Research and Application of Influence of Black Rod and Gray Rod on Control Rod Drop Time in Nuclear Power Plant

-

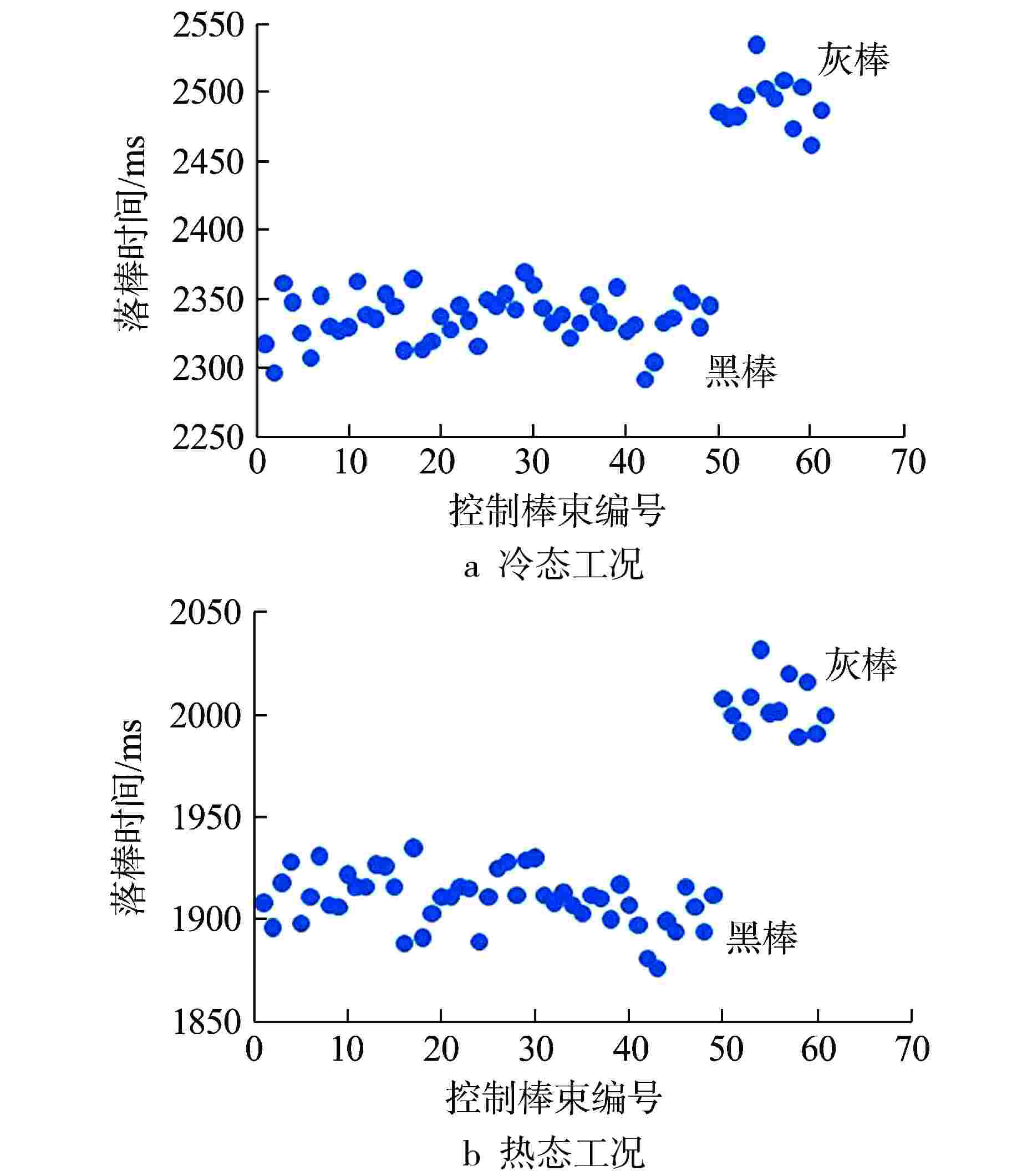

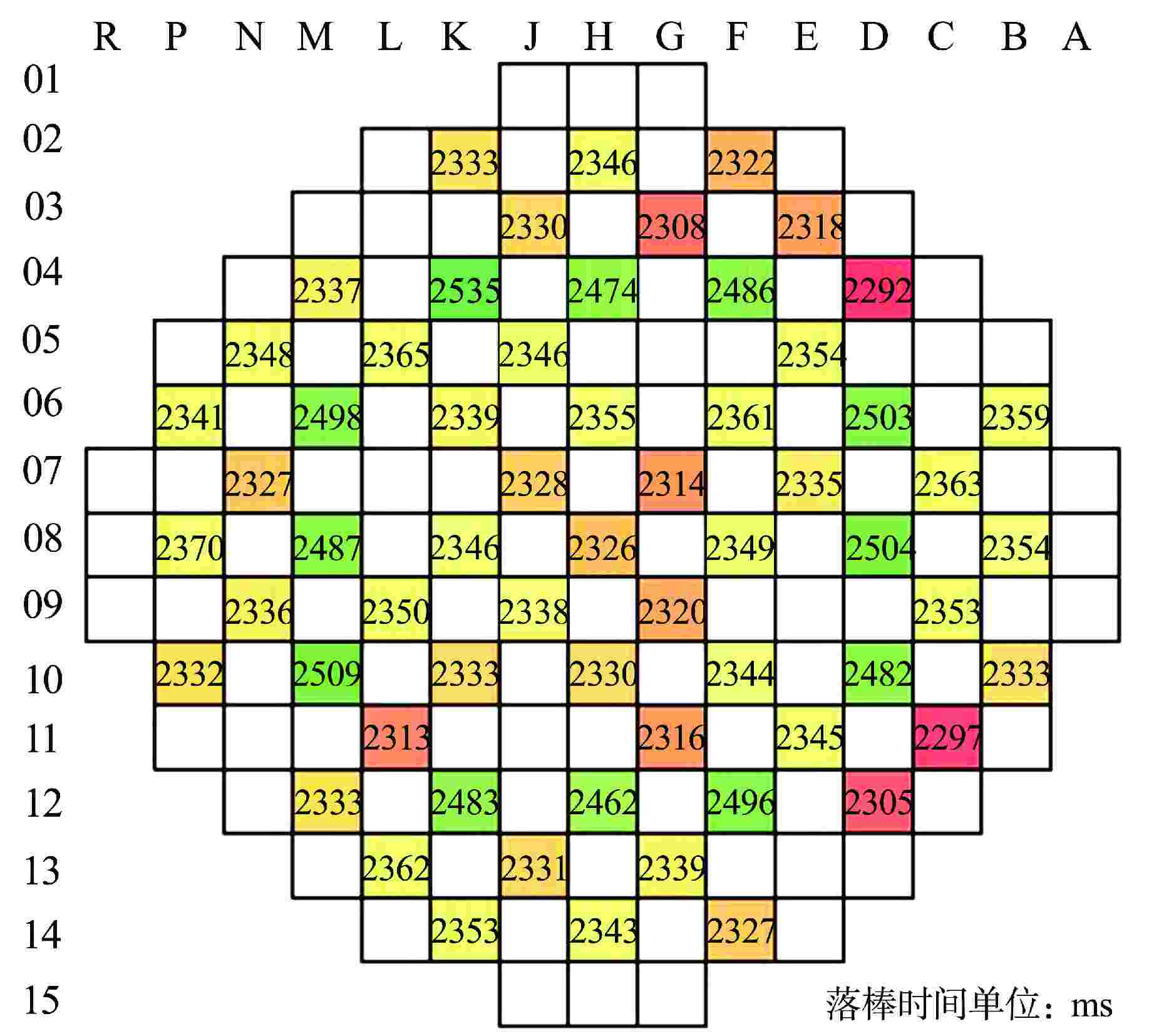

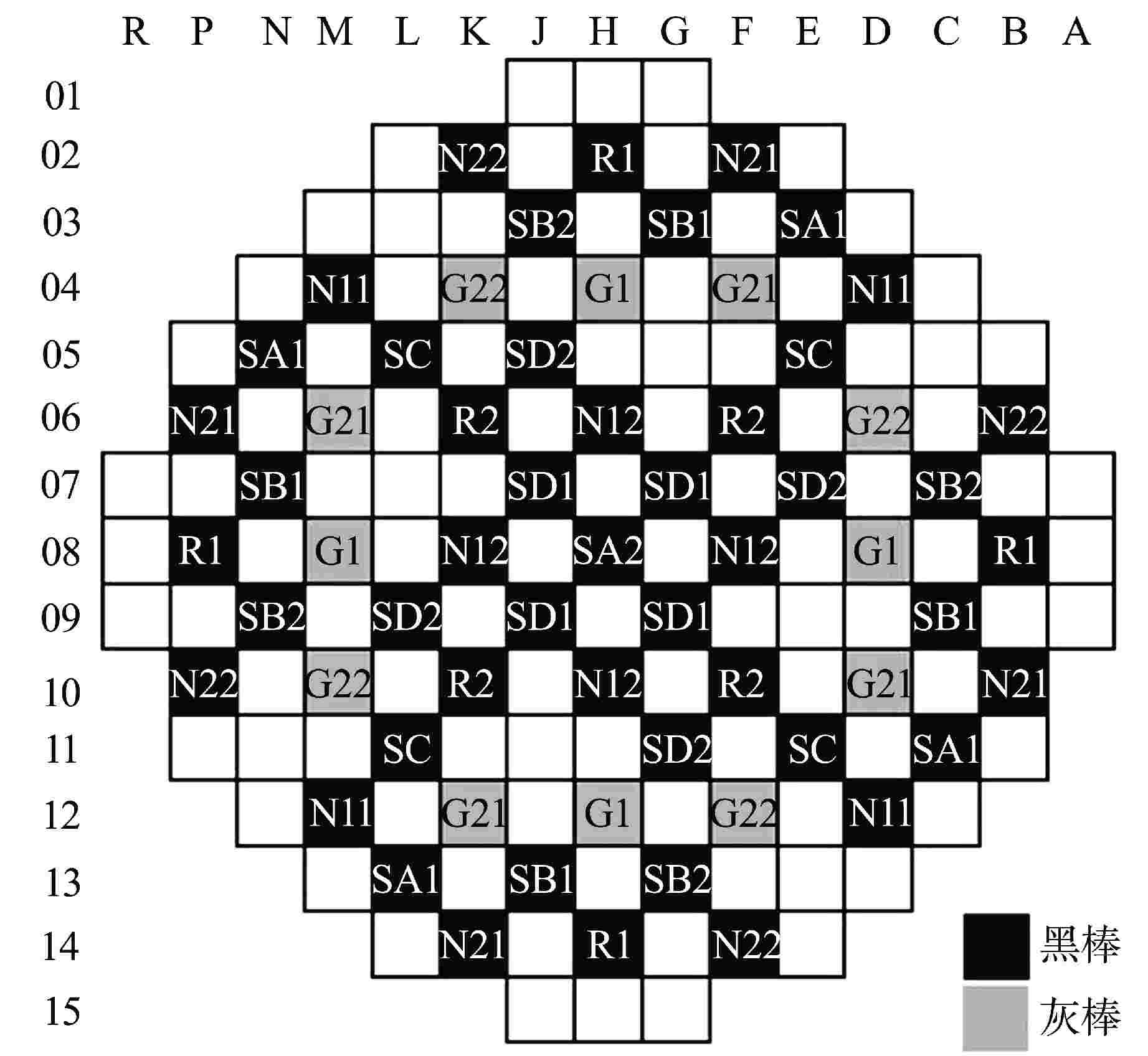

摘要: 为实现核电厂控制棒组件落棒时间的更精细化管理,根据中国改进型三环路压水堆(CPR1000)和改进型中国压水堆(ACPR1000+)核电机组控制棒组件在落棒过程中的受力分析以及在11台机组中的试验结果,研究发现在机组调试启动阶段和运行期间,堆芯流量分配差异对控制棒组件落棒时间的影响可忽略不计,但黑棒和灰棒因材质不同所引起的质量差异对落棒时间影响明显,因灰棒较黑棒质量少8.5 kg,则灰棒较黑棒落棒时间平均长约4.6%,且试验结果与理论预期相符。据此,建议分别考虑黑棒和灰棒的落棒时间一致性检查,并首次提出了以5倍标准差作为落棒时间一致性检查评价验收准则,较原验收准则可实现更精准、更细化的落棒时间一致性评价。Abstract: In order to achieve more accurate and detailed drop time of control bank in nuclear power plant, based on the force analysis of control rod assembly in Chinese Pressurized Reacter 1000 MW (CPR1000) and Advanced Chinese Pressurized Reactor 1000 MW (ACPR1000+) nuclear power units and the test results of 11 units, it is found that the influence of core flow distribution difference on the drop time of control rod assembly is negligible during the commissioning and start-up of the units, but the influence of mass difference due to different materials of black rod and gray rod on the drop time is obvious. The average drop time of gray rod is about 4.6% longer than that of black rod because the mass of gray rod is 8.5 kg less than that of black rod. The test results are consistent with the theoretical expectation. Accordingly, it is suggested that the drop time consistency check of black rod and gray rod should be considered separately, and the acceptance criterion of drop time consistency check with 5 times standard deviation is put forward for the first time, which can achieve more accurate and detailed drop time consistency valuation than the original acceptance criterion.

-

Key words:

- Black rod /

- Gray rod /

- Rod drop time /

- Influence analysis /

- New criterion

-

表 1 11台核电机组不同试验工况下灰棒较黑棒落棒时间增加比例对比

Table 1. Comparison of Increase Ratio of Drop Time of Gray Rod Compared with Black Rod under Different Test Conditions forEleven Units

机组 冷态工况下增加比例/% 热态工况下增加比例/% T4 T5 T6 T5+T6 Ttotal T4 T5 T6 T5+T6 Ttotal AA-1 −6.4 5.4 8.8 6.4 4.5 10.5 4.0 7.1 4.9 5.0 AA-2 11.0 4.5 7.8 5.5 4.1 −14.1 4.8 6.9 5.4 5.0 AA-3 −2.3 5.7 10.1 7.1 5.0 4.3 3.7 7.8 4.9 4.8 AA-4 2.3 5.6 6.6 5.9 4.3 2.4 4.3 7.6 5.2 5.2 AZ-5 2.8 5.4 9.6 6.8 5.0 3.2 3.9 7.6 5.0 5.0 AZ-6 −1.2 5.9 8.8 6.9 5.0 −0.5 2.8 7.7 4.3 4.1 PY-5 0.0 5.1 8.7 6.3 4.5 3.9 4.0 7.1 4.9 4.9 PY-6 1.9 5.2 9.0 6.5 4.7 −1.6 4.3 8.2 5.4 5.2 BL-1 3.3 4.7 7.5 5.6 4.1 −10.1 3.4 6.9 4.4 4.0 BL-2 4.5 4.5 6.3 5.1 3.7 5.3 3.2 5.0 3.7 3.8 AB-4 9.2 4.9 9.9 6.4 4.7 −13.7 4.1 9.0 5.5 4.9 平均值 2.3 5.2 8.5 6.2 4.5 −1.1 3.9 7.4 4.9 4.7 表 2 11台机组灰棒与黑棒落棒时间的标准差

Table 2. Standard Deviation of Drop Time of Gray Rod Compared with Black Rod for Eleven Units

机组 冷态工况 热态工况 黑棒 灰棒 黑棒 灰棒 ∆Tmax/ms δ/ms ∆Tmax/δ ∆Tmax/ms δ/ms ∆Tmax/δ ∆Tmax/ms δ/ms ∆Tmax/δ ∆Tmax/ms δ/ms ∆Tmax/δ AA-1 51.9 21.6 2.4 46.1 24.5 1.9 40.8 17.1 2.4 25.1 11.9 2.1 AA-2 69.2 26.5 2.6 60.7 30.4 2.0 30.4 15.7 1.9 31.3 17.6 1.8 AA-3 56.6 20.8 2.7 42.3 22.3 1.9 40.9 15.1 2.7 36.4 16.5 2.2 AA-4 64.2 21.6 3.0 67.1 33.0 2.0 34.9 14.4 2.4 20.5 10.2 2.0 AZ-5 44.7 17.5 2.6 41.7 18.0 2.3 33.9 13.1 2.6 27.0 12.2 2.2 AZ-6 73.7 23.4 3.1 43.7 21.2 2.1 54.2 20.0 2.7 18.7 9.9 1.9 PY-5 56.5 21.7 2.6 37.8 19.1 2.0 38.4 16.7 2.3 35.0 15.3 2.3 PY-6 57.8 18.1 3.2 37.8 19.4 1.9 30.9 13.7 2.3 34.3 20.2 1.7 BL-1 43.8 18.1 2.4 28.8 15.8 1.8 26.8 10.1 2.6 13.9 6.8 2.0 BL-2 55.4 24.4 2.3 19.4 10.9 1.8 33.5 15.7 2.1 44.4 14.9 3.0 AB-4 50.0 16.3 3.1 43.6 18.9 2.3 57.5 14.5 4.0 23.5 13.0 1.8 最大值 73.7 26.5 3.2 67.1 33.0 2.3 57.5 20.0 4.0 44.4 20.2 3.0 平均值 56.7 20.9 2.7 42.6 21.2 2.0 38.4 15.1 2.6 28.2 13.5 2.1 表 3 BS-3号机组灰棒和黑棒落棒时间的标准差

Table 3. Standard Deviation of Drop Time of Gray Rod Compared with Black Rod for Unit 3 in BS Nuclear Power Plant

试验条件 黑棒 灰棒 ∆Tmax/ms δ/ms ∆Tmax/δ ∆Tmax/ms δ/ms ∆Tmax/δ 冷态工况 42.0 15.4 2.7 41.6 16.7 2.5 热态工况 45.0 14.2 3.2 25.3 12.0 2.1 -

[1] 杨方亮,杨晓晨,刘佳,等. 控制棒驱动线落棒行为动力学仿真技术研究[J]. 机械设计与制造工程,2017, 46(2): 27-29. [2] 于建华,魏泳涛,孙磊,等. 控制棒组件在流体环境中下落时所受阻力的计算[J]. 核动力工程,2001, 22(3): 236-241. [3] 孙磊,于建华,魏永涛,等. 控制棒组件落棒时间与历程计算[J]. 核动力工程,2003, 24(1): 59-62,76. [4] 张吉斌,高希龙,何航行,等. 控制棒落棒动力学数值计算[J]. 核动力工程,2020, 41(6): 218-223. [5] 张恒凯,柳继坤,赵云涛,等. CPR1000型核电机组控制棒组件落棒时间的验收准则初步优化[J]. 核科学与工程,2022, 42(6): 1291-1295. [6] 马超,陈平,肖忠,等. 不同流量下控制棒落棒数值模拟研究[J]. 核动力工程,2015, 36(S2): 90-92. [7] 张明乾,冉小兵,刘言午,等. CPR1000反应堆三维数值模拟分析及验证[J]. 核技术,2013, 36(10): 100601. [8] 张明乾,段远刚,于晓雷,等. ACPR1000+反应堆整体水力特性数值分析与比较[J]. 核动力工程,2013, 34(6): 52-54,60. [9] 张恒凯,赵云涛,时孟晨,等. 控制棒驱动机构固定钩爪打开时间的验收准则优化[J]. 核动力工程,2021, 42(6): 179-182. [10] 盛骤,谢式千,潘承毅. 概率论与数理统计[M]. 第四版. 北京: 高等教育出版社,2008: 100-106. -

下载:

下载: