Experimental Investigation on Minimum Film Boiling Temperature during Quenching of FeCrAl

-

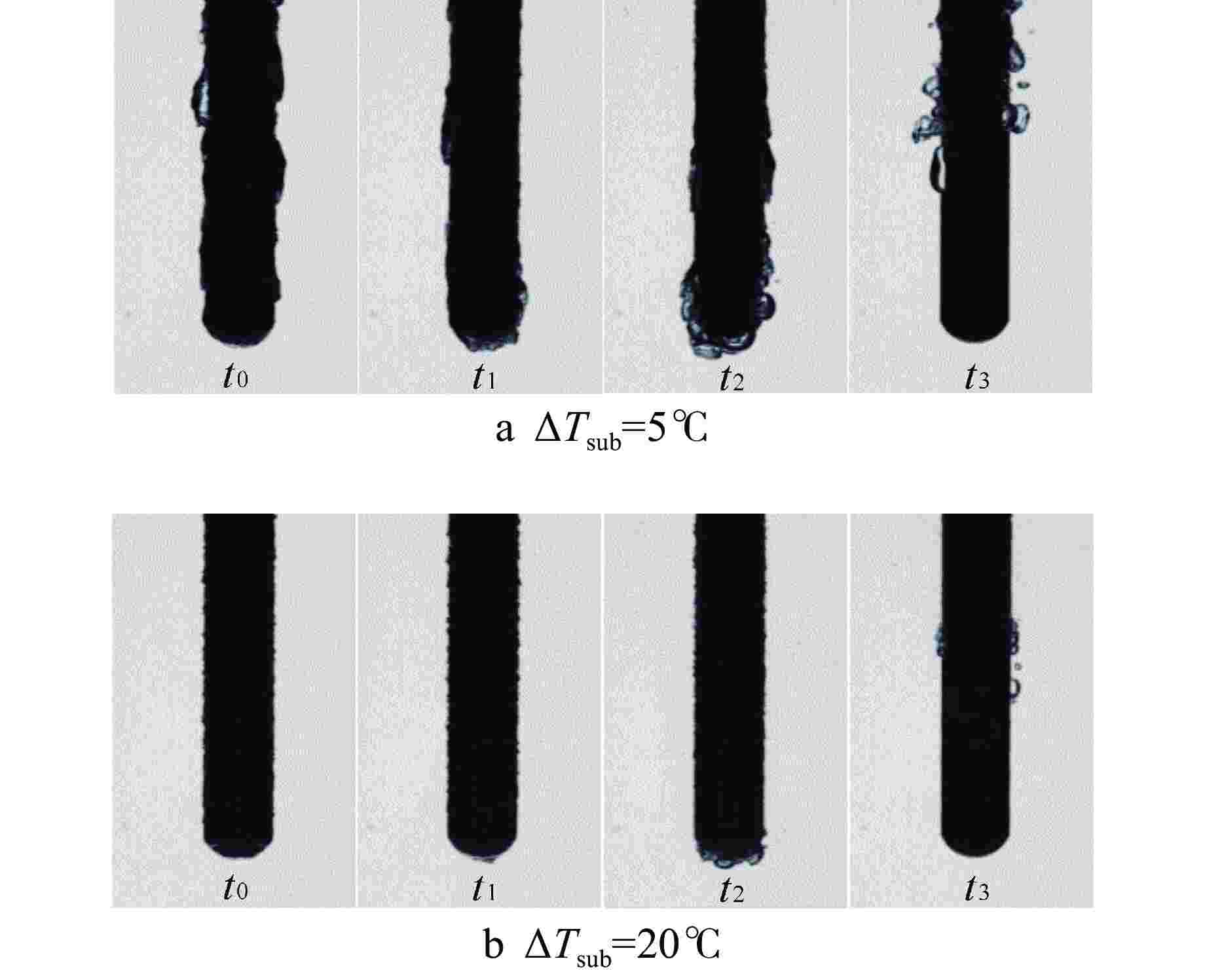

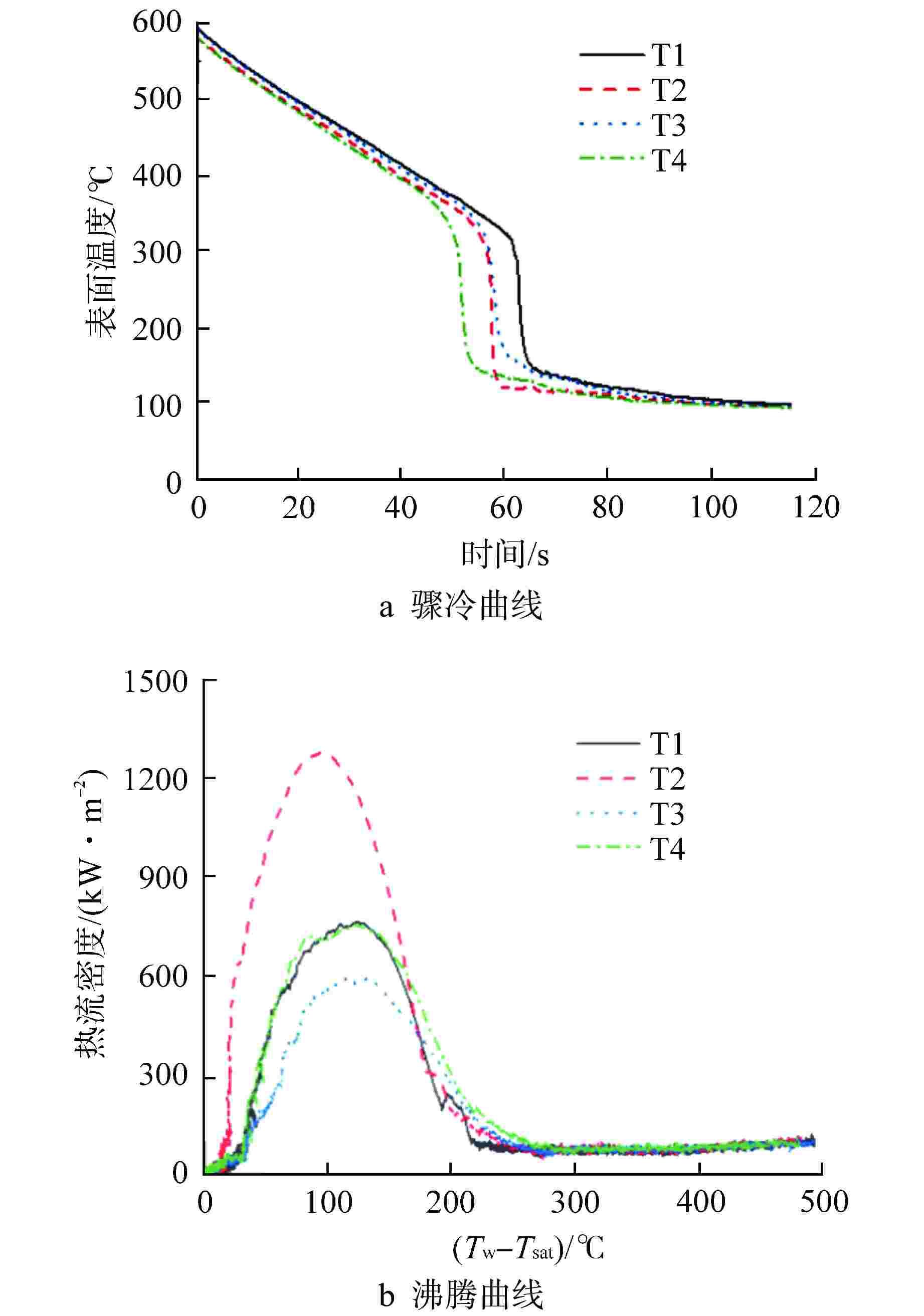

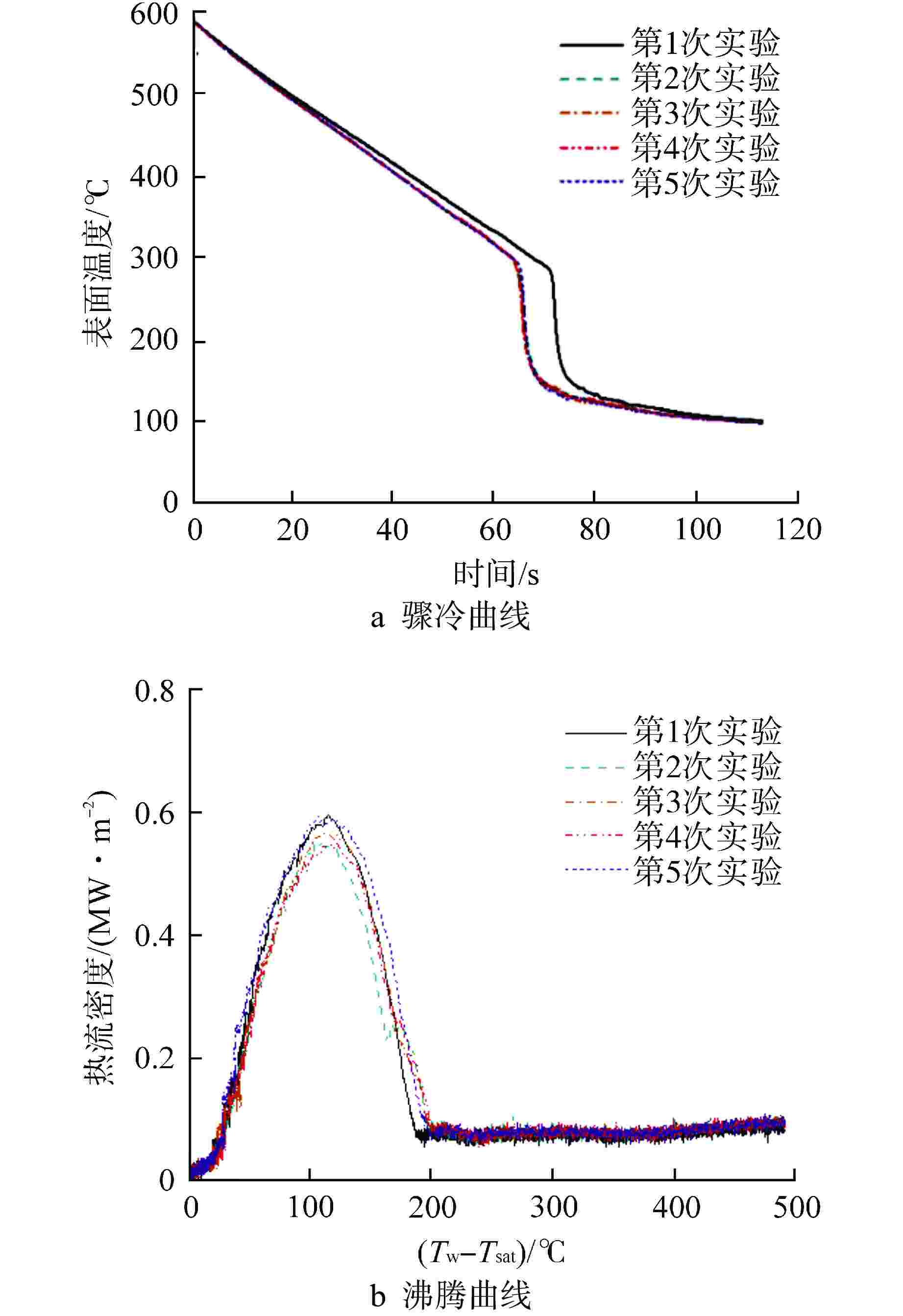

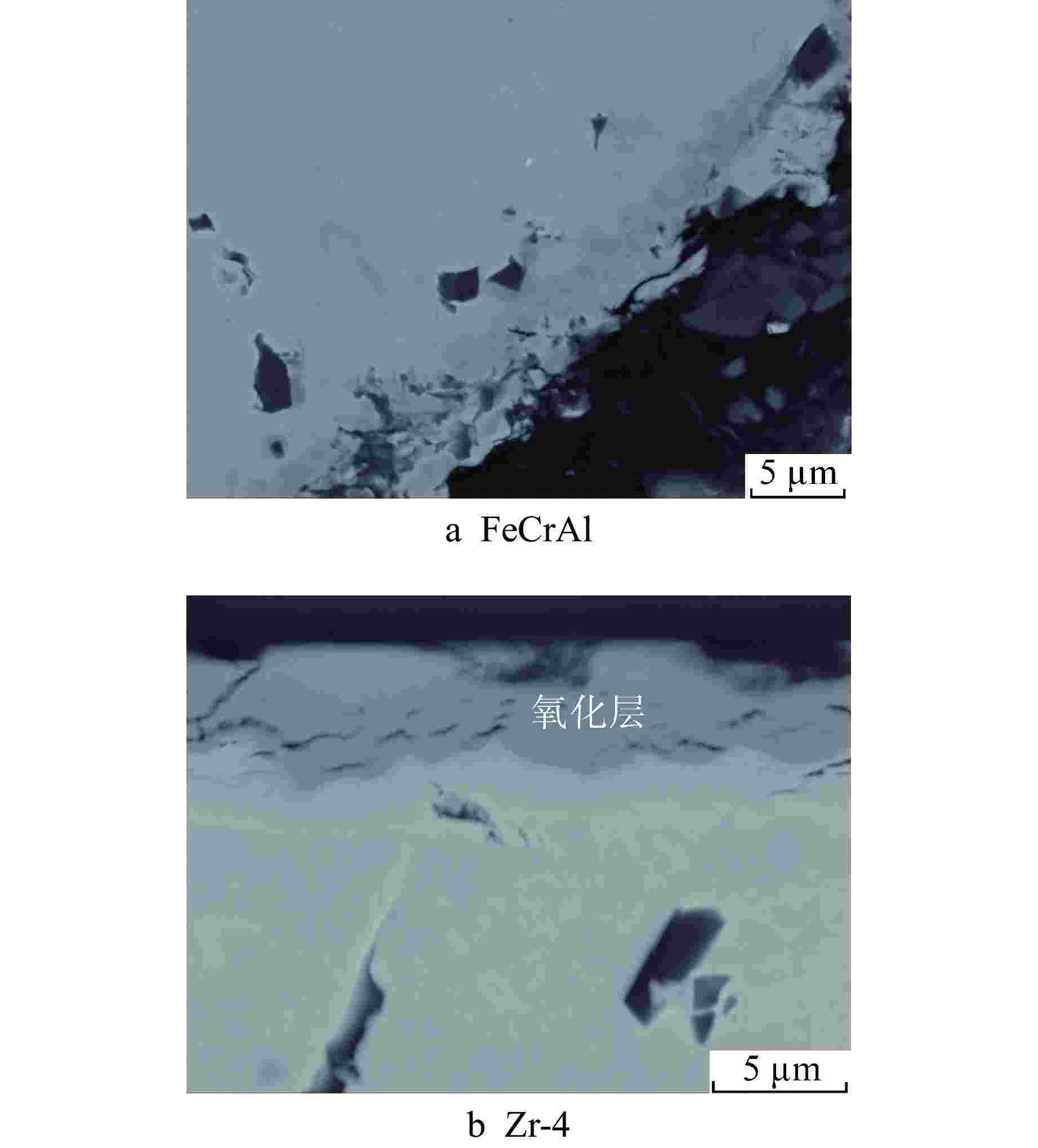

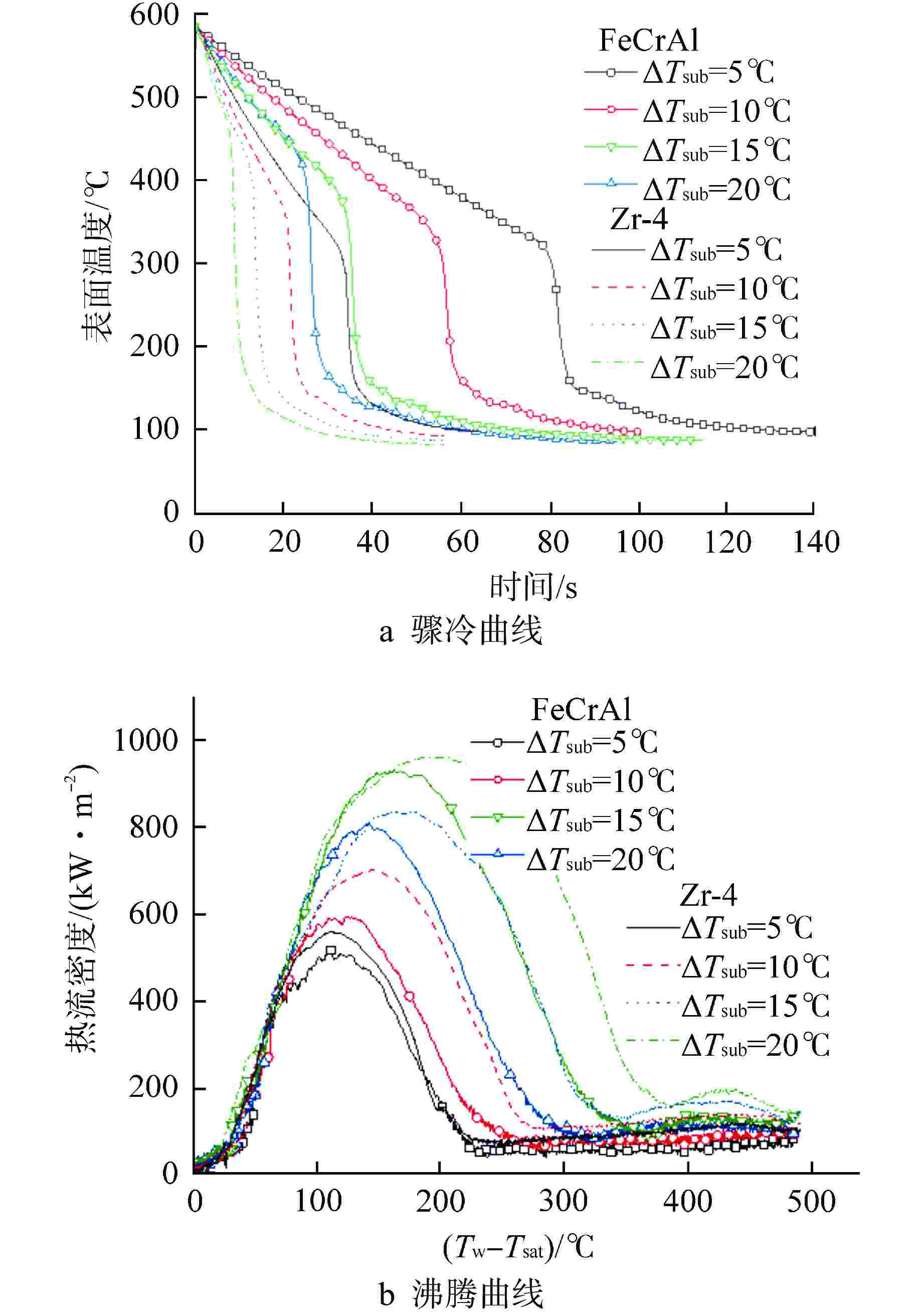

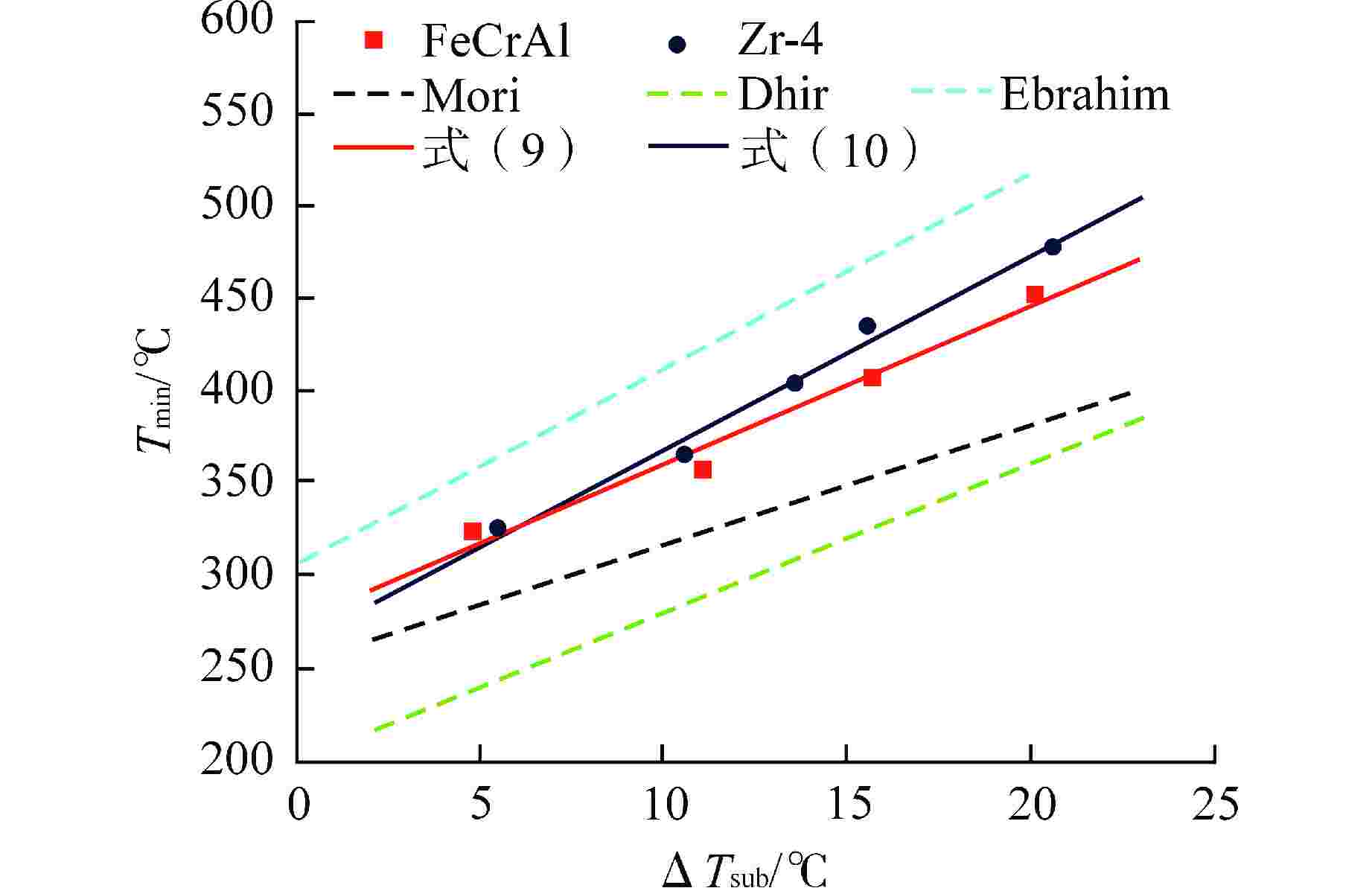

摘要: 铁铬铝(FeCrAl)作为事故容错燃料(ATF)包壳的主要候选材料,能够抑制反应堆在严重事故下产氢释能的风险,提高反应堆的事故耐受能力。本文基于可视化方法研究了FeCrAl和Zr-4在骤冷过程中的沸腾传热行为。通过一维导热反问题求解计算FeCrAl的表面热流密度和温度,分析了表面氧化、固体热物性对铁铬铝骤冷行为的影响。研究结果表明随着过冷度的增大,骤冷时间减小,最小膜态沸腾温度增大;随着固体热物性(ρcp)w的增大,骤冷时间增大,最小膜态沸腾温度减小。由于铁铬铝优异的高温抗氧化性,其骤冷过程的沸腾传热行为受表面氧化的影响可忽略不计。

-

关键词:

- 事故容错燃料(ATF) /

- 固体热物性 /

- 骤冷行为 /

- 最小膜态沸腾温度

Abstract: FeCrAl is proposed as one of the candidate materials of accident tolerant fuel (ATF) cladding, which can suppress hydrogen generation under severe accident condition, and improve reactor accident tolerance. In this paper, the boiling heat transfer behavior of FeCrAl and Zr-4 during quenching is studied based on visualization method. The surface heat flux and temperature of FeCrAl are calculated by solving one-dimensional inverse heat conduction problem, and the effects of surface oxidation and solid thermophysical properties on the quenching behavior of FeCrAl are analyzed. The results show that as the liquid subcooling degree increases, the quenching duration of FeCrAl is decreased, and the minimum film boiling temperature increases. With the increase of solid thermophysical property (ρcp)w, the quenching duration increases and the minimum film boiling temperature decreases. Because of the excellent high-temperature oxidation resistance of FeCrAl, the effect of surface oxidation on its boiling heat transfer behavior during quenching can be ignored. -

表 1 FeCrAl和Zr-4的表面特性和热物性

Table 1. Surface Characteristics and Thermophysical Properties of FeCrAl and Zr-4

包壳材料 密度ρ/

(kg·m−3)热导率λ/

(W·m−1·K−1)比热容cp/

(J·kg−1·K−1)粗糙度/μm 接触角 FeCrAl 7100 13 460 0.2 93.4˚ Zr-4 6550 13.4 286 0.2 103.8˚ 表 2 最小膜态沸腾温度与过冷度的线性关系式

Table 2. Linear Relationship between Minimum Film Boiling Temperature and Subcooling Degree

关系式 形式 偏差 $ {E}_{1} $ $ {E}_{2} $ Dhir $ {T}_{\mathrm{m}\mathrm{i}\mathrm{n}}=8{\Delta T}_{\mathrm{s}\mathrm{u}\mathrm{b}}+201 $ 0.193 0.202 Mori $ {T}_{\mathrm{m}\mathrm{i}\mathrm{n}}=6.4{\Delta T}_{\mathrm{s}\mathrm{u}\mathrm{b}}+253.2 $ 0.114 0.126 Ebrahim $ {T}_{\mathrm{m}\mathrm{i}\mathrm{n}}=10.5{\Delta T}_{\mathrm{s}\mathrm{u}\mathrm{b}}+307 $ 0.176 0.196 式(9) $ {T}_{\mathrm{m}\mathrm{i}\mathrm{n}}=8.6\Delta {T}_{\mathrm{s}\mathrm{u}\mathrm{b}}+274.4 $ 0.019 0.022 式(10) $ {T}_{\mathrm{m}\mathrm{i}\mathrm{n}}=10.4\Delta {T}_{\mathrm{s}\mathrm{u}\mathrm{b}}+265.3 $ 0.012 0.014 -

[1] KIM H, BUONGIORNO J, HU L W, et al. Nanoparticle deposition effects on the minimum heat flux point and quench front speed during quenching in water-based alumina nanofluids[J]. International Journal of Heat and Mass Transfer, 2010, 53(7-8): 1542-1553. doi: 10.1016/j.ijheatmasstransfer.2009.11.029 [2] SINHA J. Effects of surface roughness, oxidation level, and liquid subcooling on the minimum film boiling temperature[J]. Experimental Heat Transfer, 2003, 16(1): 45-60. doi: 10.1080/08916150390126478 [3] ZINKLE S J, TERRANI K A, GEHIN J C, et al. Accident tolerant fuels for LWRs: a perspective[J]. Journal of Nuclear Materials, 2014, 448(1-3): 374-379. doi: 10.1016/j.jnucmat.2013.12.005 [4] TERRANI K A, Accident tolerant fuel cladding development: Promise, status, and challenges[J]. Journal of Nuclear Materials, 2018, 501: 13-30. [5] KANG J Y, KIM S H, JO H, et al. Film boiling heat transfer on a completely wettable surface with atmospheric saturated distilled water quenching[J]. International Journal of Heat and Mass Transfer, 2016, 93: 67-74. doi: 10.1016/j.ijheatmasstransfer.2015.09.049 [6] SESHADRI A, SHIRVAN K. Quenching heat transfer analysis of accident tolerant coated fuel cladding[J]. Nuclear Engineering and Design, 2018, 338: 5-15. doi: 10.1016/j.nucengdes.2018.07.020 [7] 王泽锋,邓坚,王嘉庚,等. 锆-4在冷却水中的骤冷沸腾传热实验研究[J]. 核动力工程,2021, 42(1): 186-191. [8] BECK J V, BLACKWELL B, CLAIR JR C R S. Inverse heat conduction: Ill-posed problems[M]. New York: Wiley, 1985. [9] DUFFEY R B, PORTHOUSE D T C. The physics of rewetting in water reactor emergency core cooling[J]. Nuclear Engineering and Design, 1973, 25(3): 379-394. doi: 10.1016/0029-5493(73)90033-2 [10] DHIR V K, PUROHIT G P. Subcooled film-boiling heat transfer from spheres[J]. Nuclear Engineering and Design, 1978, 47(1): 49-66. doi: 10.1016/0029-5493(78)90004-3 [11] MORI M, TODA S, OCHIAI M A, et al. Transient cooling process of fuel rod in reactivity initiated accident[J]. Journal of Nuclear Science and Technology, 1980, 17(6): 413-424. doi: 10.1080/18811248.1980.9732605 [12] EBRAHIM S A, CHANG S, CHEUNG F B, et al. Parametric investigation of film boiling heat transfer on the quenching of vertical rods in water pool[J]. Applied Thermal Engineering, 2018, 140: 139-146. doi: 10.1016/j.applthermaleng.2018.05.021 -

下载:

下载: