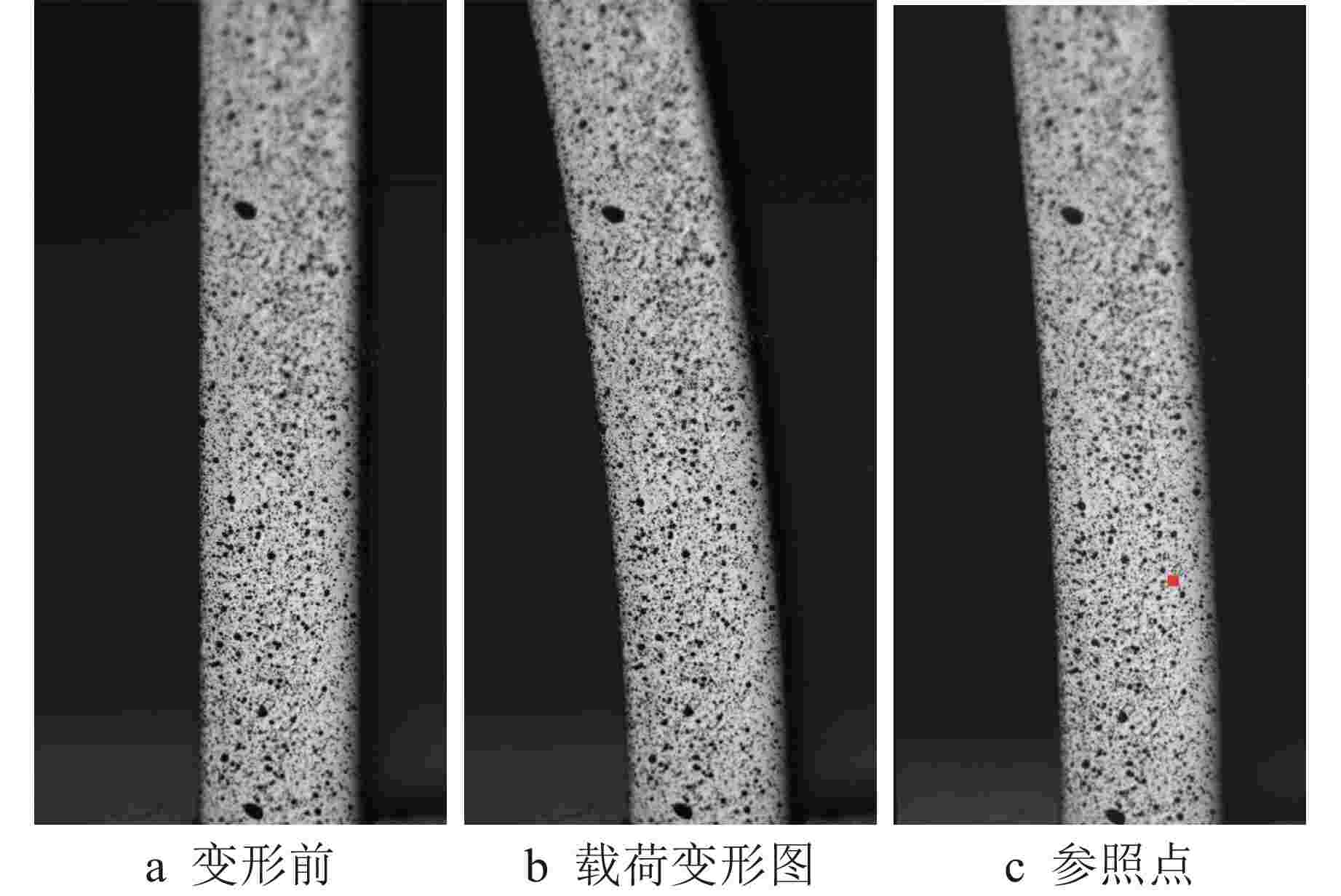

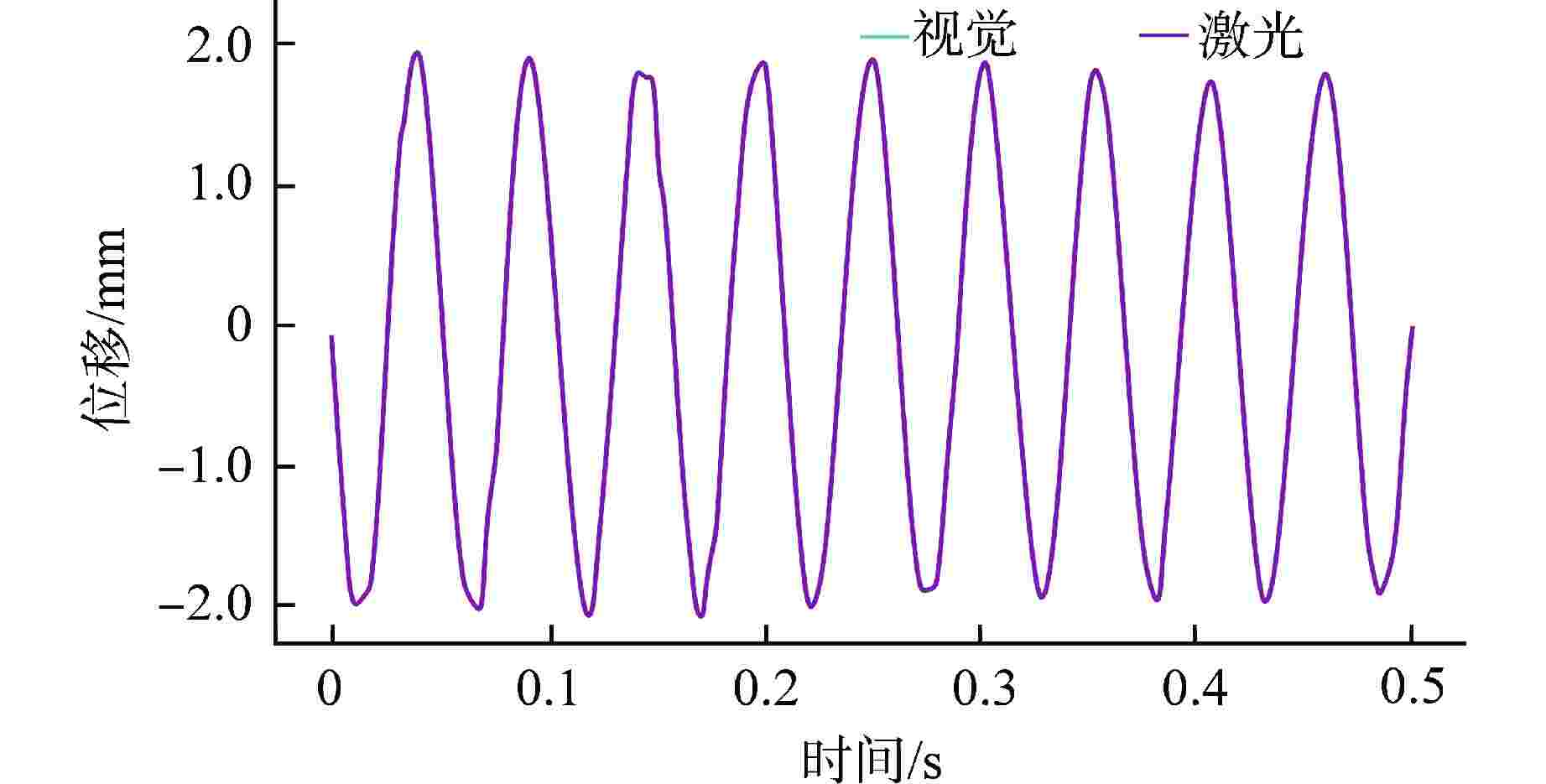

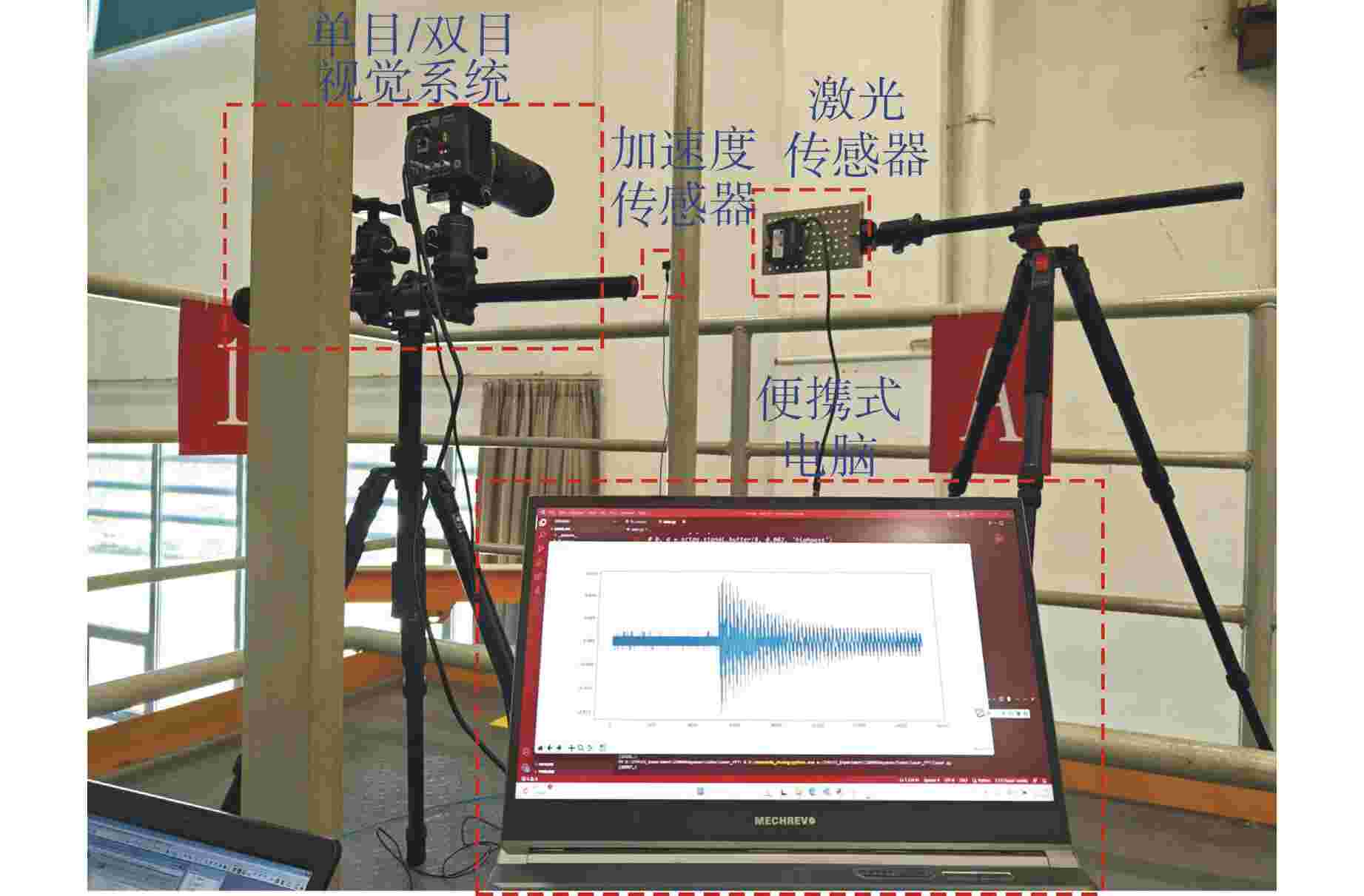

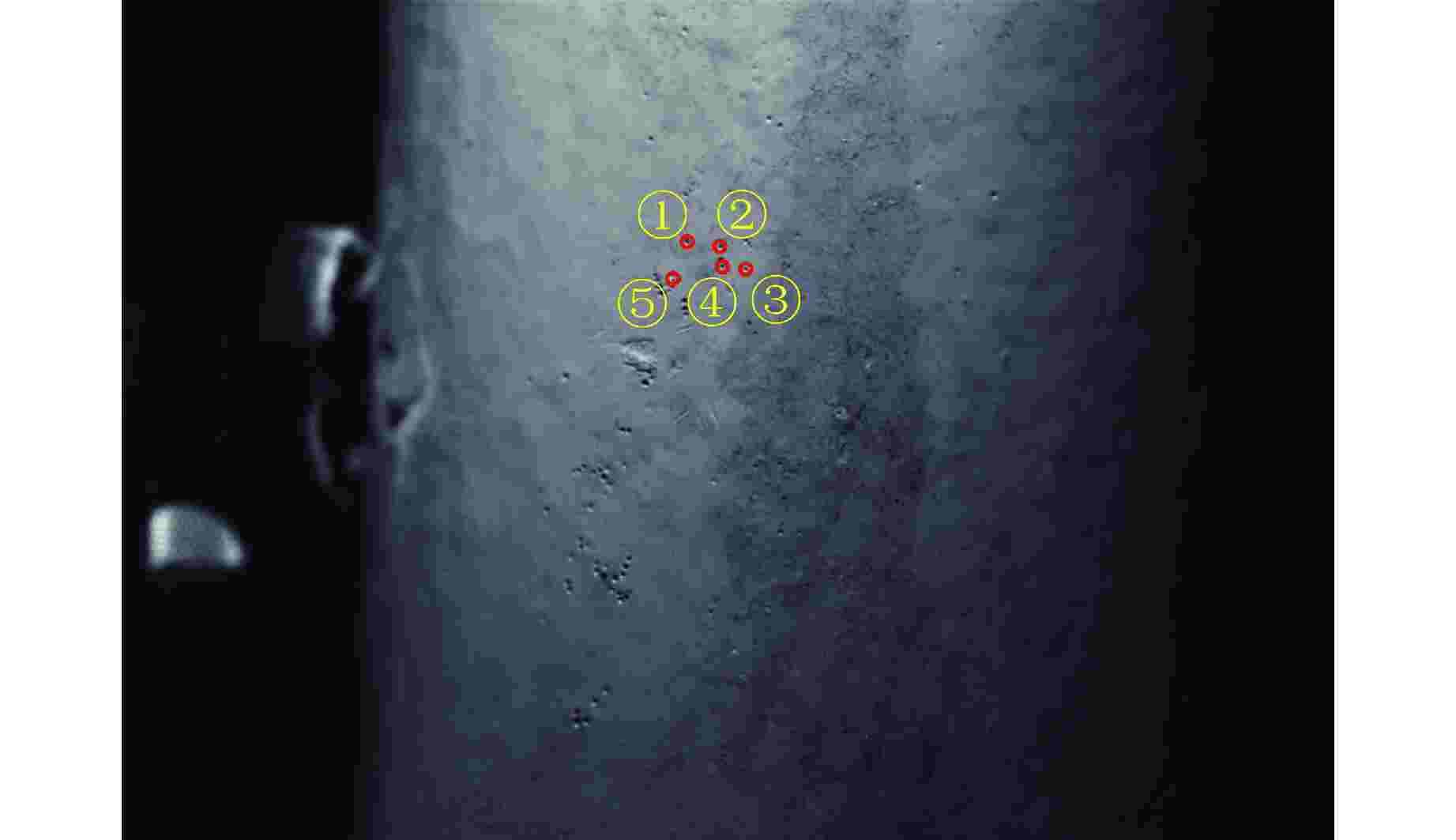

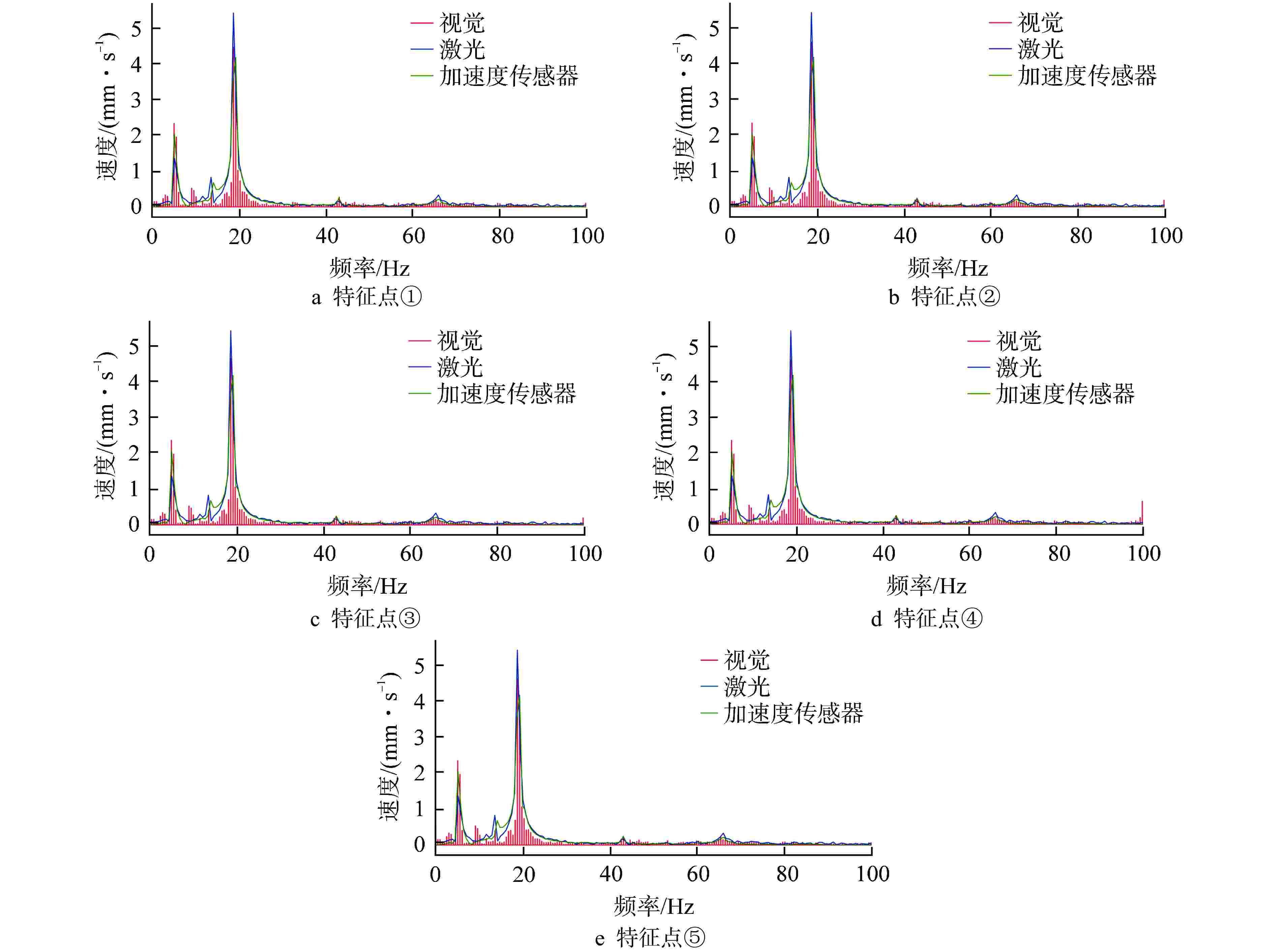

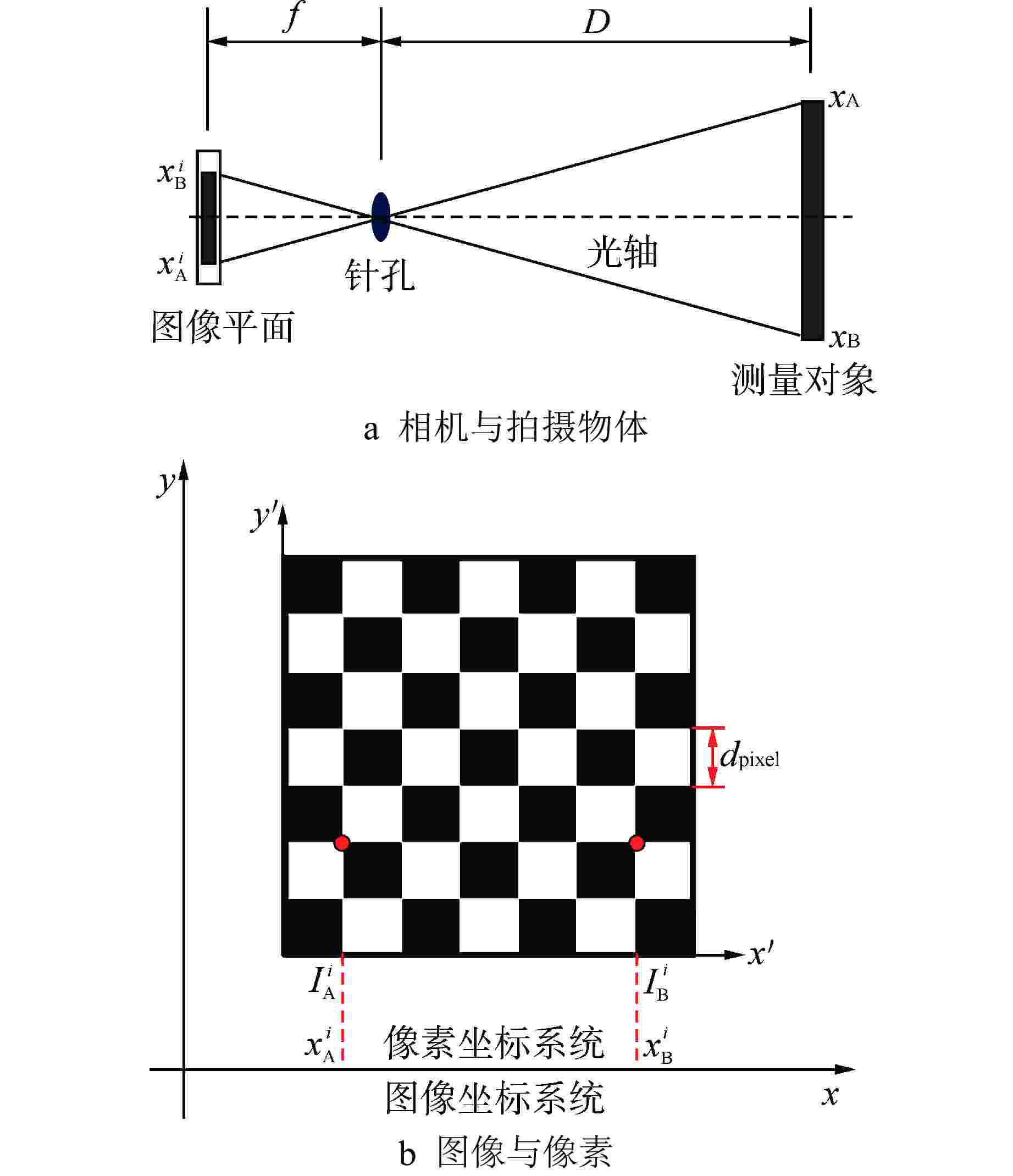

摘要: 为改善接触式测量手段难以对薄壁管、小支管等结构振动响应进行有效测量的问题,本文提出了基于视觉测量条件下,通过相机标定算法和光流算法计算不同时刻的相邻帧光流,实现对管道二维方向的无标记视觉结构运动测量。以悬臂梁和核电管道两种典型结构为对象进行试验验证,对测量对象随机取点的计算数据与激光位移传感器、加速度传感器等测量结果进行了对比。结果表明,管道振动的视觉测量计算结果与激光位移传感器和加速度传感器测量结果基本一致,相对误差小于4.9%,因此,本文所提无标记视觉测量算法可作为管道振动测量的一种非接触式测量选择方案。Abstract: In order to improve the problem that the vibration response of thin-walled pipes and small branch pipes is difficult to be effectively measured by contact measurement method, this paper proposes to calculate the optical flow of adjacent frames at different times based on the camera calibration algorithm and optical flow algorithm under the condition of visual measurement, so as to realize the unmarked visual structure motion measurement in the two-dimensional direction of the pipeline. Experimental verification was conducted on two typical structures, cantilever beam and nuclear power pipeline, and the measurement results of random points were compared with those of laser displacement sensor and acceleration sensor. The results indicate that the results of visual measurement of pipeline vibration are basically consistent with those of laser displacement sensor and acceleration sensor, and the relative error is less than 4.9%. Therefore, the unmarked visual structure motion measurement algorithm proposed in this paper can be used as a non-contact measurement option for pipeline vibration measurement.

-

Key words:

- Visual measurement /

- Optical algorithm /

- Piping vibration

-

表 1 不同方法频率计算结果

Table 1. Frequency Results of Different Methods

1阶频率/Hz 2阶频率/Hz 3阶频率/Hz 计算 激光 视觉 计算 激光 视觉 计算 激光 视觉 19.74 19.24 19.04 123.04 122.14 122.91 344.24 343.04 343.91 表 2 3种测量方法的振动速度RMS值对比

Table 2. Comparison of Velocity RMS Values of Three Measurement Methods

特征点 振动速度RMS值/(mm·s−1) 相对误差/% 激光 加速度传感器 视觉 ① 6.75 6.64 6.95 4.67 ② 6.96 4.82 ③ 6.93 4.37 ④ 6.92 4.22 ⑤ 6.94 4.52 表 3 3种方法的固有频率测量值对比

Table 3. Comparison of Nature Frequency Results of Three Measurement Methods

类型 固有频率测量值/Hz 相对误差/% 激光 加速度传感器 视觉 1阶 5.30 5.32 5.11 3.95 2阶 18.90 19.01 18.75 1.37 -

[1] HOU R R, XIA Y. Review on the new development of vibration-based damage identification for civil engineering structures: 2010-2019[J]. Journal of Sound and Vibration, 2021, 491: 115741. doi: 10.1016/j.jsv.2020.115741 [2] RAO A S, NGUYEN TN, PALANISWAMI M, et al. Vision-based automated crack detection using convolutional neural networks for condition assessment of infrastructure[J]. Structural Health Monitoring, 2021, 20(4): 2124-2142. doi: 10.1177/1475921720965445 [3] AGATHOS K, TATSIS K E, VLACHAS K, et al. Parametric reduced order models for output-only vibration-based crack detection in shell structures[J]. Mechanical Systems and Signal Processing, 2022, 162: 108051. doi: 10.1016/j.ymssp.2021.108051 [4] CARDEN E P, FANNING P. Vibration based condition monitoring: a review[J]. Structural Health Monitoring, 2004, 3(4): 355-377. doi: 10.1177/1475921704047500 [5] 贺锋涛,左波,张冠芳. 基于光纤振动幅度的激光散斑控制[J]. 西北大学学报: 自然科学版,2015, 45(1): 28-30. [6] 吴世松. 中远程光纤激光多普勒微振动检测技术研究[D]. 北京: 中国科学院大学(中国科学院长春光学精密机械与物理研究所),2020. [7] 陈玉娟,石芸苧,王立梅. 电涡流振动位移传感器动态校准技术研究[J]. 工业计量,2013, 23(S1): 11-12. [8] PAN B, XIE H M, XU B Q, et al. Performance of sub-pixel registration algorithms in digital image correlation[J]. Measurement Science and Technology, 2006, 17(6): 1615-1621. doi: 10.1088/0957-0233/17/6/045 [9] JAVH J, SLAVIČ J, M BOLTEŽAR. The subpixel resolution of optical-flow-based modal analysis[J]. Mechanical Systems and Signal Processing, 2017, 88: 89-99. doi: 10.1016/j.ymssp.2016.11.009 [10] 郭天. 面向结构健康监测的高空间分辨率振动测量与损伤识别算法[D]. 西安: 西安交通大学,2019. -

下载:

下载: